Chemical nickel-plating method for capacitive touch screen indium tin oxide (ITO) wiring

A capacitive touch screen, chemical nickel plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of fast etching of ITO film, poor coating adhesion, weak sensitization solution selectivity, etc. problem, to achieve the effect of operation spirituality, low cost and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Electroless nickel plating is performed as follows:

[0041] (1) Degreasing: Put the glass substrate with ITO film into the ethanol solution for 3-5 minutes and put the glass substrate that has been sonicated in ethanol into the alkaline degreasing solution (the formula is 15g / L NaOH, 20g / L Na of L 3 PO 4, 20g / L Na 2 CO 3 , 10g / L sodium silicate, 3g / L OP emulsifier) for ultrasonic degreasing for 10 minutes, then rinse with deionized water;

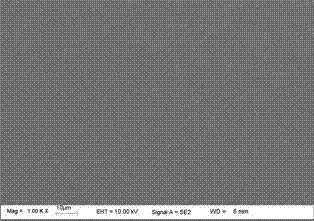

[0042] (2) Etching: Put the degreased ITO thin film glass into the etching solution (the formula is 50g / L KHS 2 o 8 , 40g / L Na 2 SO 4 , 1mL / L concentrated H 2 SO 4 , 4g / L NH 4 HF 2 , 15g / L citric acid), coarsened at 30°C for 5 minutes, then put the ITO glass into deionized water and ultrasonicated for 1 minute; its morphology is shown in figure 2 ;

[0043] (3) Sensitization: Put the etched ITO thin film glass into self-made sensitization solution A (see Table 1) and sensitize it at 30°C for 6 minutes, t...

Embodiment 2

[0050] Embodiment 2 is different from Embodiment 1 in following 4 steps:

[0051] (2) Etching: The difference from Example 1 is that the etching solution formula is 50g / L KHS 2 o 8 , 40g / L Na 2 SO 4 , 1.5mL / L concentrated H 2 SO 4 , 4g / L NH 4 HF 2 , 15g / L citric acid, roughening time is 8 minutes;

[0052] (3) Sensitization: the difference from Example 1 is that the sensitization time is 7 minutes;

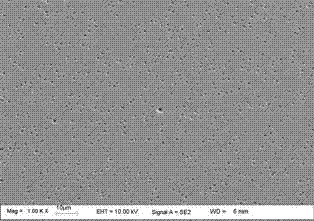

[0053] (4) Activation: The difference from Example 1 is that the formula of the activation solution is 0.2g / L PdCl 2 , 3mL / L concentrated HCl; its morphology after the subsequent reduction operation is shown in Figure 4 , see the energy spectrum Figure 5 ;

[0054] (6) Electroless nickel plating: The difference from Example 1 is that electroless plating is carried out in an acidic bath with a pH of 4.7, and its topography is shown in Figure 7 .

[0055] After this step, the ITO thin film is electroless nickel-plated, and the analysis spectrum shows that:

[0056] ...

Embodiment 3

[0059] Embodiment 3 is different from Embodiment 1 in following 4 steps:

[0060] (2) Etching: The difference from Example 1 is that the etching solution formula is 40g / L KHS 2 o 8 , 40g / L Na 2 SO 4 , 1.5mL / L concentrated H 2 SO 4 , 4g / L NH 4 HF 2 , 15g / L citric acid, the roughening time is 8 minutes, its appearance is shown in image 3 ;

[0061] (3) Sensitization: The difference from Example 1 is that the sensitization time is 8 minutes;

[0062] (4) Activation: The difference from Example 1 is that the formula of the activation solution is 0.3g / L PdCl 2 , 5mL / L concentrated HCl; the activation time is 8 minutes;

[0063] (6) Electroless nickel plating: The difference from Example 1 is that electroless plating is carried out in an acidic bath with pH 5.0, and its topography is shown in Figure 8 .

[0064] After this step, the ITO thin film is electroless nickel-plated, and the analysis spectrum shows that:

[0065] 1. by image 3 (After etching) you can see th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com