Chemical processing method of coal chemical industry recycled circulating cooling water

A technology of circulating cooling water and chemical treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as research concentration, achieve a high degree of automation, and reduce phosphorus Good content and anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of composite scale and corrosion inhibitors, raw materials prepared in parts by weight: 9 parts of polyepoxysuccinic acid, 18 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, bis-1,6 hexamethylene 19 parts of triaminepentamethylene phosphonic acid, 25 parts of scale inhibitor and dispersant, 1 part of benzotriazole, and 9 parts of deionized water; preparation: first add polyepoxysuccinic acid to 2-phosphonic acid butane- 1,2,4-tricarboxylic acid, put in a container and mix evenly, add bis-1,6 hexamethylene triamine pentamethylene phosphonic acid, scale inhibitor and dispersant, deionized water in turn, stir for 35 minutes, keep the temperature at 35°C, then add benzotriazole, continue to stir for 60 minutes, and keep the temperature at 35°C to obtain a composite scale and corrosion inhibitor;

[0023] The preparation of antiscaling and dispersing agent: 300 parts of deionized water and 490 parts of maleic anhydride are sucked into the reaction ket...

Embodiment 2

[0026] Medicament is prepared in parts by weight:

[0027] Preparation of composite scale and corrosion inhibitor: 11 parts of polyepoxysuccinic acid, 22 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, bis-1,6 hexamethylene triamine pentamethylene phosphine 21 parts of acid, 35 parts of scale inhibitor and dispersant, 3 parts of benzotriazole, and 28 parts of deionized water; Put it in a container, mix well, add bis-1,6 hexamethylene triamine pentamethylene phosphonic acid, scale inhibitor dispersant, deionized water in sequence, stir for 35 minutes, keep the temperature at 35 ° C, then add benzene Triazole, continue to stir for 60 minutes, and keep the temperature at 35°C to obtain a composite scale and corrosion inhibitor;

[0028] The preparation of antiscaling and dispersing agent: 290 kg of deionized water and 500 kg of maleic anhydride are sucked into the reaction kettle through the pump in turn, start stirring, and stir at room temperature until the maleic ...

Embodiment 3

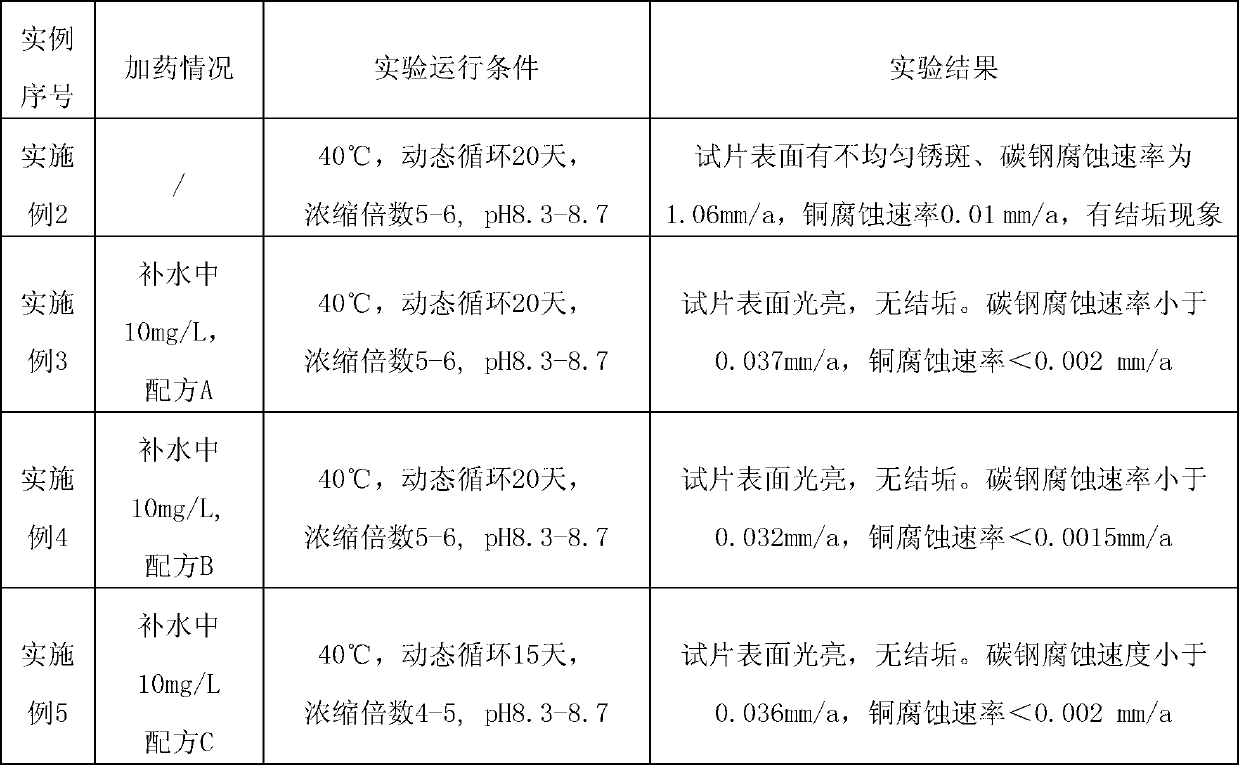

[0031] Composite scale and corrosion inhibitor test results verification:

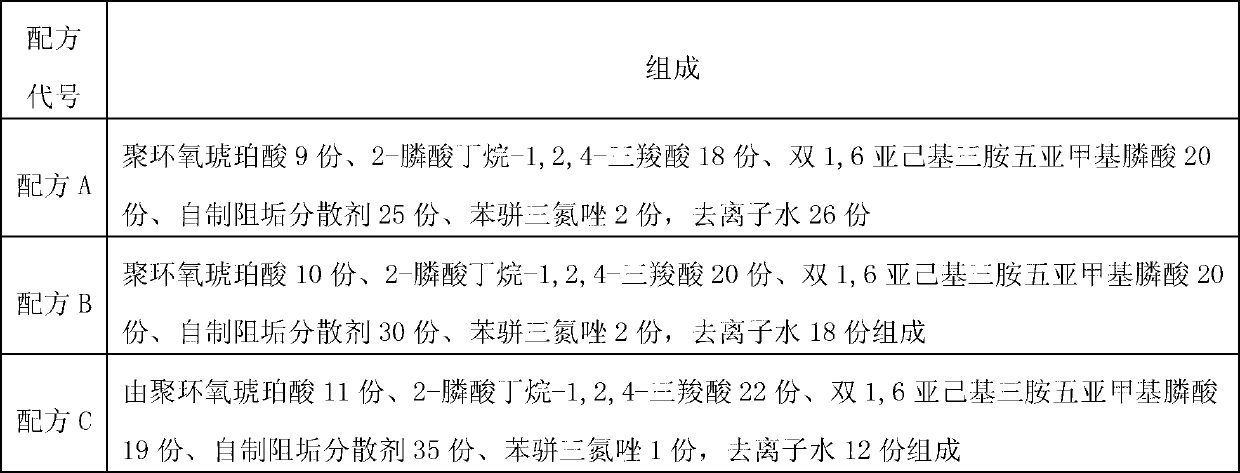

[0032] The object of water treatment is wastewater from a coal-to-methanol plant. The designed treatment formula and water quality control are shown in Table 1 and Table 2.

[0033] Table 1 Compound scale and corrosion inhibitor formula and code

[0034]

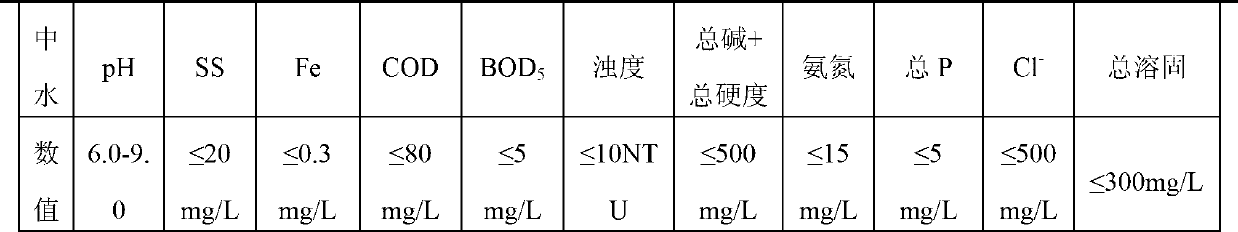

[0035] Water quality control indicators in Table 2

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com