Flue gas temperature control music early warning heat pipe heat exchange device

A heat exchange device and flue gas technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of no alarm measures, and the degree of intelligence needs to be improved, so as to avoid low-temperature corrosion and smooth discharge , the effect of avoiding the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

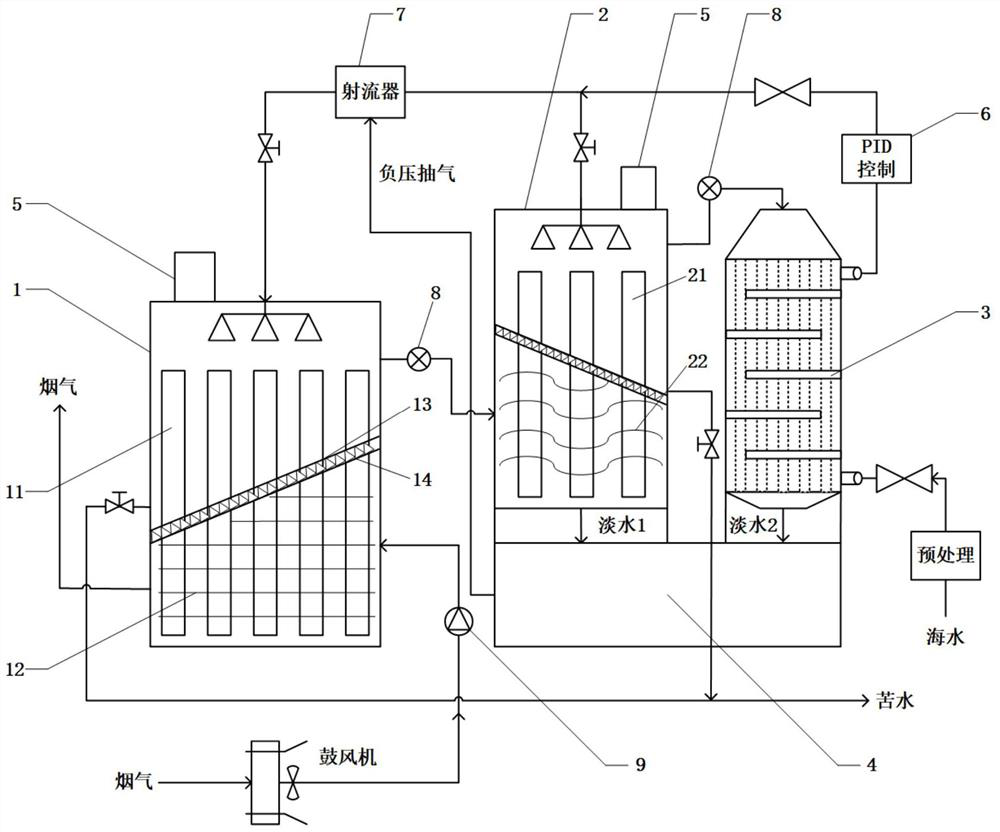

[0036] The technical solutions in the embodiments of the present invention will be supplemented below with reference to the accompanying drawings in the embodiments of the present invention.

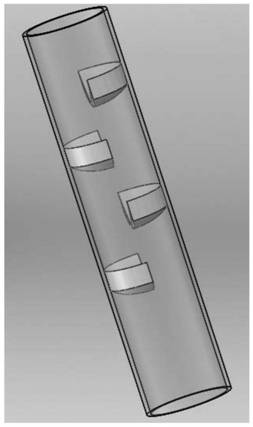

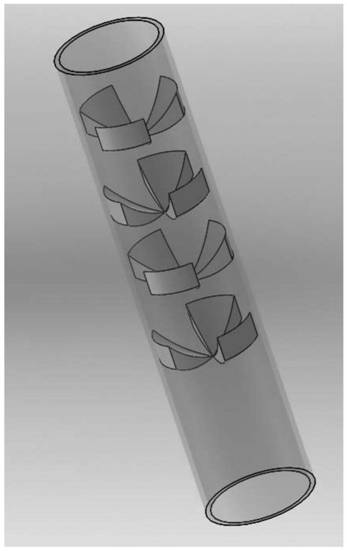

[0037] A heat pipe heat exchange device for flue gas temperature control music early warning, see figure 1The one-effect distiller 1 in the device includes a shell, a heat pipe and a partition plate are arranged in the shell, and the partition plate divides the heat pipe into a hot end located at the upper part and a cold end located at the lower part, and the heat pipe includes a flue gas inlet. and seawater inlet, the flue gas inlet is set at the lower part of the partition plate, the seawater inlet is set at the upper part of the shell, the flue gas is passed into the cold end of the heat pipe, and the heat of the flue gas is transferred to the upper hot end through the cold end of the heat pipe. The cold seawater entered by the seawater inlet is distilled, and the flue gas is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com