Patents

Literature

41results about How to "Mild curing conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry-film lubricant and method of use thereof

InactiveCN101492630AEasy to adjustImprove wear resistanceAdditivesBase-materialsAntioxidantHeat sensitive

The invention provides an environmental friendly dry-film lubricant and a use method thereof, which belongs to the technical field of lubricant preparation. The dry-film lubricant comprises a solid lubricant, a dispersing agent, an anti-wear additive, an antioxidant, a reaction promoter, and a film-coated resin monomer; counted in weight percentage, the components and weight ratio thereof are as follows: 10 to 60 percent of solid lubricant, 0.5 to 5 percent of dispersing agent, 2 to 10 percent of anti-wear additive, 1 to 3 percent of antioxidant, 0 to 0.5 percent of reaction promoter, as well as 35 to 80 percent of film-coated resin monomer; the monomer of acrylic ester type is used to initiate copolymerization in situ to form a solid lubricant film. The dry-film lubricant does not contain organic volatiles, has a gentle preparation condition, and has a usage temperature range from -20 DEG C to 250 DEG C. The environmental friendly dry-film lubricant is suitable for the lubricating anti-wear coating on the parts of heat-sensitive base materials like plastics, alloys, and the like, in particular, and is suitable for the lubricating anti-wear coatings of running-in and high / low temperature sliding parts without oil lubrication and spare parts, as well as of microseism wear parts.

Owner:泰州市嘉鼎新材料有限公司

Epoxy resin adhesive and preparation method thereof

ActiveCN105950027AEasy accessIncreased shear strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPolyamide

The invention relates to a high-temperature resistant and high-toughness epoxy resin adhesive and a preparation method thereof. With the use of common epoxy resin, a toughening agent, an acrylic oligomer, a modified polyamide curing agent and the like, the epoxy resin adhesive has good toughness, and excellent breaking elongation and elasticity modulus, and can maintain higher shear strength at high temperature. The preparation method is simple, the process can be regulated and controlled easily, the cost is low, and the high-temperature resistant and high-toughness epoxy resin adhesive can be cured at room temperature, is particularly applicable to fragile material adhering, and is the high-performance adhesive with both high strength and high elastoplasticity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

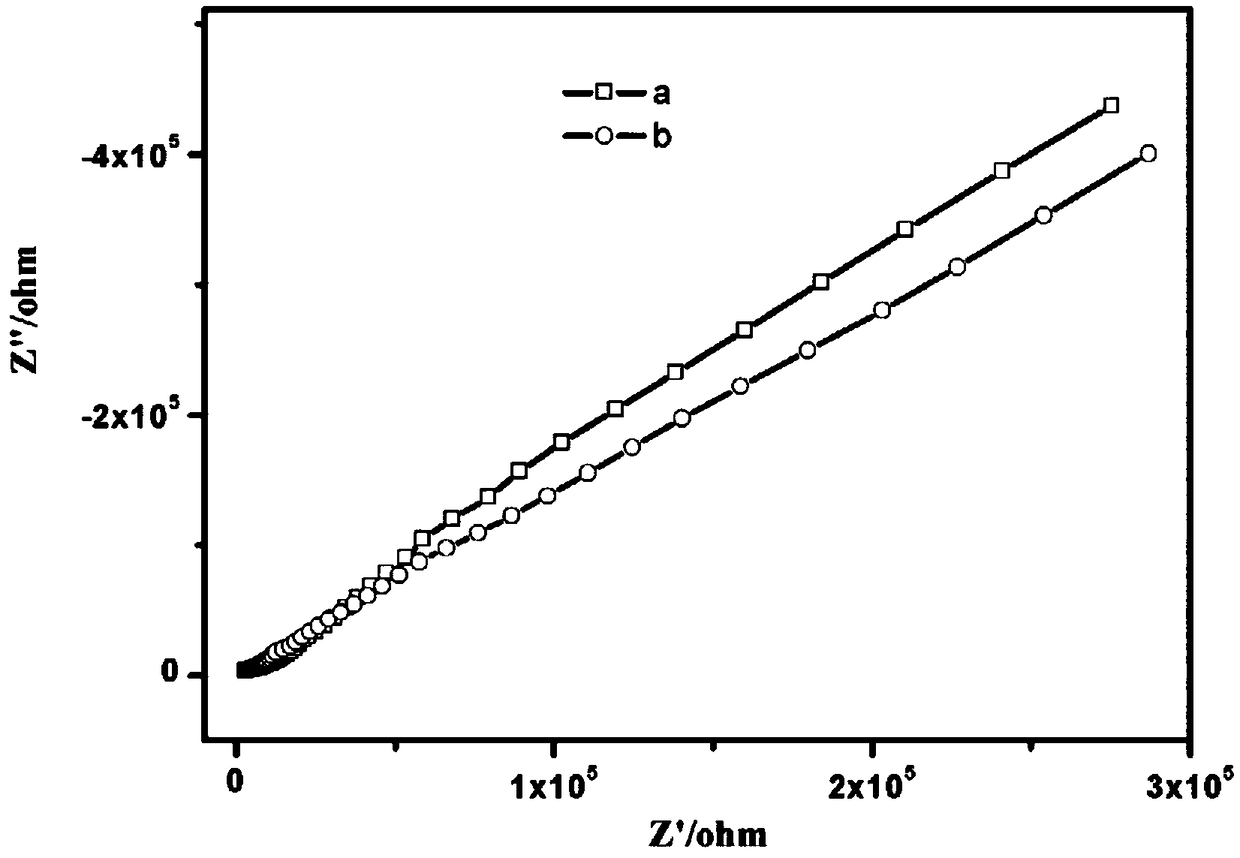

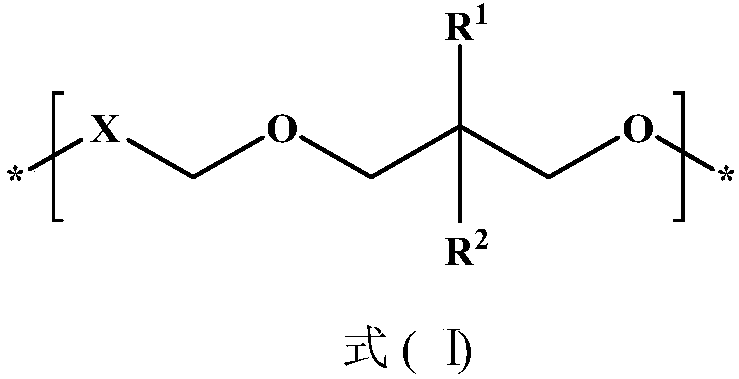

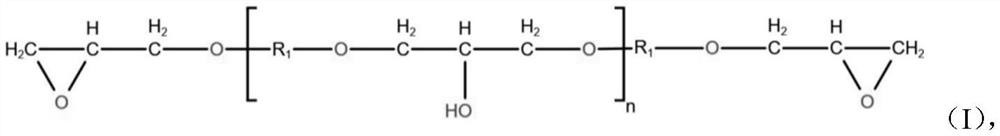

Alkyd resin modified polymer electrolyte as well as preparation method and application thereof

ActiveCN109401693AImprove flexibilityHigh mechanical strengthNon-macromolecular adhesive additivesAmide/imide polymer adhesivesFiberPolymer science

The invention relates to an alkyd resin modified polymer electrolyte as well as a preparation method and application thereof. The preparation method comprises the following steps that alkyd resin andone or more monomers of acrylamide, methacrylamide, acrylonitrile, methyl acrylate, methyl methacrylate and monofunctional or polyfunctional polyethylene glycol acrylate / polyethylene glycol methacrylate are subjected to copolymerization in an organic solvent under the action of an initiator, then an electrolyte body, a plasticizer and ionic non-conductive or ionic conductive inorganic nano-particles or nano-fibers are added into a copolymer, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte; or the alkyd resin and an ionic conductive polymer are dissolved in the organic solvent, the electrolyte body, the plasticizer and the ionic non-conductive or ionic conductive inorganic nano-particles or the nano-fibers are added to perform blending, and uniform mixing is carried out so as to obtain the alkyd resin modified polymer electrolyte. The invention provides the novel high-performance polymer electrolyte and the preparation method thereof.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Preparation method of polyvinyl alcohol medical sponge

The invention relates to a preparation method of sponge, in particular to a preparation method of polyvinyl alcohol medical sponge, and belongs to the technical field of the preparation of a medical dressing. Polyvinyl alcohol is used as a raw material to prepare the methacrylic acylation polyvinyl alcohol with optical activity groups by means of reaction of hydroxyl groups and isocyano groups, and the methacrylic acylation polyvinyl alcohol is foamed and polymerized by means of ultraviolet rays to obtain the polyvinyl alcohol medical sponge. According to the preparation method, an ultraviolet cross-linking curing technology is used, no cross-linking agent is added, so that the toxicity problem caused by the introduction of aldehydes cross-linking agents and hydrazines foaming agents in a traditional polyvinyl alcohol sponge preparation process can be completely avoided, and the biological compatibility is good. Meanwhile, the prepared polyvinyl alcohol medical sponge is soft in texture, good in adaptability to a wound surface, good in dressing property and capable of being widely applied to drainage wounds such as a burnt wound, an ulcer wound and the like. The preparation method is low in cost, simple in process and suitable for the industrialized production.

Owner:WUHAN TEXTILE UNIV

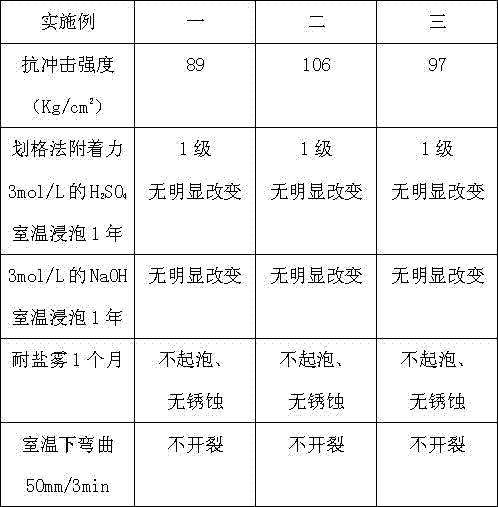

High-temperature-wear-resistant anticorrosive paint as well as preparation method and application thereof

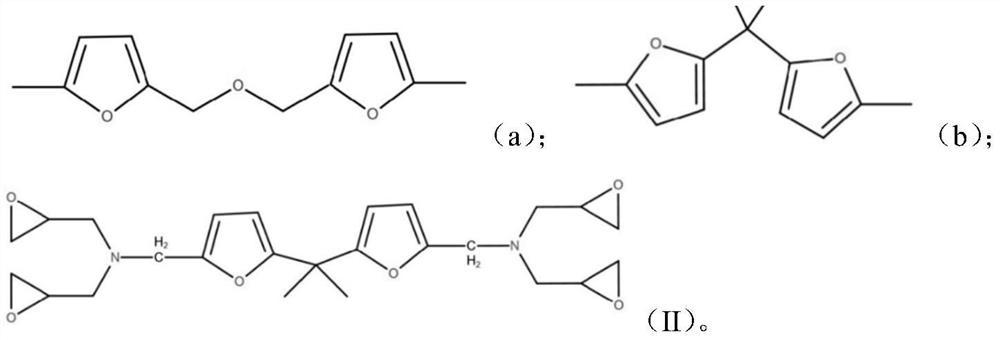

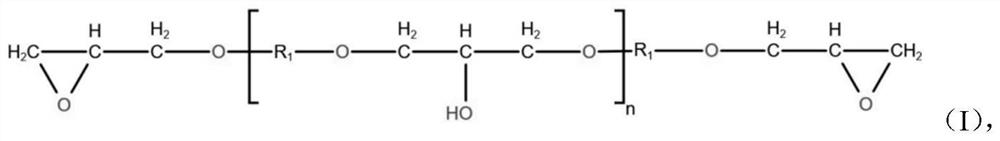

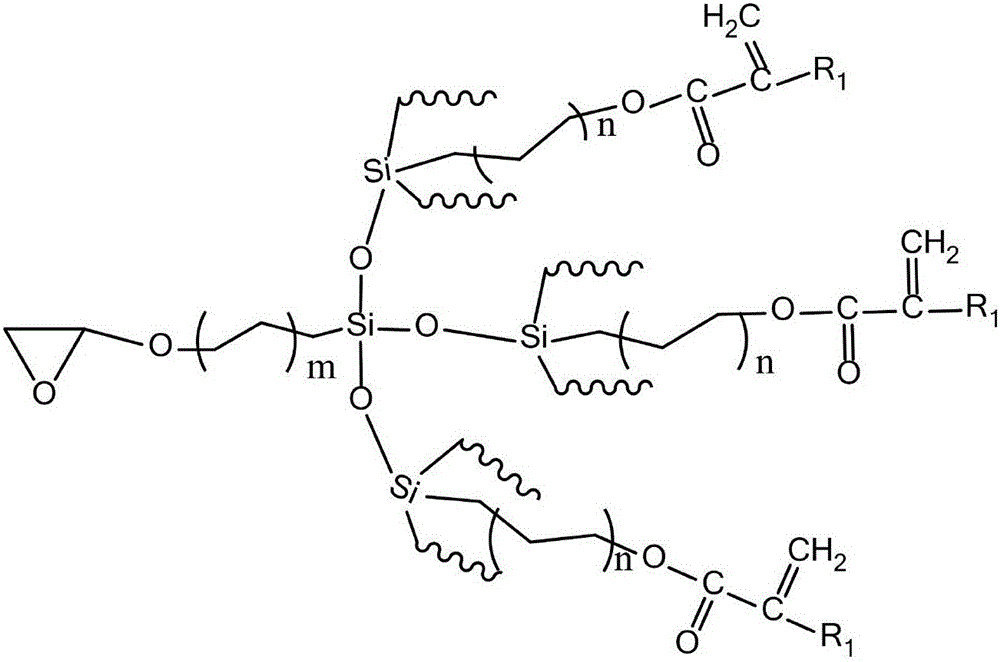

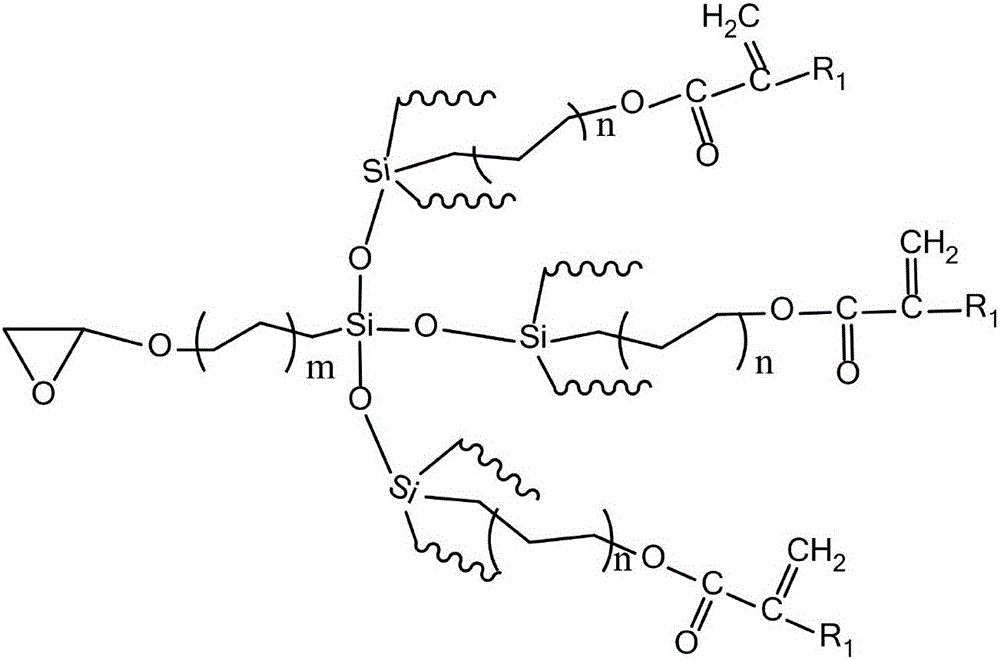

ActiveCN113248959AGood dispersionCompact appearanceFireproof paintsLiquid surface applicatorsEpoxyFuran

The invention relates to a high-temperature-wear-resistant anticorrosive paint and a preparation method and an application thereof, a combination of furan modified epoxy resin with a specific structure is selected as a film forming substance, the high temperature resistance, corrosion resistance and other properties of the epoxy resin and furan resin are utilized, and functionalized graphene is selected as a heat-conducting and anticorrosive component, epoxy polyether-polysiloxane is used as a dispersion functional component, good dispersion of graphene, the filler and other components is realized, the coating with good and compact appearance is prepared, the coating has excellent high temperature resistance, wear resistance, corrosion resistance and the like, can meet the high-temperature corrosion resistance requirements of the surfaces of the four tubes of the boiler, and meanwhile, the method has the advantages of simple process, simple operation, mild curing conditions, short time required for complete curing, low energy consumption ratio of the curing process, and high greenization degree of the process.

Owner:深圳优易材料科技有限公司

Epoxy based silicon tackifier and organosilicon conductive insulating gel prepared from same

The invention discloses an epoxy based silicon tackifier and organosilicon conductive insulating gel prepared from the same. The tackifier is formed by hydrolytic condensation of vinyl siloxane and expoxy-based siloxane under the acidic condition, and the organosilicon conductive insulating gel is obtained by mixing the tackifier with vinyl silicone oil, a catalyst, hydrogen contained silicon oil and a thermal conductive filler and subjecting the mixture to stirring, vacuum defoaming, warming and curing. Epoxy groups are introduced to a hydrogen silicon oil contained side chain through hydrosilylation, the problem about poor compatibility of the former tackifier and matrix resin is solved, shortcomings that a traditional epoxy resin based material is poor in thermal resistance and prone to yellowing and aging are overcome by applying the tackifier to preparation of the organosilicon conductive insulating gel, and the prepared organosilicon conductive insulating gel has the advantages of good thermal resistance, high mechanical strength and good adhesiveness.

Owner:FOSHAN CENT FOR FUNCTIONAL POLYMER MATERIALS & FINE CHEM

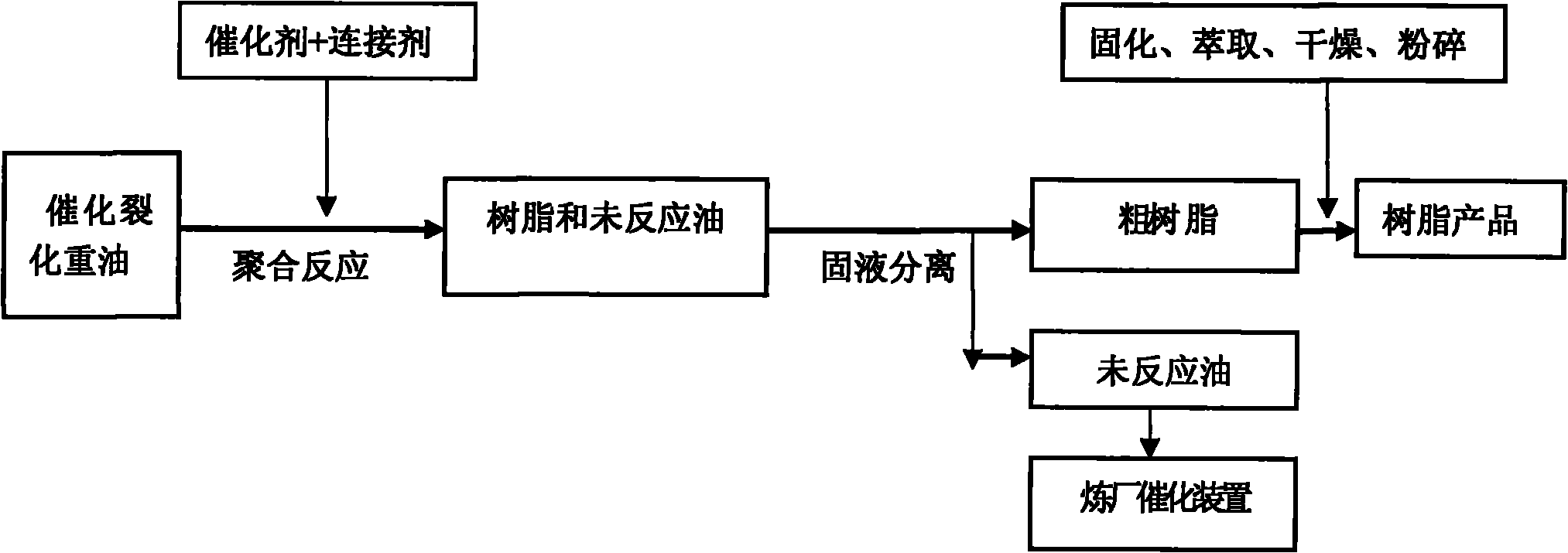

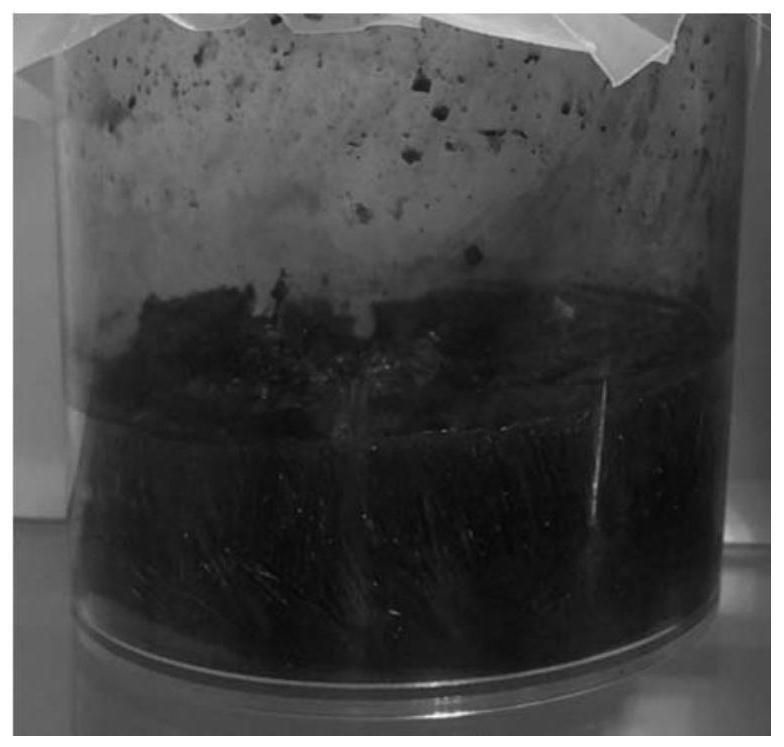

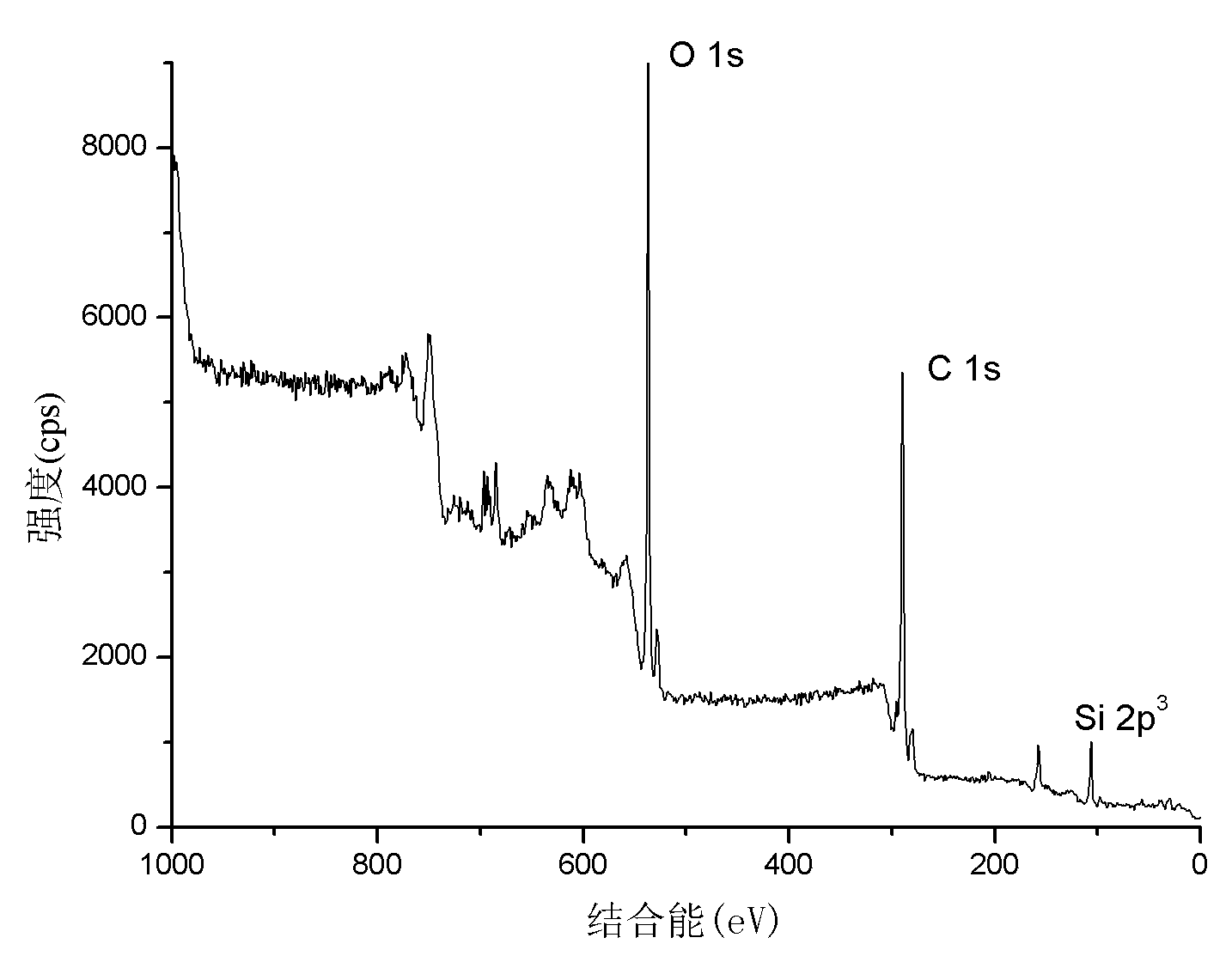

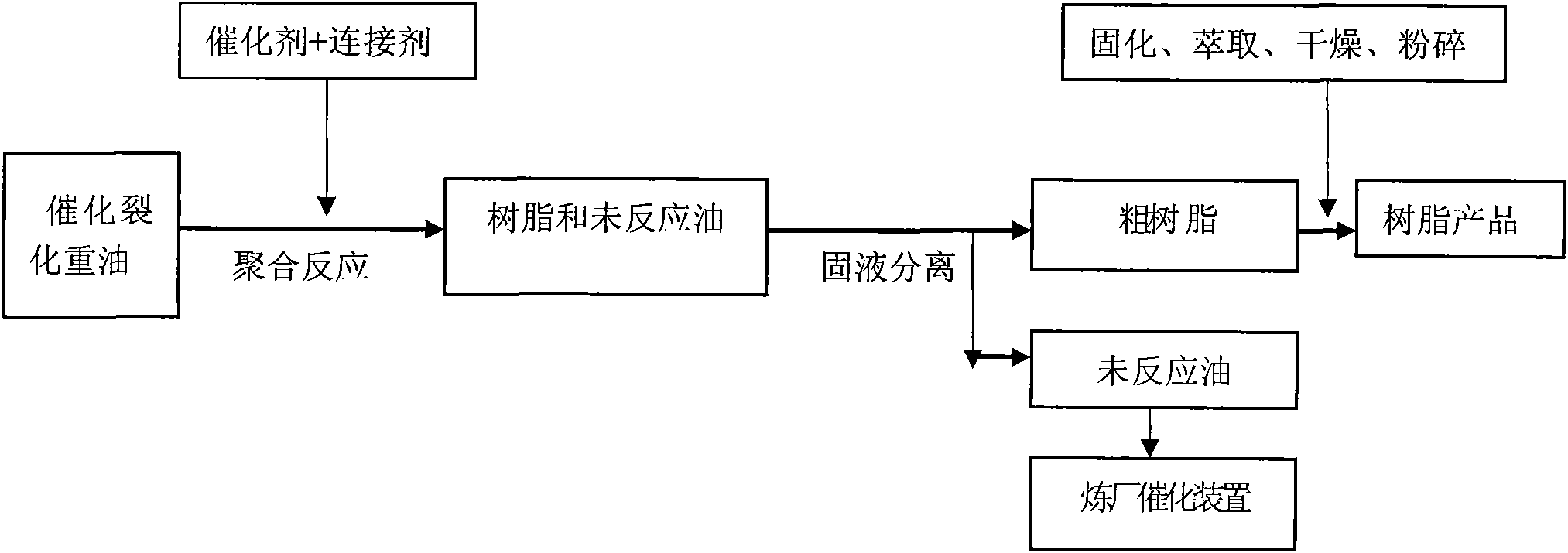

Novel process for utilizing catalytic cracked heavy oil and condensed multinuclear anime prepared with same

ActiveCN102040727AImprove melt fluidityEasy to processCatalytic crackingAdhesivesSocial benefitsHeat resistance

The invention provides a novel process for utilizing catalytic cracked heavy oil, comprising the step of the synthesis of catalytic cracked heavy oil. The invention discloses a novel process for utilizing the catalytic cracked heavy oil of oil refineries, comprising the steps of: directly synthesizing condensed polynuclear anime by using the catalytic cracked heavy oil as a raw material, separating solid from liquid, refining solid resin, and returning feed oil, which is not involved in reaction, to a catalytic cracking device of a refinery to be used as a high-quality catalytic cracked raw material. The novel process has high utilization rate on the catalytic cracked heavy oil, is environmental-friendly and free of pollutant emission and can generate favorable economic and social benefits. The invention further provides the condensed polynuclear anime obtained with the novel process, and the condensed polynuclear anime has the advantages of good heat resistance, favorable self-lubricating property and favorable combinability with other materials, has the 10% thermal gravimetric temperature being above 380 DEG C and the final carbonization yield being above 50%, and can serve as C / C and C / plastic composite material matrices to be applied to various fields.

Owner:CHINA PETROLEUM & CHEM CORP

Graphene conductive printing ink

The invention provides a graphene conductive printing ink. The graphene conductive printing ink comprises, by weight, 4.71 to 5.62% of phenolic resin, 83.12 to 84.08% of graphene, 2.6 to 3.5% of ethyl cellulose, 4.26 to 4.75% of ethanol, 1.2 to 1.36% of Al2O3 powder and 3.13 to 3.42% of SiO2 powder.

Owner:NINGBO MORSH TECH

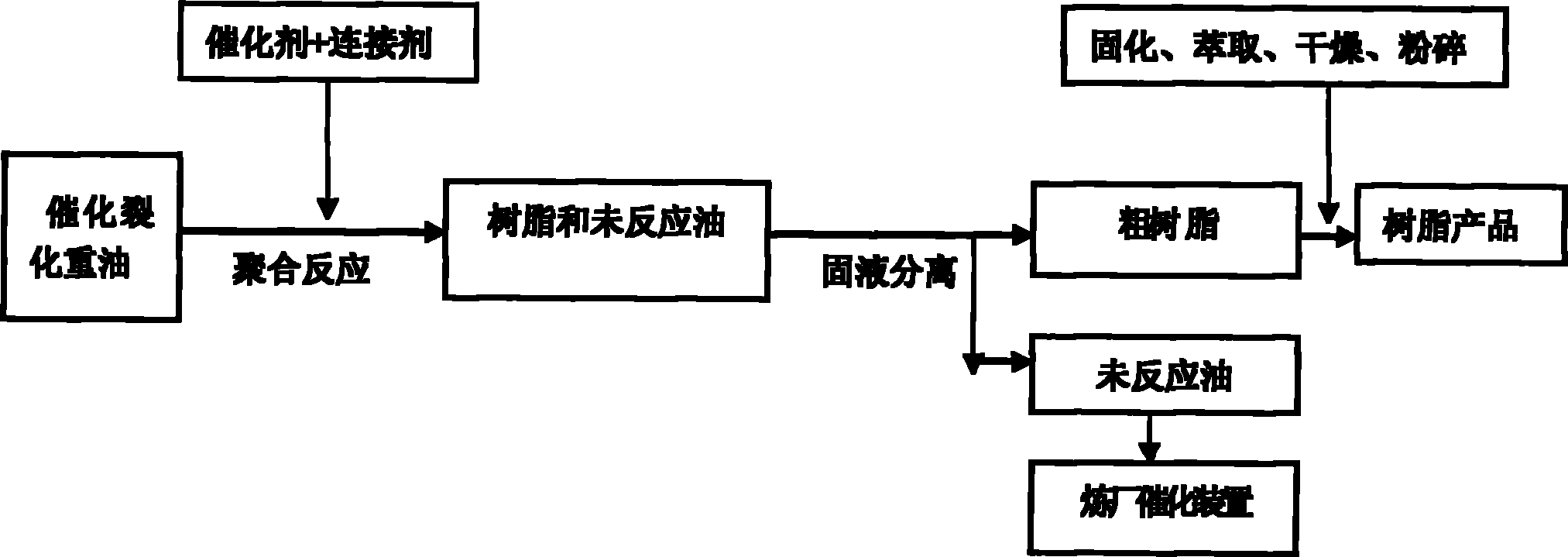

MXene-based electrothermal ink and preparation method and application thereof

ActiveCN113372765AImprove stabilityExcellent Joule heating characteristicsInksScreen printingPolymer science

The invention discloses MXene-based electrothermal ink as well as a preparation method and application thereof, and belongs to the technical field of electrothermal ink. The electrothermal printing ink comprises MXene nanosheets, xanthan gum and water, the mass fraction of the MXene is 5-35%, and the mass ratio of the MXene to the xanthan gum is (300-200): (1-10). The preparation method comprises the following steps: firstly, adding the xanthan gum powder into the water, and fully mixing to prepare a bonding base material; and then fully dispersing the MXene powder into the bonding base material to prepare the MXene-based electrothermal ink. The MXene-based electrothermal ink is good in stability, low in solid content, green, environment-friendly and low in cost, when the MXene-based electrothermal ink is used for silk-screen printing, the curing temperature is low, an obtained silk-screen printing electrothermal film can shield 99.99% of electromagnetic waves under the X wave band, and the electromagnetic shielding characteristic is excellent; moreover, stable temperature rise can be realized under a relatively low driving voltage, effective work in a severe cold environment can be realized, a heat preservation effect is achieved, and potential application prospects are realized.

Owner:WUHAN UNIV OF TECH

Graphene conductive ink and preparation method thereof

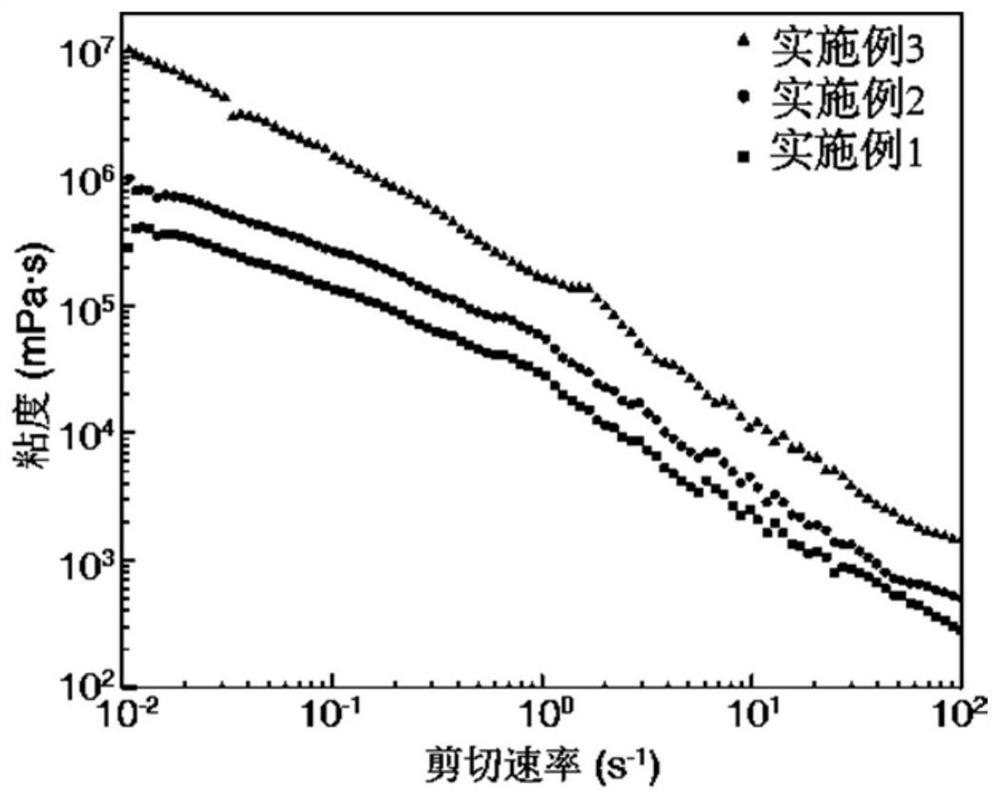

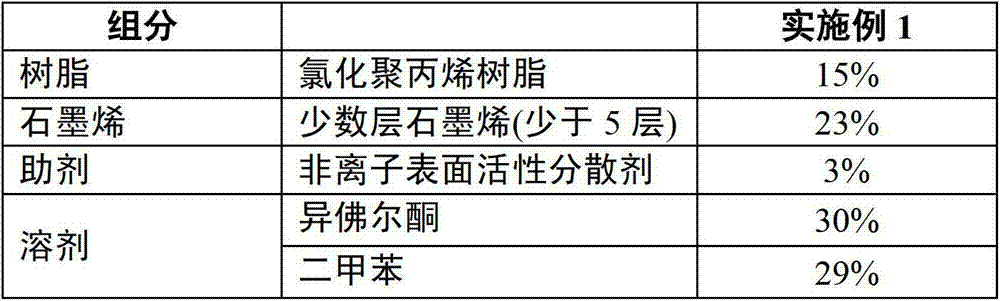

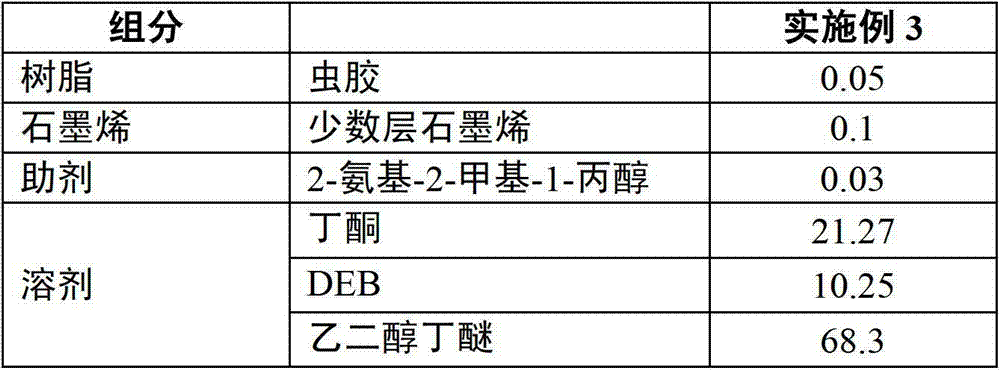

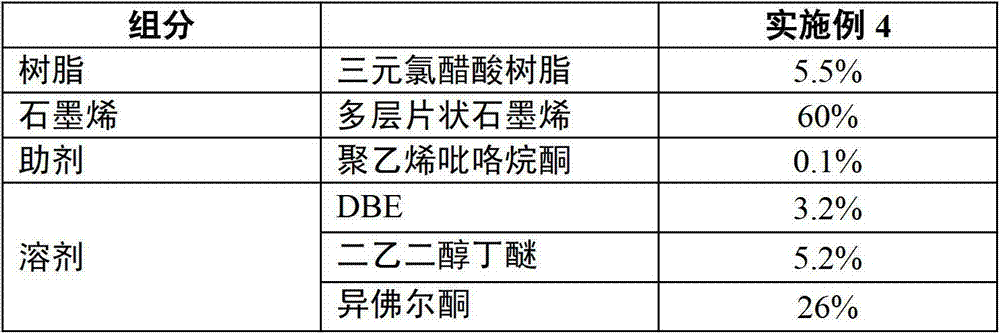

ActiveCN103113786BImprove thermal conductivityImprove mechanical propertiesInksConductive materialsSolvent

The invention relates to graphene conductive ink comprising the following components by weight percent: 0.01-25% of resin, 0.1-95% of graphene, 0.1-30.0% of assistant, and 5.0-99.79% of solvent. The two-dimensional conductive material graphene is used for the conductive ink; the graphene with special ratio is adopted as a conductive phase; the resin is taken as a binder; the assistant and the solvent are used for assisting; the prepared ink is good in anti-sedimentation property, and adjustable in viscosity and rheological behavior, and can be used for flexibly printing on the surfaces of a plurality of substrates; and the ink is stable in mechanical property, stable in electrical properties, oxidation resistance, acid resistance, alkali resistance and resistance to a chemical solvent after being cured.

Owner:SUZHOU NIUJIAN NEW MATERIAL

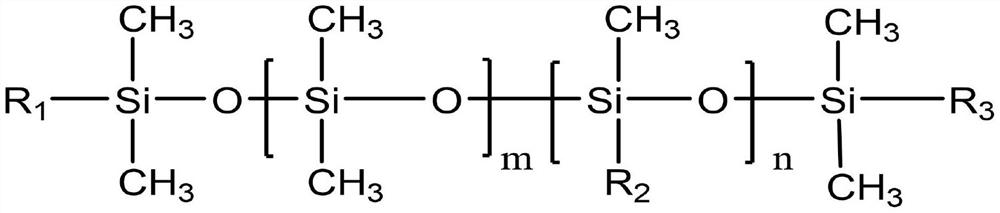

Addition-crosslinking silicone resin compositions

InactiveCN100491470CDoes not require long curing timeExtend curing timeOptical elementsPolymer scienceOrganosilicon

Addition crosslinking siloxane resin composition, which comprises (1) 100 parts by weight of general formula R 1 a R 2 b R 3 c SiO (4-a-b-c) / 2 (1) polyorganosiloxane, (2) 50 to 200 parts by weight of general formula R 1 d h 2 e R 3 f SiO (4-d-e-f) / 2 The polyorganosiloxane of (II), or (3) 200 parts by weight of general formula R of (substituting components (1) and (2)) 1 g R 2 h R 3 i h k SiO (4-g-h-i-k) / 2 (III) polyorganosiloxane, (4) 1 to 100 parts by weight of general formula R 1 l R 2 m R 3 n SiO (4-l-m-n) / 2 (IV) Alkenyl-rich polyorganosiloxane, and (5) 1 to 100 parts by weight hydrogen-rich formula R (additionally or in place of component (4)) 1 o h p R 3 q SiO (4-o-p-g) / 2 (V) a polyorganosiloxane, and (6) a sufficient amount of catalyst.

Owner:WACKER CHEM GMBH

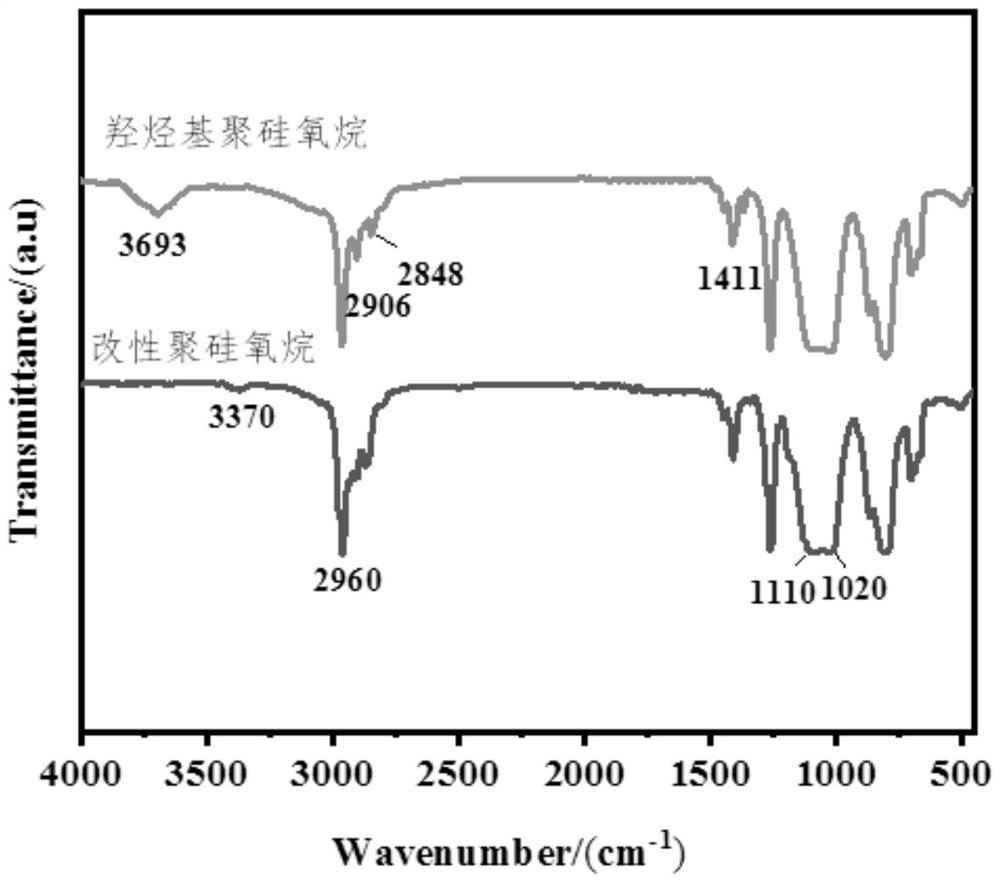

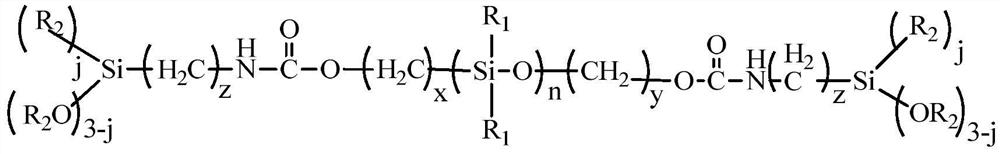

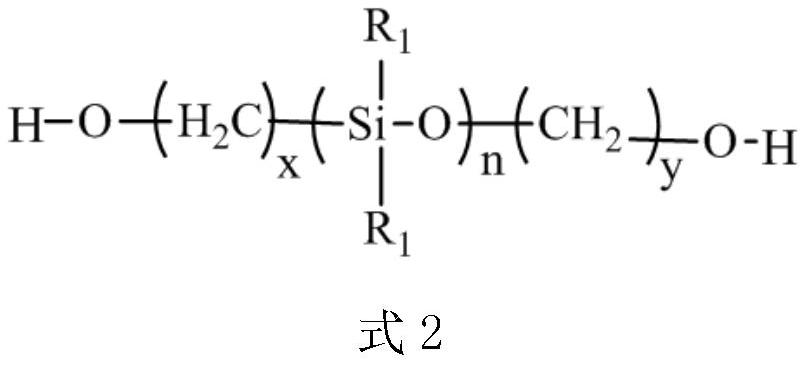

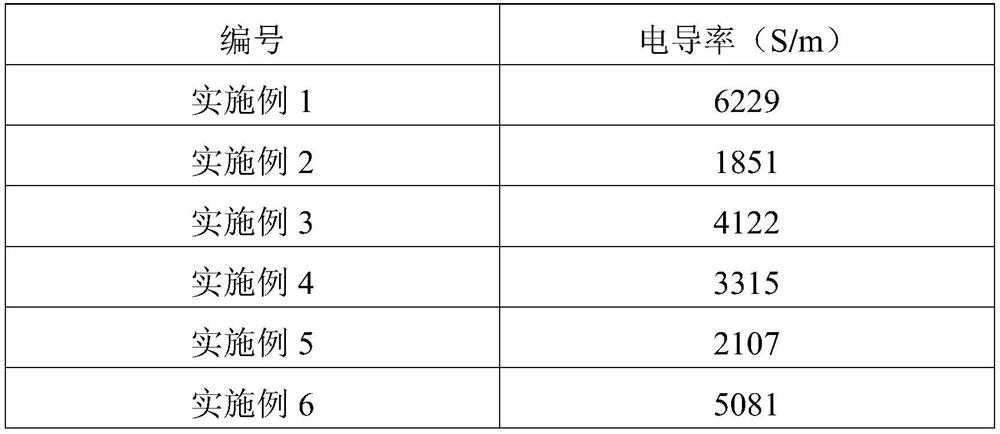

Moisture-curable modified polysiloxane and preparation method and application thereof

The invention relates to moisture-curable modified polysiloxane and a preparation method and application thereof. The modified polysiloxane is obtained by carrying out addition reaction on double-terminal hydroxyl alkyl polysiloxane and isocyanato alkoxy silane. The modified polysiloxane has a single linear structure, has a siloxy end group, can be moisture-cured at room temperature, has stable viscosity before and after curing, and has the advantages of mild curing conditions, no curing depth limitation and deep curing. The modified polysiloxane is applied to preparation of room-temperature vulcanized silicone rubber, the problem of 'viscosity peak' existing in the traditional polysiloxane curing process can be fundamentally solved, the storage stability of the product is improved, meanwhile, normal curing of the product is guaranteed, and the prepared silicone rubber composition is excellent in performance and has good application value.

Owner:肇庆市武大环境技术研究院

Water-based graphene conductive ink and preparation method thereof

The embodiment of the invention discloses a water-based graphene conductive ink and a preparation method thereof, and belongs to the technical field of printed electronic materials. The water-based graphene conductive ink is prepared from the following raw materials in percentage by weight: 0.1 to 30 percent of expandable graphite, 0.5 to 15.4 percent of water-based polymer resin, 0.1 to 30 percent of an auxiliary agent and 30 to 97.4 percent of a solvent. The water-based graphene conductive ink has remarkable advantages in the aspect of conductivity, the conductivity can reach up to 1.87 * 10< 4 > to 3.79 * 10 < 4 > S / m, and the water-based graphene conductive ink further has the advantages of being light in printed pattern mass, good in printing adaptability, mild in curing condition, low in cost and the like. Meanwhile, the raw materials are low in price and harmless and non-toxic to human bodies and the environment, the requirements of ecological friendliness and sustainable development are met, and industrial production is met.

Owner:深圳石墨烯创新中心有限公司

CNT:SNC:PEDOT ternary water-based conductive ink and preparation method thereof

ActiveCN112341865ABroaden research directionImprove resource utilizationInksAmmonium sulfateFlexible electronics

The invention discloses a CNT:SNC:PEDOT ternary water-based conductive ink and a preparation method thereof. The method comprises the following steps: adding carbon nanotubes into a sulfated nanocellulose aqueous dispersion, and conducting uniform dispersing to obtain a CNT:SNC dispersion; adding an EDOT monomer into the CNT:SNC dispersion, and conducting uniform stirring to obtain a mixed liquid;and adding ammonium persulfate and ferric chloride into the mixed solution, and carrying out polymerization reaction in an inert atmosphere to obtain the CNT:SNC:PEDOT ternary water-based conductiveink. The CNT:SNC:PEDOT ternary conductive ink has the advantages of being water-based, environment-friendly, good in stability, good in adhesive force, free of heating curing, high in universality andthe like. Meanwhile, due to the advantages of stable dispersion, high conductivity, excellent printing adaptability, excellent coating mechanical stability and the like, the conductive ink provided by the invention is expected to be applied to printing of various flexible electronic devices.

Owner:SOUTH CHINA UNIV OF TECH

Water-soluble graphene electric-conduction ink and preparation method thereof

The invention provides a water-soluble graphene electric-conduction ink and a preparation method thereof, wherein the water-based graphene electric-conduction ink composite material comprises water-soluble graphene powder, a linking resin material, an auxiliary agent and a solvent. According to the present invention, the large-batch water-soluble graphene electric-conduction ink can be prepared according to the experimental method of the present invention; deionized water is used as the solvent to replace the traditional organic solvent, the linking resin is selected, and the ratio is used, such that the water-soluble graphene electric-conduction ink having characteristics of good electric conductivity, good toughness, good compression molding and good impact resistance and meeting the adhesion requirement is blended; based on the excellent electric conductivity of the graphene component, the electric conduction stability of the product is increased, and the resistivity is reduced; andthe disadvantages of environment pollution and high cost of the traditional electric-conduction ink are overcome, and the water-soluble graphene electric-conduction ink is expected to be mass-produced.

Owner:厦门泰启力飞科技有限公司

Adhesive filler for splicing light porous composite material and preparation method of adhesive filler

ActiveCN112300748ASatisfy assembly glueMeet Gap FillingNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberPtru catalyst

The invention provides an adhesive filler for splicing a light porous composite material and a preparation method of the adhesive filler. The adhesive filler is obtained by the following steps: weighing 100 parts by mass of hydroxyl-terminated polysiloxane, and putting the hydroxyl-terminated polysiloxane into a mixing container; weighing 0-30 parts by mass of white carbon black, 10-40 parts by mass of chopped fibers, 10-50 parts by mass of hollow spheres, 5-15 parts by mass of an antioxidant filler and 0-30 parts by mass of a diluent, putting the above weighed materials into the mixing container, and conducting physical stirring and mixing at room temperature; and weighing 3-10 parts by mass of a cross-linking agent and 0.5-2 parts by mass of a catalyst, adding the cross-linking agent andthe catalyst into the mixed material, and continuously conducting stirring to be used for splicing the light porous composite material. The adhesive filler has good chemical and physical adaptabilitywith a low-density composite material matrix, and meanwhile, has the characteristics of high-temperature ablation resistance, oxidation resistance, high-temperature sealing, low density and low thermal conductivity, and meets the requirements of splicing, bonding, gap filling and repairing of the light porous composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparation method of resistive screen hardening liquid

The invention belongs to the field of electronic products, and particularly relates to a preparation method of resistive screen hardening liquid. The method particularly comprises the following steps: mixing a silane coupling agent and glycidyl ether according to a certain ratio, performing hydrolysis by a proper amount of mixed liquid of deionized water, alcohols and acetylacetone for 15-24 hours; mixing the hydrolyzed product with a solvent according to a ratio of 2:3, adding a proper amount of a levelling agent and an antifoaming agent to obtain the mobile phone screen hardening liquid. An outer screen of a resistive screen (a PET film) is soaked with a 0.1 mol / L sodium hydroxide solution for 5 min, and is cleaned; then the film surface is uniformly coated with the hardening liquid by methods of dip-coating or roller coating, dried and cured at 70 DEG C for 30 min to obtain a hardened resistive outer screen with a pencil hardness of up to 6H. The preparation method of the invention has the characteristics of simple process and low cost, can enhance the surface hardness of resistive screens, improve scraping resistance, and prolong the service life of resistive screens.

Owner:FUDAN UNIV

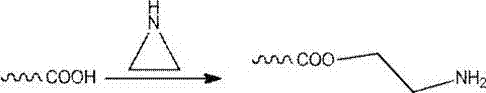

Interior coating for can and preparation method of interior coating

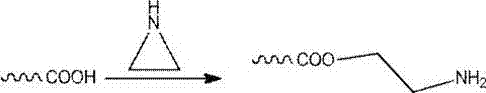

ActiveCN107384153AUniform cross-network structureImprove performancePolyester coatingsCross-linkMannich reaction

The invention provides a preparation method of a can. The preparation method comprises the following steps: firstly, synthesizing terminal carboxyl polyester by a body melting method, and then modifying the polyester by using an ethylene imine modifier; secondly, adding phenolic resin, amino resin and an assistant into the modified polyester, and uniformly stirring to form the required coating. According to the preparation method disclosed by the invention, ethylene imine is added, and carboxyl and the ethylene imine are enabled to generate a ring-opening reaction; a terminal carboxyl is introduced into a polyester structure, and high-activity amino can participate in cured cross-linking of phenolic resin at lower temperature by Mannich reaction, so that a homogenous cross-linked reticular structure can be formed. According to the method, a design idea of a traditional polyester composite coating is completely changed; the polyester is modified and is further jointly cross-linked in a system, so that the polyester and a second component can be cured to form the homogenous reticular structure. The performance of a polyester / phenolic curing system is improved, and the generality of a formula is also improved; meanwhile, curing conditions of the polyester / phenolic curing system are milder compared with those of ordinary phenolic, so that energy sources are saved, and easiness in construction is realized.

Owner:中瀚新材料科技有限公司

Carbon dot-organic silicon composite fluorescent material as well as preparation method and application thereof

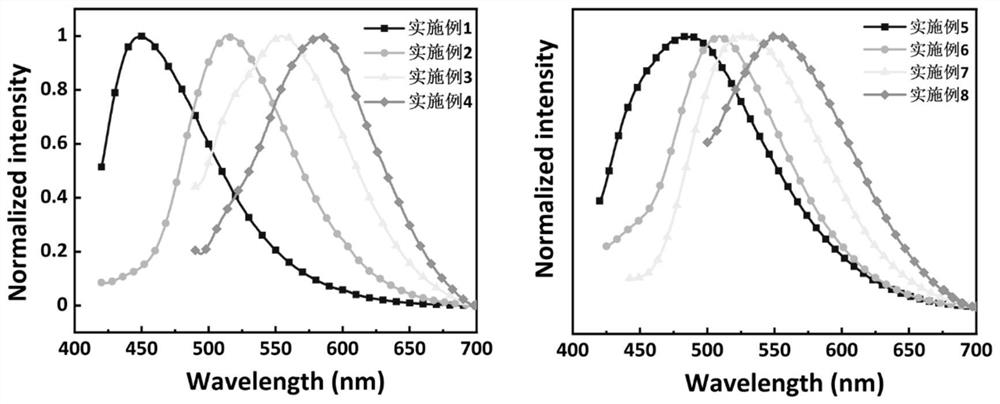

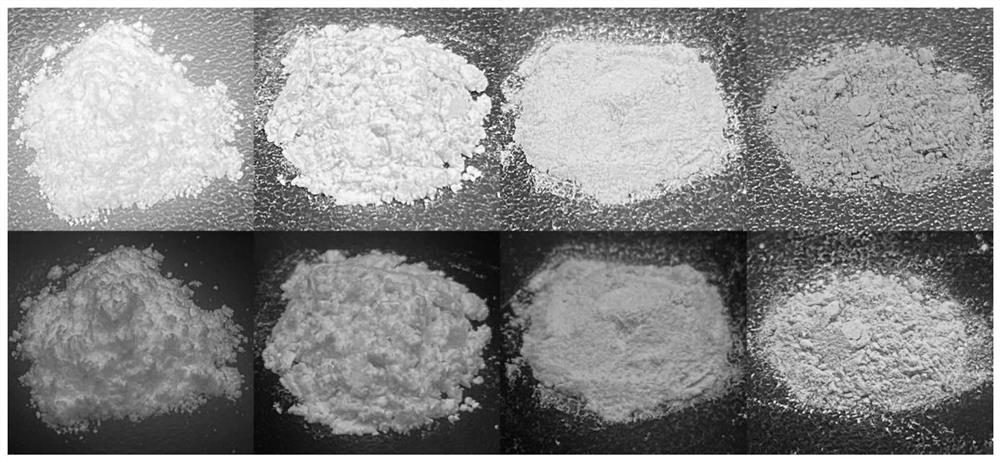

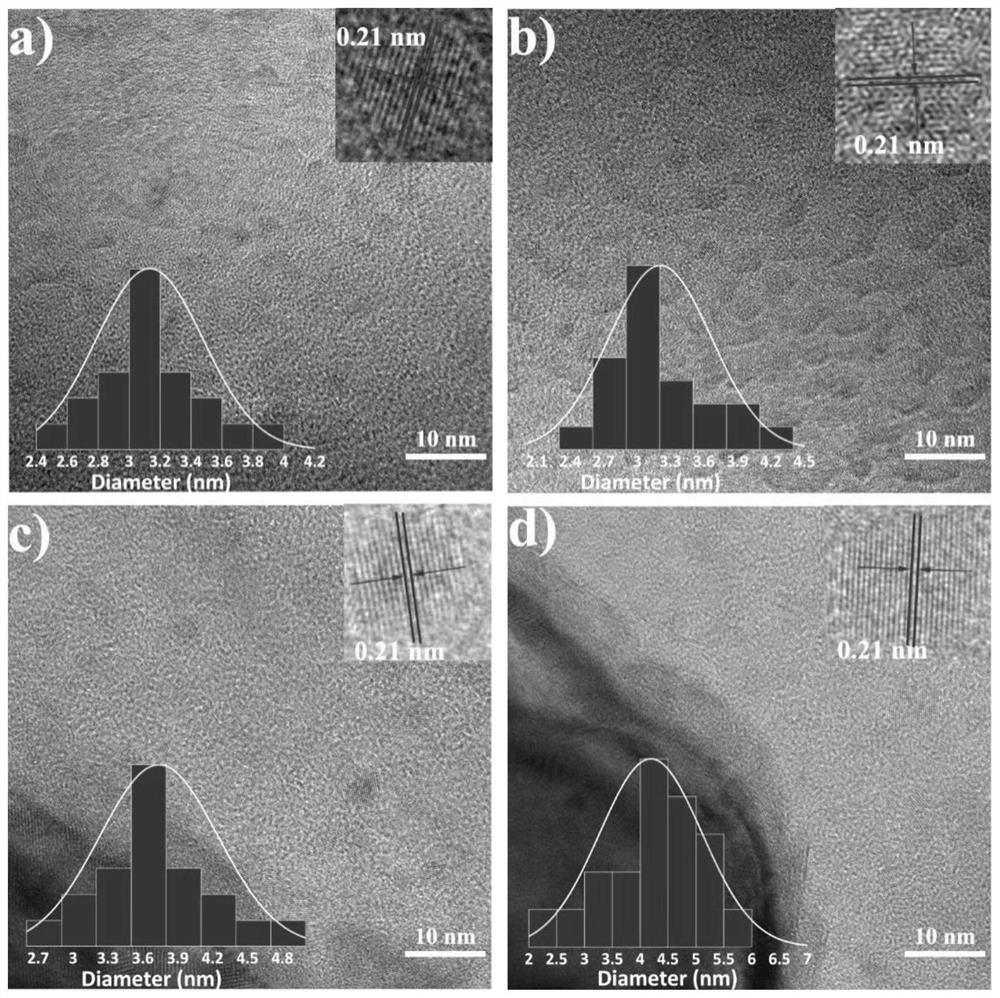

PendingCN114574197AIncrease the molar ratioReduce the ratioLuminescent compositionsPhotovoltaic energy generationSolar lightFluorescent light

The invention discloses a carbon dot-organic silicon composite fluorescent material as well as a preparation method and application thereof, and belongs to the technical field of optical functional materials. The preparation method comprises the following steps: adding a mixed reactant containing micromolecular organic acid and / or salt thereof, amino-containing organosilane and the like into a mixed solvent consisting of deionized water and absolute ethyl alcohol, uniformly mixing, and carrying out solvothermal reaction on the obtained mixed reaction solution at the reaction temperature of 180-200 DEG C for 4-12 hours; and after the reaction is finished, centrifuging, washing and drying the obtained product to obtain the carbon dot-organic silicon composite fluorescent material. The fluorescent light of the composite fluorescent material is regulated and controlled from blue light to orange light, and the composite fluorescent material has stable solid-state fluorescent light and can be used for constructing an efficient light-emitting solar light collector. The method has the advantages of easiness in preparation and purification, greenness, no toxicity and the like, and has good theoretical research and practical application values. The method for preparing the light collector is simple and convenient, and is suitable for large-scale production.

Owner:HUBEI UNIV

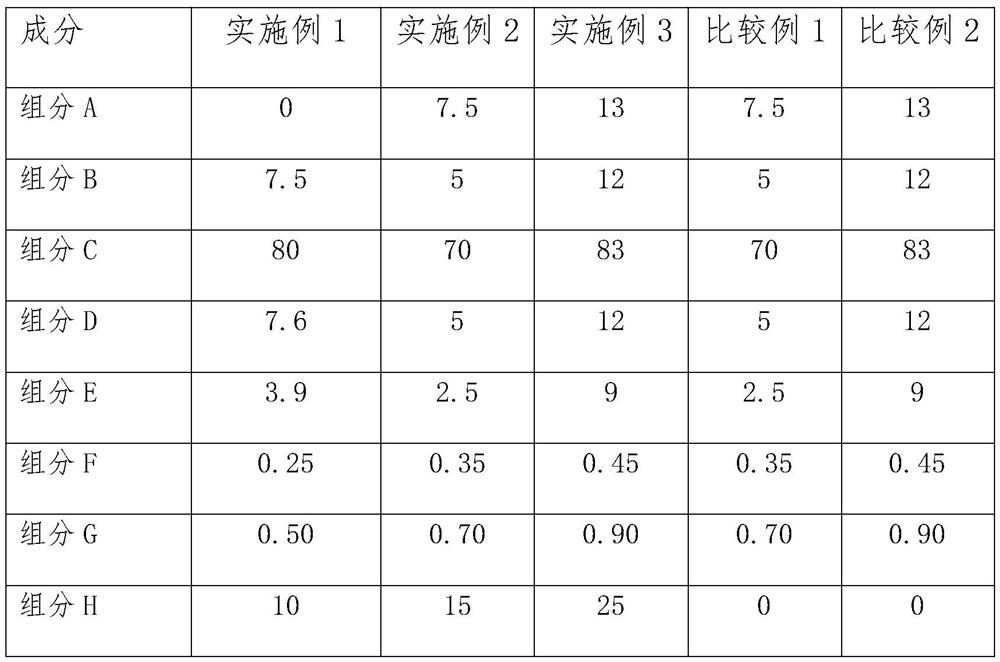

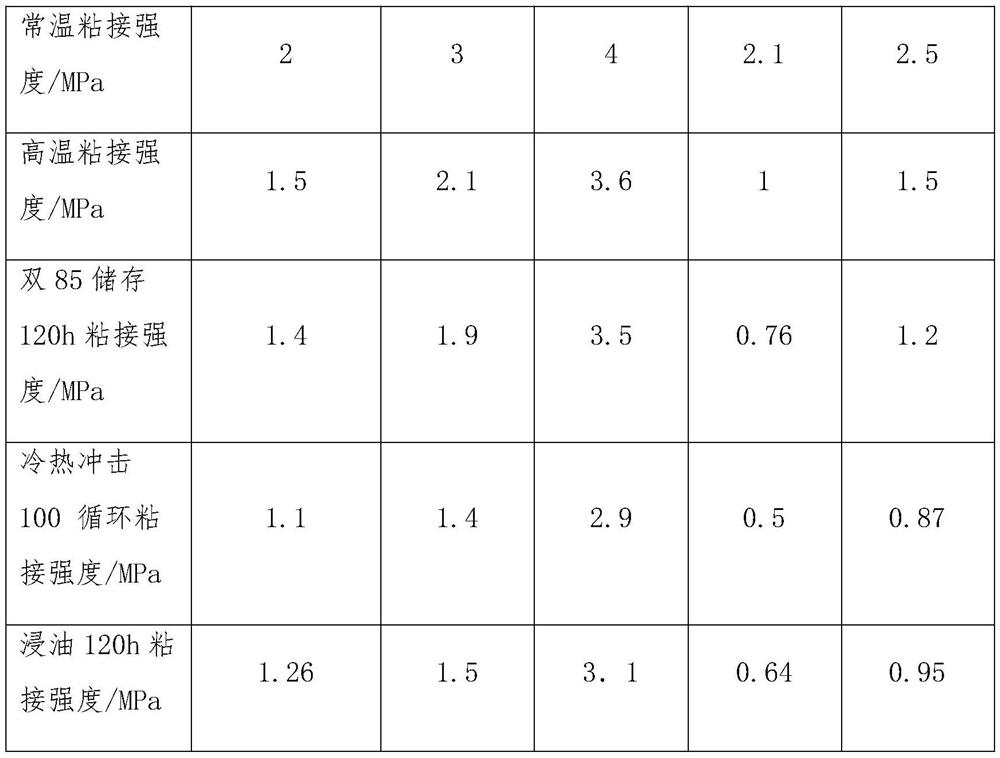

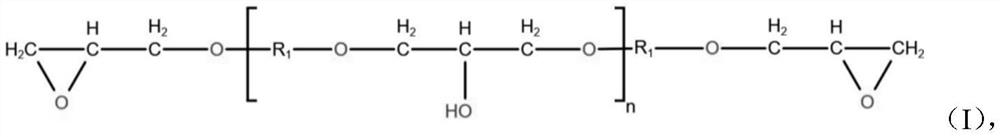

UV-cured silica gel for lead sealing

InactiveCN112724927AGood weather resistanceGood oil resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilica gelMethyl palmoxirate

The invention relates to the technical field of organic silicon photocuring new materials, and discloses UV curing silica gel for lead sealing, which is composed of the following components: 0 to 15 parts of a component A; 5 to 15 parts of a component B; 70 to 85 parts of a component C; 5 to 15 parts of a component D; 2.5 to 10 parts of a component E; 0.1 to 0.5 part of a component F; 0.2 to 1.0 part of a component G; and 10 to 25 parts of a component H; wherein the component A is methyl vinyl MDT type silicon resin, the component B is methyl vinyl MQ type silicon resin, the component C is high-viscosity (CH3)2(CH2=CH)SiO1 / 2 terminated linear structure polysiloxane, the component D is low-viscosity (CH3)2(CH2=CH)SiO1 / 2 terminated linear structure polysiloxane, the component E is terminal side hydrogen structure polysiloxane, the component F is a photoinitiator, the component G is an inhibitor, and the component H is magnetic powder. The magnetic powder is adopted to increase the bonding force between the lead and the metal surface, so that the silica gel still has higher bonding strength at high temperature, and the practicability of the optical adhesive is enhanced.

Owner:浙江中特化工有限公司

Process method for automobile bottom plate powder coating

InactiveCN107418386AEasy to operateImprove protectionPretreated surfacesAnti-corrosive paintsMelt extrusionElectric field

The invention discloses a process method for automobile bottom plate powder coating. The process method comprises the following steps: preparing raw materials, uniformly mixing the raw materials, performing melting extrusion by using a double-screw extruder, and finally crushing and grinding so as to obtain a powder coating; performing sand blasting roughening on an automobile bottom plate, performing ejection degreasing cleaning, performing hot water cleaning treatment, and performing drying treatment; preheating the pretreated automobile bottom plate, and performing powder coating operation on the surface of the preheated automobile bottom plate by using an electrostatic spray gun in an electric field environment; and performing high-temperature curing on the coated automobile bottom plate, cooling, performing quality inspection, and packaging after qualification, thereby obtaining a coated automobile bottom plate. The process method disclosed by the invention is simple to operate, mild in curing condition and short in curing time, and an obtained coating film has good properties of corrosion resistance, rusting resistance, collision prevention, noise prevention, wearing resistance, impact resistance and the like, is high in strength, good in dispersibility and good in adhesion property, plays a good protection role on an automobile bottom plate, is capable of effectively prolonging the service life of the automobile bottom plate, and is worthy of popularization.

Owner:ANHUI TIANYU AUTO PARTS MFG

Graphene conductive printing ink and method for preparing same

InactiveCN109749518AShort curing time at room temperatureImprove conductivityInksCompression moldingPrinting ink

The invention provides a graphene conductive printing ink composite material. The graphene conductive printing ink composite material mainly comprises, by ratio (according to the mass percents), 1-40wt% of graphene, 10-60wt% of resin-based bonding materials, 10-30wt% of auxiliaries and the like. Graphene conductive printing ink can be prepared according to an experiment method on a large scale. The graphene conductive printing ink composite material has the advantages that the conductive printing ink prepared by the aid of the experiment method is high in electric conductivity and good in toughness, compression molding performance and impact resistance; the shortcomings of environmental pollution and high cost of the traditional conductive printing ink can be overcome, and large-scale commercial production can be expected.

Owner:厦门泰启力飞科技有限公司 +1

High-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures and preparation method thereof

PendingCN114605948AImprove thermal stabilityHigh curing activityNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to the field of high polymer materials and preparation, and particularly discloses a high-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures and a preparation method of the high-temperature-resistant and high-strength epoxy adhesive capable of being cured at medium and low temperatures. The curing temperature of the adhesive is effectively reduced, and meanwhile, the high-temperature adhesive property of the adhesive is remarkably improved. And the viscosity of the adhesive is adjusted through the filler. The epoxy adhesive can be cured at medium and low temperature (not more than 110 DEG C), and the tensile-shear strength at 250 DEG C is not less than 6.5 MPa. The epoxy adhesive provided by the invention is simple in preparation method, mild in curing condition and suitable for construction operation in various occasions.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Dry-film lubricant and method of use thereof

The invention provides an environmental friendly dry-film lubricant and a use method thereof, which belongs to the technical field of lubricant preparation. The dry-film lubricant comprises a solid lubricant, a dispersing agent, an anti-wear additive, an antioxidant, a reaction promoter, and a film-coated resin monomer; counted in weight percentage, the components and weight ratio thereof are as follows: 10 to 60 percent of solid lubricant, 0.5 to 5 percent of dispersing agent, 2 to 10 percent of anti-wear additive, 1 to 3 percent of antioxidant, 0 to 0.5 percent of reaction promoter, as wellas 35 to 80 percent of film-coated resin monomer; the monomer of acrylic ester type is used to initiate copolymerization in situ to form a solid lubricant film. The dry-film lubricant does not contain organic volatiles, has a gentle preparation condition, and has a usage temperature range from -20 DEG C to 250 DEG C. The environmental friendly dry-film lubricant is suitable for the lubricating anti-wear coating on the parts of heat-sensitive base materials like plastics, alloys, and the like, in particular, and is suitable for the lubricating anti-wear coatings of running-in and high / low temperature sliding parts without oil lubrication and spare parts, as well as of microseism wear parts.

Owner:泰州市嘉鼎新材料有限公司

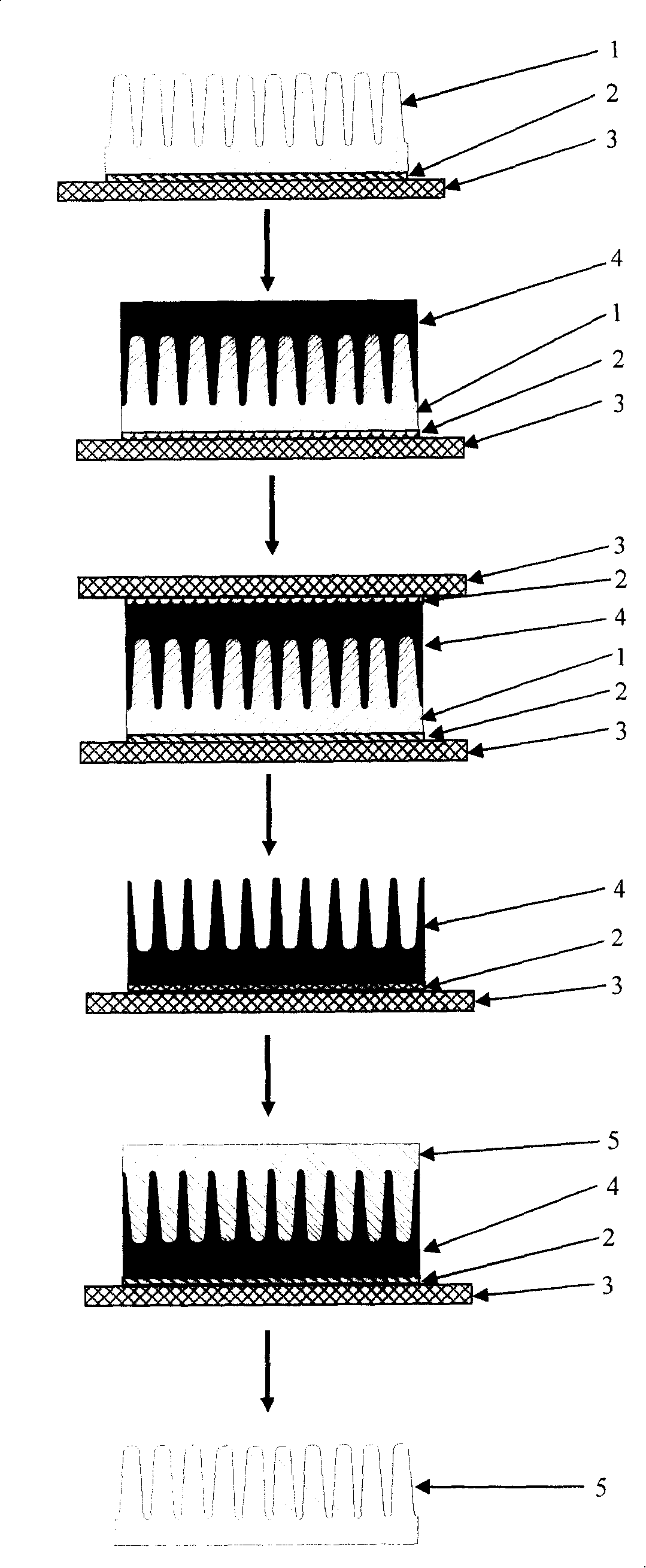

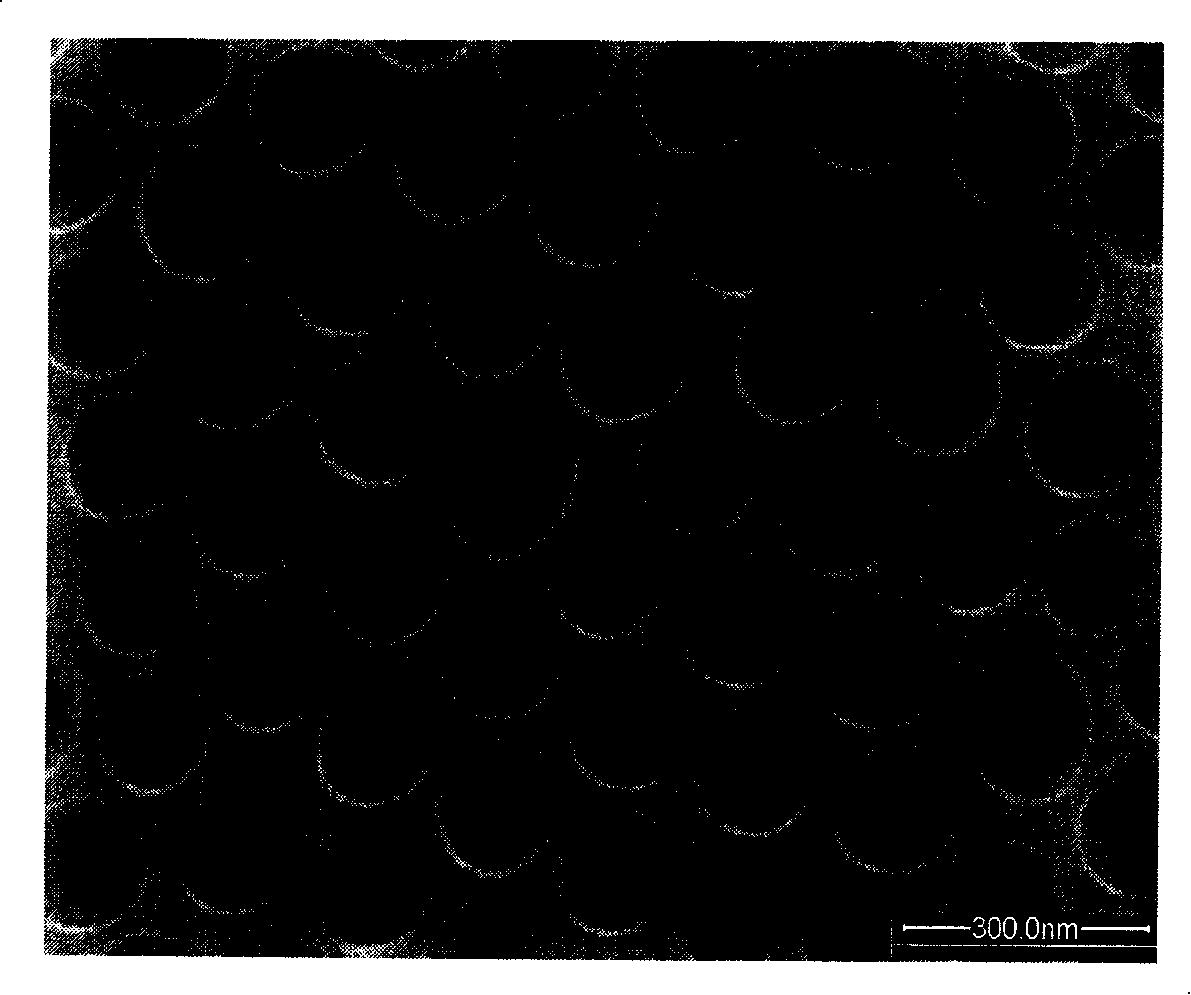

Biological template method for preparing antireflection film

InactiveCN100380139CExact copySimple processIndividual molecule manipulationCoatingsNanostructureNanometre

A biological template method for preparing anti¿Creflection film includes plating template with biological nanostructure of metal by means of vacuum¿Cvaporization plating to obtain negative structure corresponding to biological template on metal film, using metal negative structure as template to cast organic polymer to obtain organic polymer film having identical nanostructure to biological template on film surface after solidification.

Owner:PEKING UNIV

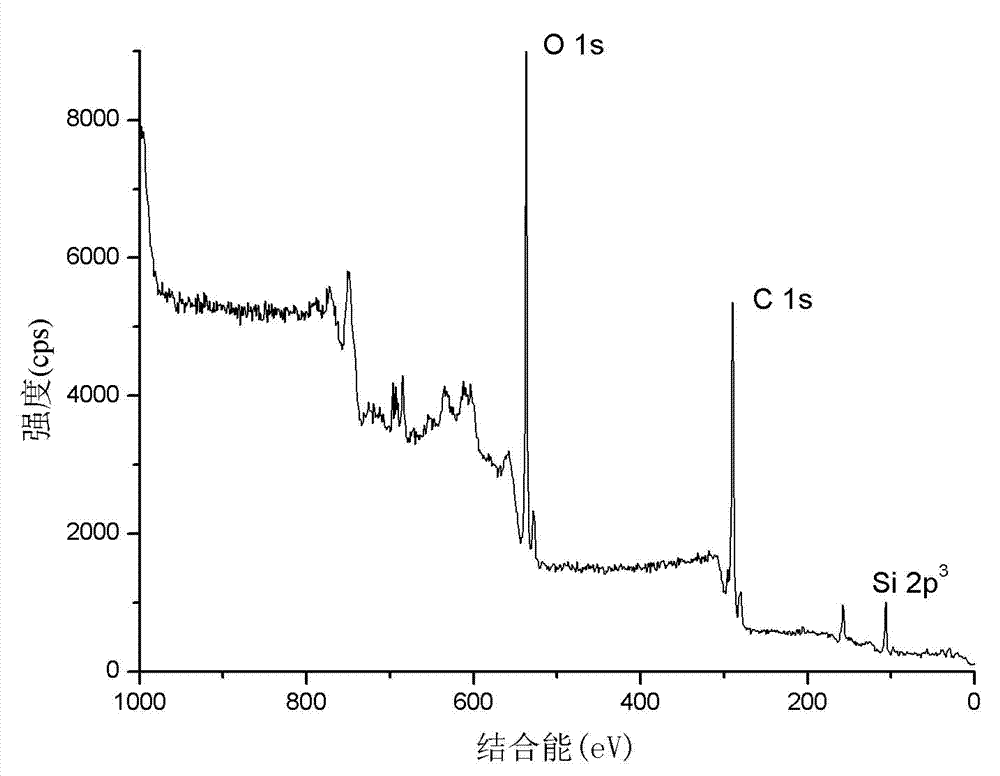

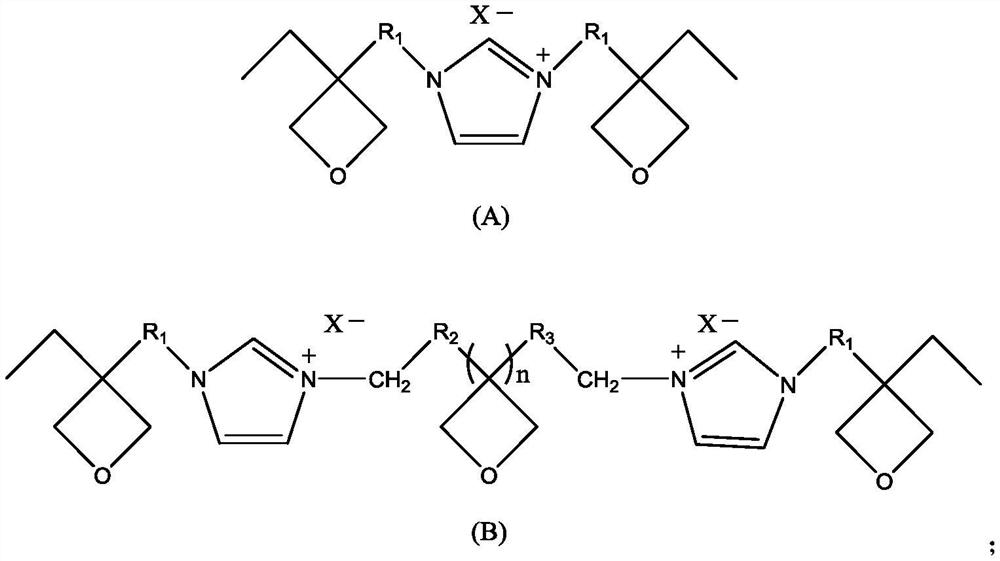

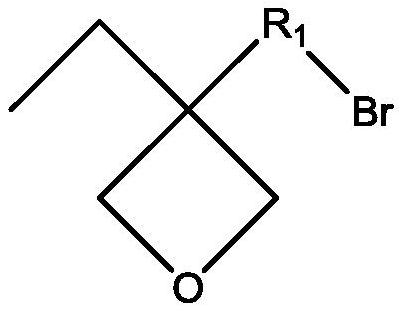

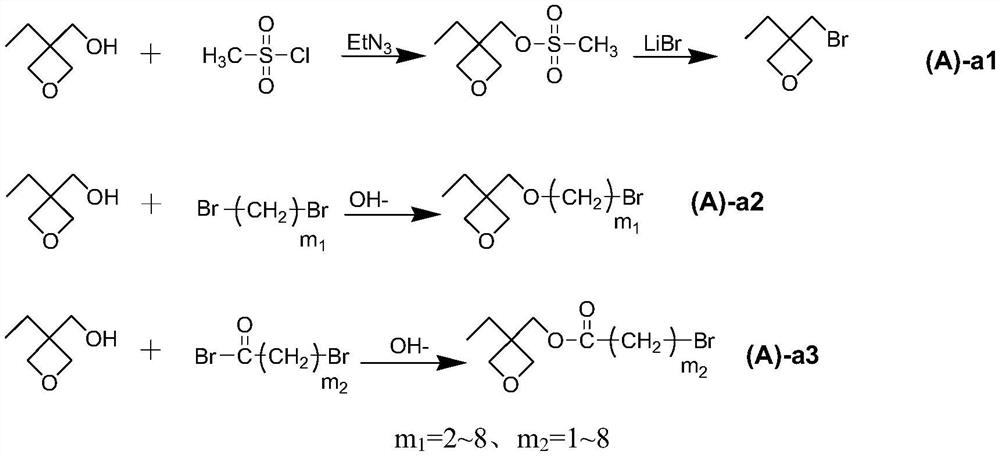

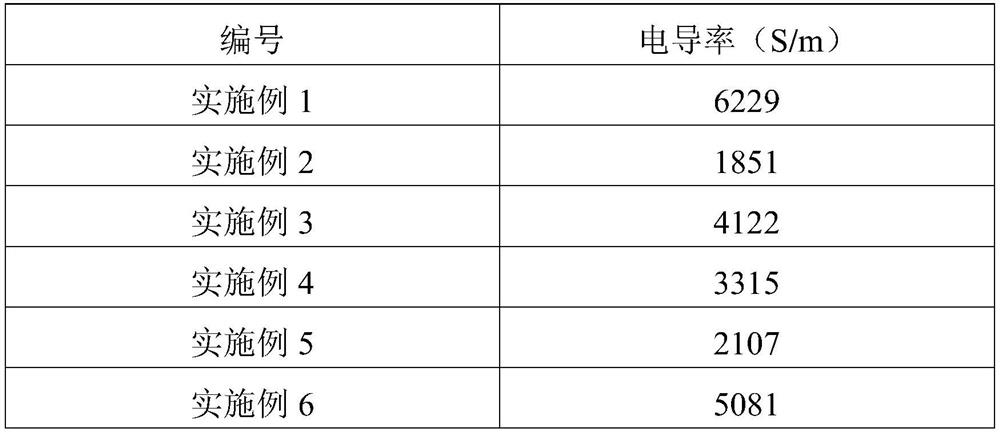

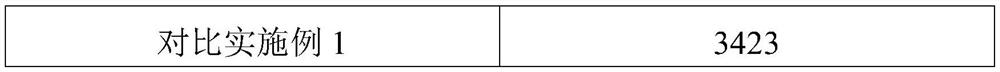

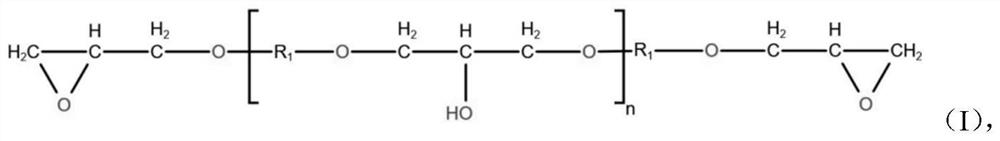

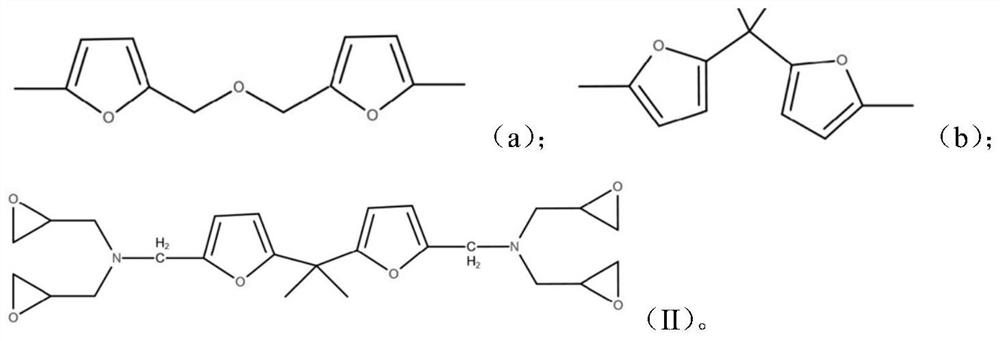

Ionic liquid containing cationic polymerizable group as well as preparation method and application of ionic liquid

ActiveCN114380809AImprove conductivityMild curing conditionsOrganic chemistryElectrically-conductive paintsCationic polymerizationConductive coating

The invention relates to a cationic polymerizable group-containing ionic liquid as well as a preparation method and application thereof. The ionic liquid with the cationic polymerizable group can be a mononuclear cation system or a binuclear cation system, and the cation is an alkyl imidazole cation with the cationic polymerizable group. According to the functional ionic liquid containing cationic polymerization provided by the invention, the ionic liquid is used as an active monomer of light-cured resin, and contains a large number of transferable free ions during curing in a coating, so that the ionic liquid has relatively high ionic conductivity, and the application potential of the ionic liquid in an antistatic or conductive coating is shown.

Owner:TONGJI UNIV

Preparation method of resistive screen hardening liquid

The invention belongs to the field of electronic products, and particularly relates to a preparation method of resistive screen hardening liquid. The method particularly comprises the following steps: mixing a silane coupling agent and glycidyl ether according to a certain ratio, performing hydrolysis by a proper amount of mixed liquid of deionized water, alcohols and acetylacetone for 15-24 hours; mixing the hydrolyzed product with a solvent according to a ratio of 2:3, adding a proper amount of a levelling agent and an antifoaming agent to obtain the mobile phone screen hardening liquid. An outer screen of a resistive screen (a PET film) is soaked with a 0.1 mol / L sodium hydroxide solution for 5 min, and is cleaned; then the film surface is uniformly coated with the hardening liquid by methods of dip-coating or roller coating, dried and cured at 70 DEG C for 30 min to obtain a hardened resistive outer screen with a pencil hardness of up to 6H. The preparation method of the invention has the characteristics of simple process and low cost, can enhance the surface hardness of resistive screens, improve scraping resistance, and prolong the service life of resistive screens.

Owner:FUDAN UNIV

Novel process for utilizing catalytic cracked heavy oil and condensed multinuclear anime prepared with same

Owner:CHINA PETROLEUM & CHEM CORP

A kind of cnt:snc:pedot ternary water-based conductive ink and preparation method thereof

ActiveCN112341865BBroaden research directionImprove resource utilizationInksCarbon nanotubeFlexible electronics

Owner:SOUTH CHINA UNIV OF TECH

A kind of anti-corrosion paint resistant to high temperature wear and its preparation method and application

ActiveCN113248959BGood dispersionCompact appearanceFireproof paintsLiquid surface applicatorsEpoxyFuran

The invention provides a high-temperature wear-resistant anti-corrosion coating and a preparation method and application thereof. A combination of furan-modified epoxy resins with a specific structure is selected as a film-forming substance, and the high-temperature and corrosion-resistant properties of epoxy resin and furan resin are used. performance, and the selection of functionalized graphene as the thermal conductivity and anti-corrosion components, and the selection of epoxy polyether-polysiloxane as the dispersing functional component, the good dispersion of graphene, fillers and other components is achieved, and the prepared A coating with good appearance and compactness, the coating has excellent high temperature resistance, wear resistance, corrosion resistance and other properties, which can be applied to the high temperature anti-corrosion requirements of the four-tube surface of the boiler. At the same time, the process is simple, the operation is simple, and the curing conditions are mild , the time required for complete curing is shorter, the energy consumption ratio of the curing process is reduced, and the degree of greenness of the process is high.

Owner:深圳优易材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com