Environment-friendly vapor phase corrosion inhibitor and preparation method thereof

A gas-phase corrosion inhibitor, an environment-friendly technology, applied in the field of environment-friendly gas-phase corrosion inhibitor and its preparation, can solve problems such as economic loss, metal corrosion, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

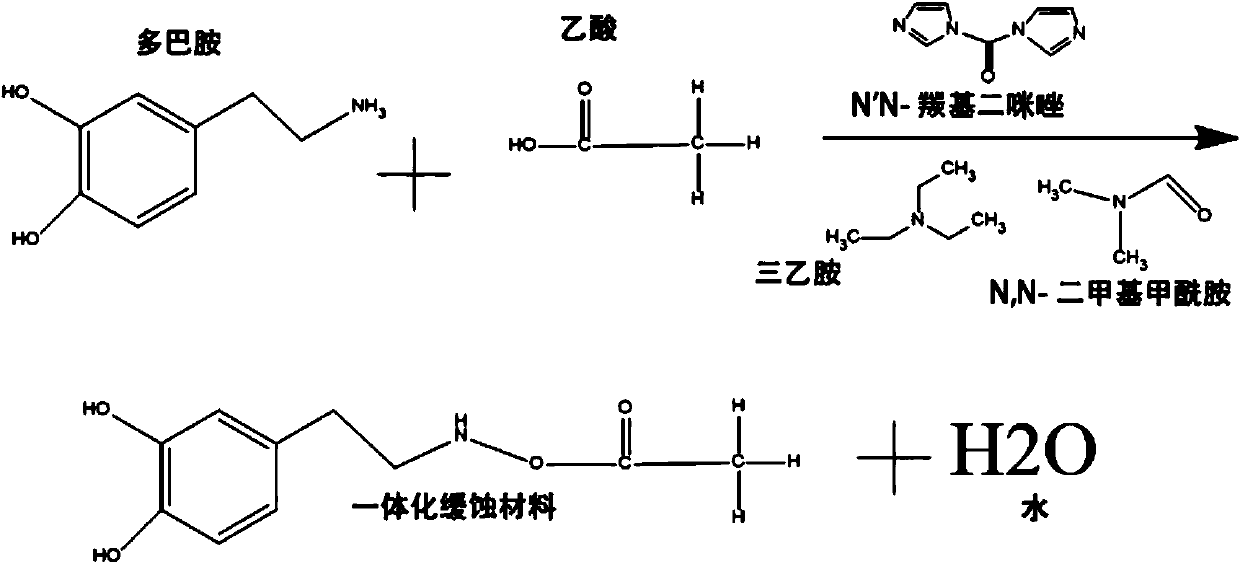

[0063] As some optional embodiments, the preparation method of the integrated sustained-release material includes:

[0064] According to the first mass part, dopamine, N,N-dimethylformamide, N,N'-carbonyldiimidazole, triethylamine and acetic acid are mixed and reacted to obtain a reaction precipitate. Wash and dry to obtain an integrated sustained-release material.

[0065] The above preparation method does not have an amide condensation reaction, wherein N,N-dimethylformamide is used as solvent, N,N'-carbonyldiimidazole is used as catalyst, acetic acid is used as carboxylic acid source, dopamine is used as amine source, and triethylamine is used to adjust pH.

[0066] As some optional embodiments, the reaction includes: reacting for 12-24 hours under the conditions of a temperature of 15-35° C. and a stirring rate of 500-1000 rpm / min.

[0067] The temperature is limited to 15-35°C. If the temperature is too high, the amide bond will be broken, which is not conducive to the rea...

Embodiment 1

[0085] Preparation of integrated corrosion-inhibiting materials:

[0086] Take 15 parts of dopamine and add it to the three-necked flask, add 100 parts of N,N-dimethylformamide to it, then take 5 parts of N,N'-carbonyldiimidazole, and 5 parts of triethylamine and add it to the three-necked flask, Finally, 6 parts of acetic acid were added to the three-necked flask, the temperature was 15-35 °C, and the stirring speed was 500 rpm, and the reaction was carried out for 12 hours. An all-in-one material for dopamine and acetic acid was prepared and set aside.

[0087] Preparation of environment-friendly gas phase corrosion inhibitor:

[0088] Take 10 parts of the integrated material prepared in step (1), 5 parts of aminotrimethylene phosphonic acid, 5 parts of L-alanine, 1 part of sodium dodecylbenzenesulfonate, 3 parts of phytic acid, and 10 parts of urea, 1 part of flavonoids, 5 parts of sodium gluconate, 100 parts of deionized water, mechanical stirring for 10 minutes, stirrin...

Embodiment 2

[0090] Preparation of integrated corrosion-inhibiting materials:

[0091] Take 20 parts of dopamine and add it to the three-necked flask, add 150 parts of N,N-dimethylformamide to it, then take 8 parts of N,N'-carbonyldiimidazole, and 8 parts of triethylamine and add it to the three-necked flask, Finally, 10 parts of acetic acid was added to the three-necked flask, the temperature was 15-35 °C, and the stirring speed was 700 rpm, and the reaction was carried out for 18 hours. An all-in-one material for dopamine and acetic acid was prepared and set aside.

[0092] Preparation of environment-friendly gas phase corrosion inhibitor:

[0093] Take 15 parts of the integrated material prepared in step (1), 7 parts of hydroxyethylidene diphosphonic acid, 6 parts of polyaspartic acid, 2 parts of sodium dodecylbenzene sulfonate, 3 parts of phytic acid, and 15 parts of urea , 2 parts of flavonoids, 7 parts of sodium gluconate, 120 parts of deionized water, mechanical stirring for 12min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com