Chemical nickel plating process of Mg-Gd-Y-Zr magnesium alloy

An electroless nickel and magnesium alloy plating technology, applied in liquid electroless plating, metal material coating process, coating and other directions, can solve the problem that Mg-Gd-Y-Zr magnesium alloy is not suitable, and the research report of surface protection technology is extremely high. Less problems, failure to be plated, etc., to achieve the effect of good stability of the plating solution, strong bonding force, and easy maintenance

Inactive Publication Date: 2010-11-24

CENT SOUTH UNIV

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there are very few research reports on the surface protection technology of Mg-Gd-Y-Zr alloys.

Magnesium alloys are difficult-to-plate substrates, so pre-plating pretreatment is necessary, and the substrate has a great influence on pre-treatment. The existing pre-treatment methods are not suitable for Mg-Gd-Y-Zr magnesium alloys, resulting in There are many problems in the process, such as partial failure to be plated, defects such as peeling and bubbling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

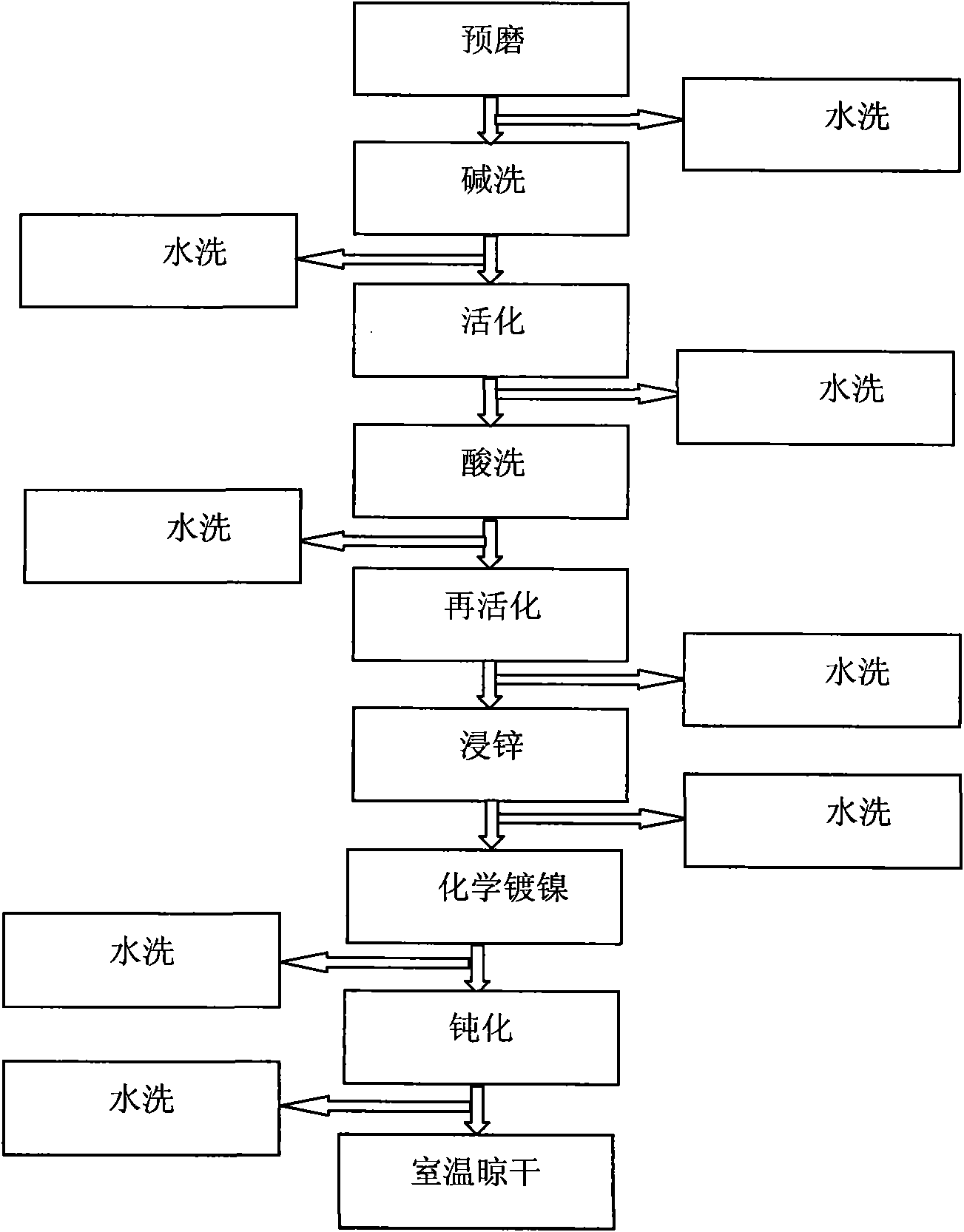

[0019] Combine below figure 1 The flow process in the Mg-Gd-Y-Zr magnesium alloy electroless nickel plating method of the present invention is described.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

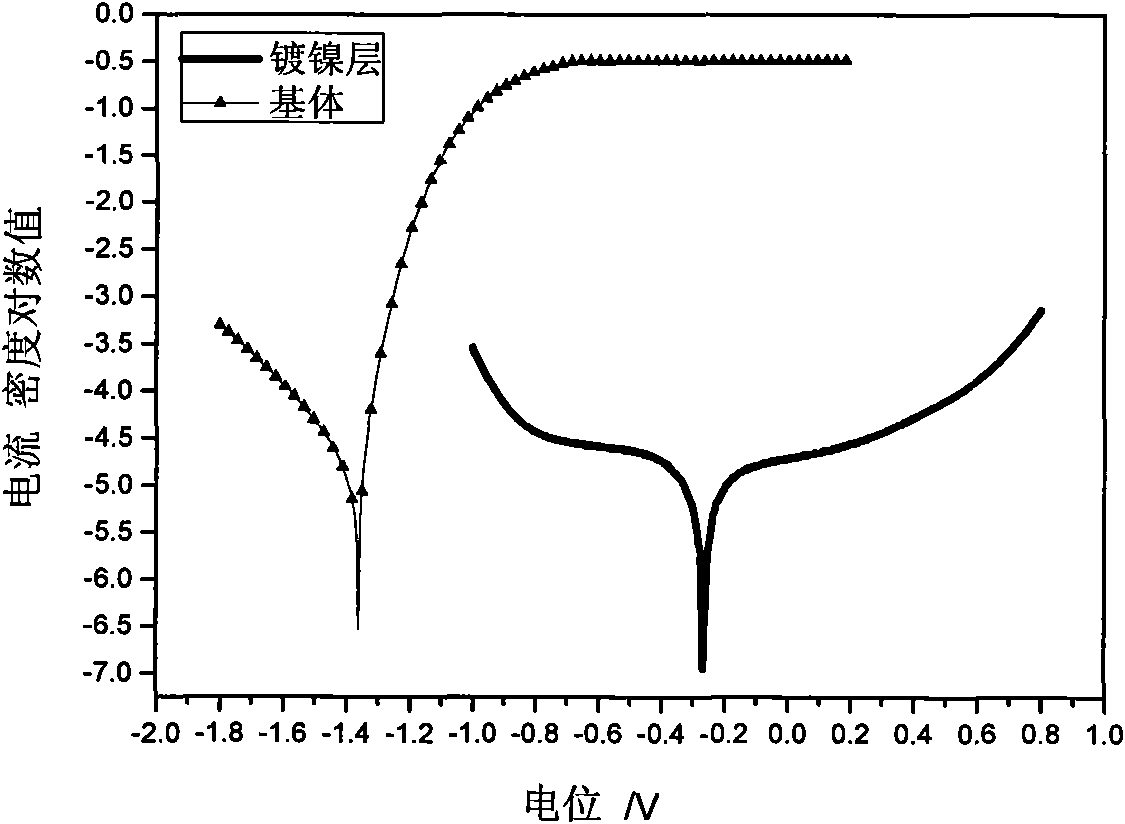

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Login to View More

Abstract

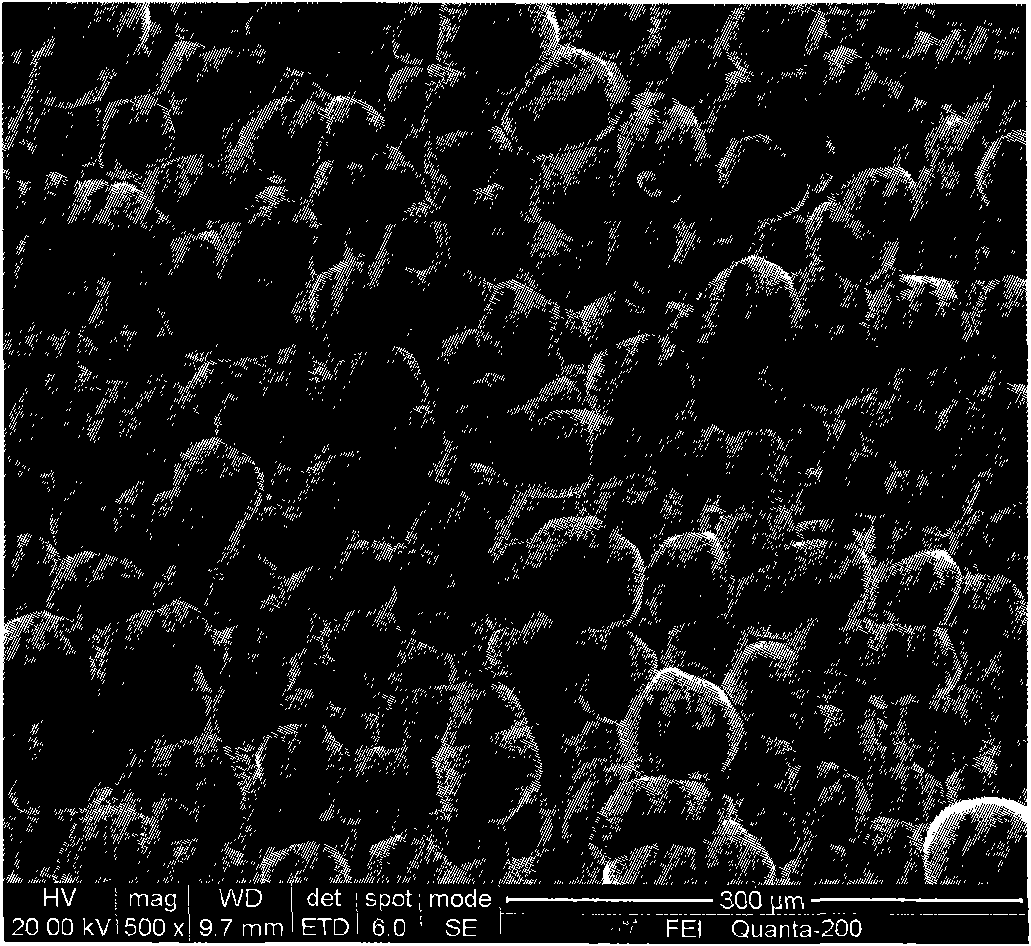

The invention relates to a chemical nickel plating method of an Mg-Gd-Y-Zr (wt%) magnesium alloy. The method comprises pre-plating pretreatment of a magnesium alloy matrix and deposition of a chemical nickel plating layer through chemical nickel plating, wherein the pre-plating pretreatment process comprises five steps of removing oil, activating, acid-washing, reactivating and zinc galvanizing; chemical nickel plating solution takes basic nickel carbonate as main salt, sodium hypophosphite as a reducing agent, hydrofluoric acid as a corrosion inhibitor, lactic acid as a complex agent and mixed liquor of cadmium sulfate and potassium iodate as a brightening agent; and a plating component is subject to zinc galvanizing and then electroless plating at the temperature about 85 DEG C to obtain the bright, flat, uniform and compact nickel plating layer. The chemical nickel plating method is applicable to chemical nickel plating on the surface of the Mg-Gd-Y-Zr magnesium alloy, thus achieving the purpose of protecting the magnesium alloy. The chemical nickel plating method has the advantages of fast plating speed, good protectiveness, simple operation and easy control.

Description

technical field [0001] The invention relates to a Mg-Gd-Y-Zr magnesium alloy electroless nickel plating process, which belongs to the field of metal corrosion and protection. Background technique [0002] Magnesium alloys have excellent properties such as high specific strength, good impact resistance, and light weight, making them have broad application prospects in aerospace, electronics, and automotive industries. However, magnesium alloys have high chemical activity and are prone to corrosion, so their poor corrosion resistance restricts their further popularization and application. Therefore, magnesium alloys must be subjected to surface protection treatment before practical application. Electroless nickel plating is one of the simplest and most economical surface protection technologies widely used, which can make magnesium alloys obtain good corrosion resistance and wear resistance, as well as weldability and electrical conductivity as well as metallic texture and ap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C18/36C23C18/18

Inventor 刘楚明金晶傅圣利高艳蕊

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com