High-strength bolt steel capable of shortening wire rod procedures and wire rod modifying process thereof

A technology of high-strength bolts and wire rods, which is applied in the direction of improving process efficiency, etc., can solve the problems of poor quality stability of high-strength bolt steel and long process of wire rod reforming, etc., to solve poor quality stability, improve spheroidization rate, and stable quality good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0066] Table 1. Chemical composition of example and comparative steels, % by weight

[0067]

[0068] Table 2 Embodiment Wire Rod Transformation Process

[0069]

[0070] Table 3 Example Wire Rod Reforming Process Parameters

[0071]

[0072]

[0073] Table 4 embodiment heat treatment process

[0074] Numbering

Quenching temperature

tempering temperature

a

880

400

b

880

450

c

880

500

7 --> d

880

550

e

880

600

f

880

650

[0075] Table 5 specific embodiment and test result

[0076]

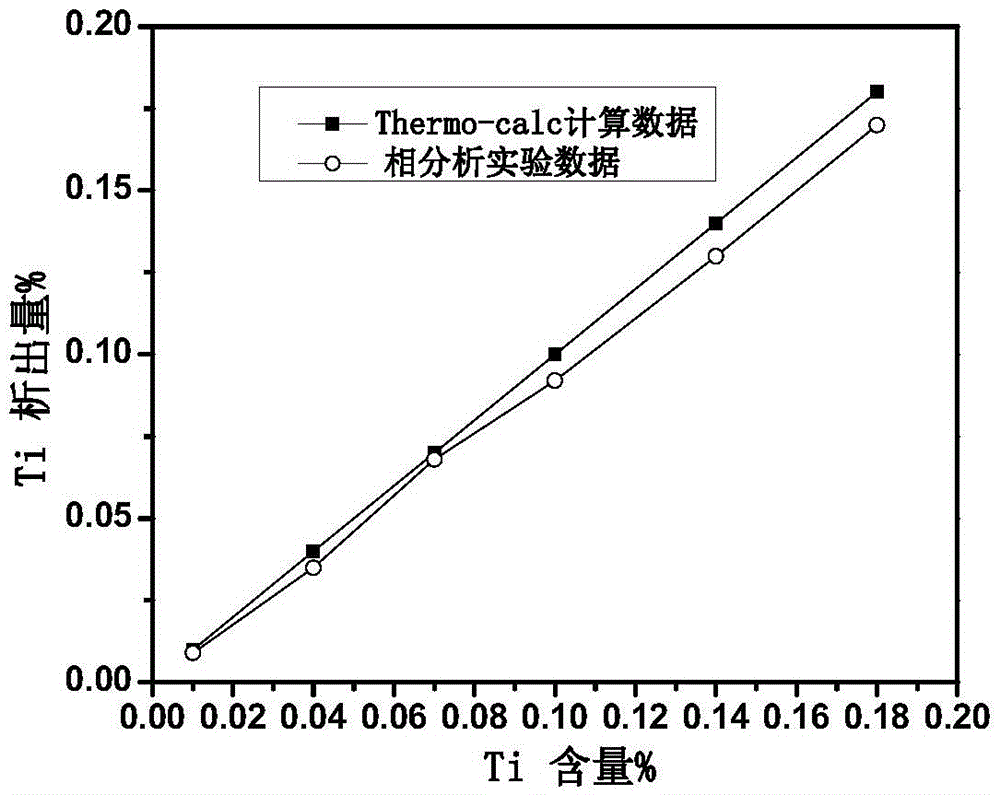

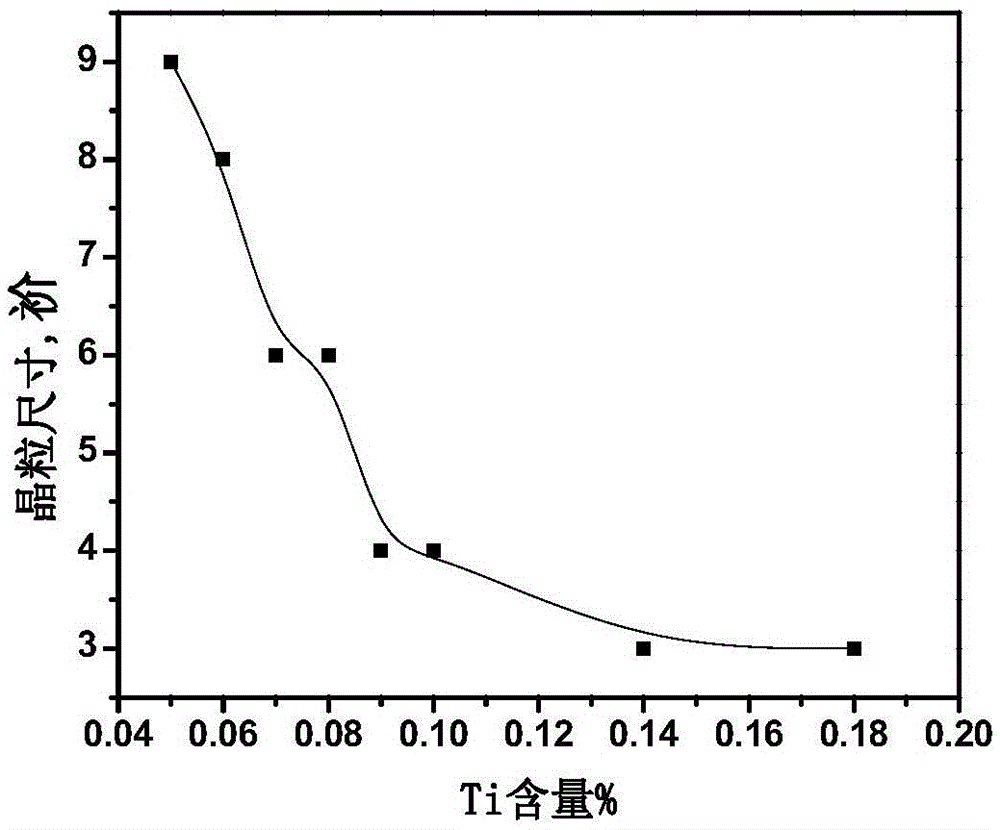

[0077] It can be seen from Table 1 that after the invention steel adopts precipitation strengthening instead of solid solution strengthening, the C content in the steel is reduced from 0.42% of the traditional high-strength bolt steel to 0.25-0.32%, and the precipitation of the microalloying element Ti refines the original austenite. Grain to 3-8μm ( Figure 10 ), improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com