Reverse pulse plating composition and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

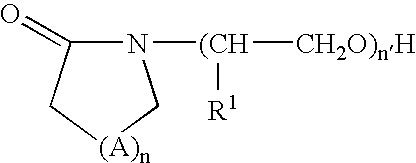

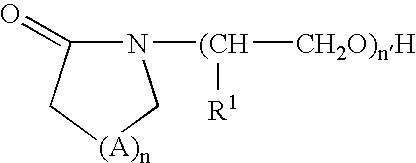

Image

Examples

example 1

Compositions to Reduce or Eliminate Whiskers

Eight copper metal electroplating baths were prepared to verify the ability of chloride to prevent or reduce whisker (dendrite) formation on copper metal surfaces during electroplating of copper on a substrate. Each electroplating composition or bath was an aqueous bath that contained 80 grams / liter of copper sulfate pentahydrate as the metal ion source, 225 grams / liter of sulfuric acid to maintain the pH of the baths at 4.0. Chloride ion concentration in each of the baths was 25 ppm. The chloride ion source was HCl. In addition to the foregoing components, each bath also contained a carrier component at a concentration of either 0.25 ppm or 1 ppm, and a brightener (BSDS) in an amount of either 0.1 ppm or 0.2 ppm to provide a chloride to brightener ratio of either 125:1 or 250:1. Carriers that were employed in each solution are disclosed in the table below. All of the carriers listed in the table below are block copolymers.

Each bath wa...

example 2

Whisker Reduction

Four electroplating baths were prepared to verify the function of the pulse waveform with respect to the formation for whiskers (dendrites). All four baths contained the same concentration of chemical components, and all substrates were plated using the same anodes, and tank assembly. The anodes were freshly etched prior to each plating experiment. The concentration of inorganic components in each bath was 82 g / L CuSO4.5H2O, 216.5 g / L H2SO4, and Cl- / brightener ratio was 44. The concentration of suppressor in each bath was 15 ml / l. In a 1.5 liter Haring plating cell, a 15 cm×6.3 cm copper clad panel was electroplated at 10.7 mA / cm2 in each plating bath using a different pulse waveform as shown in the Table. After plating, the boards were physically scanned for whiskers, see Table. As shown in the Table, as the forward wave was made longer, the number of whiskers was reduced significantly. This effect was particularly marked as the forward wave reaches 50 ms and abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com