Ice flower crack coating and preparation method and curing method

A technology for cracked coatings and ice flakes, which is applied in the direction of epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high energy consumption of ice cracked coatings, uneven ice cracks, poor coating performance of coatings, etc., and achieve high speed Fast, uniform ice cracks, good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

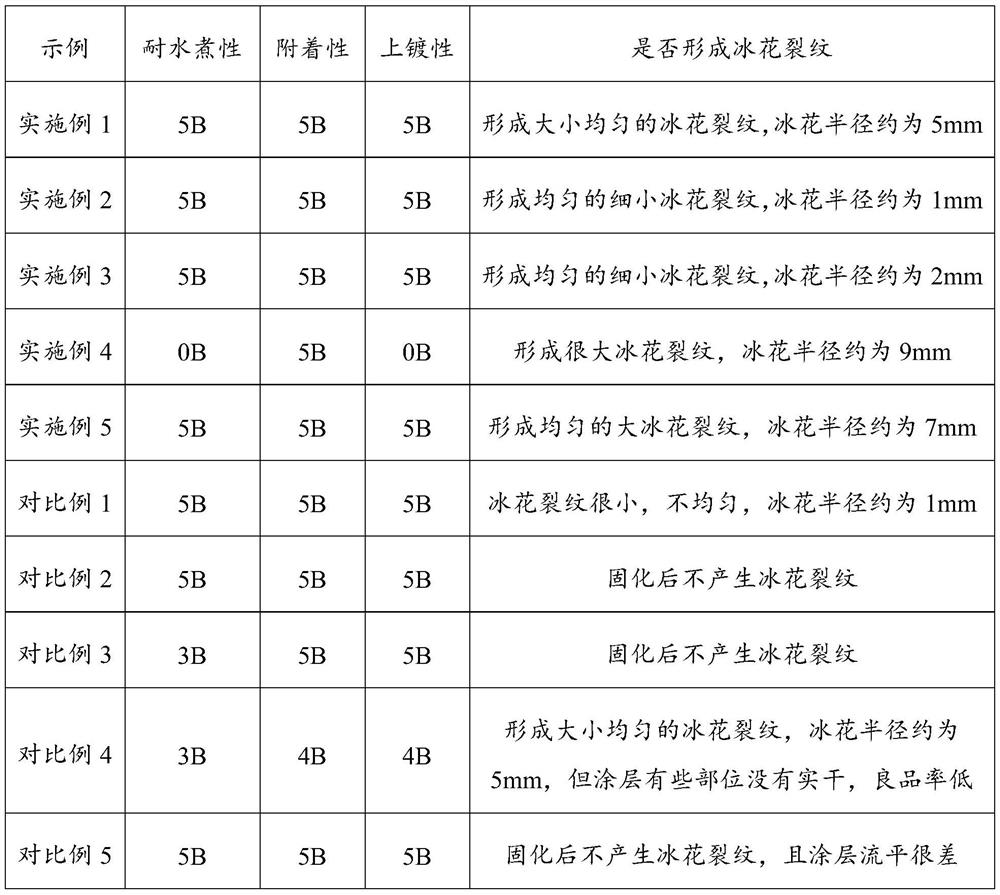

Examples

Embodiment 1

[0032] This embodiment provides an ice flower crack coating comprising 10 kg of six functional aromatic urethane acrylate (CN975), 22 kg fatty acid modified epoxy acrylate (Eb3701), 7 kgHDDa, 3 kgtpmTa, 10 kg diphenone, 1KG activation And 50kg mixed solvent (mixed solvent specifically comprises ethyl acetate and butyl acetate of 1: 1).

[0033] The preparation method of the above coating includes the following steps.

[0034] Each of the raw materials is referred to in the above quality, and the ice flower crack coating is obtained after mixing.

Embodiment 2

[0036] This embodiment provides an ice flower crack coating comprising 9kg hexafunctional aromatic urethane acrylate (CN975), 24 kg fatty acid modified epoxy acrylate (EB3701), 7 kgHDDa, 3 kgtpmta, 10 kg diphenone, 1KG activation And 50kg mixed solvent (mixed solvent specifically comprises ethyl acetate and butyl acetate of 1: 1).

[0037] The preparation method of the above coating includes the following steps.

[0038] Each of the raw materials is referred to in the above quality, and the ice flower crack coating is obtained after mixing.

Embodiment 3

[0040] This example provides an ice flower crack coating comprising 15 kg of hexafunctional aromatic polyurethane acrylate, 30 kg fatty acid modified epoxy acrylate, 8 kgHDDA, 8 kg of diphenyl ketone, 1 kg reactive amine and 50 kg of toluene.

[0041] The preparation method of the above coating includes the following steps.

[0042] Each of the raw materials is referred to in the above quality, and the ice flower crack coating is obtained after mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com