Chemical copper plating liquid and preparation method thereof

A technology of electroless copper plating and complexing agent, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of cumbersome process, complex composition, instability, etc., to improve the plating speed and improve the stability. The effect of smoothness and uniformity of copper plating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

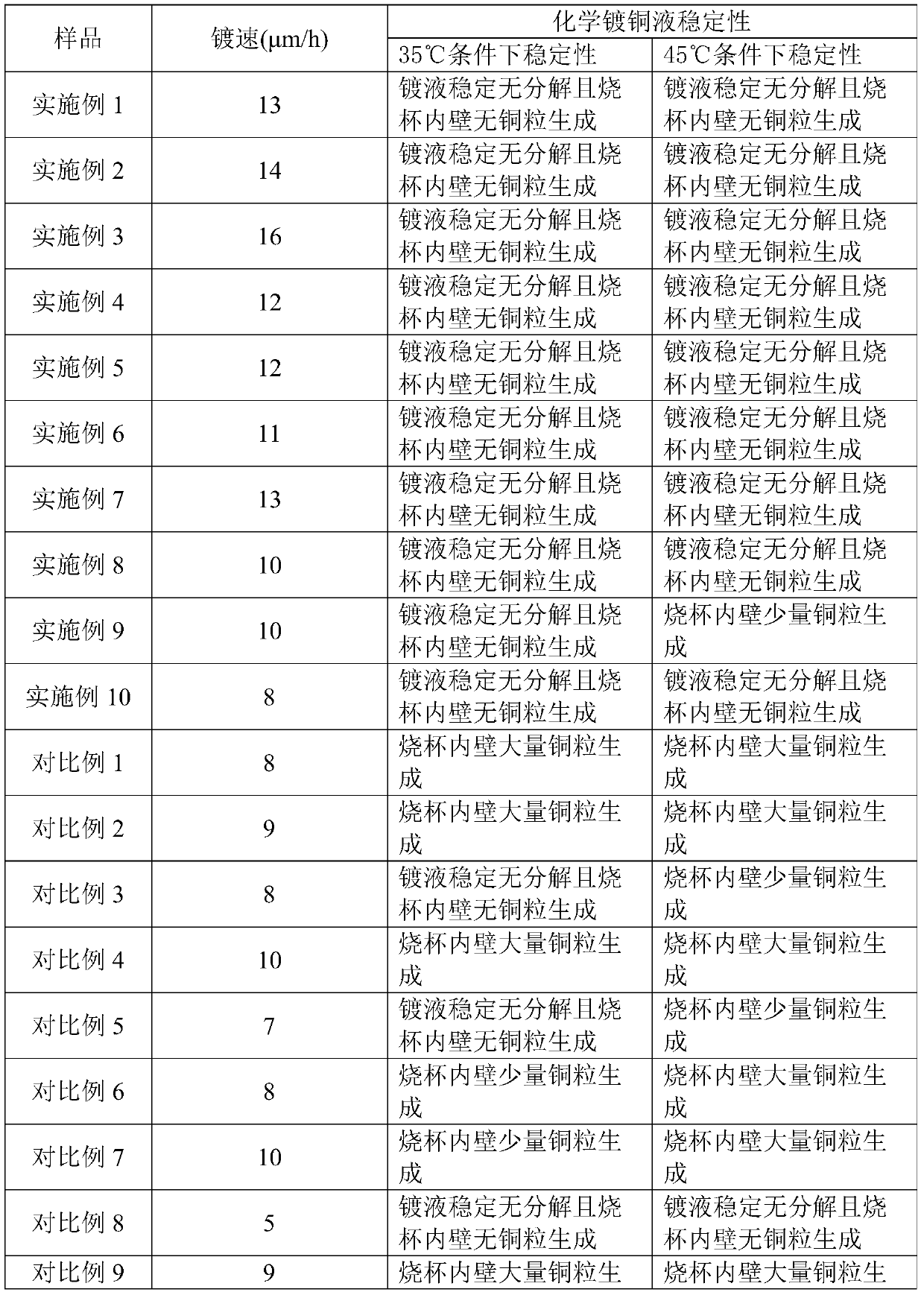

Examples

Embodiment 1

[0038] This embodiment provides an electroless copper plating solution and a preparation method thereof.

[0039] Wherein, the electroless copper plating solution includes the following components: copper sulfate 8g / L, formaldehyde 6g / L, potassium sodium tartrate 10g / L, EDTA tetrasodium 8g / L and 2,2'-bipyridine 0.0001 g / L, wherein the solvent is deionized water, and sodium hydroxide is used to adjust the pH of the above copper plating solution to 12.

[0040] The preparation method of present embodiment electroless copper plating solution is as follows:

[0041] First mix copper sulfate with deionized water for the first time, then mix with potassium sodium tartrate, tetrasodium edetate, 2,2'-bipyridine and formaldehyde for the second time in turn, and use hydrogen oxidation after the mixing is completed The pH of the above-mentioned copper plating solution was adjusted to 12 with sodium, and finally the volume was constant with water to obtain the electroless copper plating ...

Embodiment 2

[0043] This embodiment provides an electroless copper plating solution and a preparation method thereof.

[0044]Wherein, the electroless copper plating solution comprises the following components: copper sulfate 8g / L, formaldehyde 6g / L, potassium sodium tartrate 30g / L, tetrasodium edetate 5g / L and thiourea 0.001g / L, wherein , the solvent is deionized water, and the pH of the above-mentioned copper plating solution is adjusted to 12.5 using sodium hydroxide.

[0045] The preparation method of present embodiment electroless copper plating liquid is as follows:

[0046] First mix copper sulfate with deionized water for the first time, then mix with sodium potassium tartrate, tetrasodium ethylenediaminetetraacetic acid, thiourea and formaldehyde for the second time in turn, after the mixing is completed, use sodium hydroxide to coat the above copper The pH of the solution was adjusted to 12.5, and finally the volume was constant with water to obtain the electroless copper platin...

Embodiment 3

[0048] This embodiment provides an electroless copper plating solution and a preparation method thereof.

[0049] Wherein, the electroless copper plating solution comprises the following components: copper sulfate 8g / L, formaldehyde 6g / L, potassium sodium tartrate 50g / L, tetrasodium edetate 3g / L and thiosemicarbazide 0.001g / L, Wherein, the solvent is deionized water, and sodium hydroxide is used to adjust the pH of the copper plating solution to 13.

[0050] The preparation method of present embodiment electroless copper plating liquid is as follows:

[0051] First mix copper sulfate with deionized water for the first time, then mix it with potassium sodium tartrate, tetrasodium ethylenediaminetetraacetic acid, thiosemicarbazide and formaldehyde for the second time. The pH of the copper solution was adjusted to 13, and finally the volume was constant with water to obtain the electroless copper plating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com