Preparation method of phosphorus-free green environment-friendly scale inhibitor

A technology of green environmental protection and antiscalant, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of high price, achieve low cost, good product quality, energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

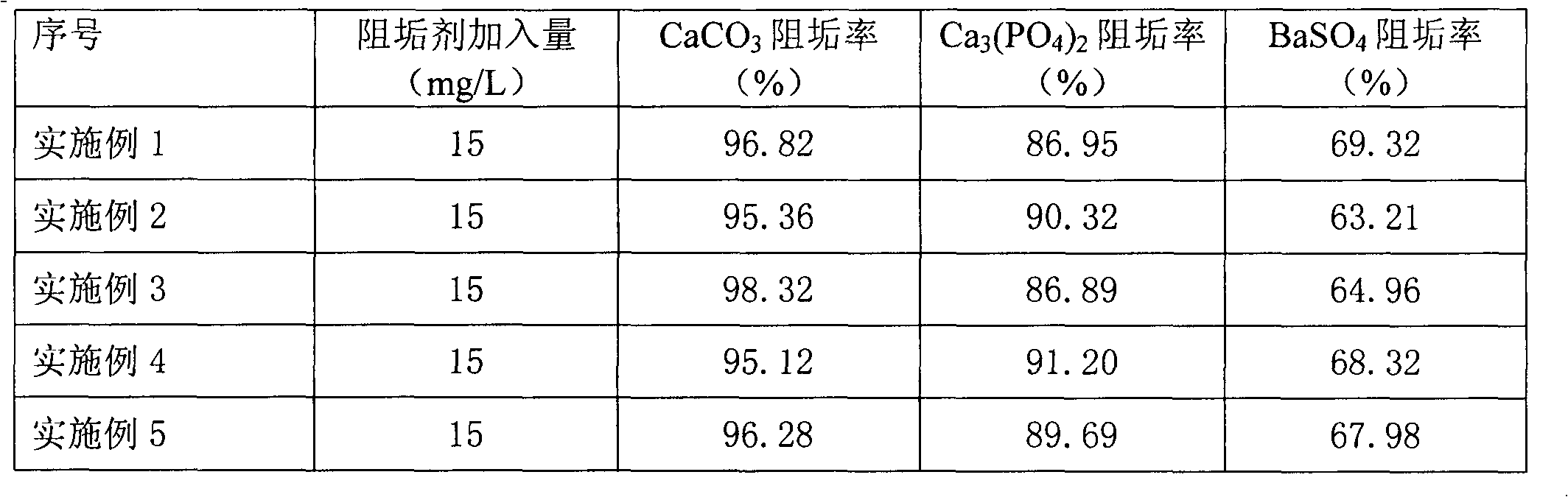

Examples

Embodiment 1

[0014] (1) Take 14g of maleic anhydride in a small cup, dissolve it in 20mL of water, heat it to 50°C to make it fully hydrolyzed, cool to room temperature, add 15mL of acrylic acid to make solution (I);

[0015] (2) Dissolve 10g sodium allyl sulfonate and 5g ammonium persulfate in 20mL water to form solution (II);

[0016] (3) Dissolve 35g of aconitic acid in 60mL of water, the temperature rises to 50°C, and solution (I) is added dropwise under stirring, after the dropwise addition is completed, the temperature is raised to 80°C for 30min at a constant temperature, then the temperature is increased to 80°C. Add solution (II) dropwise, and react at a constant temperature of 80°C for 3 hours after all the addition is completed, stop the reaction, add 50% NaOH solution dropwise to the product at about 50°C, adjust the pH to weak alkaline, and obtain a reddish-brown transparent Liquid, that is, quaternary phosphorus-free green environmental protection scale inhibitor.

Embodiment 2

[0018] (1) Take 20g of maleic anhydride in a beaker, dissolve in 25mL of water, heat to 55°C to make it fully hydrolyzed, cool to room temperature, add 15mL of acrylic acid to form solution (I);

[0019] (2) Dissolve 16g sodium allyl sulfonate and 7g ammonium persulfate in 25mL water to form solution (II);

[0020] (3) Dissolve 40g of aconitic acid in 50mL of water, and the temperature rises to 60°C, and solution (I) is added dropwise under stirring. After the dropwise addition is completed, the temperature is raised to 85°C for constant temperature reaction for 30min, and then the temperature is increased to 85°C. Add solution (II) dropwise, after all the addition is completed, react at a constant temperature of 85°C for 3 hours, stop the reaction, add 50% NaOH solution dropwise to the product at about 50°C, adjust the pH to weak alkaline, and obtain a reddish-brown transparent Liquid, that is, quaternary phosphorus-free green environmental protection scale inhibitor.

Embodiment 3

[0022] (1) Take 18g of maleic anhydride and place it in a beaker, dissolve it in 20mL of water, heat it to 60°C to make it fully hydrolyzed, cool to room temperature, add 15mL of acrylic acid to make solution (I);

[0023] (2) Dissolve 10g sodium allyl sulfonate and 5g ammonium persulfate in 20mL water to form solution (II);

[0024] (3) Dissolve 45g of aconitic acid in 60mL of water, the temperature rises to 60°C, and solution (I) is added dropwise under stirring, after the dropwise addition is completed, the temperature is raised to 75°C for constant temperature reaction for 30min, and then the temperature is increased to 75°C. Add solution (II) dropwise, after all the addition is completed, react at a constant temperature of 75°C for 4 hours, stop the reaction, add 50% NaOH solution dropwise to the product at about 50°C, adjust the pH to weak alkaline, and obtain a reddish-brown transparent Liquid, that is, quaternary phosphorus-free green environmental protection scale inh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com