Fluoroplastic-steel air preheater with anti-corrosive and anti-blockage functions

An air preheater and preheater technology, applied in heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve problems affecting working life and heat exchange performance, ash and slagging, low temperature corrosion, etc. , to achieve the effect of solving flue gas condensation, improving operation cycle and preventing low temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

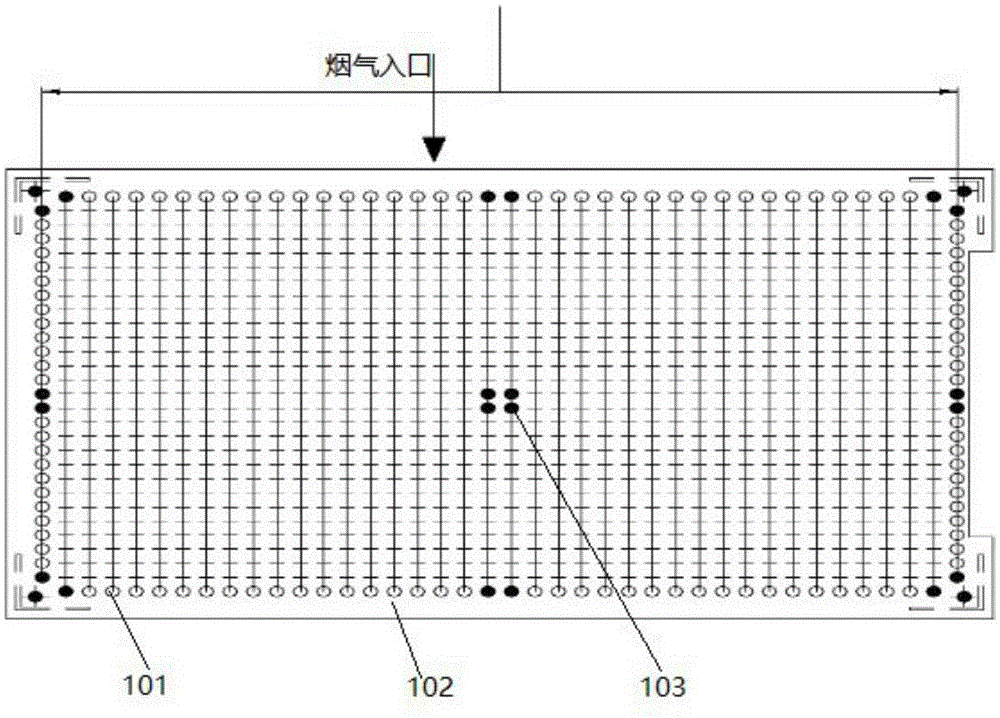

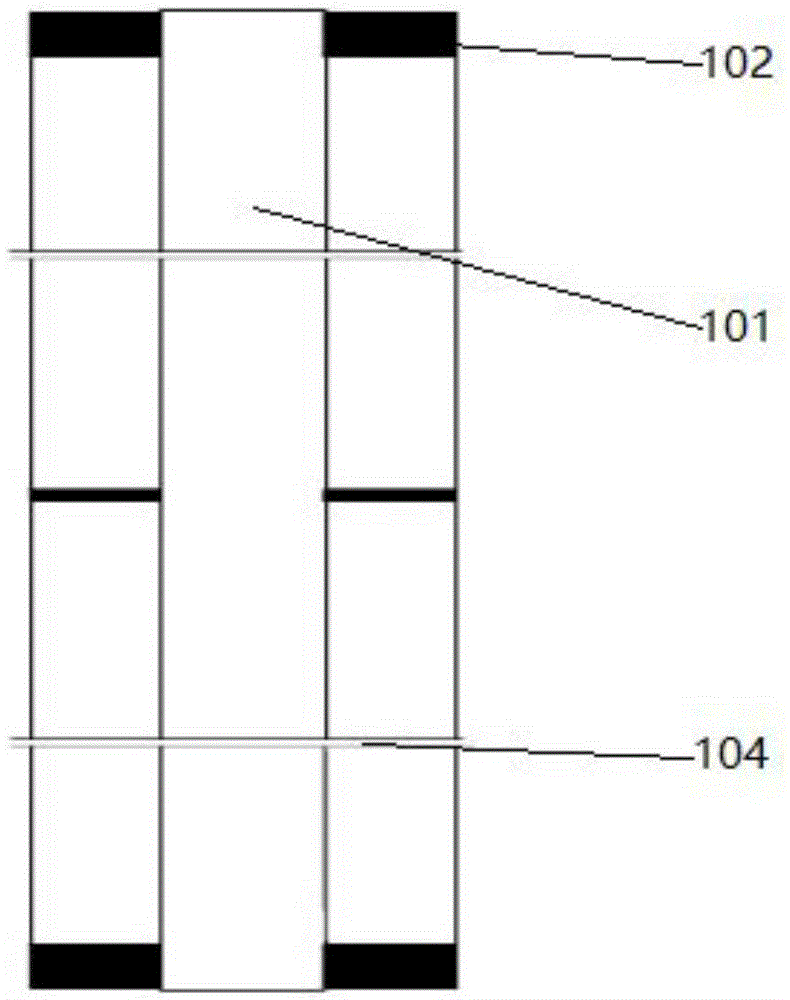

[0043] Such as Figure 1-5 As shown, a fluorine-plastic steel air preheater with anti-corrosion and anti-blocking functions includes a number of fluorine-plastic steel pipes 101 arranged in parallel at intervals and two tube sheets 102 respectively arranged at both ends of the fluorine-plastic steel pipe 101. The fluorine-plastic steel The tube 101 is made of a fluoroplastic tube coated with a stainless steel tube. The two ends of the fluoroplastic steel tube 101 are respectively fixedly connected to the tube plate 102 through the tube expansion process. The side wall of the fluoroplastic steel tube 101 faces the preheater Smoke inlet.

[0044] In the present invention, fluorine-plastic coated stainless steel tubes are used to make fluorine-plastic steel tubes, and the fluoroplastics have excellent performances of anti-corrosion and anti-clogging dust on the flue gas side, while the use of stainless steel tubes on the air side can not only enhance the heat transfer performance...

Embodiment 2

[0048] This embodiment is based on Embodiment 1. Preferably, the fluoroplastic tube is made of graphite-added fluoroplastic. Fluoroplastics are made of graphite-added fluoroplastics with high thermal conductivity. This material not only maintains the advantages of general fluoroplastics, such as low adhesion, corrosion resistance, wear resistance, etc., but also has higher thermal conductivity than general fluoroplastics. With high thermal conductivity, it can be made into fluoroplastic tubes with thicker walls, which overcomes the shortcomings of common fluoroplastic tubes, which are easy to shake and deform due to flue gas erosion due to their thin walls, which affects the life of the equipment and the heat exchange effect.

Embodiment 3

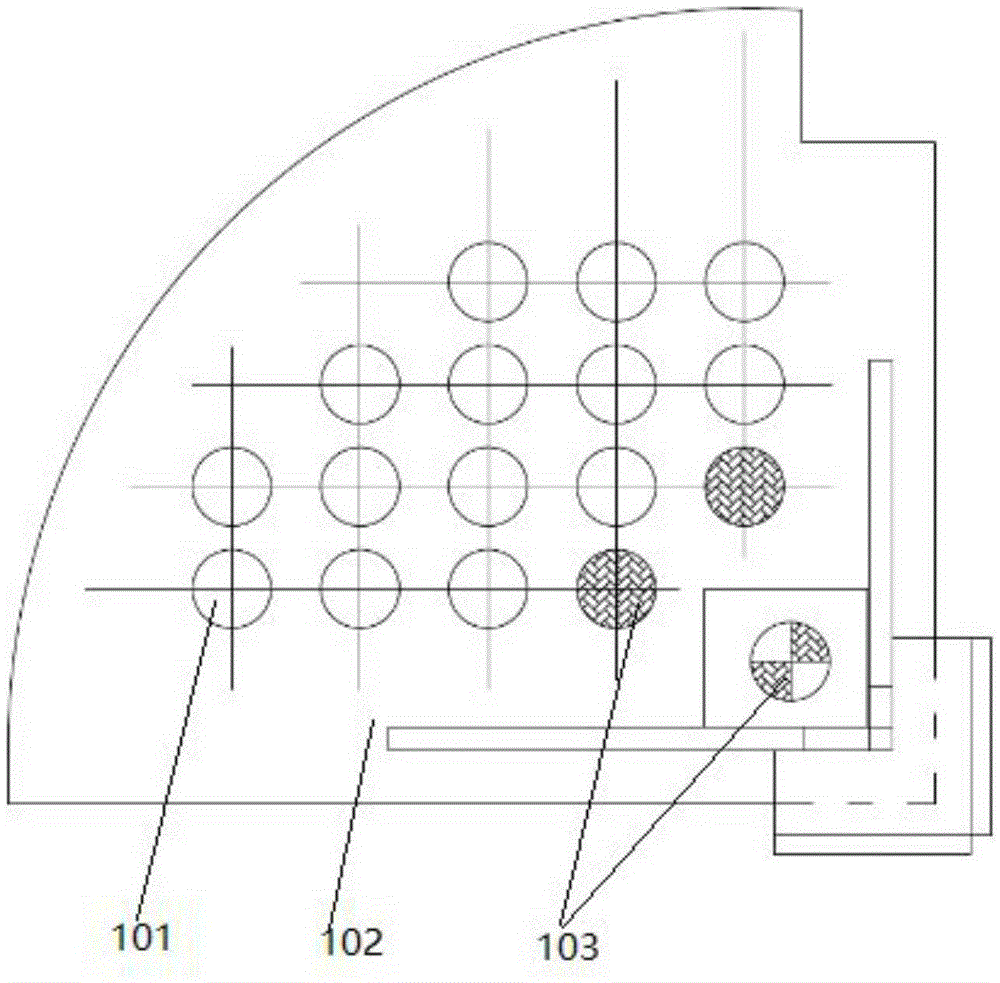

[0050] In order to improve the strength and impact resistance of the overall structure, in this embodiment, preferably, brace tubes 103 are arranged between the tube sheets 102, and the two ends of the brace tubes 103 are respectively fixedly connected to the on the tube sheet 102. By setting the brace tube, it can connect and support the two tube sheets, and at the same time support the fluoroplastic steel tube, making the overall structure more stable.

[0051] In this embodiment, preferably, the cross-section of the tube plate 102 is a rectangular structure, and the two ends of the stay tube 103 are respectively fixedly connected to the top corners and the centerlines of the four sides of the two tube plates 102 .

[0052] Further preferably, in this embodiment, in order to prevent the stretching tube from affecting the heat exchange effect of the fluoroplastic steel pipe, preferably, the stretching tube 103 and the fluoroplastic steel pipe 101 are arranged parallel to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com