PCB electroplating device

An electroplating device and electroplating solution technology, applied in the direction of plating tanks, electrolytic processes, electrolytic components, etc., can solve problems such as energy waste, achieve the effects of saving energy waste, increasing flow rate and flow, and increasing deep plating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

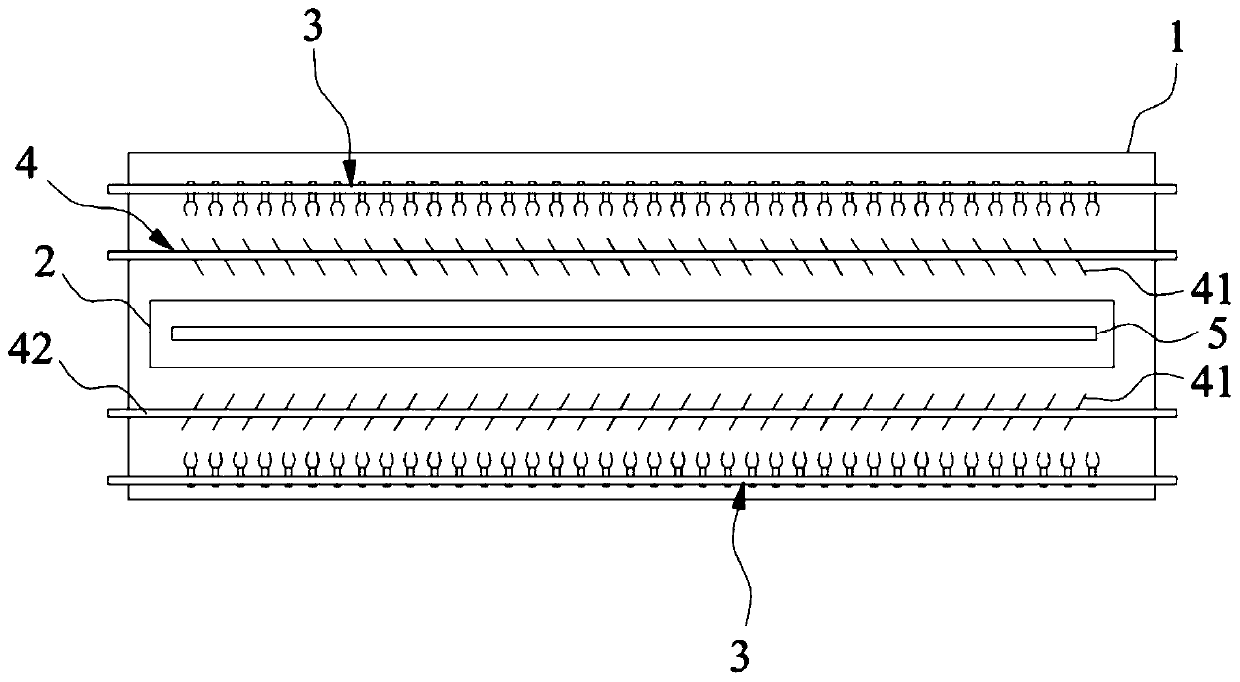

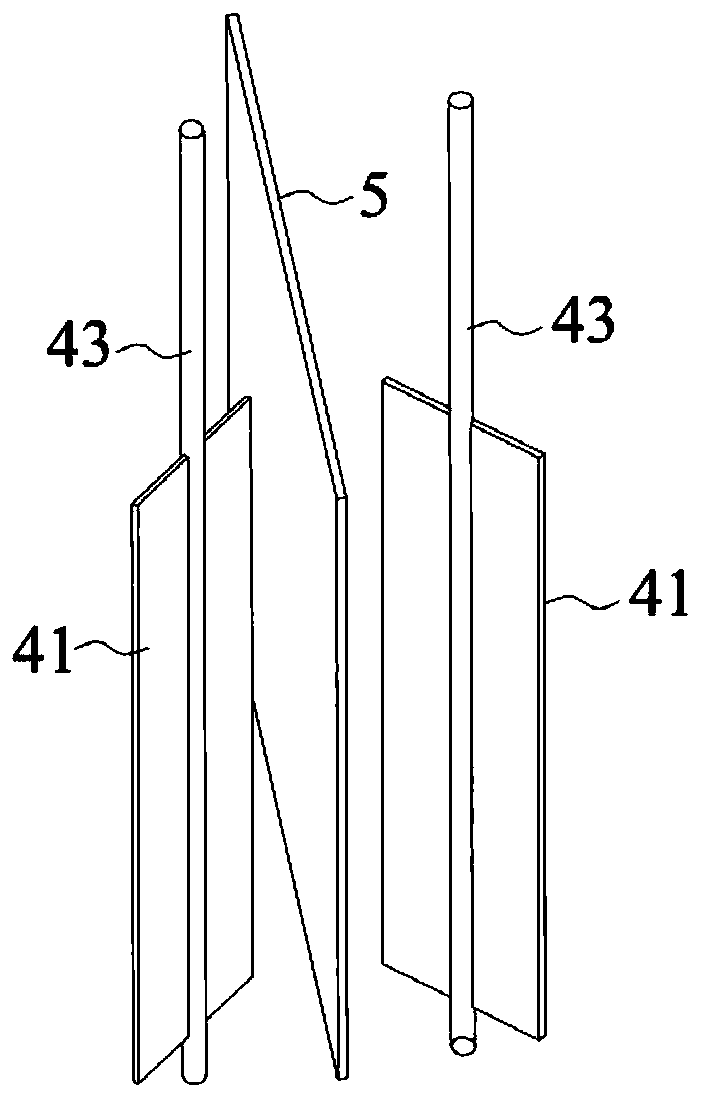

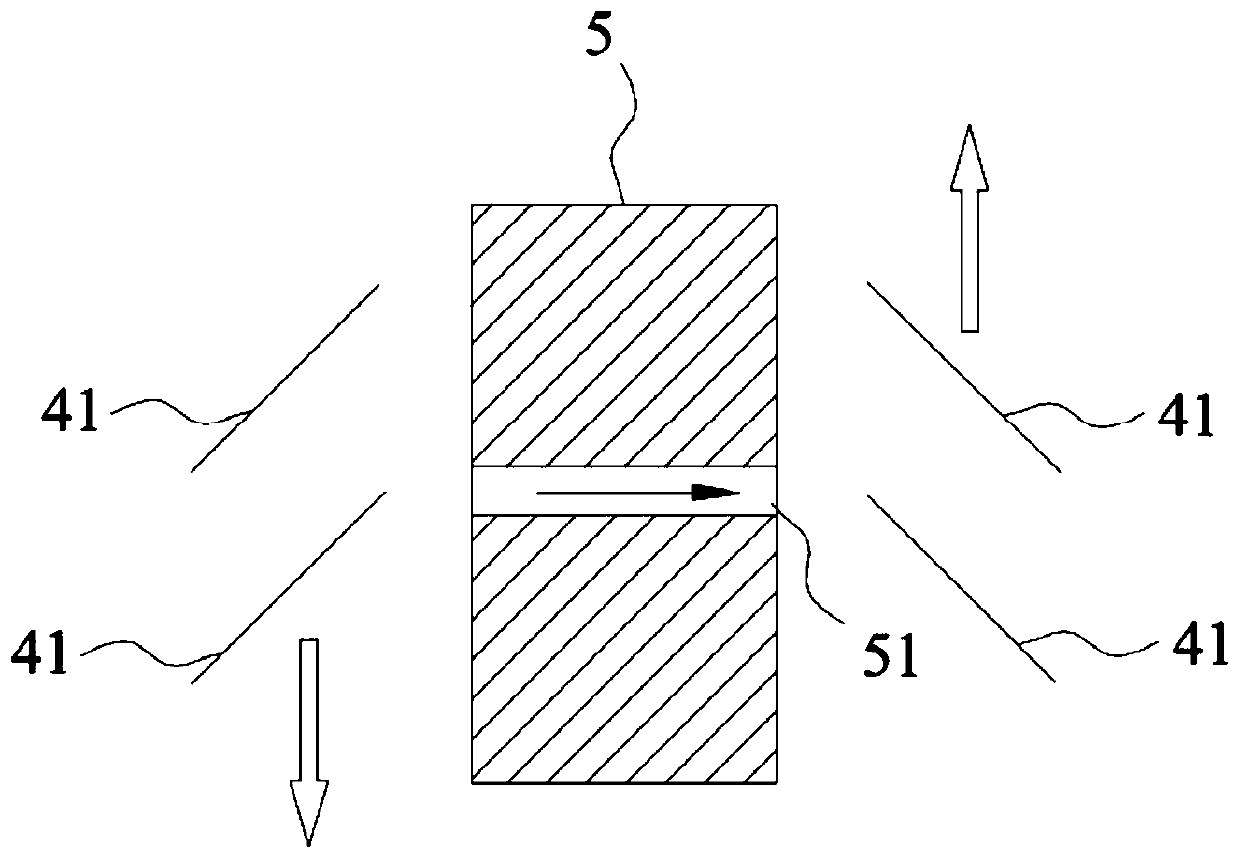

[0038] Such as Figure 1~4 As shown, this embodiment provides a PCB electroplating device, which includes an electroplating tank 1 , a fixture 2 , two anodes 3 and a spoiler assembly 4 . The electroplating tank 1 is used to accommodate the electroplating solution. The fixture 2 is used to clamp the PCB5, and can make the PCB5 be immersed in the electroplating solution along the vertical direction. Both anodes 3 are configured to be immersed in the electroplating solution and are respectively located on two sides of the PCB 5 . The spoiler assembly 4 is configured to be immersed in the electroplating solution, and the spoiler assembly 4 can push the electroplating solution from one side of the PCB5 through the drill hole 51 on the PCB5 to the other side of the PCB5. In this embodiment, the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com