Hazardous waste incineration line flue gas purification treatment system

A flue gas purification and treatment system technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of incomplete flue gas purification and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

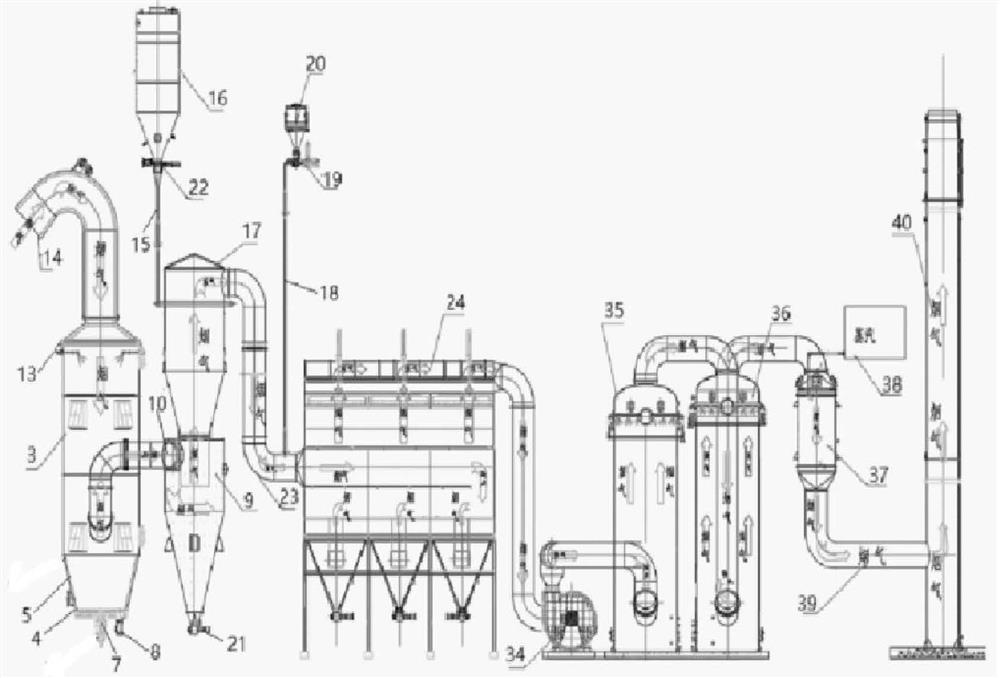

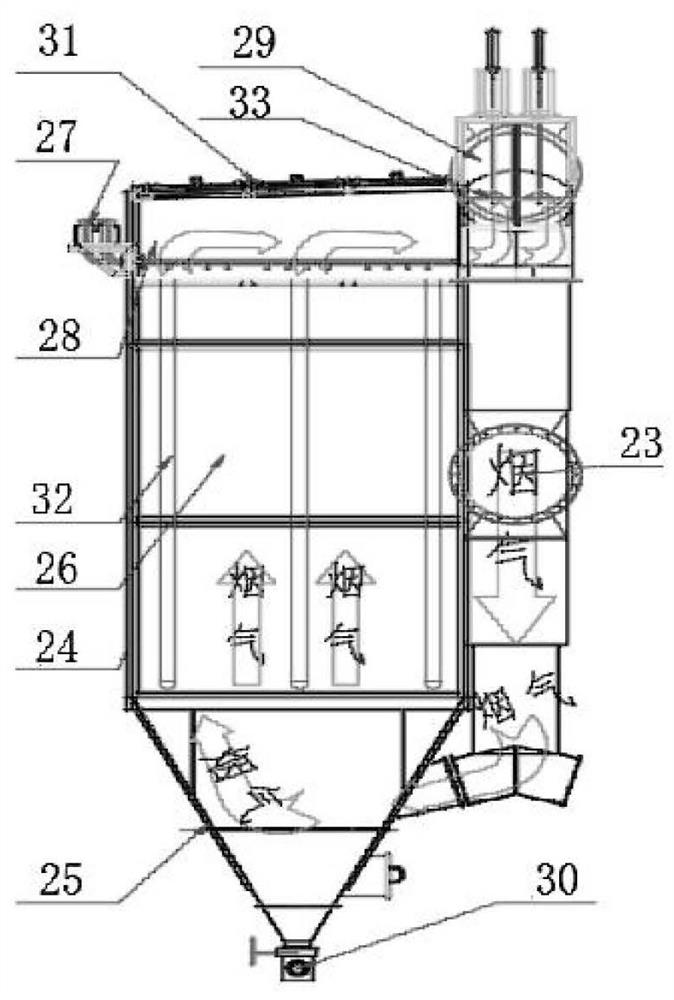

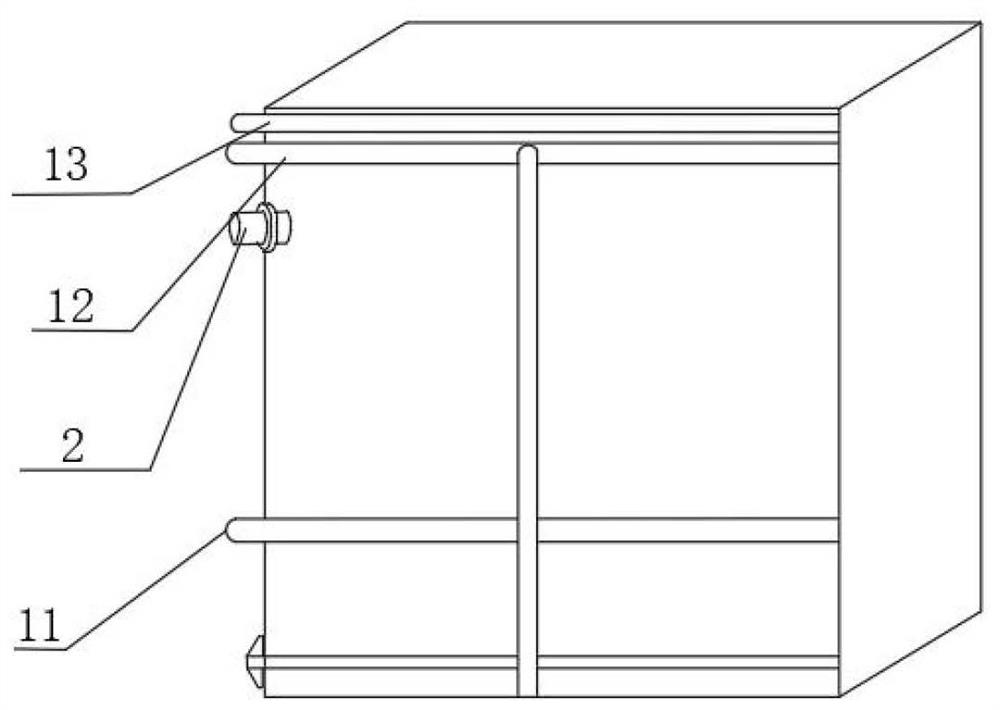

[0022] Such as Figure 1-3As shown, a hazardous waste incineration line flue gas purification treatment system includes a quench tower 3, a cyclone dust collector 9, a dry deacidification tower 17, a filter bag 32, a wet scrubber 35, an lye neutralization tower 36, and a steam heating Device 37 and chimney 40, the outer wall of quenching tower 3 is fixedly connected with quenching tower spray gun cooling water ring pipe 13, quenching tower spray gun compressed air ring pipe 12, quenching spray gun group 2, quenching tower spray gun protection wind ring pipe 11, quenching tower 3 The upper end is provided with the flue gas inlet 14 of the quenching tower, the lower end of the quenching tower 3 is provided with a spray gun compressed air inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com