Extra-hardness chrome plating additive and application thereof

An additive and hardness technology, applied in the field of electrochrome plating, can solve the problems of increased labor intensity, cumbersome process, and fast accumulation of impurities, etc., and achieve the effect of eliminating the need for mechanical polishing process, simple process operation, and bright and meticulous coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare ultra-high hardness chrome plating additives according to the following weight concentration:

[0033] Sodium methylene disulfonate: 10g / L

[0034] Cerium sulfate: 0.1g / L

[0035] Sodium tungstate: 0.5g / L;

[0036] The above components are mixed to obtain the composite chrome plating additive of this embodiment.

[0037] The standard chromium plating solution contains 220g / L chromic anhydride, 2.2g / L sulfuric acid, and 3g / L trivalent chromium. The above-mentioned ultra-high hardness chromium plating additives are added to the standard chromium electroplating solution. Process parameters: current density 60A / dm 2 , the temperature is 55°C, the ratio of anode to cathode area is greater than 2:1, and the electroplating time is 1 hour. Select an iron-based rod-shaped piece with a diameter of 10mm and a length of 100mm (substrate surface roughness Ra≤0.1) for plating, and inspect the coating.

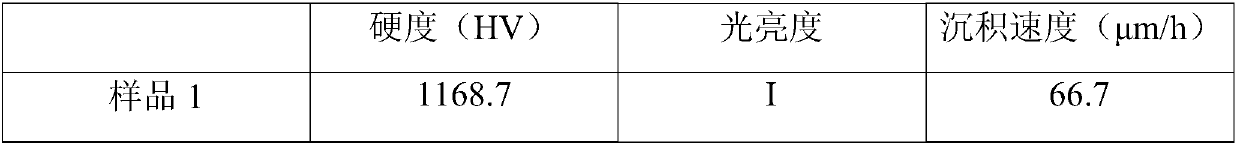

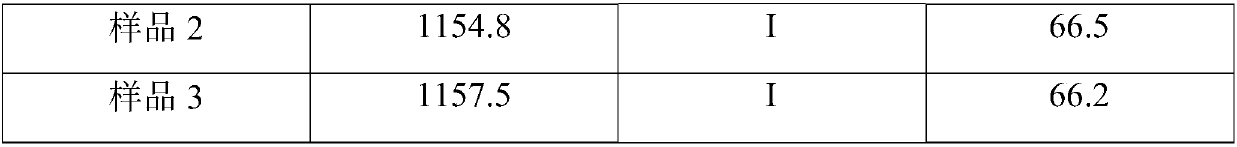

[0038] The test results show that the coating is bright and fine, t...

Embodiment 2

[0045] Prepare ultra-high hardness chrome plating additives according to the following weight concentration:

[0046] Methanesulfonic acid: 5g / L

[0047] Formic acid: 5g / L

[0048] Cerium sulfate: 0.05g / L

[0049] Sodium molybdate: 1g / L;

[0050] The above components are mixed to obtain the composite chrome plating additive of this embodiment.

[0051] The standard chromium plating solution contains 220g / L chromic anhydride, 2.2g / L sulfuric acid, and 3g / L trivalent chromium. The above-mentioned ultra-high hardness chromium plating additives are added to the standard chromium electroplating solution. Process parameters: current density 60A / dm 2 , the temperature is 55°C, the ratio of anode to cathode area is greater than 2:1, and the electroplating time is 1 hour. Select an iron-based rod-shaped piece with a diameter of 10mm and a length of 100mm for plating, and inspect the coating.

[0052] The test results show that the coating is bright and fine, the Vickers hardness...

Embodiment 3

[0056] Prepare ultra-high hardness chrome plating additives according to the following weight concentration:

[0057] Methanesulfonic acid: 5g / L

[0058] Sodium methylene disulfonate: 5g / L

[0059] Cerium sulfate: 0.1g / L

[0060] Sodium tungstate: 1g / L;

[0061] The standard chromium plating solution contains 220g / L chromic anhydride, 2.2g / L sulfuric acid, which contains 3g / L. The above-mentioned ultra-high hardness chromium plating additives are added to the standard chromium electroplating solution. Process parameters: current density 60A / dm 2 , the temperature is 55°C, the ratio of anode to cathode area is greater than 2:1, and the electroplating time is 1 hour. Select an iron-based rod-shaped piece with a diameter of 10mm and a length of 100mm for plating, and inspect the coating.

[0062] The test results show that the coating is bright and fine, the Vickers hardness is stable above 1150HV, the brightness of the coating is basically stable at grade I, and the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com