Silicon tetrachloride hydrogenation method

A technology of silicon tetrachloride and hydrogen chloride gas, applied in the direction of halogenated silicon compounds, halogenated silanes, etc., to achieve the effect of improving yield and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

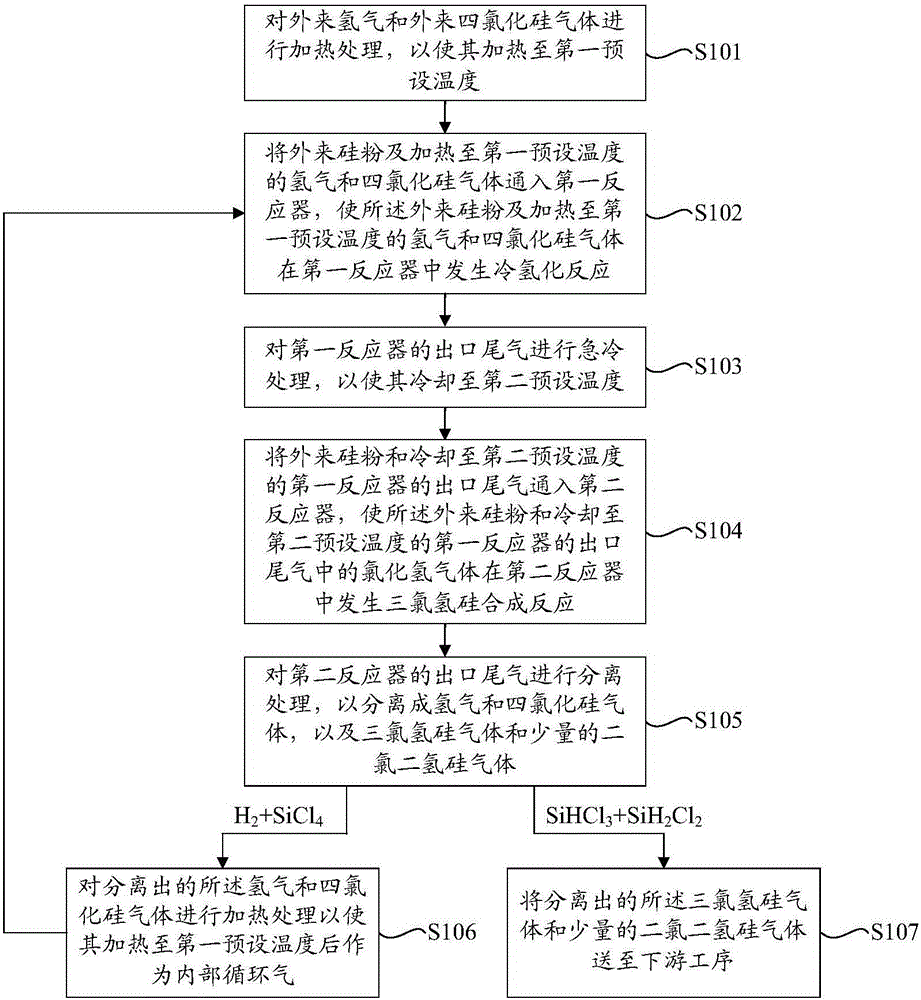

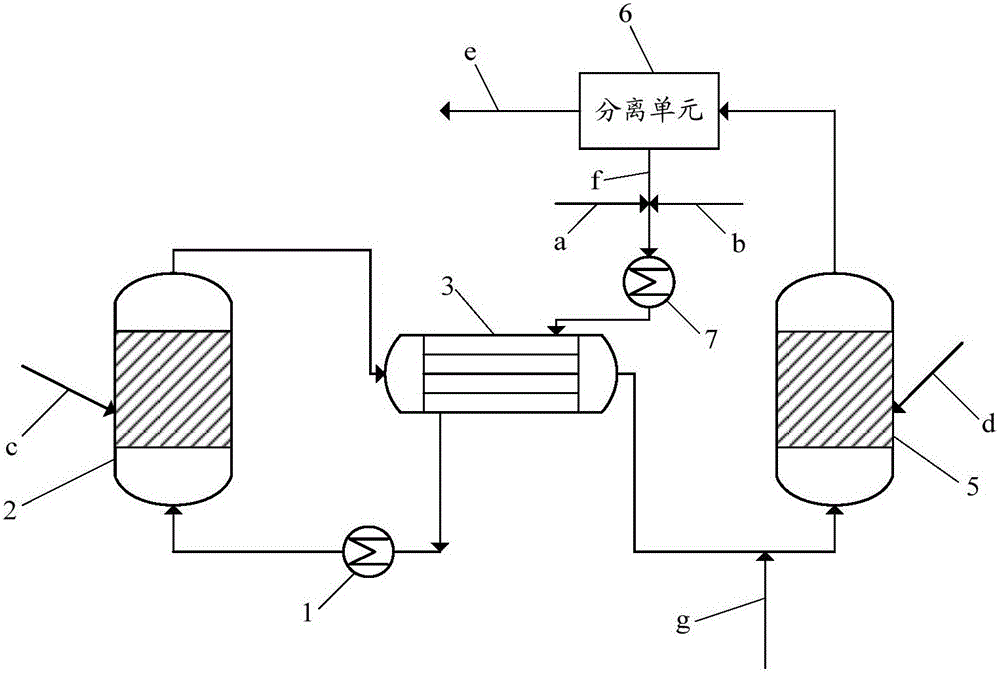

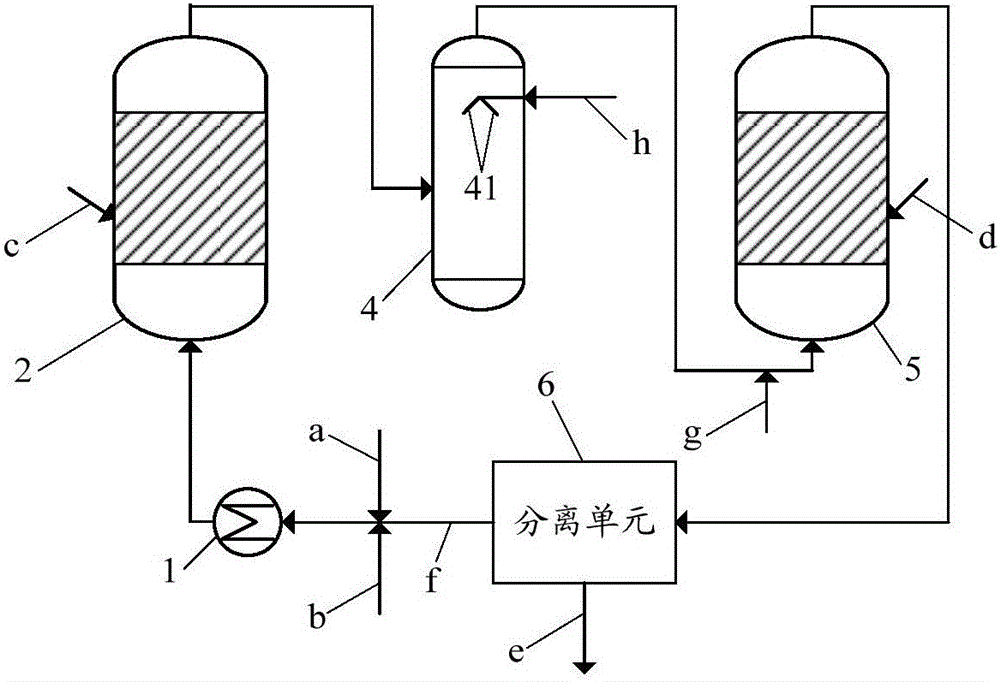

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] The inventor finds by contrasting laboratory research situation and actual production situation, the reason that the actual conversion rate of silicon tetrachloride is lower than laboratory conversion rate and theoretical conversion rate except reaction space time (being reaction time, equal to space velocity in the cold hydrogenation reaction) The reciprocal of ) is not enough to reach chemical equilibrium, and it is also related to the decomposition of trichlorosilane in the tail gas produced by the cold hydrogenation reaction. Specifically, in the cold hydrogenation reactor, due to the rapid reaction of silicon powder and hydrogen chloride, the first step of the cold hydrogenation reaction will be constantly pushed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com