Chemical plating nickel-tungsten-phosphorus alloy solution for magnesium alloy and treatment process thereof

A technology of electroless nickel-tungsten-phosphorus plating and alloy solution, which is applied in the field of metal surface treatment, can solve the problems of high cost and high price, and achieve the effects of low cost, high plating speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

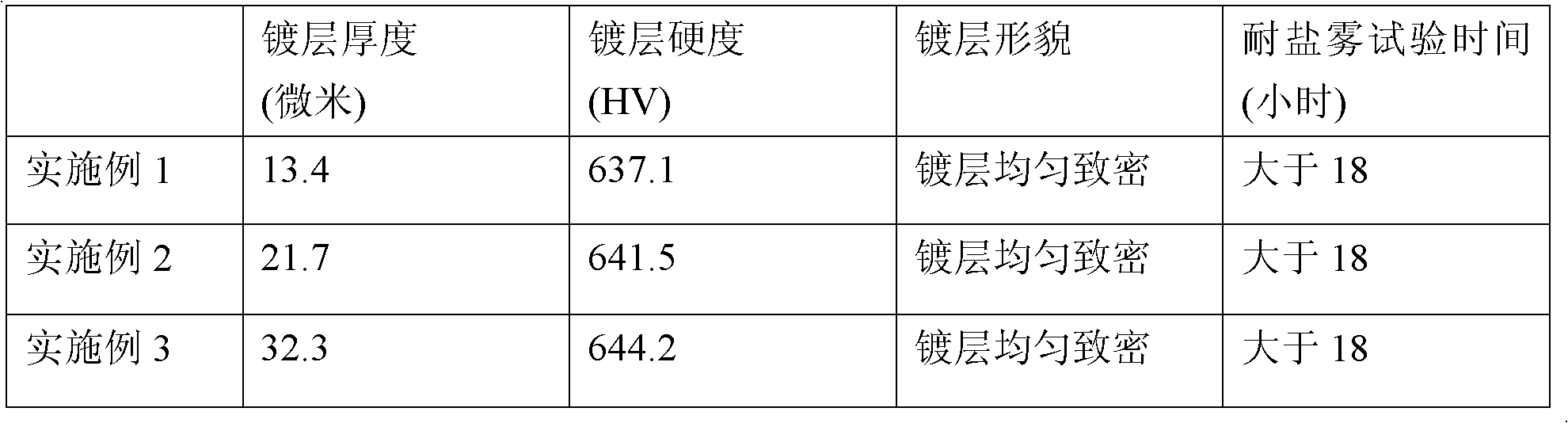

Embodiment 1

[0024] Weigh the reagents according to the following formula: 5 grams of nickel sulfate, 5 grams of sodium tungstate, 20 grams of sodium citrate, 8 grams of sodium carbonate, 12 grams of sodium hypophosphite, 0.5 mg of thiourea, and 8 grams of ammonium bifluoride; The reagents are respectively dissolved in a small amount of water, then mixed, and diluted to 1 liter with water to obtain a magnesium alloy electroless nickel-tungsten-phosphorus plating solution. Adjust the pH to 8-9 with concentrated ammonia water for later use.

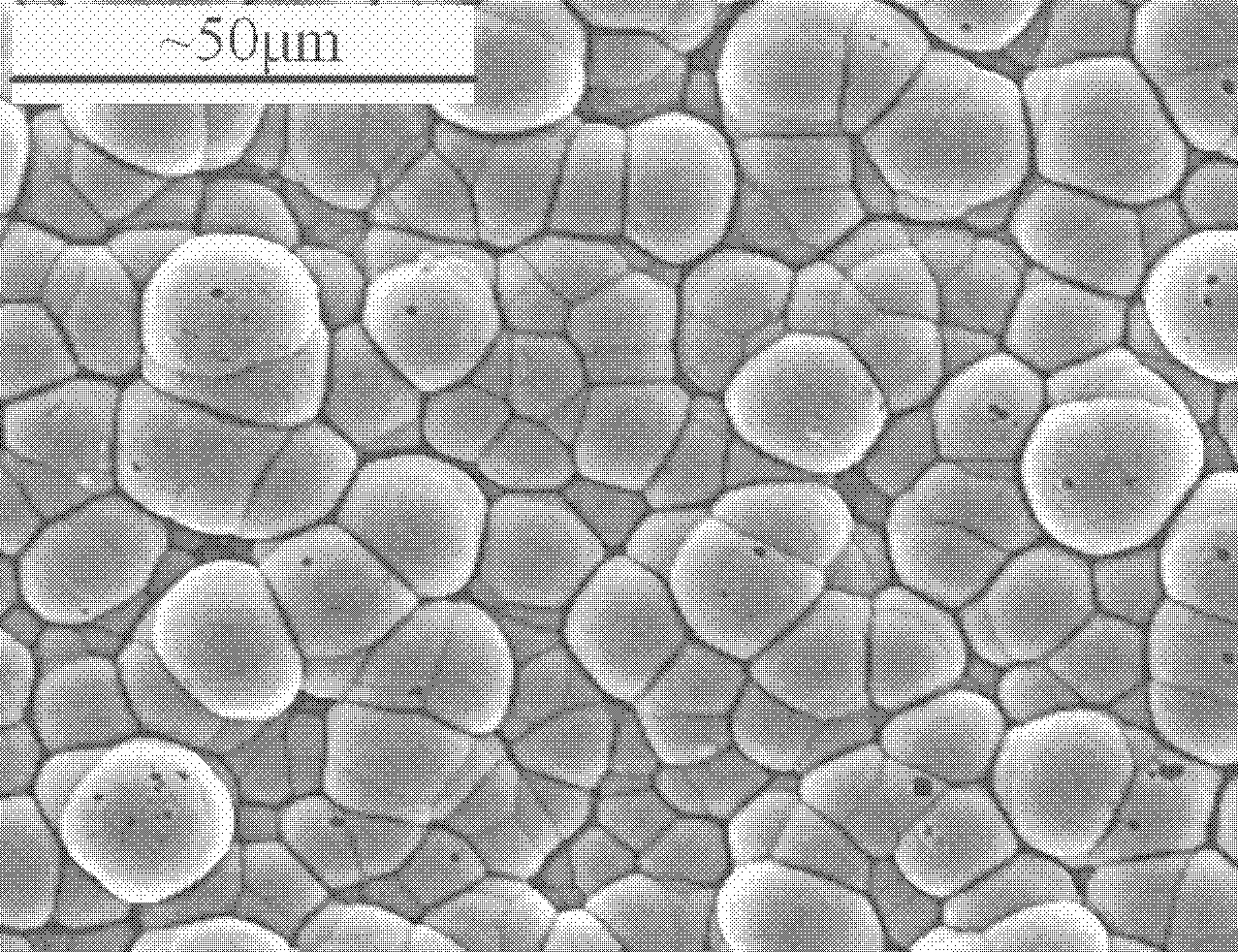

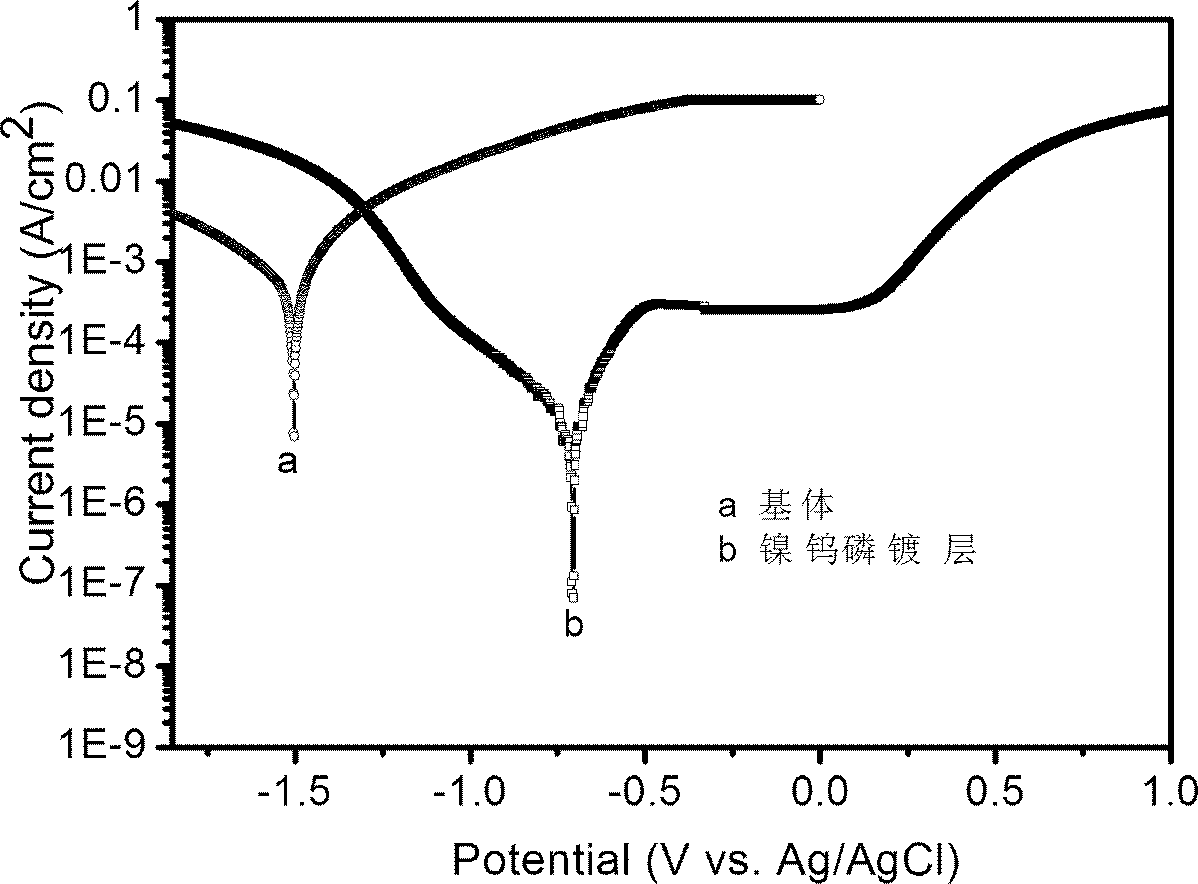

[0025] Thoroughly degrease the AZ91D magnesium alloy sample in alkaline degreasing solution and clean water respectively, then put it into a nitric acid solution with a mass concentration of 15% for 40 seconds, wash it with water, and put it into hydrofluoric acid with a mass concentration of 40% Process for 5-10 minutes and wash off in water. Then immerse in the clarified plating solution prepared and filtered above, perform chemical plating at 85°C-9...

Embodiment 2

[0027] Weigh the reagents according to the following formula: 15 grams of nickel sulfate, 7.5 grams of sodium tungstate, 40 grams of sodium citrate, 10 grams of sodium carbonate, 15 grams of sodium hypophosphite, 0.5 mg of thiourea, and 10 grams of ammonium bifluoride; The reagents are respectively dissolved in a small amount of water, then mixed, and diluted to 1 liter with water to obtain a magnesium alloy electroless nickel-tungsten-phosphorus plating solution. Adjust the pH to 8-9 with concentrated ammonia water for later use.

[0028] The AZ91D magnesium alloy sample was thoroughly degreased in alkaline degreasing solution and clear water respectively, and then placed in a nitric acid solution with a mass concentration of 15% for 40 seconds. After washing with water, it was treated in hydrofluoric acid with a mass concentration of 40% for 5 -10 minutes, wash off in water. Then immerse in the above-prepared and filtered clarified plating solution, perform chemical plating...

Embodiment 3

[0030] Weigh the reagents according to the following formula: 20 grams of nickel sulfate, 12 grams of sodium tungstate, 50 grams of sodium citrate, 20 grams of sodium carbonate, 25 grams of sodium hypophosphite, 1 mg of thiourea, and 10 grams of ammonium bifluoride; The reagents are respectively dissolved with a small amount of water, and then mixed and diluted to 1 liter to obtain a magnesium alloy electroless nickel-tungsten-phosphorus plating solution. Adjust the pH to 8-9 with concentrated ammonia water for later use.

[0031] The AZ91D magnesium alloy samples were thoroughly degreased in alkaline degreasing solution and clear water respectively, then placed in a nitric acid solution with a mass concentration of 15% for 40 seconds, washed with water, and then treated in hydrofluoric acid with a mass concentration of 40% Leave on for 5-10 minutes and wash off in water. Then immerse in the prepared and filtered clarified plating solution above, perform chemical plating at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com