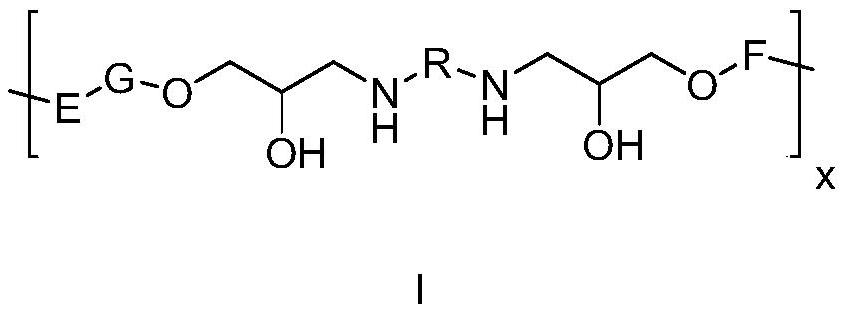

A kind of bio-based furan epoxy resin polymer and its preparation method and application

A technology of epoxy resin and polymer, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of low biological safety of products, low degree of greening of raw materials, high energy consumption in the polymerization process, etc., and achieve good biological safety, The curing method is simple and the energy consumption ratio is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

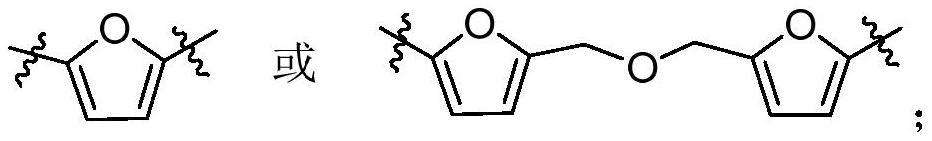

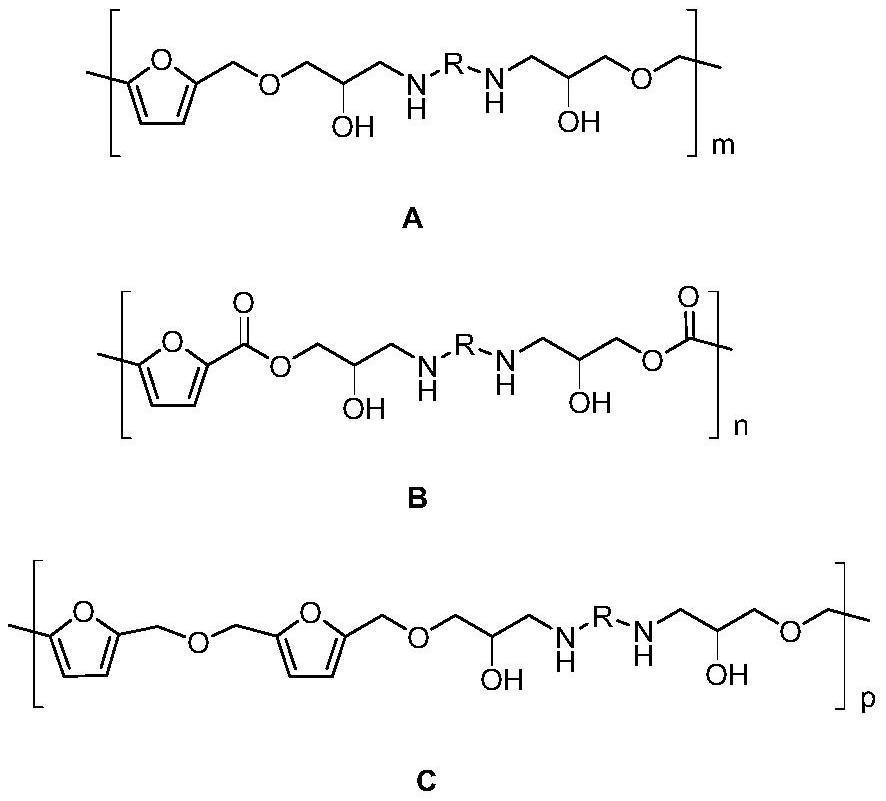

Method used

Image

Examples

Embodiment 1

[0049] Weigh 13g of furan epoxy resin IV in the reaction bottle, stir to remove the air, and then add 2.8g of curing agent ethylene glycol polyether diamine I at 10°C under nitrogen atmosphere, then stir to remove the air, and quickly Stir for 30 minutes to ensure that the material is evenly mixed. Remove the nitrogen atmosphere, remove the air bubbles in the mixture under vacuum and depressurize, and then let it stand still; pour the material on the PTFE template, move it into a nitrogen curing box at 70°C, and cure it for 3 hours, and then cool it naturally under the nitrogen atmosphere to obtain a colorless and transparent ring. Oxygen resin polymer. The actual decomposition temperature of the obtained material is 310°C, the maximum decomposition temperature is 350°C, and the obtained material has good heat resistance. Judging by the infrared data, the infrared peaks of propylene oxide in the original epoxy substrate (3298 and 3375cm -1 Isointensity stretching vibration) ...

Embodiment 2

[0052]Weigh 13g of furan epoxy resin IV in the reaction bottle, stir to remove the air, and then add 4g of ethylene glycol polyether diamine II under nitrogen atmosphere at 20°C, then further stir to remove the air, and at the same time stir rapidly for 30min to confirm Make the material mix well. Remove the nitrogen atmosphere, remove the air bubbles in the mixture under vacuum and decompression, and then let it stand still; pour the material evenly on the PTFE mold plate, move it into a nitrogen curing box at 80°C, and cure it for 2 hours, and then cool it naturally under the nitrogen atmosphere to obtain light blue and transparent epoxy resin polymers. The actual decomposition temperature of the obtained material is 316°C, the maximum decomposition temperature is 358°C, and the obtained material has good heat resistance. Judging by the infrared data, the infrared peaks of propylene oxide in the original epoxy substrate (3298 and 3375cm-1 equal intensity stretching vibratio...

Embodiment 3

[0055] Weigh 13g of furan epoxy resin IV in the reaction bottle, then stir to remove the air, and then add 5.6g of ethylene glycol polyether diamine III at 20°C under nitrogen atmosphere, then further stir to remove the air, and stir rapidly for 30min at the same time Make sure the material is mixed evenly. Remove the nitrogen atmosphere, remove the air bubbles in the mixture under vacuum and decompression, and then let it stand still; pour the material evenly on the PTFE mold plate, move it into a nitrogen curing box at 60°C, and cure it for 4 hours, and then cool it naturally under the nitrogen atmosphere to obtain a yellowish transparent epoxy resin polymers. The actual decomposition temperature of the obtained material is 326°C, the maximum decomposition temperature is 338°C, and the obtained material has good temperature resistance. Judging by the infrared data, the infrared peaks of propylene oxide in the original epoxy substrate (3298 and 3375cm-1 equal intensity stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com