Method for electroplating zinc-nickel alloy on sintered neodymium iron boron

A technology of electroplating zinc-nickel and NdFeB, which is applied in the application of magnetic film to substrate and liquid application, etc. It can solve the problems of low corrosion resistance and poor deep plating ability of NdFeB magnets, etc., and increase the bonding force , the effect of reducing the harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

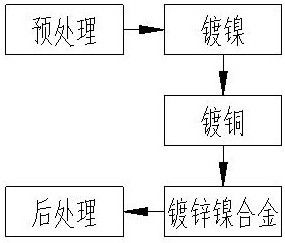

Image

Examples

Embodiment 1

[0031] A method for sintering neodymium-iron-boron electroplating zinc-nickel alloy, is characterized in that, comprises the following steps:

[0032] (1) Preprocessing:

[0033] The sintered NdFeB magnet is pretreated to obtain a pretreated magnet. The pretreatment includes chamfering treatment, degreasing treatment, pickling treatment and activation treatment, and chamfering treatment, degreasing treatment, pickling treatment and activation treatment are adopted. It is beneficial to improve the electroplating effect and avoid adverse effects on the subsequent electroplating process of NdFeB magnets;

[0034] (2) Nickel plating:

[0035] Soak the pretreated magnet in a solution of 80 degrees for electroless nickel plating, the thickness of electroless nickel plating is 2 microns, and the time is 15 minutes;

[0036] (3) Copper plating:

[0037] The nickel-plated magnet is electroplated copper. The electroplated copper is alkaline copper plating or pyrophosphate copper plat...

Embodiment 2

[0043] A method for sintering neodymium-iron-boron electroplating zinc-nickel alloy, is characterized in that, comprises the following steps:

[0044] (1) Preprocessing:

[0045] The sintered NdFeB magnet is pretreated to obtain a pretreated magnet. The pretreatment includes chamfering treatment, degreasing treatment, pickling treatment and activation treatment, and chamfering treatment, degreasing treatment, pickling treatment and activation treatment are adopted. It is beneficial to improve the electroplating effect and avoid adverse effects on the subsequent electroplating process of NdFeB magnets;

[0046] (2) Nickel plating:

[0047] Soak the pretreated magnet in a solution of 85 degrees for electroless nickel plating, the thickness of electroless nickel plating is 10 microns, and the time is 30 minutes;

[0048] (3) Copper plating:

[0049] The nickel-plated magnet is electroplated with copper. The electroplated copper is alkaline copper plating or pyrophosphate coppe...

Embodiment 3

[0055] A method for sintering neodymium-iron-boron electroplating zinc-nickel alloy, is characterized in that, comprises the following steps:

[0056] (1) Preprocessing:

[0057] The sintered NdFeB magnet is pretreated to obtain a pretreated magnet. The pretreatment includes chamfering treatment, degreasing treatment, pickling treatment and activation treatment, and chamfering treatment, degreasing treatment, pickling treatment and activation treatment are adopted. It is beneficial to improve the electroplating effect and avoid adverse effects on the subsequent electroplating process of NdFeB magnets;

[0058] (2) Nickel plating:

[0059] Soak the pretreated magnet in a solution of 82 degrees for electroless nickel plating, the thickness of electroless nickel plating is 4 microns, and the time is 20 minutes;

[0060] (3) Copper plating:

[0061] The nickel-plated magnet is electroplated with copper. The electroplated copper is alkaline copper plating or pyrophosphate copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com