R4 grade steel for mooring chain and its preparation method

A technology for mooring chains and tons of steel, which is applied in the field of steel for R4 mooring chains and its preparation. It can solve the problems of high overall alloy composition, internal cracks in materials, and affecting welding performance, so as to reduce the amount of inclusions and reduce the production cost. Cost, the effect of improving the yield of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

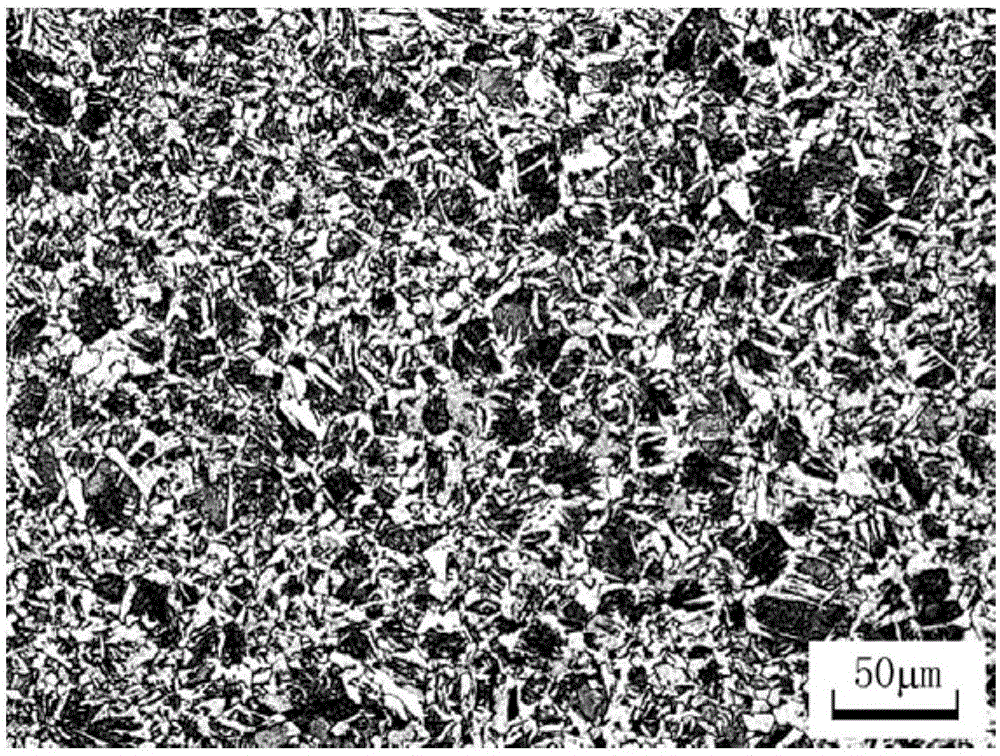

Image

Examples

Embodiment 1

[0025] Prepare a steel for mooring chains of R4 grade with a diameter of 120mm. The chemical composition of molten steel is calculated by weight percentage: C: 0.165%, Si: 0.193%, Mn: 1.29%, P: 0.020%, S: 0.015% , Cu: 0.02%, Cr: 0.95%, Ni: 0.87%, Mo: 0.33%, Al: 0.037%, As: 0.0040%, Sb: 0.0035%, Sn: 0.0028%, N: 0.0032%, O: 0.0016% , H: 0.0013%;

[0026] Its preparation method includes the steps of molten iron desulfurization, converter smelting, argon blowing, LF furnace refining, RH furnace vacuum treatment, continuous casting, billet heating, rolling, air cooling, and non-destructive testing, wherein:

[0027] When the molten iron is desulfurized, the magnesium powder desulfurization process is adopted to control the sulfur content S of the molten iron leaving the station to 0.010%, and the desulfurization slag in the tank must be cleaned;

[0028] During converter smelting, the amount of steel scrap loaded accounts for 10% of the total amount loaded; the converter adopts to...

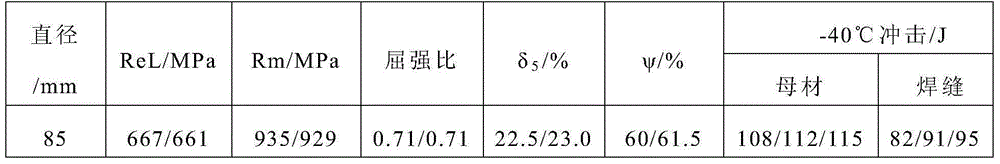

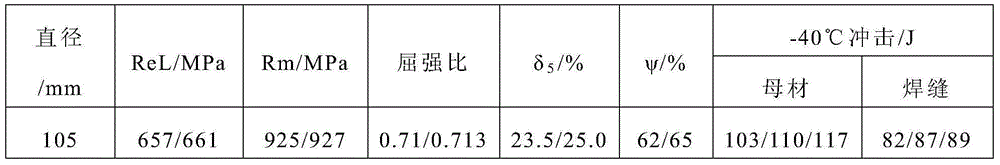

Embodiment 2

[0039] Prepare a steel for mooring chains of R4 grade with a diameter of 105mm. The chemical composition of molten steel is calculated by weight percentage: C: 0.191%, Si: 0.25%, Mn: 1.27%, P: 0.013%, S: 0.012% , Cu: 0.012%, Cr: 0.89%, Ni: 0.83%, Mo: 0.29%, Al: 0.037%, As: 0.0036%, Sb: 0.0022%, Sn: 0.0034%, N: 0.0027%, O: 0.0011% , H: 0.0009%.

[0040] The preparation method includes the steps of molten iron desulfurization, converter smelting, argon blowing, LF furnace refining, RH furnace vacuum treatment, continuous casting, billet heating, rolling, air cooling, and nondestructive testing, wherein:

[0041] When the molten iron is desulfurized, the magnesium powder desulfurization process is adopted to control the sulfur content S of the molten iron leaving the station to 0.010%, and the desulfurization slag in the tank must be cleaned;

[0042] During converter smelting, the amount of steel scrap loaded accounts for 15% of the total amount loaded; the converter adopts top...

Embodiment 3

[0053] Prepare a steel for R4 grade mooring chains with a diameter of 125mm. The chemical composition of molten steel is calculated by weight percentage: C: 0.20%, Si: 0.25%, Mn: 1.35%, P: 0.025%, S: 0.025% , Cu: 0.02%, Cr: 1.23%, Ni: 1.09%, Mo: 0.290%, Al: 0.35%, As: 0.0027%, Sb: 0.0015%, Sn: 0.0031%, N: 0.0023%, O: 0.0012% , H: 0.0014%.

[0054] The preparation method includes the steps of molten iron desulfurization, converter smelting, argon blowing, LF furnace refining, RH furnace vacuum treatment, continuous casting, billet heating, rolling, air cooling, and nondestructive testing, wherein:

[0055] When the molten iron is desulfurized, the magnesium powder desulfurization process is adopted to control the sulfur content S of the molten iron leaving the station to 0.009%, and the desulfurization slag in the tank must be cleaned;

[0056] During converter smelting, the amount of steel scrap loaded accounts for 12% of the total amount loaded; the converter adopts top-bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com