Nickel phosphorus ally electroplating liquid and electroplating process thereof

A nickel-phosphorus alloy and electroplating process technology, applied in the field of nickel-phosphorus alloy electroplating solution and its electroplating process, can solve the problems of inability to use high corrosion resistance, poor stability of the electroplating solution, and difficulty in large-scale promotion, etc. High stability and good coating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

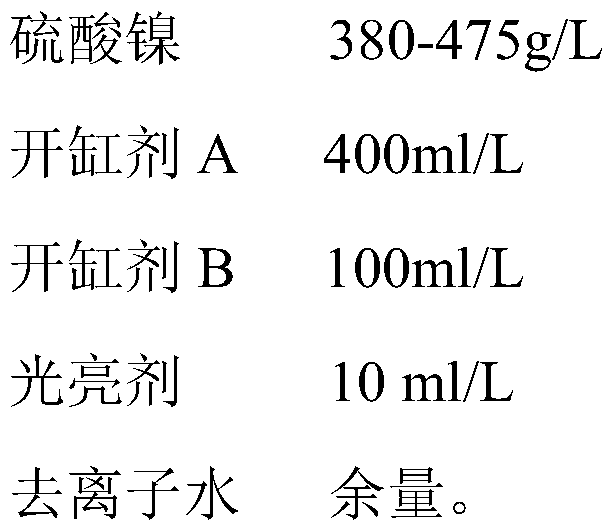

[0032] A nickel-phosphorus alloy electroplating solution is composed of the following raw materials,

[0033]

[0034] The starter agent A is the nickel-phosphorus starter agent A, and the starter agent B is the nickel-phosphorus starter agent B, which ensures the stability of the nickel-phosphorus content and provides the stability of the present invention.

[0035] Also include supplement, the phosphorus content of supplement is 25g / L, in order to adjust the phosphorus composition in the bath, when lacking, the phosphorus in the coating will drop, affect the stability of the coating, further provide the stability of the present invention .

[0036] The pH value of the plating solution is 2.2-2.7 to ensure the stability of the pH of the plating solution. If the pH is too low, the current efficiency of the plating solution will decrease and the phosphorus content in the coating will increase. If the pH is too high, the current efficiency of the plating solution will decreas...

Embodiment 2

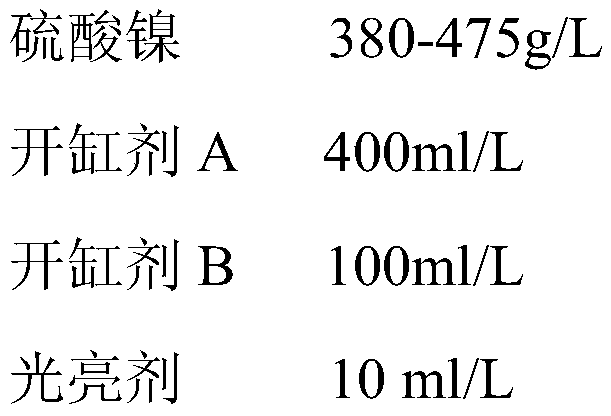

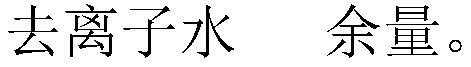

[0042] A nickel-phosphorus alloy electroplating solution is composed of the following raw materials,

[0043]

[0044]

[0045] The starter agent A is the nickel-phosphorus starter agent A, and the starter agent B is the nickel-phosphorus starter agent B, which ensures the stability of the nickel-phosphorus content and provides the stability of the present invention.

[0046] Also include supplement, the phosphorus content of supplement is 30g / L, in order to adjust the phosphorus composition in the bath, when lacking, the phosphorus in the coating will drop, affect the stability of the coating, further provide the stability of the present invention .

[0047] The pH value of the plating solution is 2.2-2.7 to ensure the stability of the pH of the plating solution. If the pH is too low, the current efficiency of the plating solution will decrease and the phosphorus content in the coating will increase. If the pH is too high, the current efficiency of the plating solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com