Adhesive filler for splicing light porous composite material and preparation method of adhesive filler

A technology of porous composite materials and fillers, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor ablation resistance and erosion resistance that cannot meet the needs of aerospace vehicles, and achieve good chemical properties. And physical compatibility, excellent bonding performance, excellent anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] According to a second aspect of the present invention, a method for preparing an adhesive filler for splicing lightweight porous composite materials is provided, comprising the steps of:

[0047] (1) Weigh 100 parts by mass of hydroxyl-terminated polysiloxane and put it into a mixing container;

[0048] (2) Weigh 0 to 30 parts by mass of white carbon black, 10 to 40 parts by mass of chopped fibers, 10 to 50 parts by mass of hollow spheres, 5 to 15 parts by mass of antioxidant fillers and 0 to 30 parts by mass of Put the diluent in the mixing container in step (1), and carry out physical stirring and mixing at room temperature with a planetary strong agitator for 5 to 30 minutes, and the stirring speed is 800 to 1200r / min;

[0049] (3) Weigh 3 to 10 parts by mass of crosslinking agent and 0.5 to 2 parts by mass of catalyst, add them to the mixed material in step (2), and continue to stir for 3 to 8 minutes. stitching.

[0050] In the present invention, the adhesive fil...

Embodiment 1

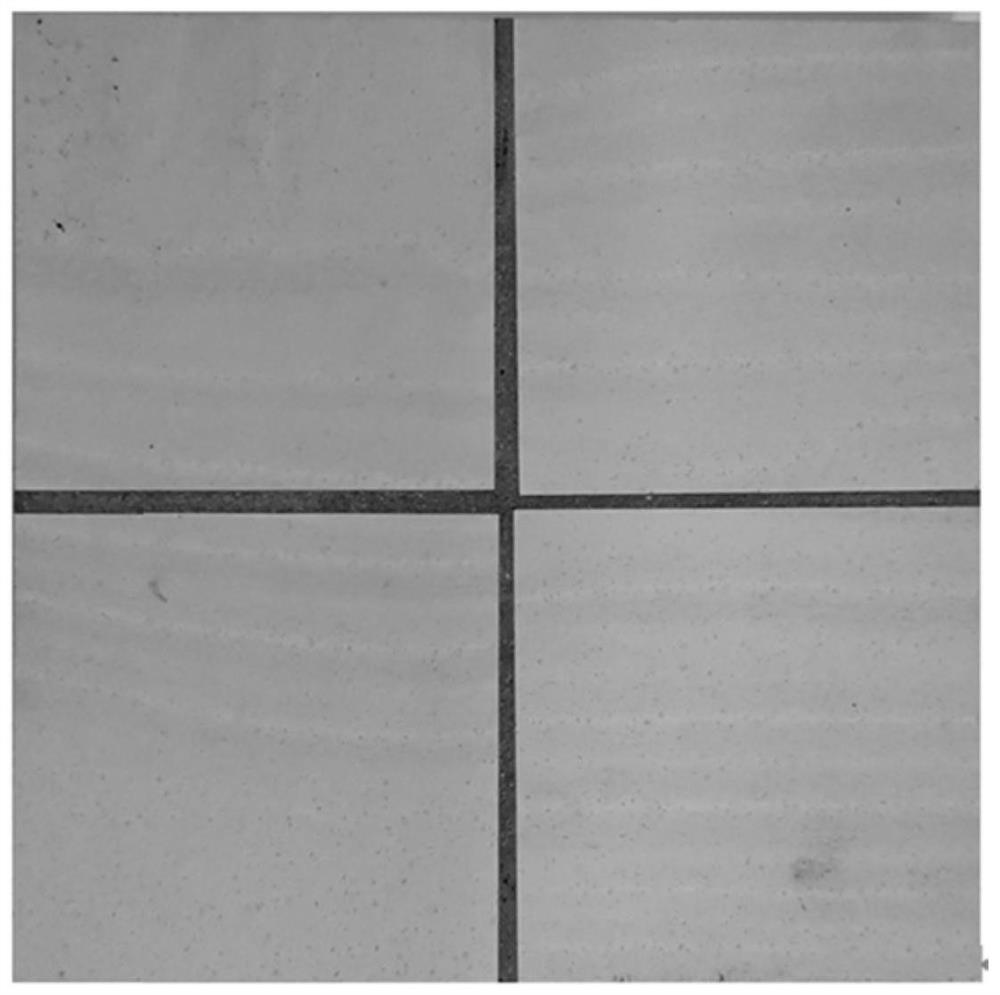

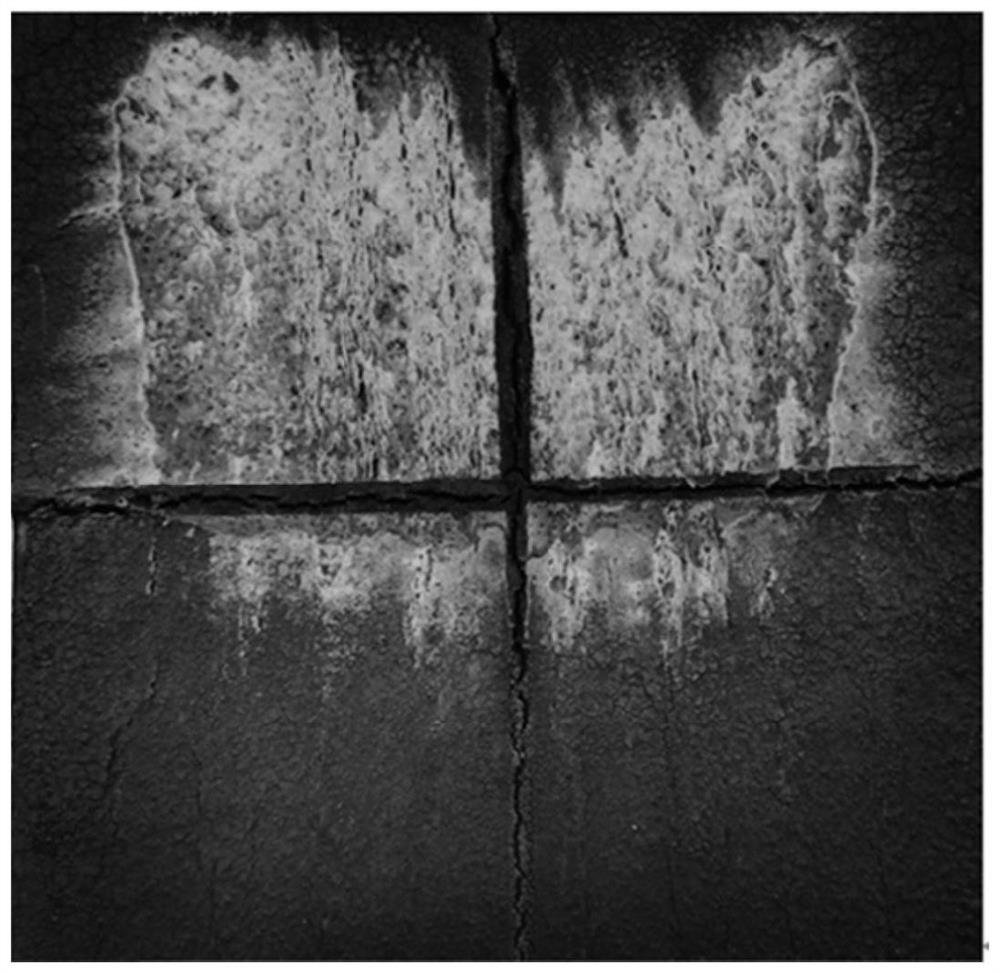

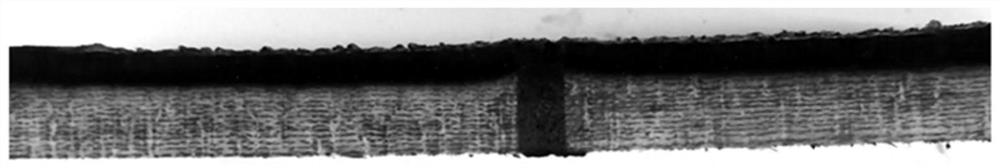

[0055] Weigh 100 g of hydroxyl-terminated polymethylphenylsiloxane (brand: 108 silicone rubber), put it into a 500 ml plastic beaker, weigh 15 g of white carbon black, 20 g of chopped quartz fibers with a length of 1 mm, and 10 g of phenolic pellets ( The average particle size is 50 μm) and 15 g of zirconium silicide (median particle size D50 is 7 μm), put into 108 silicone rubber, mix and stir with a planetary mixer for 10 minutes, and the speed is controlled at about 800 r / min. After the stirring is completed, add 1 g of dibutyltin dilaurate and 10 g of tetraethyl orthosilicate, and continue stirring for 3 minutes. Apply the mixed adhesive filler to four 100×100mm lightweight silicon hybrid phenolic-impregnated quartz fiber composites (DMS6, density 0.55g / cm3) with a syringe gun or manually. 3 , porosity 70%), spliced into a 200mm × 200mm composite splicing board, after curing at room temperature for 72 hours, as figure 1 shown. The average density of the adhesive filler...

Embodiment 2

[0057] Weigh 100g of hydroxyl-terminated polymethylsiloxane (grade: 107 silicone rubber), put it into a 500ml plastic beaker, weigh 15g of white carbon black, 30g of chopped quartz fibers with a length of 3mm, and 15g of phenolic pellets (average particle size 50 μm in diameter), 5 g of zirconium silicide (median particle size D50 is 7 μm), 15 g of ethanol diluent, put into 107 silicone rubber, mix and stir for 10 min with a planetary mixer, and control the speed at about 800 r / min. After stirring, add the POSS coupling agent of the dibutyltin dilaurate of 1g and 8g, molecular formula is ((CH 3 O) 3 SiC 3 h 6 S-C 2 h 4 -SiO 1.5 ) 8 , continue stirring for 5min. Apply the mixed adhesive filler to the gaps of four 100mm×100mm lightweight silicon hybrid phenolic-impregnated quartz fiber composites (DMS6) with a syringe gun or manually, and splice them into a 200mm×200mm composite splicing board , Cured at room temperature for 50 hours. The average density of the adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com