Carbon dot-organic silicon composite fluorescent material as well as preparation method and application thereof

A composite fluorescent and organic silicon technology, which is applied in the direction of luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve the problems of hindering application, disappearing, and decreasing fluorescence intensity, and achieve good compatibility, mild curing conditions, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

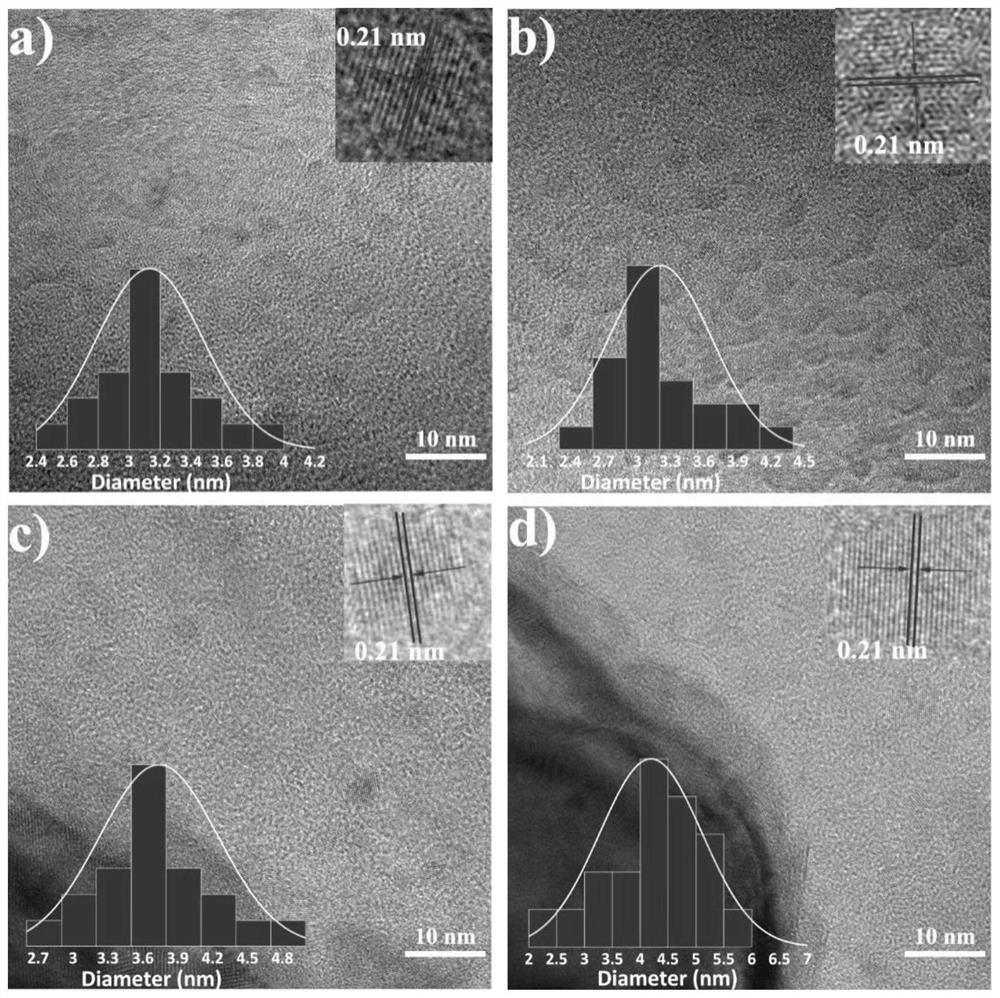

[0055] A method for preparing a carbon dot-organosilicon composite fluorescent material in this embodiment, the method specifically includes the following steps:

[0056] 0.52g of citric acid and 3.78mL of 3-aminopropyltriethoxysilane (Aladdin Reagent Company, CAS No.: 919-30-2, density: 0.95g / cm 3 ) was dissolved in a mixed solvent consisting of 10 mL of deionized water and 20 mL of anhydrous ethanol. The obtained mixed reaction solution was transferred to a Teflon-lined stainless steel autoclave, and placed in a blast drying oven at 200° C. for 12 hours. After the reaction product was centrifuged to separate the solid and the liquid, the solid was washed three times with deionized water and anhydrous ethanol, and dried in an oven at 50° C. overnight to obtain a white powder.

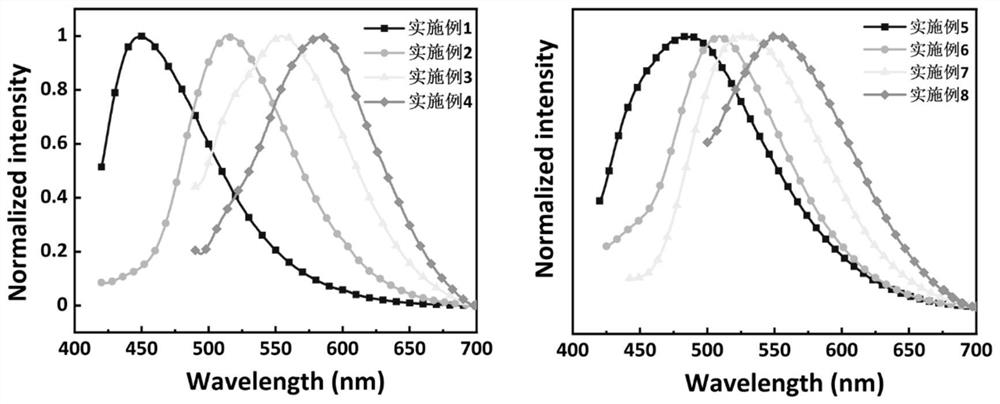

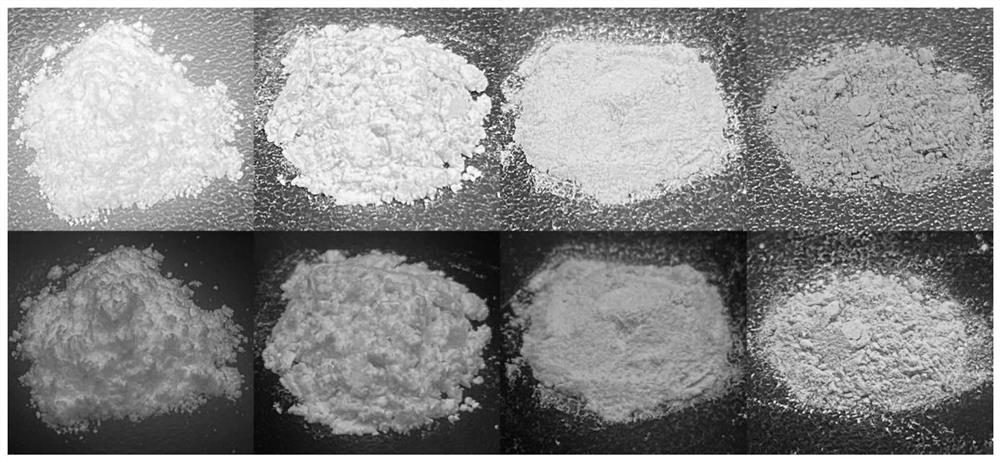

[0057] Depend on figure 1 It can be seen that the carbon dots-organosilicon composite fluorescent material prepared in this example emits blue light under a 365 nm ultraviolet lamp.

Embodiment 2

[0059] A method for preparing a carbon dot-organosilicon composite fluorescent material in this embodiment, the method specifically includes the following steps:

[0060] 0.52g of citric acid, 2.6g of urea and 3.78mL of 3-aminopropyltriethoxysilane (Aladdin Reagent Company, CAS No.: 919-30-2, density: 0.95g / cm 3 ) was dissolved in a mixed solvent consisting of 10 mL of deionized water and 20 mL of anhydrous ethanol. The obtained mixed reaction solution was transferred to a Teflon-lined stainless steel autoclave, and placed in a blast drying oven at 200° C. for 12 hours. After the reaction product was centrifuged to separate the solid and the liquid, the solid was washed three times with deionized water and absolute ethanol, respectively, and dried in an oven at 50° C. overnight to obtain a pale yellow powder.

[0061] Depend on figure 1 It can be seen that the carbon dots-organosilicon composite fluorescent material prepared in this example emits green light under a 365 nm u...

Embodiment 3

[0063] A method for preparing a carbon dot-organosilicon composite fluorescent material in this embodiment, the method specifically includes the following steps:

[0064] 0.52g of citric acid, 5.2g of urea and 3.78mL of 3-aminopropyltriethoxysilane (Aladdin Reagent Company, CAS No.: 919-30-2, density: 0.95g / cm 3 ) was dissolved in a mixed solvent consisting of 10 mL of deionized water and 20 mL of anhydrous ethanol. The obtained mixed reaction solution was transferred to a Teflon-lined stainless steel autoclave, and placed in a blast drying oven at 200° C. for 12 hours. After the reaction product was centrifuged to separate the solid and the liquid, the solid was washed three times with deionized water and absolute ethanol, and dried in an oven at 50° C. overnight to obtain a yellow powder.

[0065] Depend on figure 1 It can be seen that the carbon dots-organosilicon composite fluorescent material prepared in this example emits yellow light under a 365 nm ultraviolet lamp. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com