A compound refining method for zirconium-containing magnesium alloy

A compound refining and magnesium alloy technology, which is applied in the field of compound refining of zirconium-containing magnesium alloys, can solve the problems such as the weakening of zirconium grain refinement effect, and achieve the effect of improving grain refinement effect, less inclusion amount and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

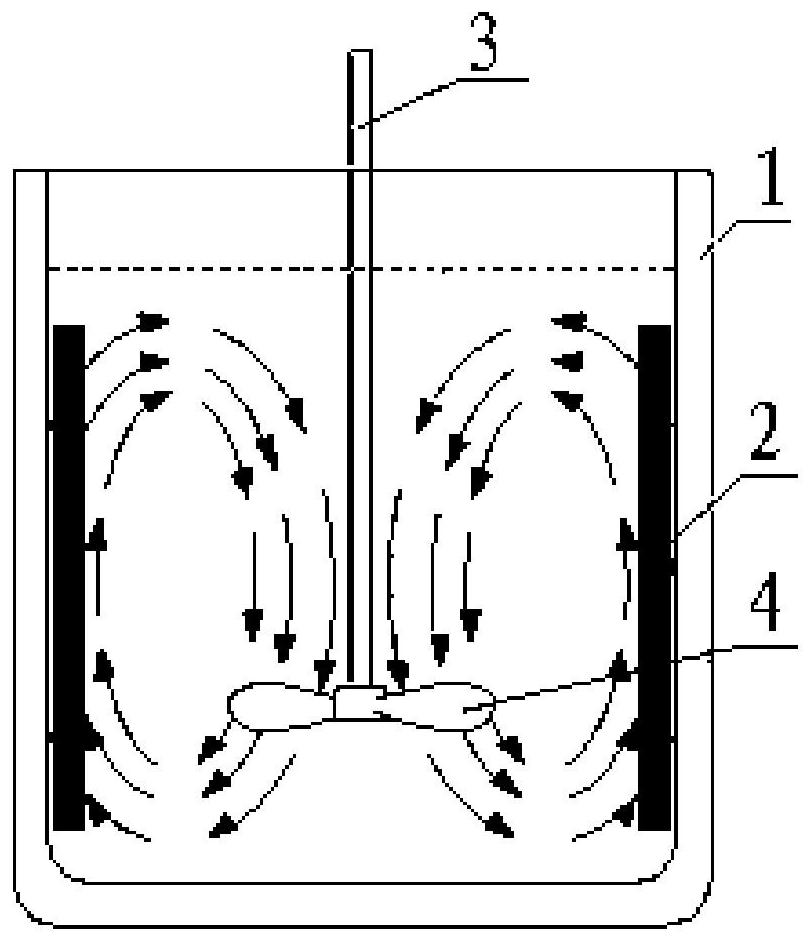

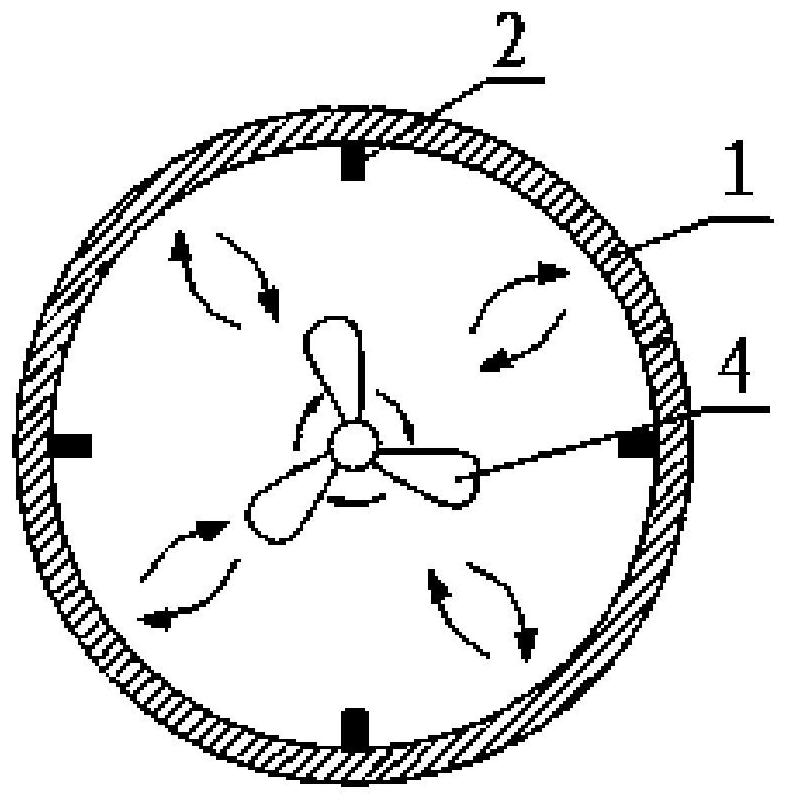

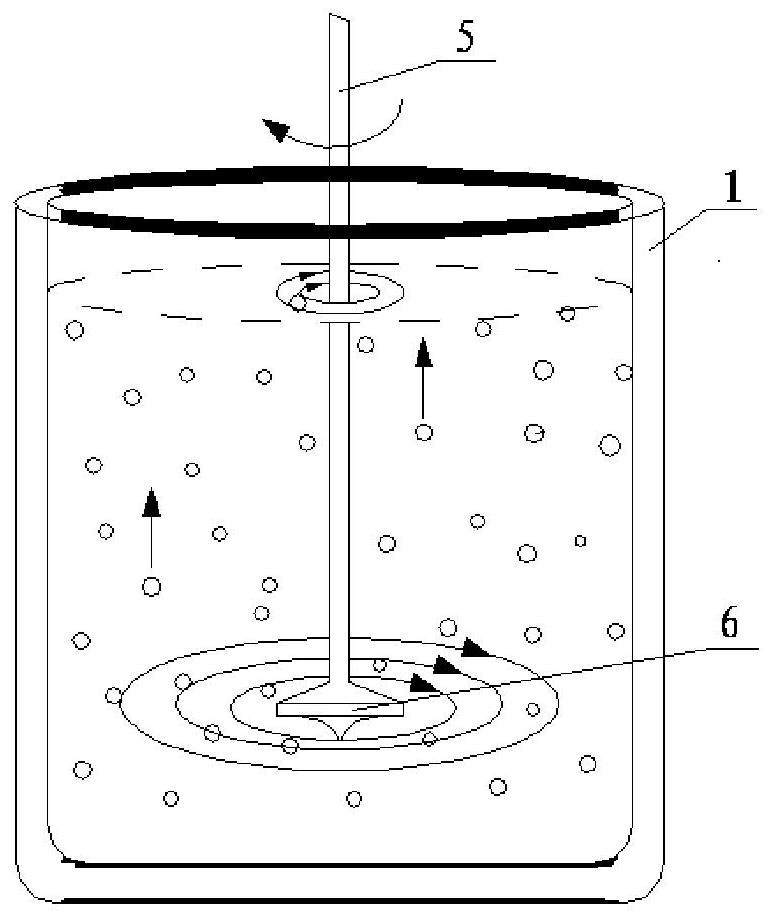

[0057] A compound refining method for a zirconium-containing magnesium alloy, comprising the steps of:

[0058] a. The first heating device 1 includes a crucible. The size of the crucible is 500 mm in inner diameter and 1000 mm in depth. After the crucible is energized and preheated to 450 ° C, 212.67 kg of magnesium ingots are added to the crucible, and the magnesium ingots are Mg>99.80wt.%, the first The heating device 1 melts the magnesium ingot into a molten magnesium melt;

[0059] b. The molten magnesium melt is stirred by a stirring device, and the stirrer 4 is located at one-third of the height of the molten magnesium melt, and the first heating device 1 continues heating to make the molten magnesium melt reach a temperature of 750° C. The magnesium melt is added with 1.50kg of zinc flakes and 20.83kg of magnesium-neodymium master alloy after preheating through the crucible. Under the above conditions, the stirring device continued to stir for 3min to obtain an interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com