Device and method for removing dust from converter smoke by dry method and recycling waste heat

A technology of dry dust removal and converter flue gas, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of water consumption, sludge and sewage, etc., and achieve the effects of high heat transfer efficiency, small resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

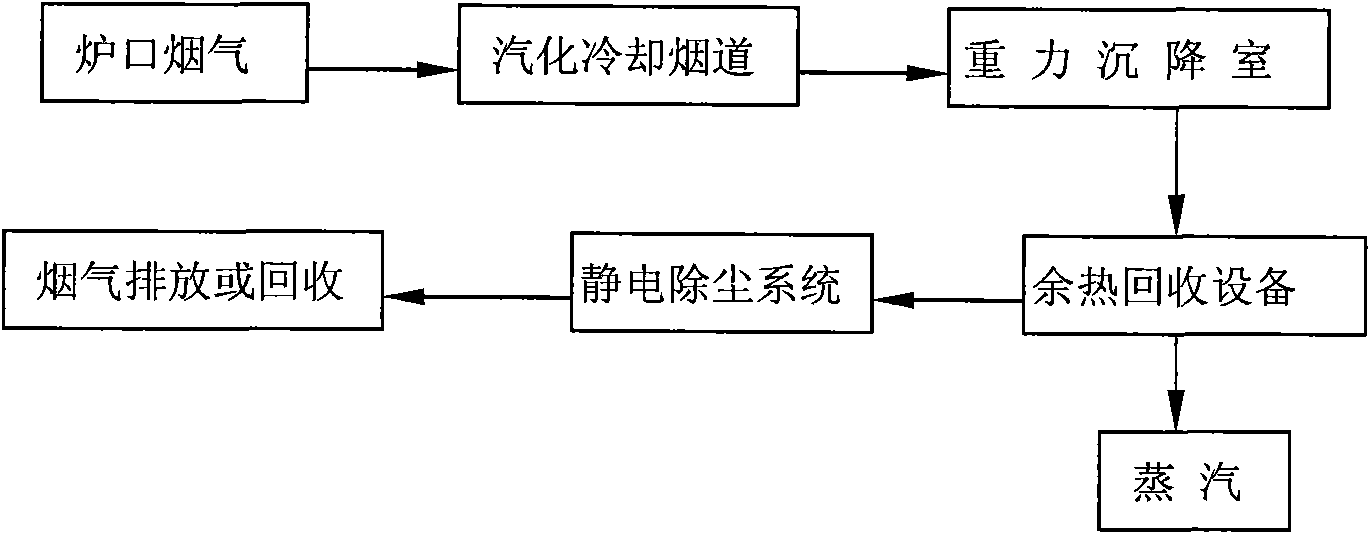

[0015] The converter flue gas dry dedusting and waste heat recovery process described in the present invention is suitable for all converter production, but according to the different requirements of steel mills, two types of converter production processes can be realized, that is, it is suitable for "unfired" converters Flue gas, also applies to "complete combustion method" converter flue gas. Two different converter flue gases differ in control accuracy. The specific implementation is to transform the existing converter vaporization cooling flue according to this process route, or directly equip the new plant with the dust removal and waste heat recovery equipment of this process.

[0016] In order to better illustrate the timely characteristics of this scheme, the scheme is further elaborated in conjunction with the accompanying drawings:

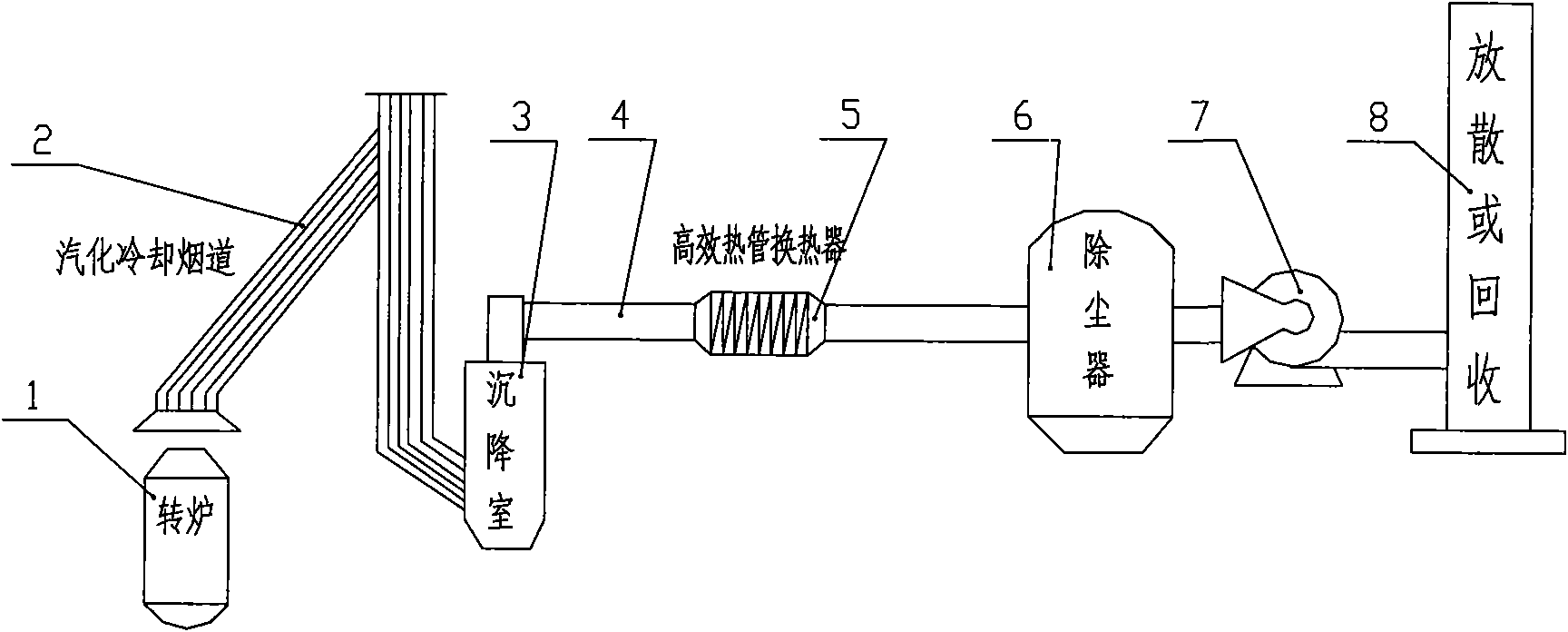

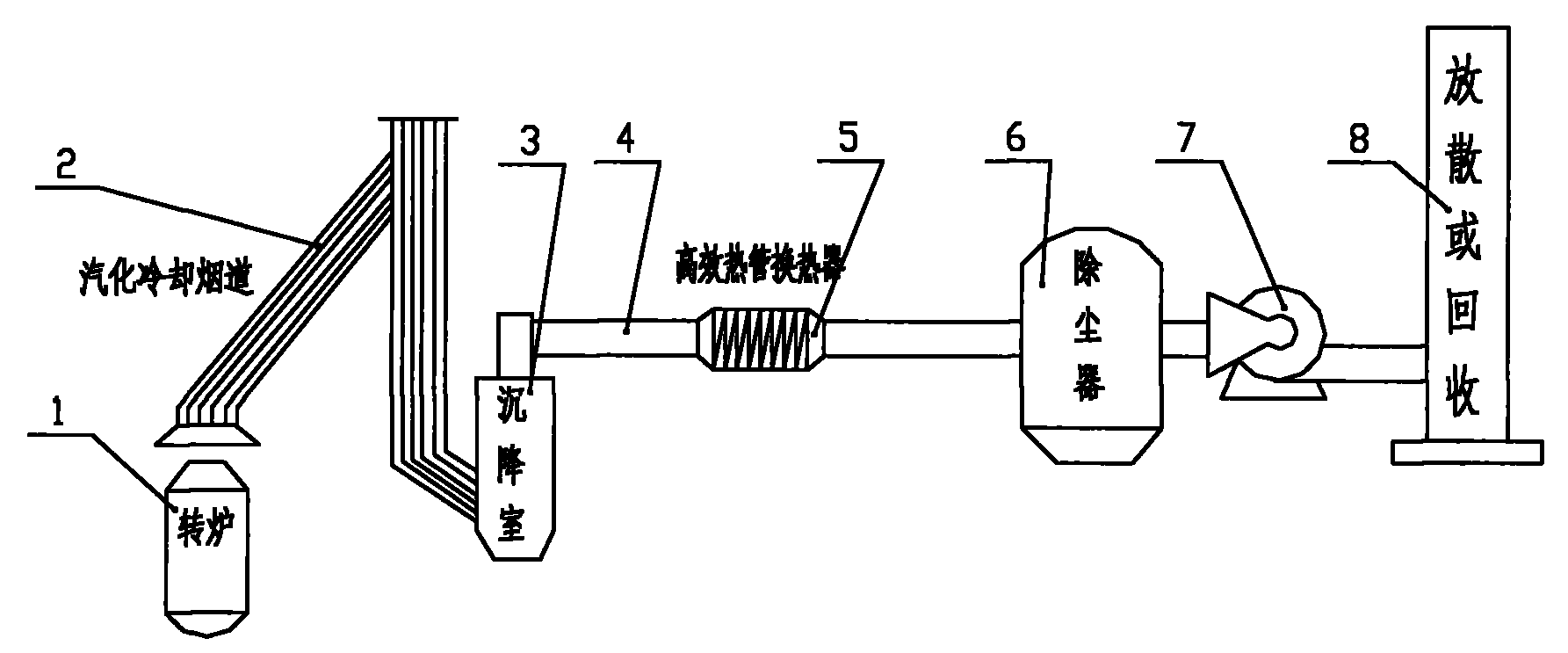

[0017] From figure 1 It can be seen that the converter flue gas dry dedusting and waste heat recovery device of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com