Scale inhibitor for oil refining technology process and preparation method thereof

A process and scale inhibitor technology, used in the petroleum industry, hydrocarbon oil treatment, treatment equipment corrosion/fouling inhibition, etc., can solve the problems of few types of scale inhibitors, pollution, poor effect, etc. Easy to use, good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

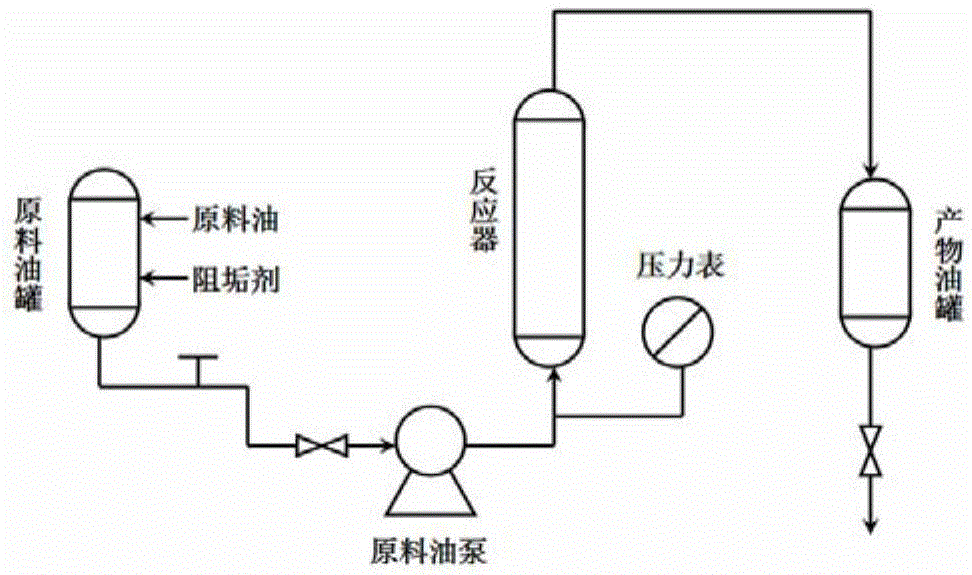

Method used

Image

Examples

Embodiment 1

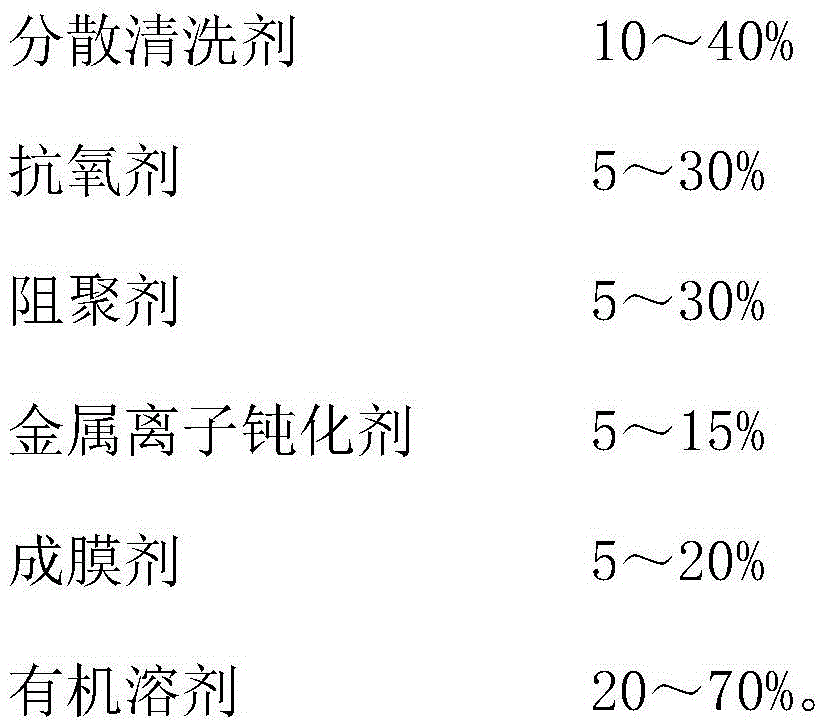

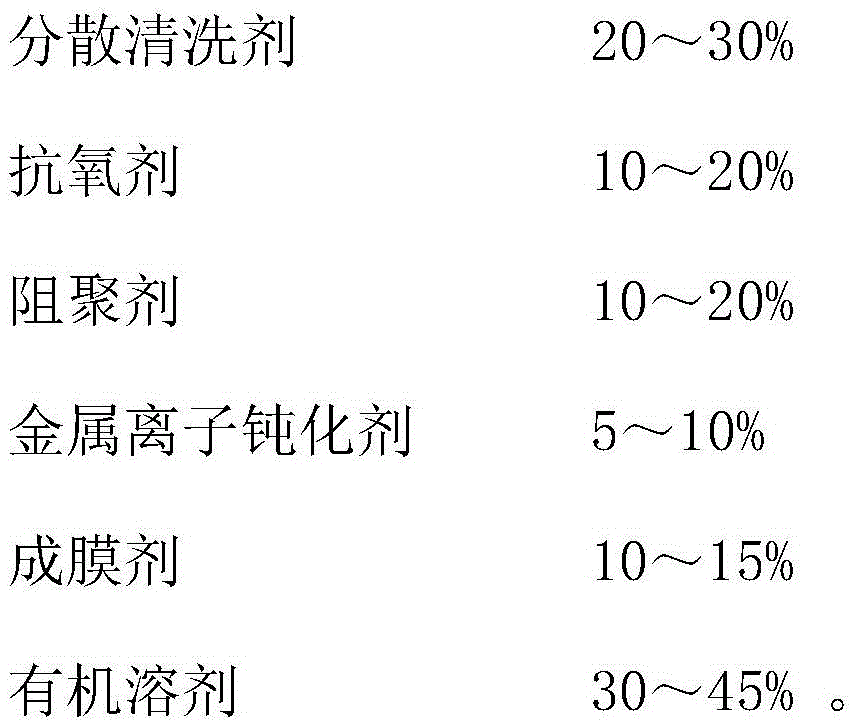

[0030] Add dispersant cleaning agent, antioxidant, polymerization inhibitor, metal ion deactivator and film forming agent into the organic solvent in proportion, heat and stir, fully dissolve and mix evenly, cool to room temperature, and filter to obtain different types of scale inhibitors Sample, its active ingredient and mass percentage composition are as shown in table 1:

[0031] Table 1

[0032]

[0033]

[0034]

Embodiment 2

[0036] In order to test the use effect of the scale inhibitor of the present invention, the laboratory static and dynamic hydrogenation evaluation tests of the scale inhibitor were carried out respectively.

[0037] 1) Static evaluation test

[0038] Add 50g of blank or additive raw material oil into a 100ml autoclave, seal it and replace it with nitrogen for 3 times, heat it at 350°C for 10h, then extract it with heptane and dry it, and check the scale inhibition according to the amount of insoluble matter Antiscalant effect of the agent, the results are shown in Table 2:

[0039] Table 2 Static test data

[0040]

[0041] Note: 1) The dosage of antiscalant is 100μg / g;

[0042] 2) Scale inhibition rate = (change of colloid after dosing / change of blank colloid content) × 100%.

[0043] The evaluation results in Table 2 show that the scale inhibition effect of the self-made scale inhibitor No. 6 sample is better than that of other scale inhibitors. Adding 100ppm to the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com