Preparation method of efficient scale inhibitor for circulating cooling water system

A technology of circulating cooling water and scale inhibitor, which is applied in the field of scale inhibitor, can solve the problems of industrial circulating cooling water, long synthesis time, simple function, etc. , good scale inhibition and dispersion performance, the effect of preventing the formation of calcium gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

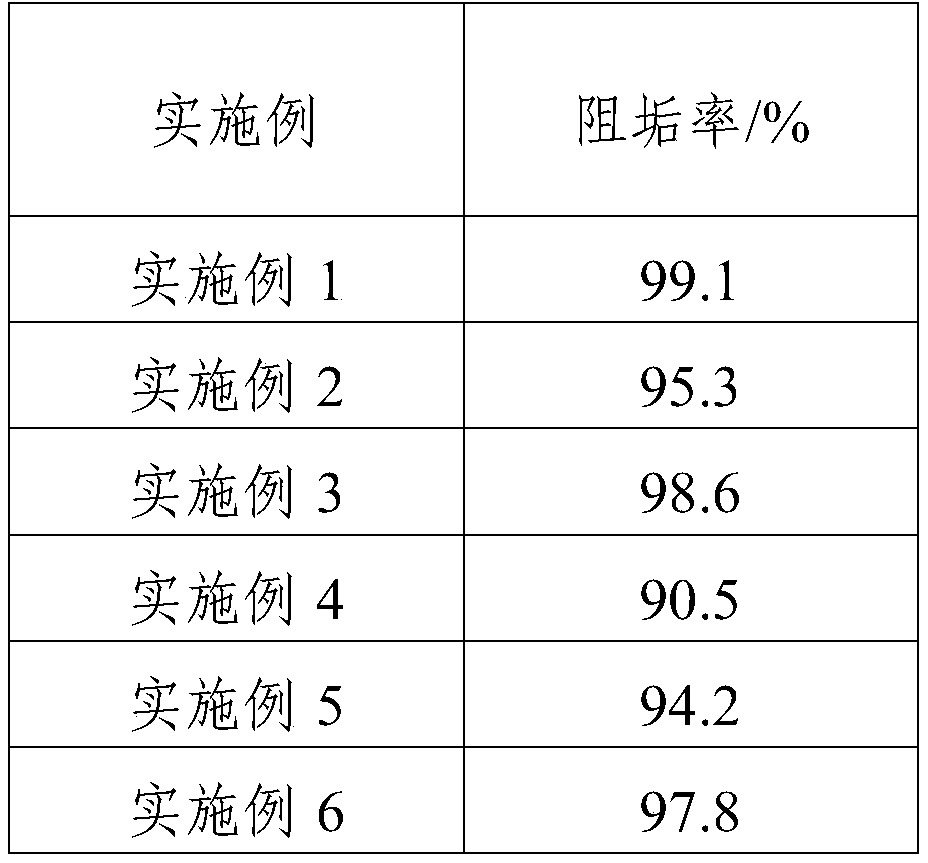

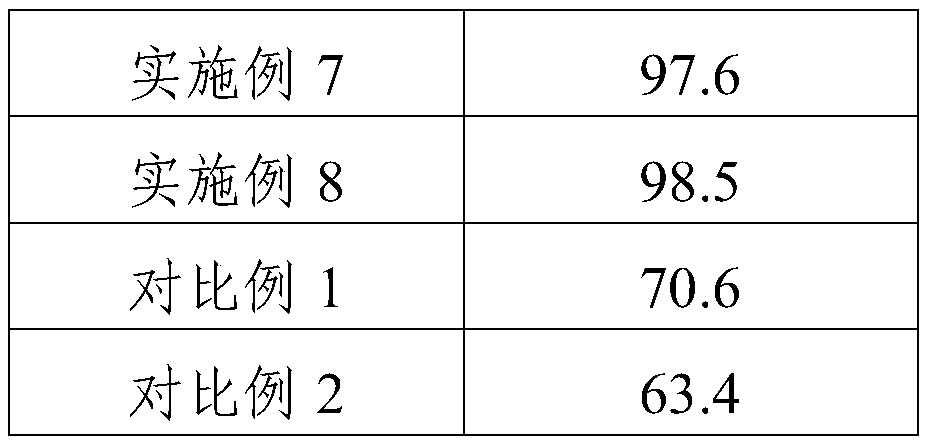

Examples

Embodiment 1

[0029] A preparation method of high-efficiency scale inhibitor for circulating cooling water system:

[0030] Add succinic anhydride and diethanolamine to dimethylacetamide according to the mass ratio of 1:1, stir and react for 2 hours, add p-toluenesulfonic acid and toluene, gradually heat up to reflux and separate the water generated by the reaction. After anhydrous generation, add benzoic acid in the system, continue stirring reaction until anhydrous generation, underpressure distillation removes solvent and small molecule, obtains hyperbranched polyamide ester, hyperbranched polyamide ester and 2-acrylamide-2- Add methylpropanesulfonic acid into deionized water at a mass ratio of 1:5.5. After ultrasonic vibration and dissolution, add ammonium persulfate solution with a mass concentration of 12% dropwise under microwave radiation heating. After the dropwise addition, react for 3 hours and cool naturally to room temperature , the viscous obtained after vacuum distillation is...

Embodiment 2

[0032] A preparation method of high-efficiency scale inhibitor for circulating cooling water system:

[0033]Add succinic anhydride and diethanolamine to dimethylacetamide according to the mass ratio of 1:1, stir and react for 1 hour, add p-toluenesulfonic acid and toluene, gradually heat up to reflux and separate the water generated by the reaction. After anhydrous generation, add α-methacrylic acid to the system, continue to stir the reaction until anhydrous generation, remove solvent and small molecule by distillation under reduced pressure, obtain hyperbranched polyamide ester, hyperbranched polyamide ester and 2-acrylamide -2-Methylpropanesulfonic acid was added to deionized water at a mass ratio of 1:5, and after being dissolved by ultrasonic vibration, ammonium persulfate solution with a mass concentration of 10% was added dropwise under microwave radiation heating, and reacted for 3 hours after the dropwise addition, and naturally Cool to room temperature, vacuum-dry t...

Embodiment 3

[0035] A preparation method of high-efficiency scale inhibitor for circulating cooling water system:

[0036] Add succinic anhydride and diethanolamine to dimethylacetamide according to the mass ratio of 1:1, stir and react for 2 hours, add p-toluenesulfonic acid and toluene, gradually heat up to reflux and separate the water generated by the reaction. After anhydrous generation, add acrylic acid to the system, continue to stir the reaction until anhydrous generation, distill under reduced pressure to remove solvent and small molecule, obtain hyperbranched polyamide ester, hyperbranched polyamide ester and 2-acrylamide-2-formaldehyde Propanesulfonic acid was added into deionized water at a mass ratio of 1:6, and after being dissolved by ultrasonic vibration, ammonium persulfate solution with a mass concentration of 20% was added dropwise under heating by microwave radiation, and reacted for 2 hours after the addition was completed, and cooled naturally to room temperature. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com