a cleaning powder

A technology of cleaning powder and builder, applied in the field of cleaning powder, can solve the problems of poor versatility and achieve the effect of good use effect, invariance and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024](1) a new type of cleaning powder, including the following components by weight: 48% inorganic base, 22% sodium hydroxyethyl phosphonate, 5% sodium citrate, 22% sodium gluconate, 1% sodium formate, 1% sodium nitrogen triaceate, 1% sodium fluoride.

[0025](2) Preparation method:

[0026]S1, first pulverizing the inorganic base by a pulverizer to 100 mesh powder;

[0027]S2, by stirring under stirring conditions, sequencing corrosion inhibitor, inorganic base, buffer, chelating agent, and stirred for 30 minutes to uniform.

[0028](3) How to use: First add new cleaning powder to water to 3% mass concentration, ultrasound cleaning at 60 ° C.

Embodiment 2-3 and comparative example 1-4

[0030]Table 1 Formulation statistics table for Examples 1-3 and Comparative Example 1-4

[0031] sample Inorganic base Hedp · NA2 Sodium citrate Sodium gluconate Sodium formate NTA, NA3 Sodium fluoride Example 1 40222015111 Example 2 30202520311 Example 3 40152715111 Contrast 1 7028--11- Contrast 2 5040--442 Contrast 3 552230-111 Contrast 44522-30111

Embodiment 2-3

[0032]Example 2-3 Novel Cleaning Powder and Comparative Example 1-4 The preparation method of cleaning powder is the same as in Example 1.

[0033]First, performance test

[0034]For Examples 1-3 clean flour, comparison 1-4 cleaning powder for performance test, specific:

[0035]1. First add the cleaning powder to water to 3% mass concentration.

[0036]2. Ultrasound washed 2 min under the condition of 60 ° C. After cleaning, drying, the drying sample glass is determined by performing performance, and the details of the measurement results are shown in Table 2.

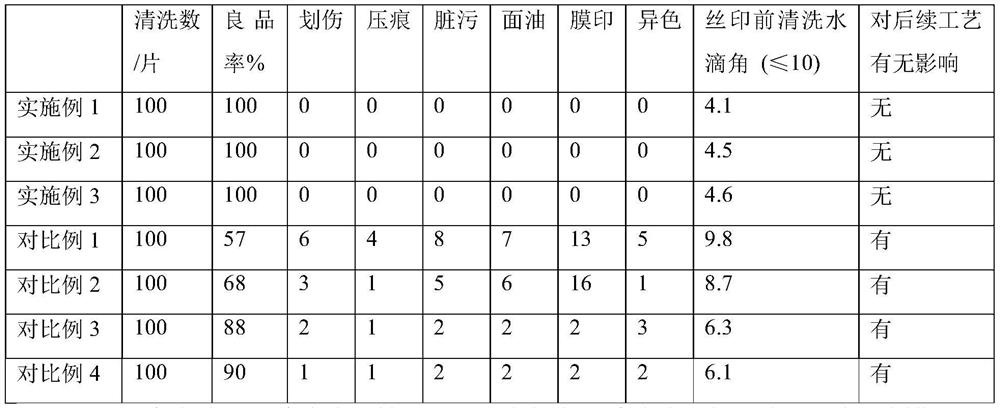

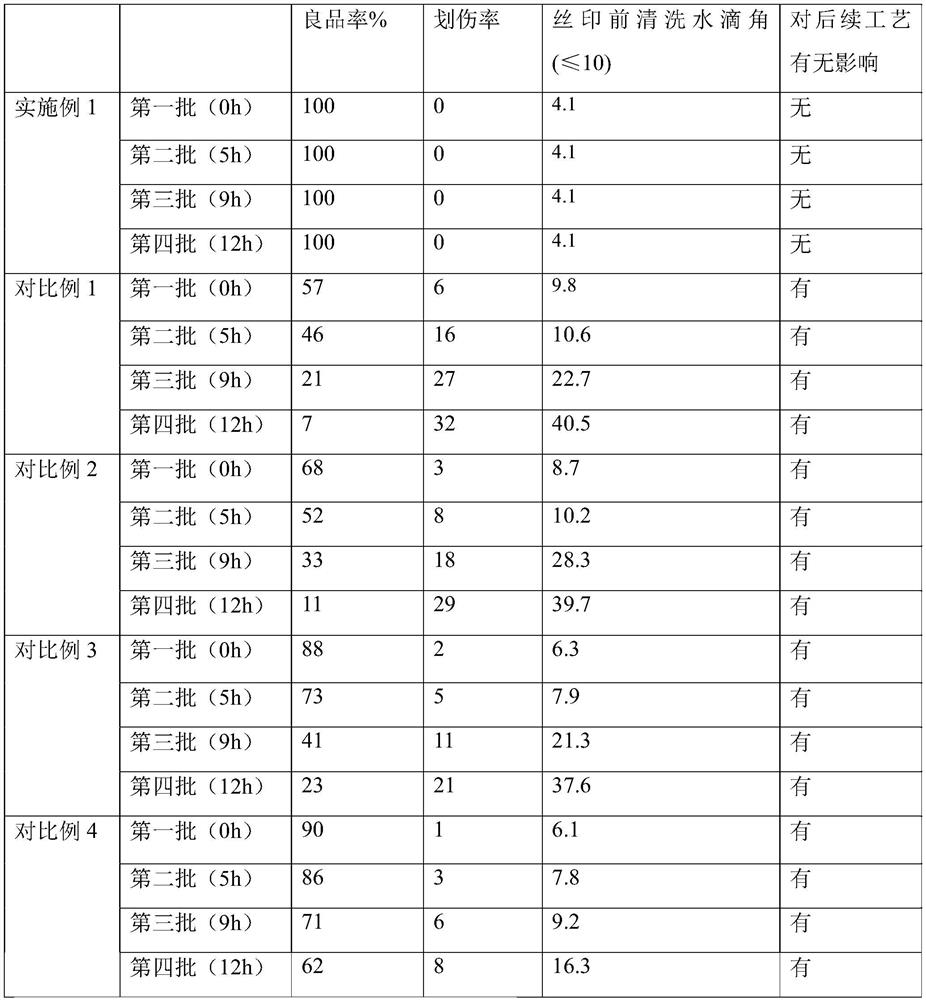

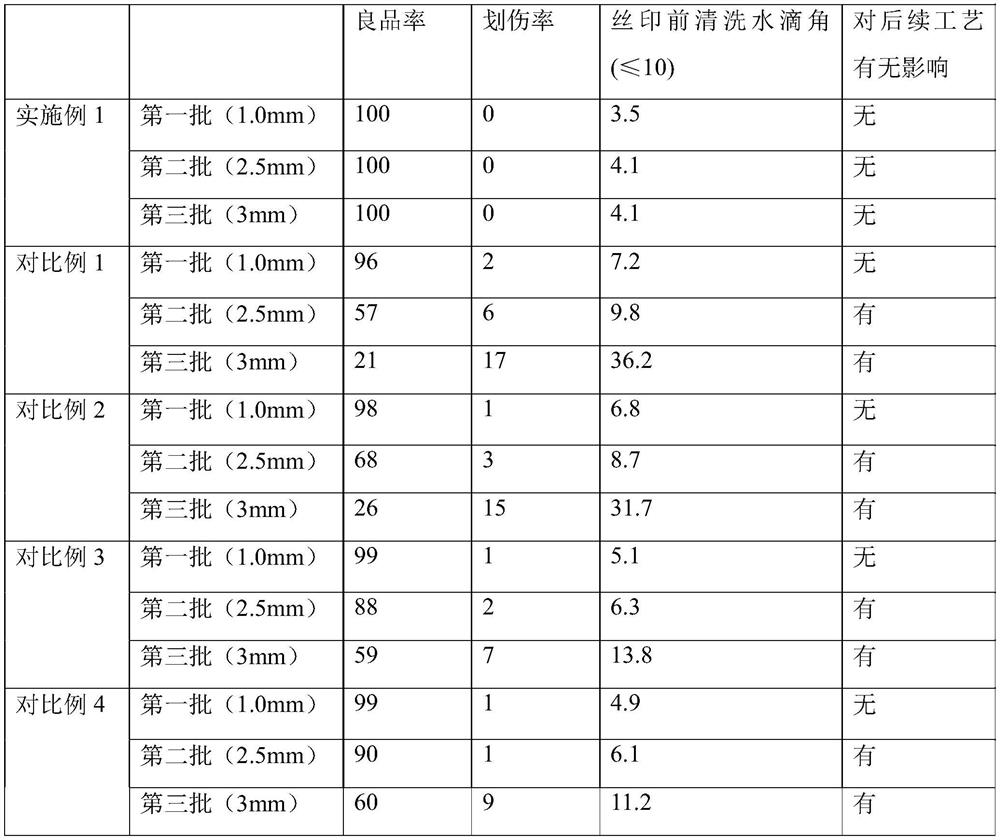

[0037]Table 2

[0038]

[0039]From the above, it is known that the application for optical glass cleaning powder relative to the existing electronic glass cleaning agent, after cleaning, the product scratches are significantly reduced by 1-6%, and the yield is increased by about 10-43%, and the droplet angle is reduced by 40-50. %about. The smaller the average of the water droplet, the higher the clean degree, the smoother the glass surface.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com