Method for electroplating metals of tin and bismuth

A technology for electroplating tin, bismuth and bismuth metal, which is applied in the field of electroplating composite metal layers on the outer lead pins of integrated circuits, can solve the problems of low manufacturing cost and fast electroplating speed, and achieve high production efficiency, fast electroplating speed, and dense crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

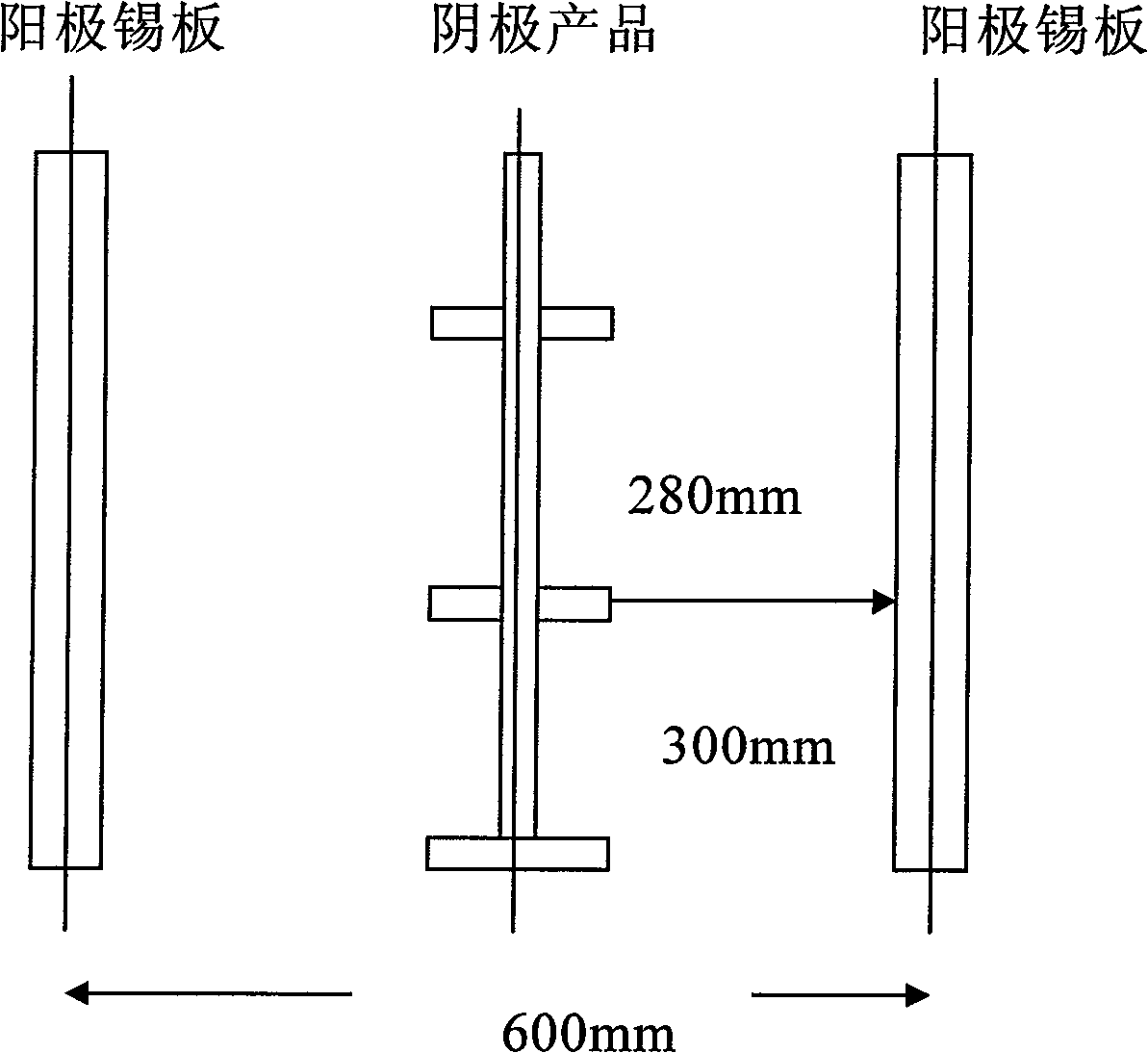

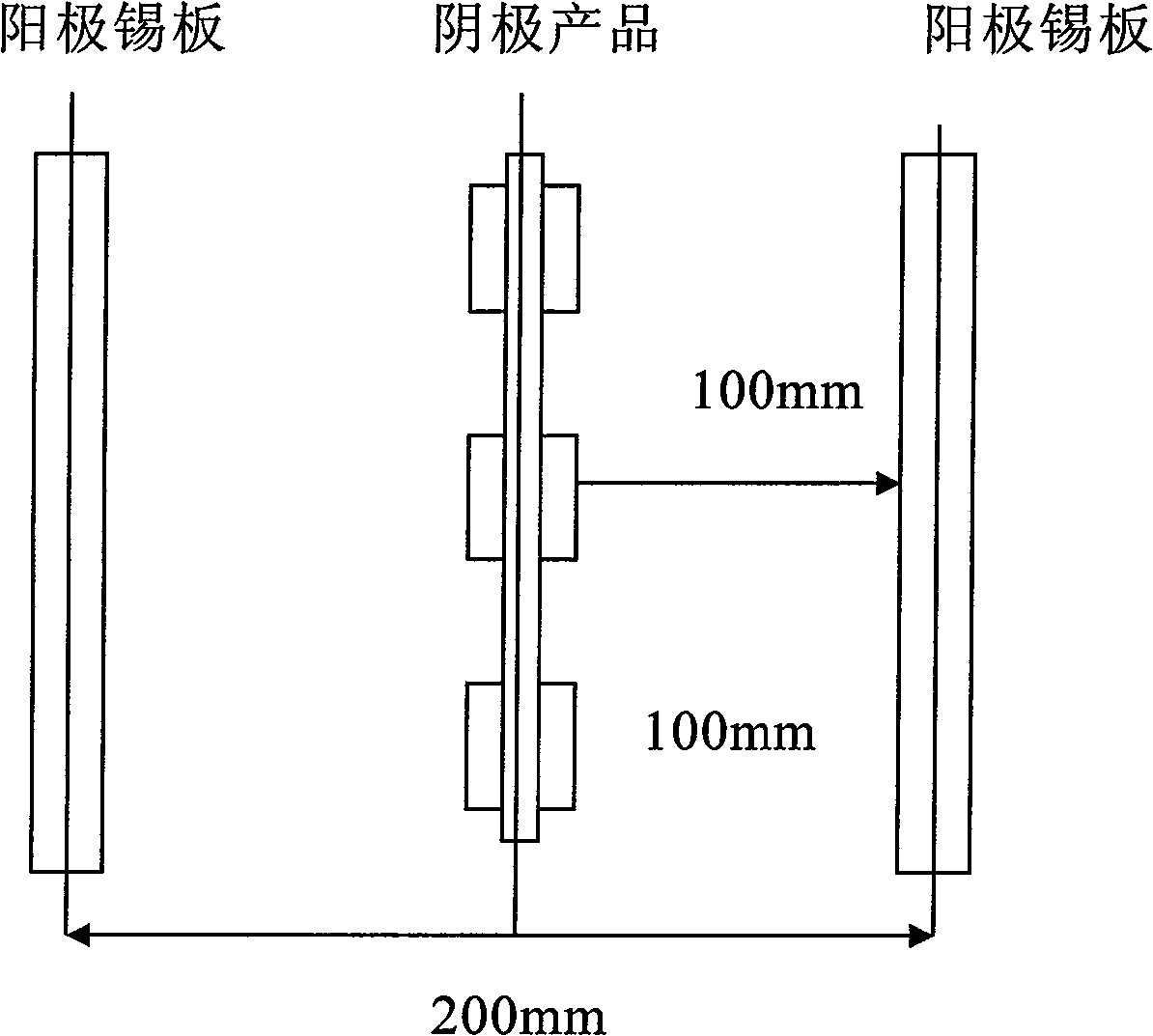

[0037] Take 50 products to be electroplated (TSOP48 integrated circuit package shell and its outer leads), such as figure 2 Attach and fix on the cathode transmission steel belt with a spring clip, and the distance between the steel belt and the two anode plates is equal, both are 100mm. The material of the anode plate is a tin plate, and the dimensions are: length 500 mm, width 30 mm, height 100 mm.

[0038] Cathode conveying steel belt speed: 4.5m / min.

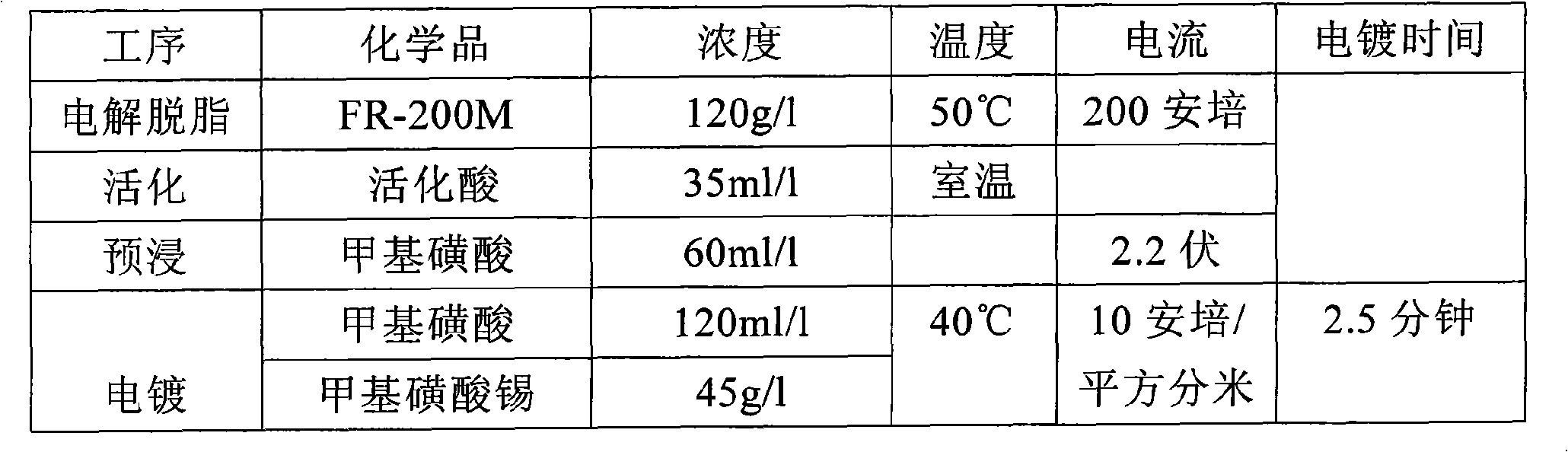

[0039] The formula of electroplating solution, electroplating process steps and process conditions are as follows.

[0040]

[0041]

[0042] The additive SNB31 in the electroplating solution formula in the above table can avoid the oxidation of divalent tin and prevent the substitution reaction between bismuth and anode tin; the additive SNB14 can make the coating bright and crystallized.

[0043] Take 10 lead electroplating samples of the integrated circuit casing in the middle of the hanging basket, test the thic...

Embodiment 2

[0049] Cathode conveying steel belt speed: 5m / min.

[0050] The formula, electroplating process steps and process conditions of the electroplating solution are as follows, and other process descriptions are the same as in Example 1.

[0051]

[0052]

[0053] Its measurement data are as follows:

[0054]

Embodiment 3

[0056] Cathode conveying steel belt speed: 5.5m / min.

[0057] The formula, electroplating process steps and process conditions of the electroplating solution are as follows, and other process descriptions are the same as in Example 1.

[0058]

[0059] Its measurement data are as follows:

[0060]

[0061]

[0062] It can be seen from the data of the above examples that the plating layer of the product electroplated by the method of the present invention has a uniform thickness and a uniform bismuth content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com