Preparation process of acid-base compound Magni coating

A preparation process, the technology of magari, applied in the field of preparation process of acid-base composite magari coating, can solve the problems of many product defects, slow plating speed, difficult drying, etc., to overcome the thin zinc layer thickness and reduce production Line running cost, product surface quality good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

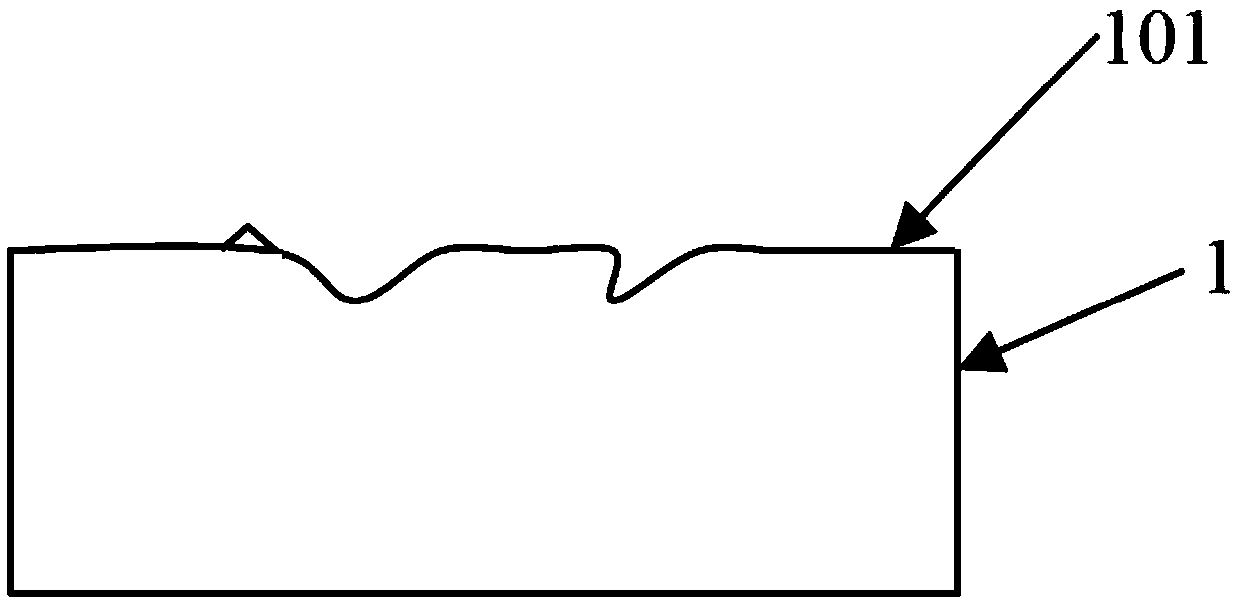

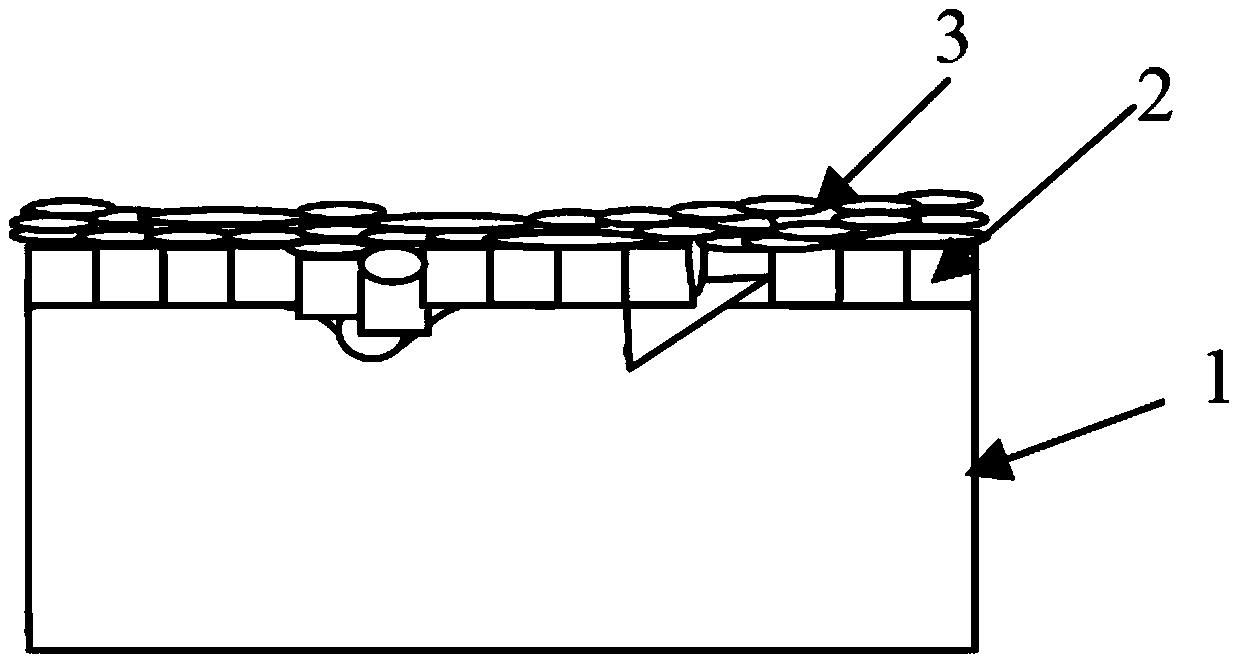

[0051] A preparation process of an acid-base composite magari coating, including pre-plating pretreatment, coating preparation, and post-plating treatment. The preparation of the coating is to first carry out potassium chloride galvanizing on the surface of a workpiece, and then carry out zinc acid Salt galvanized. Wherein: described pre-plating pretreatment comprises the steps:

[0052] S11. Hang up: hang up the workpiece to the automatic production line;

[0053] S12. Degreasing: Perform high-temperature electrolytic degreasing of the workpieces on the automatic production line in the degreasing liquid;

[0054] S13. Water washing Ⅰ: wash the workpiece twice with tap water;

[0055] S14. Acid electrolysis: acid electrolysis removes the oxide film on the surface of the workpiece;

[0056] S15. Activation;

[0057] S16. Water washing II: wash the workpiece 3 times with tap water.

[0058] The preparation of described coating comprises the steps:

[0059] S21. Potassium c...

Embodiment 2

[0070] A preparation process of an acid-base composite magari coating, including pre-plating pretreatment, coating preparation, and post-plating treatment. The preparation of the coating is to first carry out potassium chloride galvanizing on the surface of a workpiece, and then carry out zinc acid Salt galvanized. Wherein: described pre-plating pretreatment comprises the steps:

[0071] S11. Hang up: hang up the workpiece to the automatic production line;

[0072] S12. Degreasing: Perform high-temperature electrolytic degreasing of the workpieces on the automatic production line in the degreasing liquid;

[0073] S13. Water washing Ⅰ: wash the workpiece 3 times with tap water;

[0074] S14. Acid electrolysis: acid electrolysis removes the oxide film on the surface of the workpiece;

[0075] S15. Activation;

[0076] S16. Water washing II: wash the workpiece 3 times with tap water.

[0077] The preparation of described coating comprises the steps:

[0078] S21. Potassium...

Embodiment 3

[0089] A preparation process of an acid-base composite magari coating, including pre-plating pretreatment, coating preparation, and post-plating treatment. The preparation of the coating is to first carry out potassium chloride galvanizing on the surface of a workpiece, and then carry out zinc acid Salt galvanized. Wherein: described pre-plating pretreatment comprises the steps:

[0090] S11. Hang up: hang up the workpiece to the automatic production line;

[0091] S12. Degreasing: Perform high-temperature electrolytic degreasing of the workpieces on the automatic production line in the degreasing liquid;

[0092] S13. Water washing Ⅰ: wash the workpiece twice with tap water;

[0093] S14. Acid electrolysis: acid electrolysis removes the oxide film on the surface of the workpiece;

[0094] S15. Activation;

[0095] S16. Water washing II: wash the workpiece twice with tap water.

[0096] The preparation of described coating comprises the steps:

[0097] S21. Potassium chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com