Preparation method of reverse copper foil

A technology of copper foil and copper content, applied in electrolysis process, electroforming, etc., can solve the problems of low peel strength, coarse surface crystallization, residual copper on circuit boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

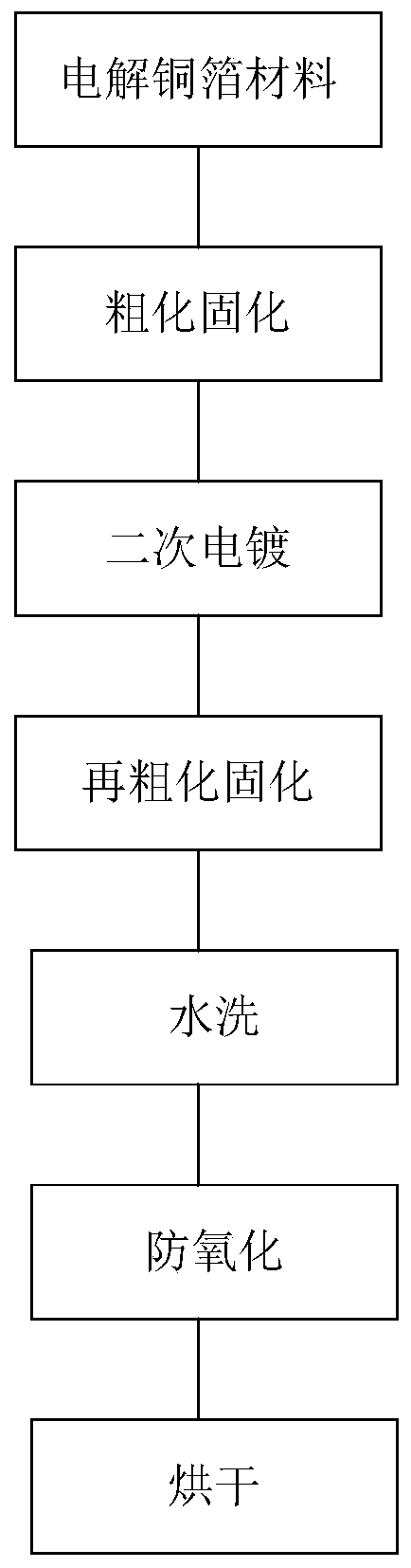

[0047] Such as figure 1 As shown, the present invention provides a process method of reverse electrolytic copper foil, which includes the following steps: the electrolyte is prepared by adding 99% cathode copper plate, sulfuric acid and deionized water into a copper-dissolving tank, and under a constant temperature of 50°C, In the production process of copper foil, the electrolyte is recycled, and the electrolytic copper is continuously precipitated from the titanium roller, thereby continuously consuming the copper in the electrolyte, and the copper in the electrolyte is continuously dissolved by the copper melting tank to replenish the copper consumed in the electrolyte. Keep the copper content in the electrolyte in balance at all times. In the process of electrolyte preparation, not only the continuous circulation of the electrolyte must be ensured, but also the composition of the electrolyte should be adjusted and stably controlled in time. The copper content in the electr...

Embodiment 2

[0049] A process method for reverse electrolytic copper foil, comprising the following steps:

[0050] Use the electrolyte preparation method in embodiment 1 to make electrolyte;

[0051] The copper content in the electrolyte is 130-220g / L, and the sulfuric acid content is 70-100g / L; the electrolyte is heated to 45 degrees, and 7 parts by mass of WH-001 additive is added to 1000 parts by volume of the electrolyte every hour, 1000 Add 3 parts by mass of WH-002 additive to the electrolytic solution by volume, add 3 parts by mass of WH-003 additive to 1000 parts by volume of the electrolytic solution, add 15 ml of 16% hydrochloric acid to the electrolytic solution and mix well, then the electrolytic solution enters the anode tank; Under the action of an electric field, the electrolyte solution has a current density of 20-30A / dm2, cations move to the cathode, and anions move to the anode for electrochemical reactions to produce single-sided electrolytic copper foil with uniform su...

Embodiment 3

[0053] A process method for reverse electrolytic copper foil, comprising the following steps:

[0054] Use the electrolyte preparation method in embodiment 1 to make electrolyte;

[0055] The copper content in the electrolyte is 130-220g / L, and the sulfuric acid content is 70-100g / L; the electrolyte is heated to 45 degrees, and 10 parts by mass of WH-001 additive is added to 1000 parts by volume of the electrolyte every hour, 1000 Add 3 parts by mass of WH-002 additive to the electrolytic solution by volume, add 5 parts by mass of WH-003 additive to 1000 parts by volume of the electrolytic solution, add 15 ml of 16% hydrochloric acid to the electrolytic solution and mix well, then the electrolytic solution enters the anode tank; Under the action of an electric field, the electrolyte solution has a current density of 20-30A / dm2, cations move to the cathode, and anions move to the anode for electrochemical reactions to produce single-sided electrolytic copper foil with uniform s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com