Composite chrome plating additive

An additive and composite technology, applied in the field of chrome plating, can solve the problems of corrosion anode and narrow bright range, decrease of coating anti-corrosion ability, difficulty in controlling process parameters, etc., achieve wide process bright range, inhibit anode corrosion, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

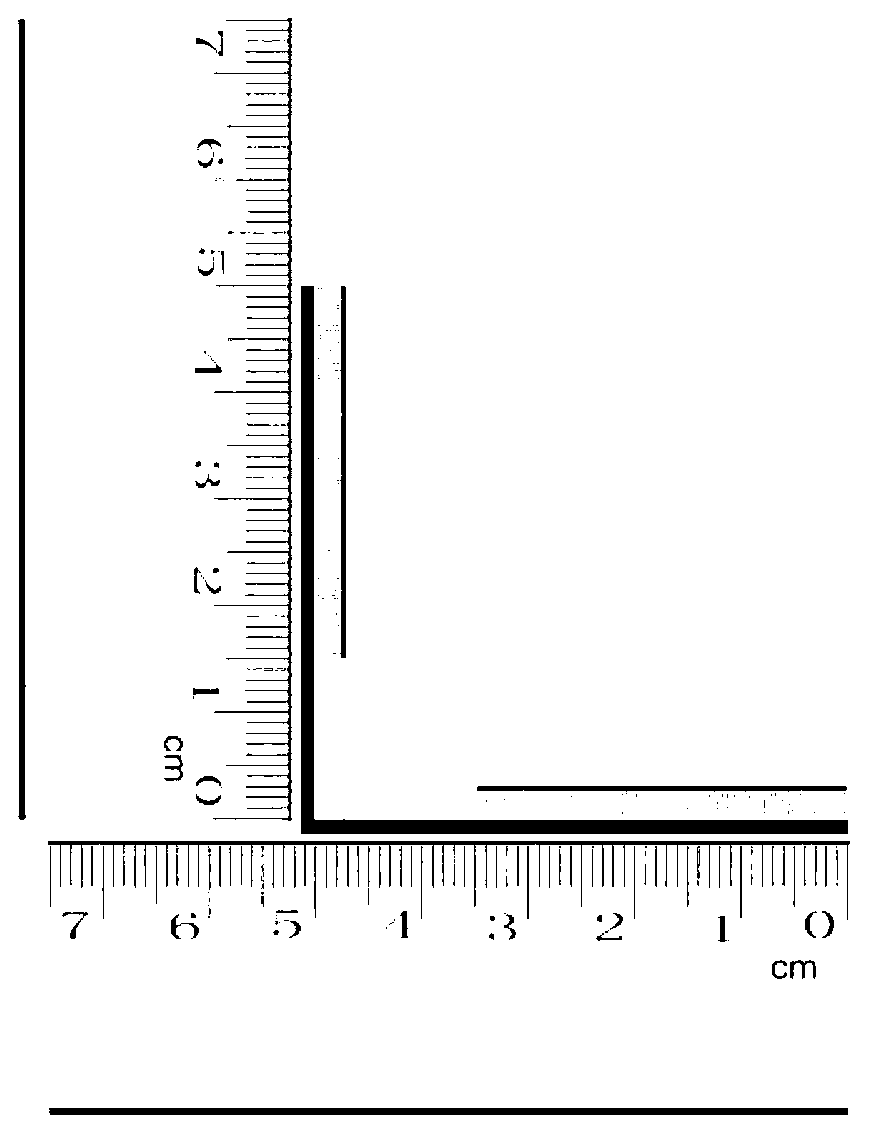

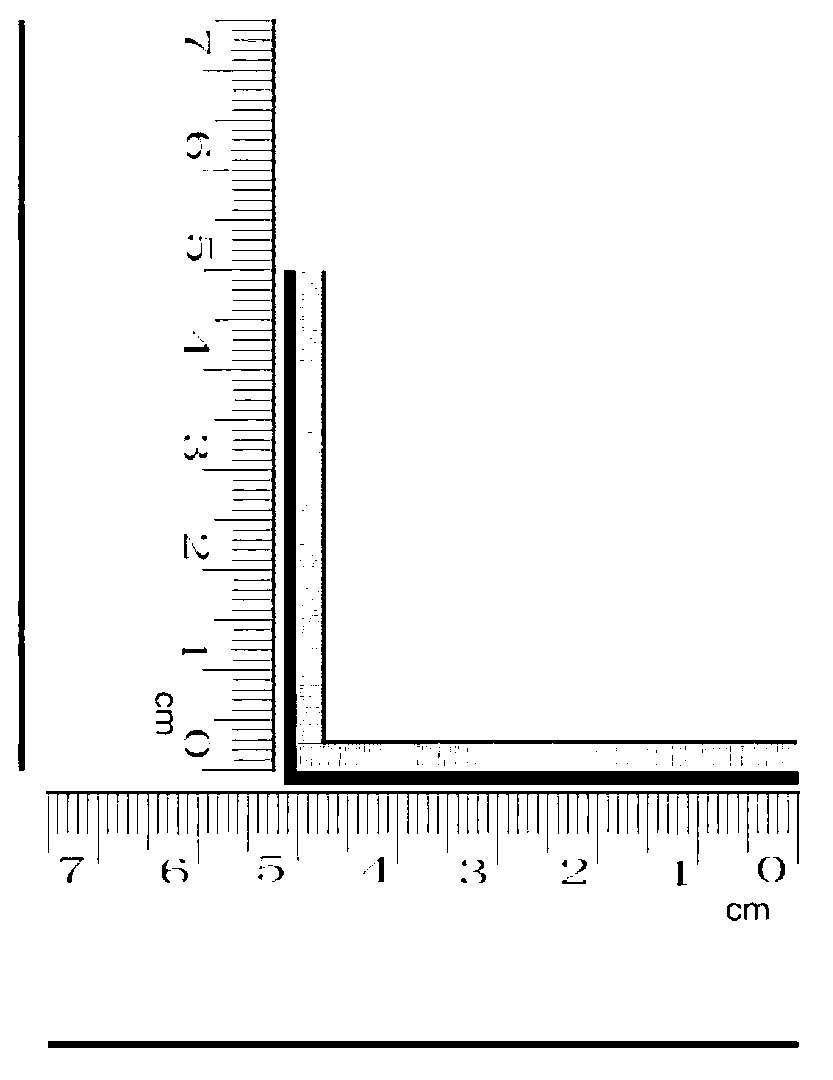

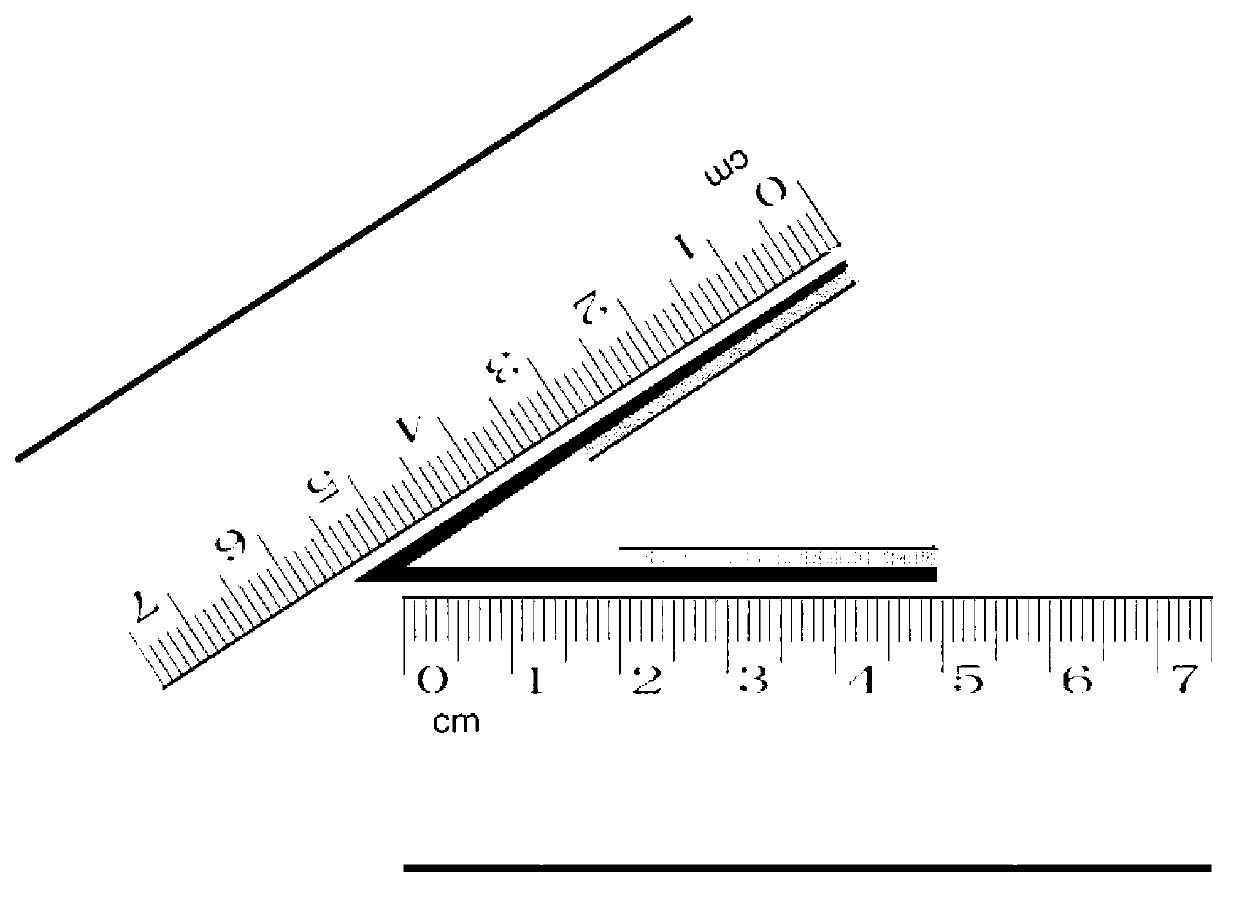

Image

Examples

Embodiment 1

[0048] Prepare composite chrome plating additives by weight as follows:

[0049] Methanedisulfonic acid: 4 grams

[0050] Methanesulfonic acid: 1 g

[0051] Sulfamic acid: 1 g

[0052]Lanthanum fluoride: 0.06 g

[0054] The above-mentioned components are mixed to obtain the composite chrome plating additive of this embodiment.

[0055] The chromium plating bath contains 150 g / L chromic anhydride and 1.5 g / L sulfuric acid, the above-mentioned composite chrome plating additive is added in an amount of 3 g / L chromium plating bath, the working process range: temperature 30°C, current density 15A / dm 2 , S anode: S cathode ≧ 2:1 (cathode, anode area ratio), time 1 hour.

[0056] After the test, the results can be seen: the coating of the entire test piece is bright and meticulous, the finish presents a mirror brightness, the hardness of the coating is high, and the Vickers hardness is 900HV. In the angle experiment, the test pieces with 90° and 30...

Embodiment 2

[0059] Prepare composite chrome plating additives by weight as follows:

[0060] Alkylsulfonic acid: 4 grams

[0061] Glycine: 0.08 g

[0062] Triazole: 0.01 g

[0063] Cerium fluoride: 0.04 g

[0065] The above-mentioned components are mixed to obtain the composite chrome plating additive of this embodiment.

[0066] Chromium plating solution, chromium plating solution contains 300 g / L chromic anhydride and 3.2 g / L sulfuric acid, the above-mentioned composite chrome plating additive is 4.18 g / L chrome plating solution, working process range: temperature 68°C, current density 50A / dm 2 , Plating time 1 hour.

[0067] After the test, the results can be seen: the coating of the entire test piece is bright and meticulous, the finish shows mirror brightness, the hardness of the coating is high, and the Vickers hardness is 1110HV. In the angle test, the test pieces with 90° and 30° angles are coated with a thickness of 55 μm. Current efficiency ...

Embodiment 3

[0081] Prepare composite chrome plating additives by weight as follows:

[0082] Methanesulfonic acid: 5.8 grams

[0083] Lanthanum fluoride 0.006 g

[0084] Chromium plating bath: chromic anhydride (CrO 3 ) 250g / L, sulfuric acid (H 2 SO 4 ) 2.6g / L, the above composite chrome plating additive 5.5g / L chrome plating solution, current density 30A / dm 2 , temperature 58°C, time 1h.

[0085] After plating inspection, the finish is mirror-bright, with a hardness of 1280HV. In the angle test, the test pieces at 90° and 30° angles have coatings, the thickness is 33 μm, and the current efficiency is 31%. The weight of the anode before plating: 34.56 grams, and the weight of the anode after plating: 29.85 grams, anode weight loss: 4.71 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com