Method for preparing solar array electrode by electro-brush plating

A silicon solar cell and array electrode technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of reduced effective area for absorbing solar energy and reduced conversion efficiency, and achieves small investment, reduced contact resistance, and fast plating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Protective film coating: coating a layer of phenolic novolac on the surface of the silicon semiconductor coated with a silicon nitride anti-reflection layer as a protective film; the silicon semiconductor has a p / n junction;

[0034] (2) Laser grooving: engraving array grooves by laser on the surface of the silicon semiconductor coated with a protective film;

[0035] (3) Surface activation treatment: After the silicon semiconductor with the array groove engraved is cleaned by fatty alcohol polyoxyethylene ether sodium sulfate with a mass percentage concentration of 5%, the groove is treated in a HF hydrochloric acid solution with a mass percentage concentration of 5%. Activation was carried out for 5 minutes to obtain a pretreated silicon semiconductor;

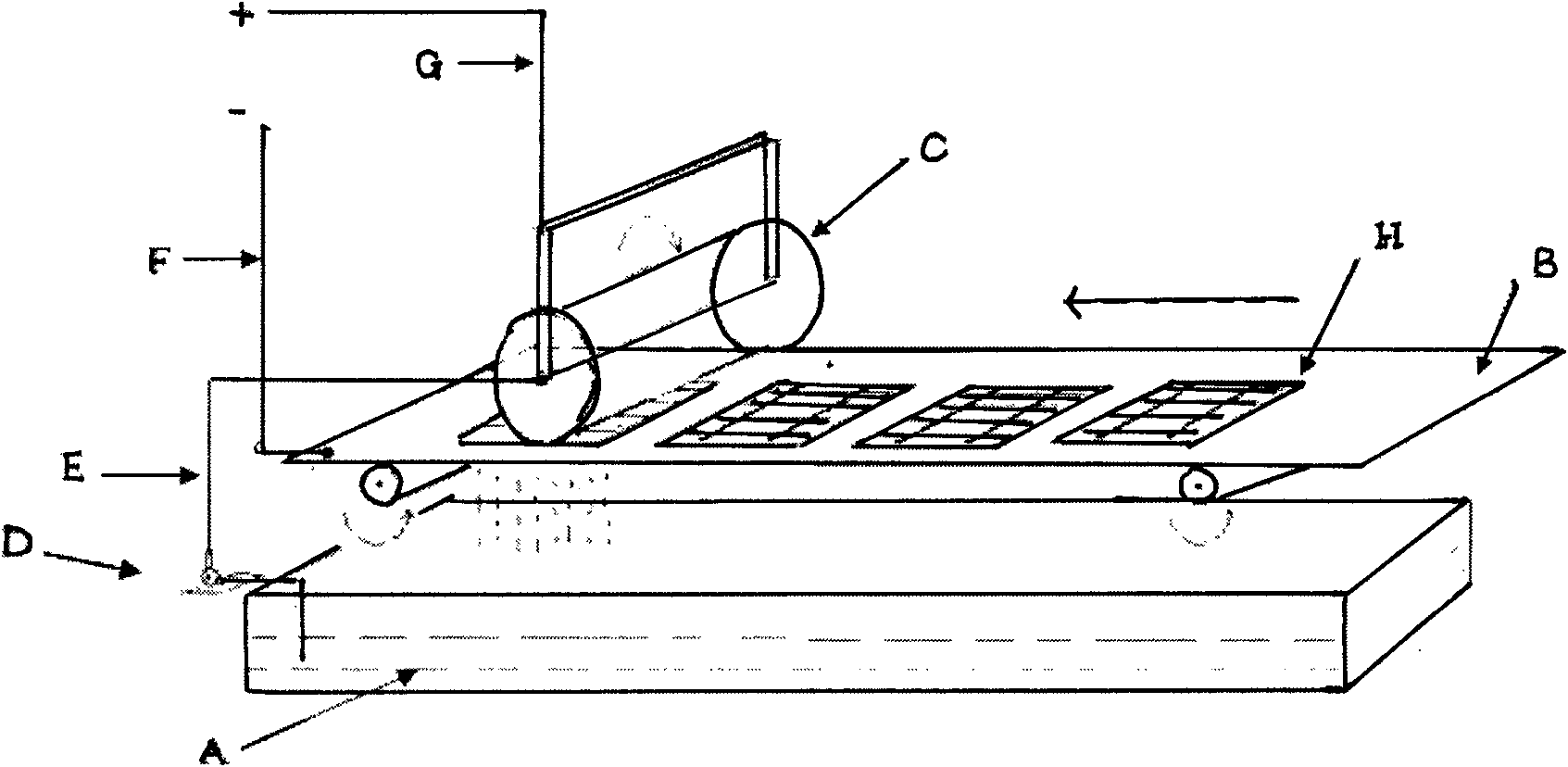

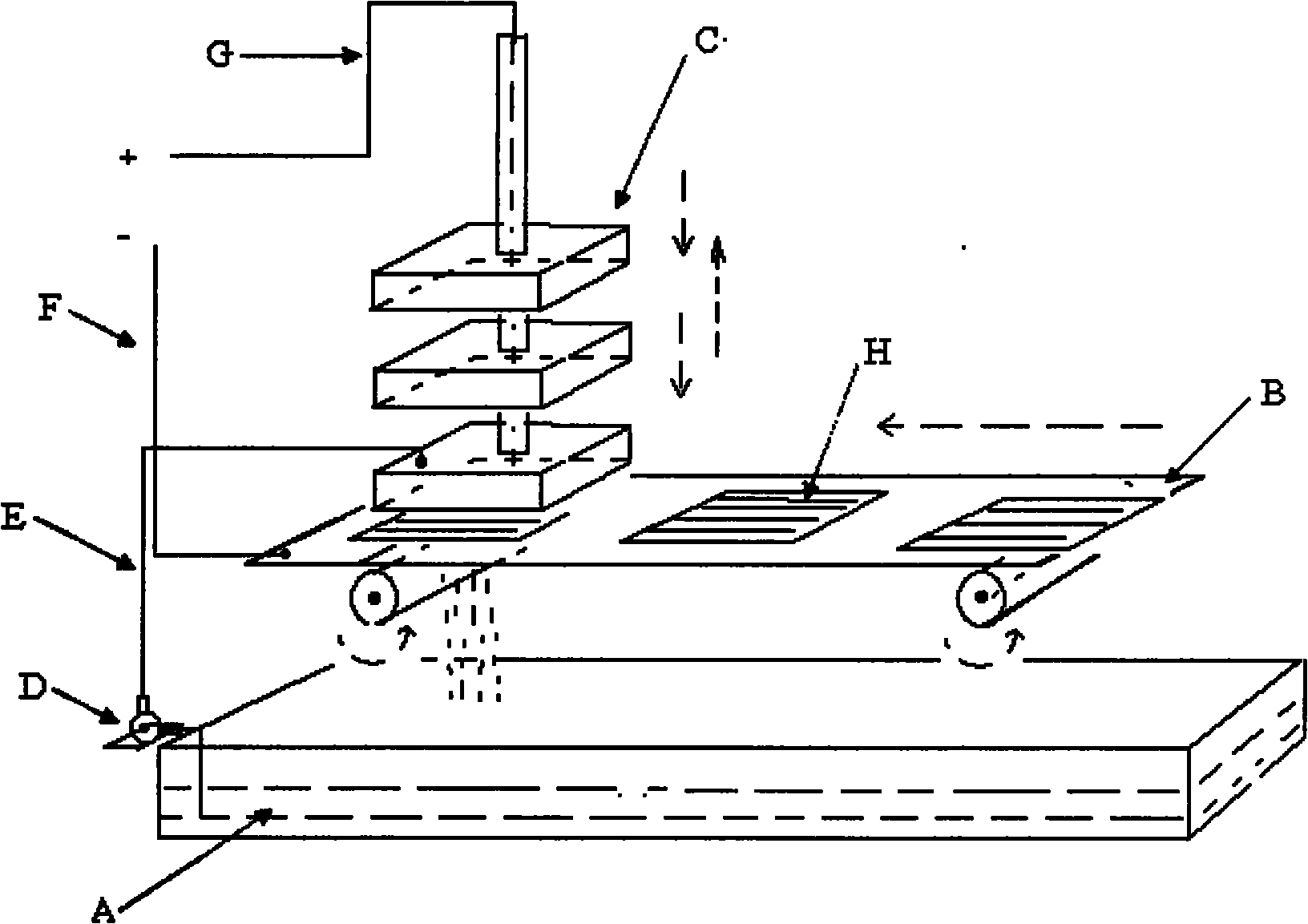

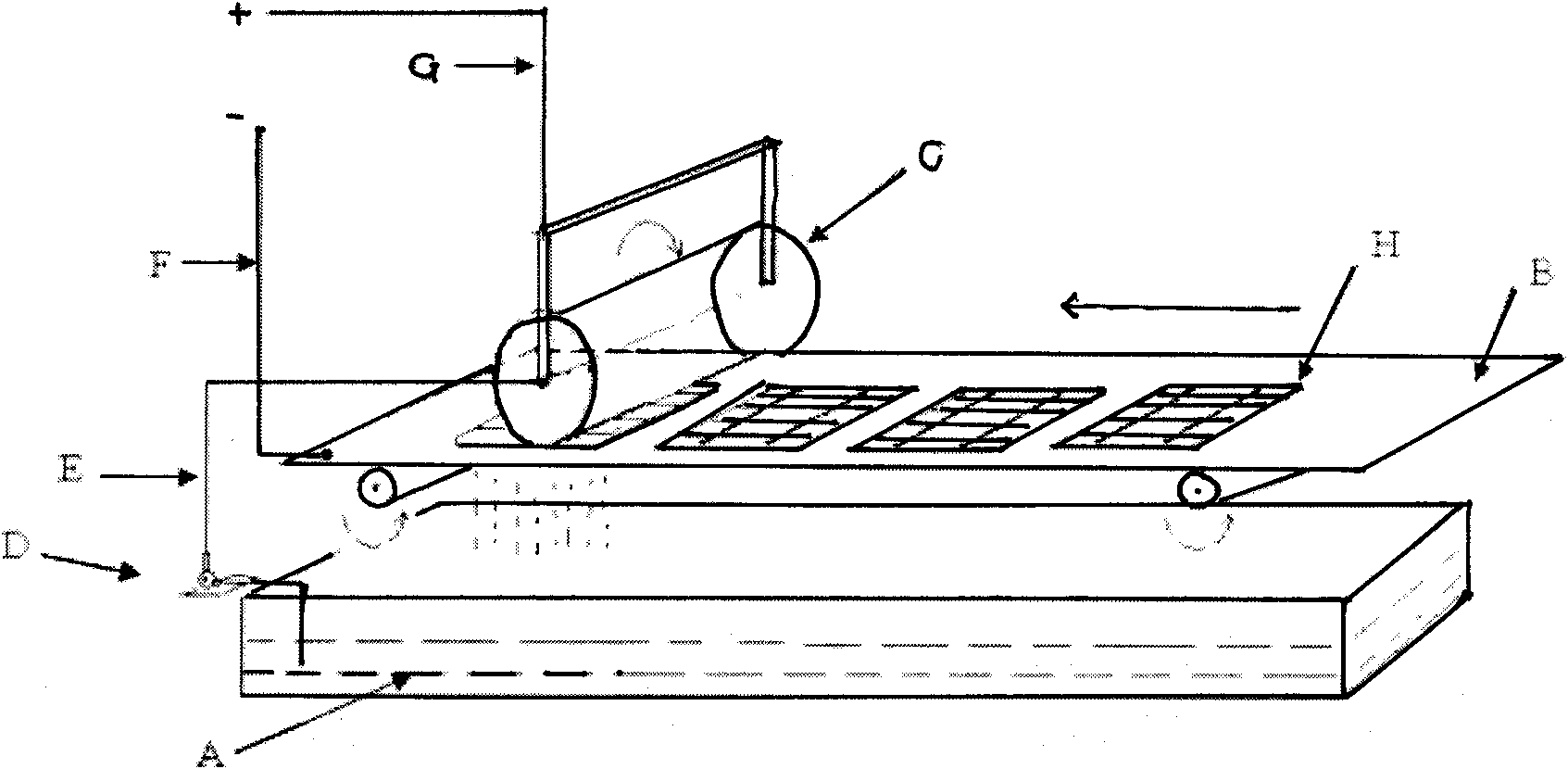

[0036] (4) Brush plating: use a conventional electroplating power supply, use the negative electrode of the power supply to connect the pretreated silicon semiconductor, connect the positive electrode of the power...

Embodiment 2

[0040](1) protective film coating: coating a layer of alkyd varnish on the surface of a silicon semiconductor coated with a porous silicon dioxide anti-reflection layer as a protective film; the silicon semiconductor has a p / n junction;

[0041] (2) Laser grooving: engraving array grooves by laser on the surface of the silicon semiconductor coated with a protective film;

[0042] (3) Surface activation treatment: After cleaning the silicon semiconductor with the array grooves with a mass percentage concentration of 0.5% sodium dodecylbenzene sulfonate, the silicon semiconductor with a mass percentage concentration of 5% HBF 4 Activate the groove for 5 minutes in a hydrochloric acid solution to obtain a pretreated silicon semiconductor;

[0043] (4) Brush plating: use a conventional electroplating power supply, use the negative electrode of the power supply to connect the pretreated silicon semiconductor, connect the positive electrode of the power supply to a mobile plating pe...

Embodiment 3

[0047] (1) protective film coating: coating a layer of nitro varnish as a protective film on the surface of a silicon semiconductor coated with a titanium dioxide anti-reflection layer; the silicon semiconductor has a p / n junction;

[0048] (2) Laser grooving: engraving array grooves by laser on the surface of the silicon semiconductor coated with a protective film;

[0049] (3) Surface activation treatment: After the silicon semiconductor with the array grooves is cleaned by sodium dodecyl sulfate with a mass percentage concentration of 2%, the NH 4 HF 2 Activate the groove for 2 minutes in a hydrochloric acid solution to obtain a pretreated silicon semiconductor;

[0050] (4) Brush plating: use a conventional electroplating power supply, use the negative pole of the power supply to connect the pretreated silicon semiconductor, connect the positive pole of the power supply to a pictographic plating pen filled with plating solution, turn on the power supply, and place the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com