CaO-ZrO2 composition, method for producing CaO-ZrO2 composition, CaO-ZrO2-containing refractory material, and casting nozzle

A technology for refractory materials and manufacturing methods, applied in casting equipment, manufacturing tools, casting melt containers, etc., can solve the problems of excessive corrosion resistance or strength reduction, inability to ensure, difficult adhesion performance, etc., and achieve the effect of reducing the amount of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0222] Examples are described below.

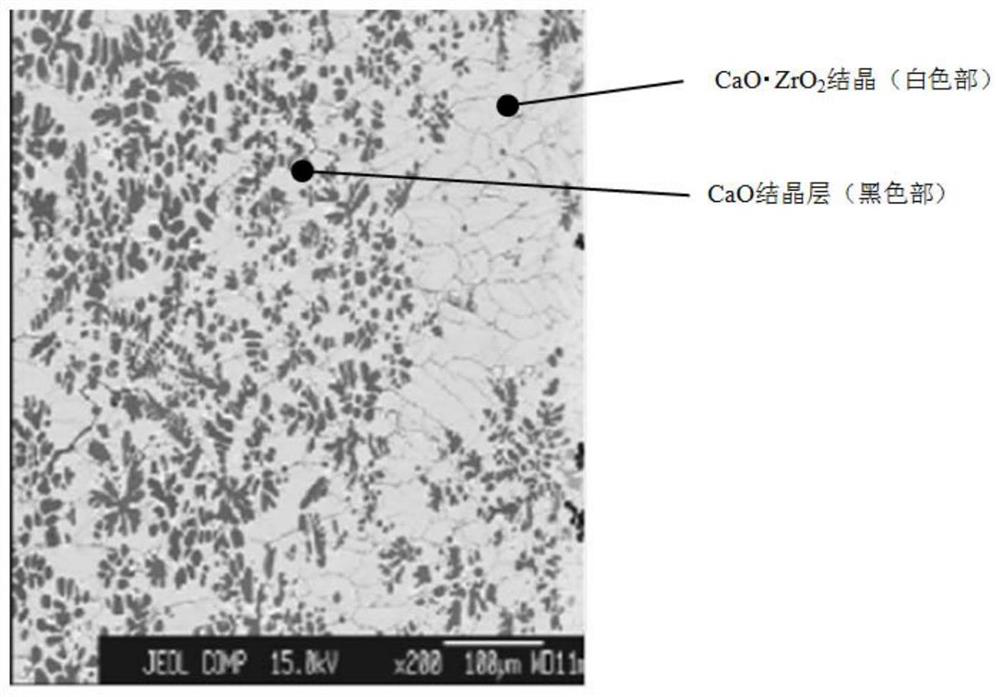

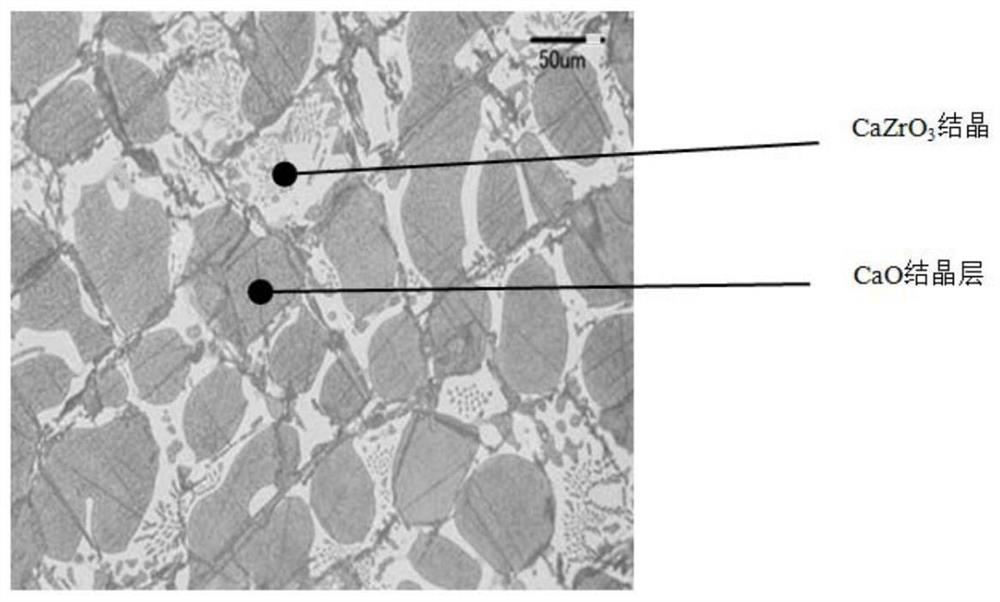

[0223] CaO-ZrO 2 Composition Example A

[0224] In the CaO-ZrO 2 In the embodiment A of composition, change CaO raw material and ZrO 2 The mass ratio of each raw material (raw material) of the raw materials, the molten state of the mixture, the presence or absence of CaO alone, and the width of CaO crystals were investigated.

[0225] The sample of this Example A was obtained under the following conditions.

[0226] Raw material (mass%) As CaO raw material (CaO source) quicklime with particle size structure ≤ 10mm was used, as ZrO 2 The source mainly uses unstable zirconia (decadeite) with a particle size structure of ≤10mm (approximately ≤3mm). In some embodiments, almost complete stable zirconia based on CaO and almost complete stable zirconia based on MgO are used. Zirconium ZrO 2 . The grain size structure of these CaO stabilized zirconia and MgO stabilized zirconia is also ≤10mm.

[0227] An electric furnace was used to melt ...

Embodiment A

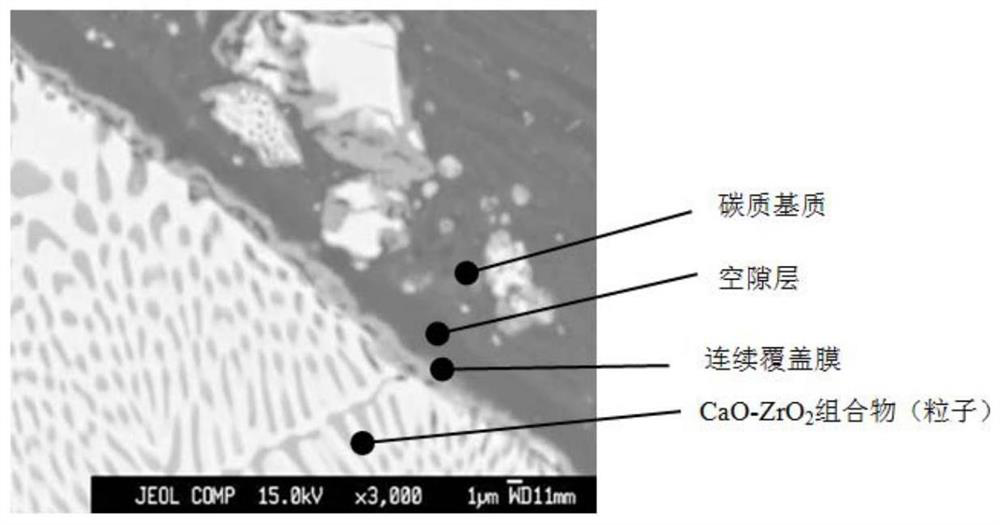

[0282] Example A of the refractory material is, for CaO / ZrO in the chemical composition of the refractory material 2 An example of investigating the influence of mass ratio on alumina adhesion and hydration resistance.

[0283] In Example A of the refractory material, CaO and ZrO are mainly used 2 The CaO-ZrO of the present invention with different proportions 2 combination. The width of the monomeric CaO crystals in any composition is ≤50 μm.

[0284] Using CaO-ZrO 2 Composition, the carbon content of the refractory material (the total amount of graphite and carbon as a binder) was made 11.8% by mass, and CaO / ZrO was changed 2 mass ratio.

[0285] Moreover, the CaO-ZrO in the present invention was also investigated 2 On the basis of the composition, other CaO-based raw materials, ZrO 2 CaO / ZrO when similar raw materials 2 The effect of mass ratio.

[0286] And, carbonation treatment was carried out to the refractory material sample other than embodiment 23, in the Ca...

Embodiment B

[0308] Example B of the refractory material is an example of investigating the effects of the ratio of the carbon component in the chemical composition of the refractory material on the alumina adhesion, hydration resistance, and thermal expansion.

[0309] In addition, the increase and decrease of the ratio of carbon components to CaO components and ZrO 2 The influence of the range of the combined amount of the ingredients was also investigated together.

[0310] For the hydration resistance test and the alumina adhesion test, the same methods and evaluation criteria as in Example A of the refractory material were used.

[0311] The coefficient of thermal expansion (%) in a non-oxidizing atmosphere at 1000° C. was measured, and thermal expansion was evaluated by setting ≦0.5% as ○ (target value, good) and <0.5% as × (poor).

[0312] The casting nozzle, which is the main and important application of the refractory material of the present invention, requires high thermal shock...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com