Preparation method of metal surface plating layer structure applicable to ocean severe corrosion environment

A metal surface, strong corrosion technology, applied in the direction of metal material coating process, etc., can solve problems such as zinc hoarfrost of the coating, achieve high corrosion resistance and wear resistance, good dispersibility, and reduce the effect of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of embodiment 1 iron and steel substrate coating structure

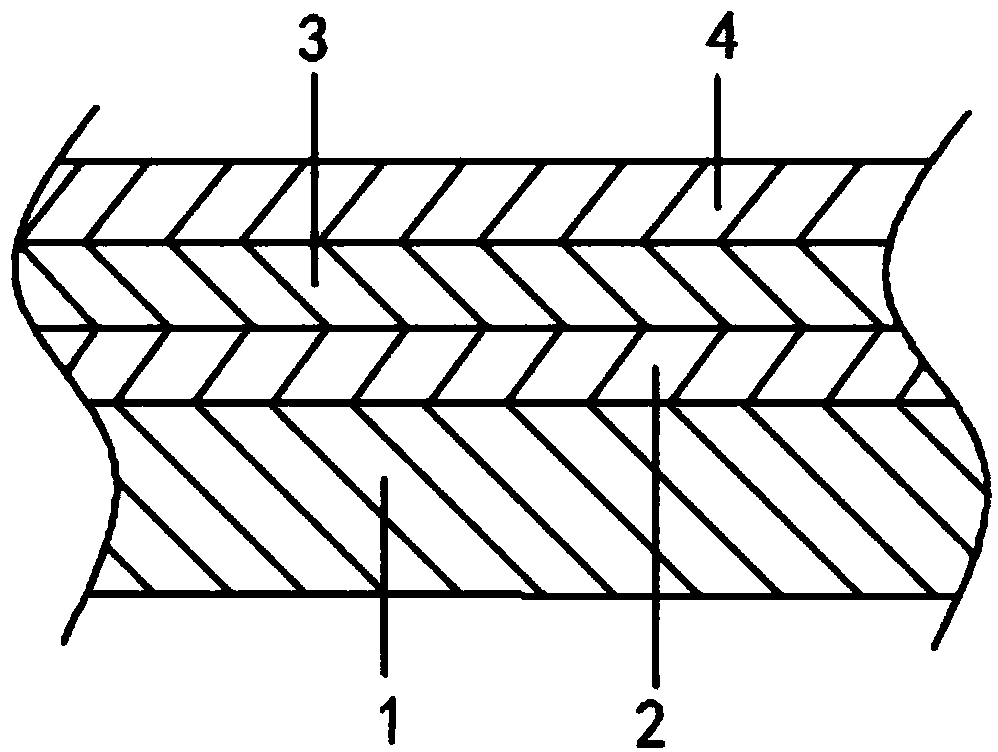

[0051] Such as figure 1 As shown, a metal surface coating structure suitable for marine strong corrosion environment, from inside to outside is 1-steel base layer, 2-cadmium plating layer, 3-passivation layer, 4-sealing layer.

[0052] Preparation:

[0053] S1. Metal substrate pre-treatment: Alkaline chemical degreasing → water washing → alkaline anode electrolytic degreasing → water washing → pickling → water washing → cathodic electrolytic degreasing → water washing → 10% sulfuric acid activation → water washing on the metal substrate. After the metal substrate;

[0054] S2. Preparation of cyanide-free cadmium plating layer: the metal substrate obtained in step S1 is prepared by using the acidic cyanide-free cadmium plating solution described in the Chinese invention application CN1062 45071A through the electroplating process to prepare a cyanide-free cadmium plating layer with a ...

Embodiment 2

[0057] The preparation method of embodiment 2 copper alloy substrate coating structure

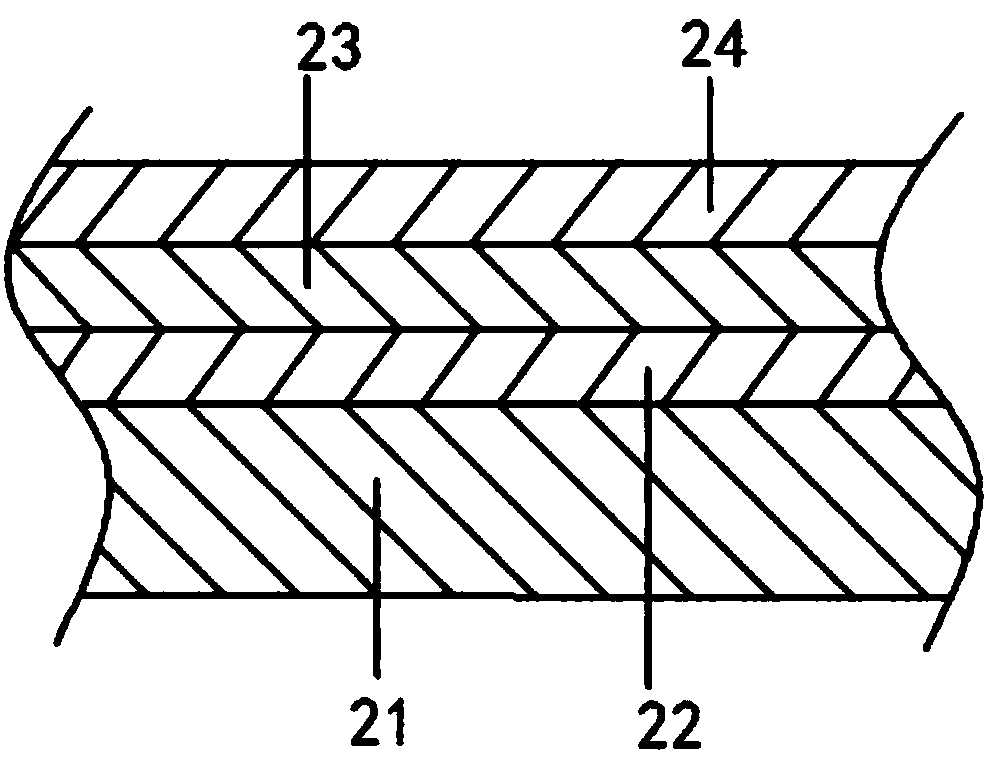

[0058] Such as figure 2 As shown, a metal surface coating structure suitable for marine strong corrosion environment, from the inside to the outside is 21-copper alloy base layer, 22-cadmium plating layer, 23-passivation layer, 24-sealing layer.

[0059] Preparation:

[0060] S1. Metal substrate pretreatment: carry out alkaline chemical degreasing → water washing → ultrasonic chemical degreasing → water washing → pickling → water washing → 10% sulfuric acid activation → water washing on the metal substrate to obtain the treated metal substrate;

[0061] S2. Preparation of cyanide-free cadmium plating layer: the metal substrate obtained in step S1 is prepared by using the acidic cyanide-free cadmium plating solution described in the Chinese invention application CN1062 45071A through the electroplating process to prepare a cyanide-free cadmium plating layer with a thickness of 16 μm to ...

Embodiment 3

[0064] The preparation method of embodiment 3 zinc alloy coating structure

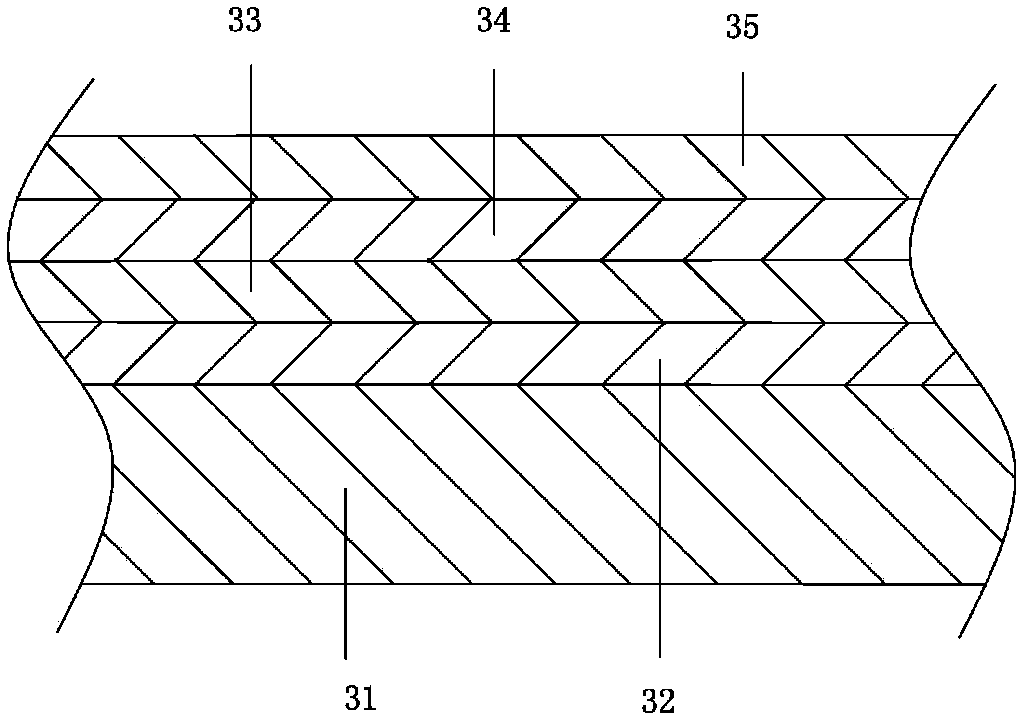

[0065] Such as image 3 As shown, a metal surface coating structure suitable for marine strong corrosion environment, from the inside to the outside is 31-zinc alloy base layer, 32-chemical pre-plating nickel layer, 33-cadmium plating layer, 34-passivation layer , 35-closed layer.

[0066] Preparation:

[0067] S1. Metal substrate pretreatment: carry out alkaline chemical degreasing → water washing → ultrasonic chemical degreasing → water washing → 5% nitric acid light → water washing → 5% sulfuric acid activation → water washing on the metal substrate to obtain the treated metal substrate. The treated metal substrate is plated with an electroless pre-nickel layer by an alkaline electroless nickel plating process, washed with water, and the plated part A is obtained;

[0068] S2. Preparation of cyanide-free cadmium plating layer: the plated part A obtained in step S1 is prepared by using the acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com