Patents

Literature

51results about How to "Meet repair needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

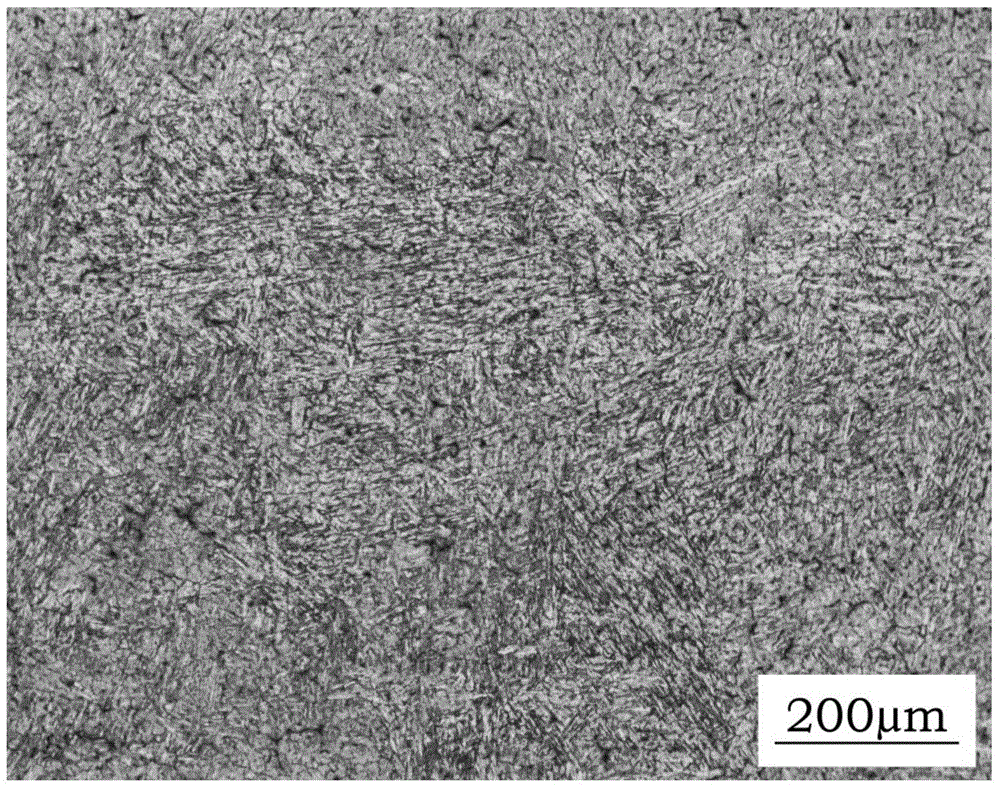

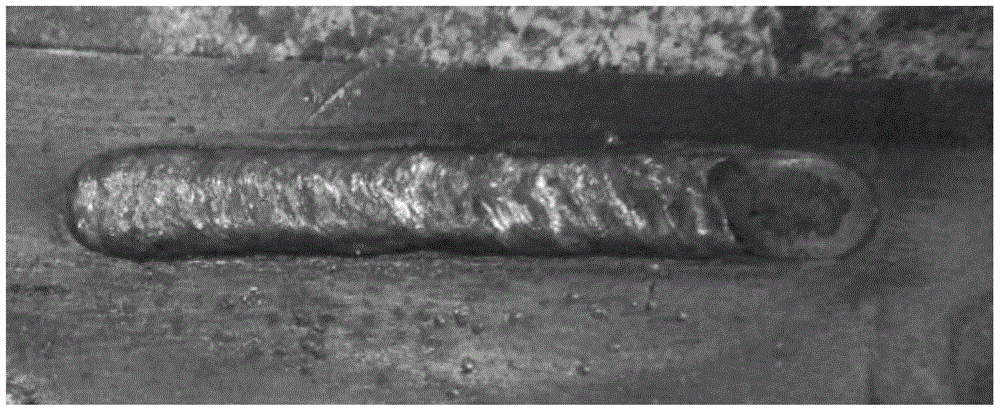

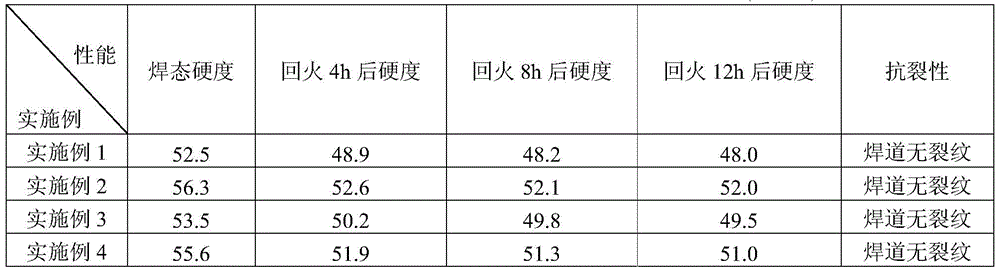

Surfacing flux-cored wire used for repairing hot-forging die

InactiveCN103862194AImprove crack resistanceNo crackArc welding apparatusWelding/cutting media/materialsCrack resistanceElectrolysis

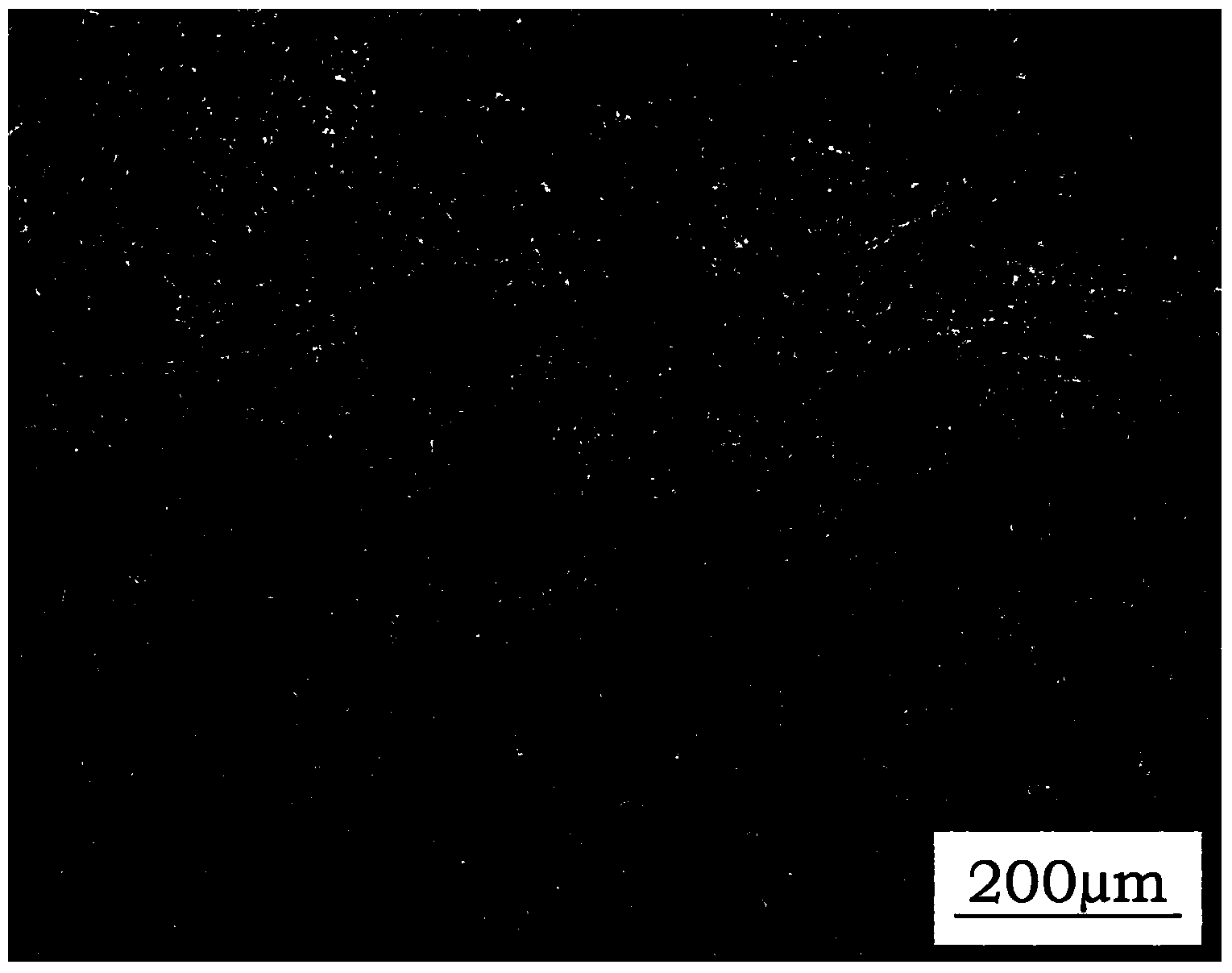

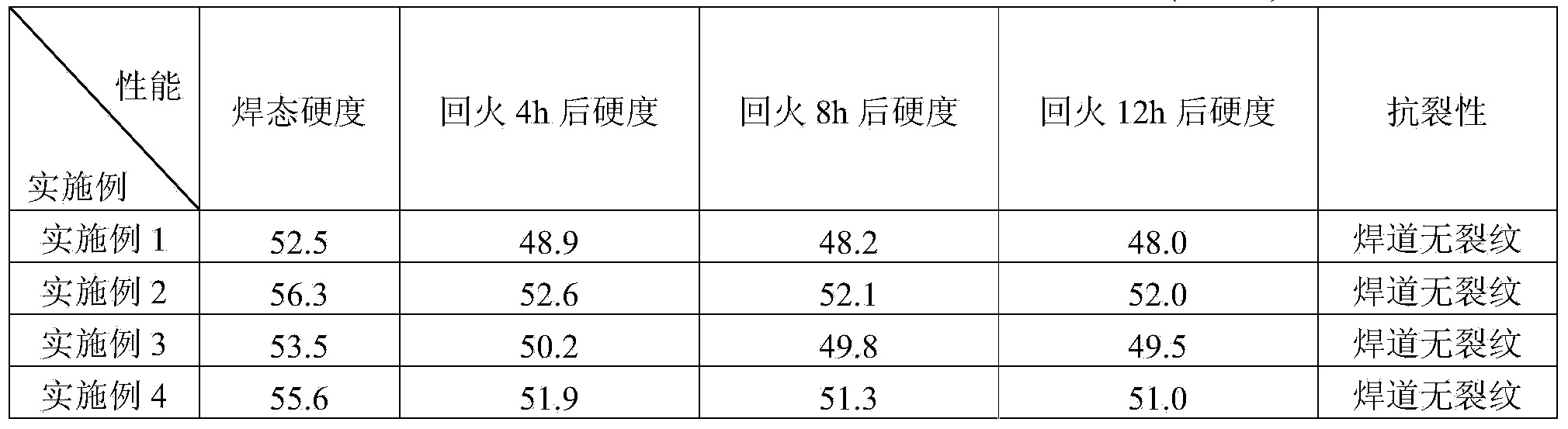

The invention discloses a surfacing flux-cored wire used for repairing a hot-forging die and belongs to the technical field of welding materials. Flux-cored powder is wrapped by adopting a carbon steel belt, and comprises the following substances in mass percentage content: 2-6 percent of sodium fluoride, 5-8 percent of calcium fluoride, 3-5.5 percent of rutile, 1-5 percent of quartz, 4.3-13.2 percent of high-carbon ferrochrome, 24.8-38.3 percent of pure chromium powder, 6-11.3 percent of nickel powder, 1.5-3.5 percent of Fe-W powder, 2.5-5.1 percent of electrolytic manganese, 14.7-27.3 percent of Fe-Mo powder, 3.6-6.1 percent of ferrosilicon powder, 0.2-1.4 percent of ferrovanadium powder and the balance of reduced iron powder. The filling rate of the flux-cored wire is 20-35 percent. Compared with traditional materials, the surfacing flux-cored wire disclosed by the invention has the advantages that (1) the thermal stability and the thermal fatigue resistance are very good, and the hardness range is 48-52HRC; (2) surfacing metal is high in crack resistance, so that preheating before welding or immediate heat treatment after welding is not needed; (3) the surfacing manufacturability is good, and the appearance of a weld is attractive.

Owner:BEIJING UNIV OF TECH

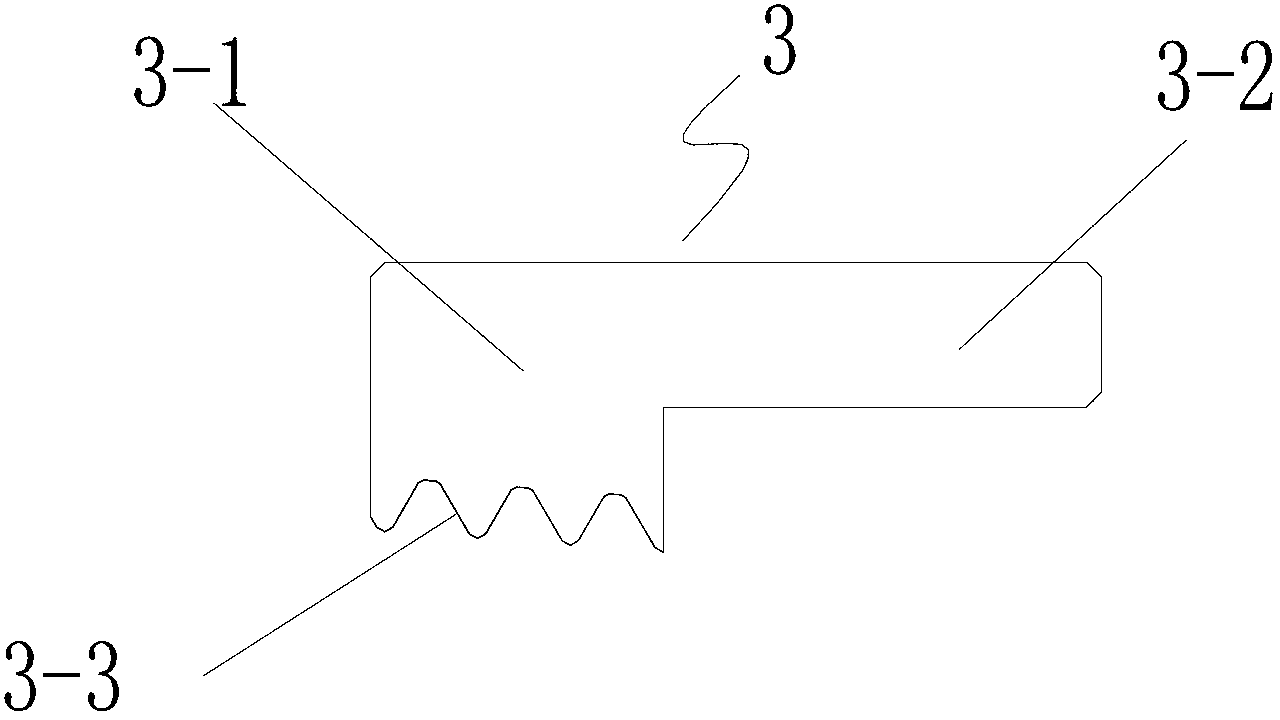

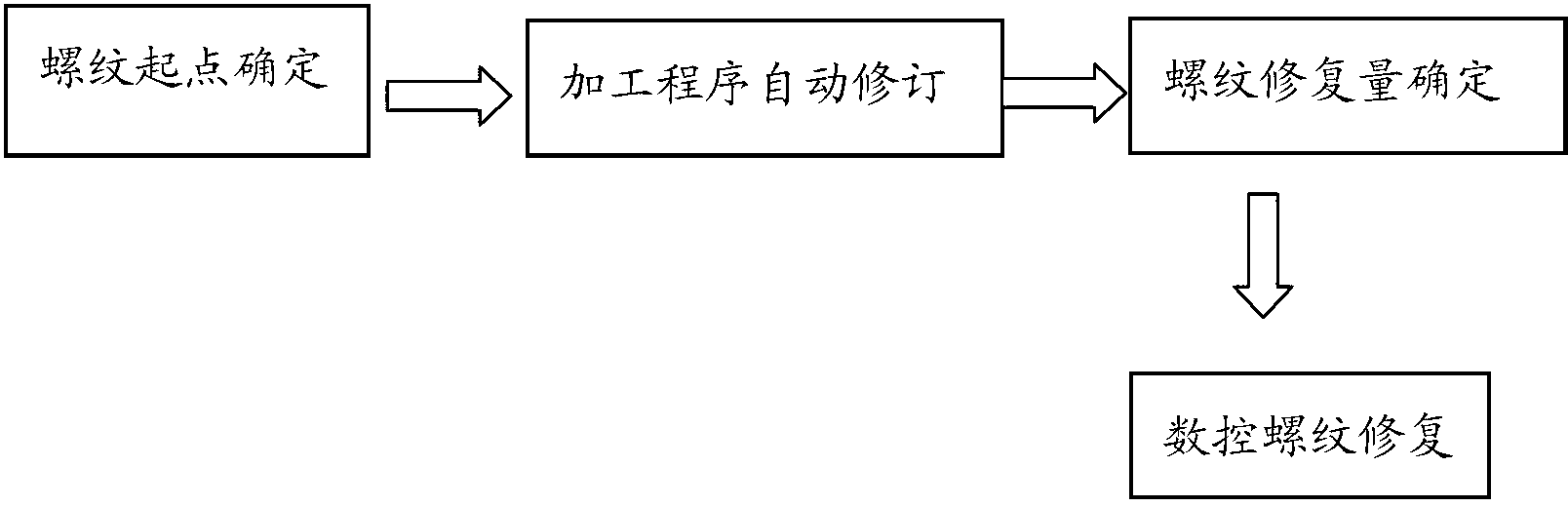

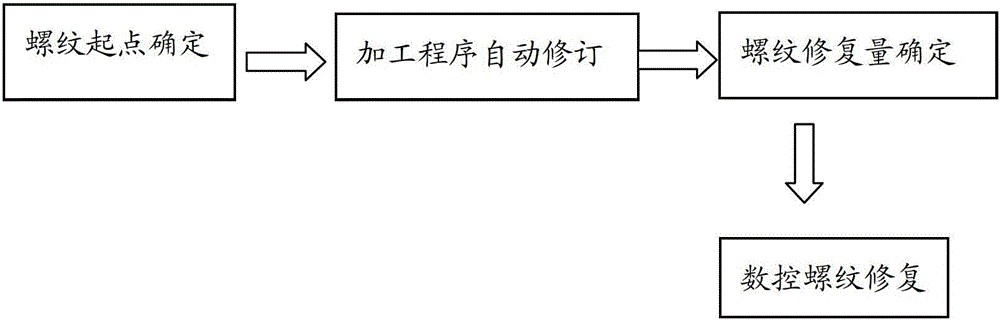

Repairing method of threads of oil drill pipe

ActiveCN103231200AImprove processing efficiencyMaster quicklyAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention relates to a repairing method of the threads of an oil drill pipe. The method comprises determining a thread start, carrying out automatic repair according to the thread start through a thread processing program, revising the thread repairing amount; and numerically controlling the thread repairing. Particularly, the method comprises the following steps: mounting a drill pipe joint to be repaired on a numerical control machine tool, utilizing a thread start searcher to determine the thread start Z1; inputting the thread start Z1 into a parameter #500, and the machine tool programs a special processing macroprogram to automatically compute out the start position of the threads; and setting a repairing amount #502 according to the actual damage amount of the drill pipe. By setting the parameters above, a thread cutter can be guaranteed to perform the repairing processing along the track of the original threads. Compared with a traditional thread repairing method, the repairing method of the threads of the oil drill pipe has the advantage that only a simple thread start searcher is required. An operator of an ordinary technical level can master the operation of the method within a short time. And due to the utilization of the numerical control machine tool, the processing efficiency is high, the quality is stable and no positioning is needed.

Owner:TIANJIN DEHUA GASOLINEEUM EQUIP MFG

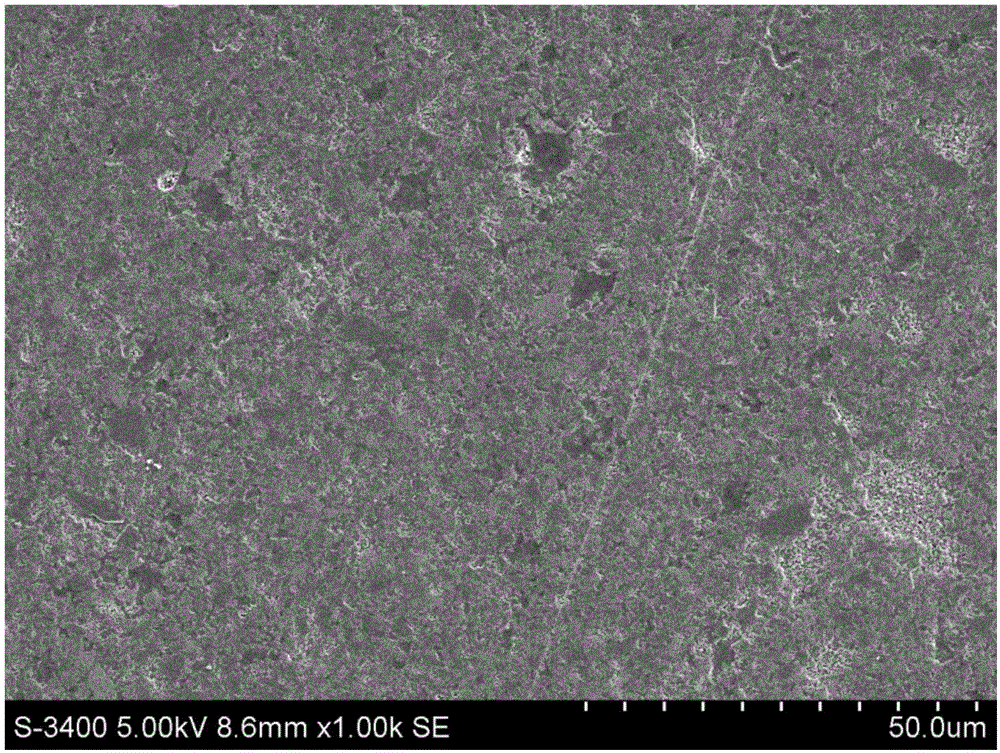

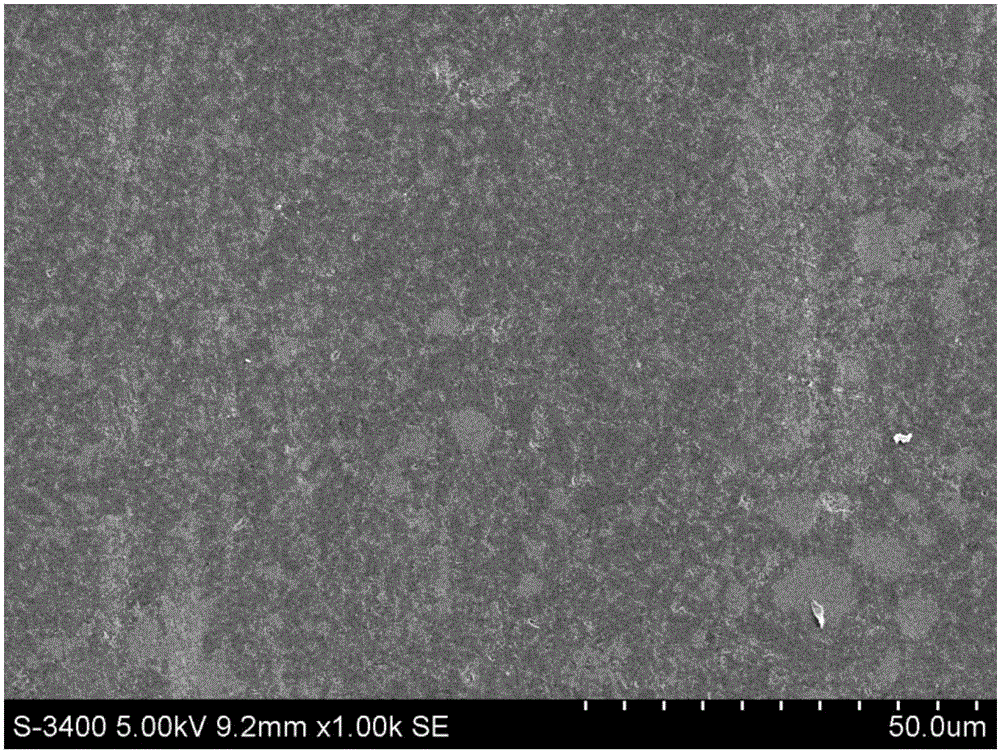

Composite ceramic material, and preparation method and application thereof

ActiveCN106830928AImprove corrosion resistanceReliable workmanshipImpression capsDentistry preparationsCompression moldingComposite ceramic

The invention relates to a composite ceramic material, and a preparation method and application thereof. Specifically, the invention relates to a method for preparing the composite ceramic material. The method comprises the following steps of compression molding, high-temperature sintering, surface treatment, osmotic treatment and resin recombination. The invention also relates to the composite ceramic material prepared by the method and the application of the composite ceramic material in preparing a repairing material for tooth bodies or other hard tissues. The method disclosed by the invention has the advantages that the technology is simple, the operation is easy, and the like; the composite ceramic material prepared by the method has the advantages that the strength is high, the machinability is good, the elastic modulus and the hardness are similar to the tooth bodies, and the like, and is particularly suitable for being used as a repairing material of the tooth bodies, for example, the composite ceramic material can be used for preparing a dental crown, a veneer, an inlay and an onlay and can also be used for repairing other hard tissues.

Owner:哈工宁伯医疗科技泰州有限公司

Torpedo ladle lining repair gunning mix

The invention relates to a torpedo ladle lining repair gunning mix, belonging to the technical field of torpedo ladles for transporting molten iron. The torpedo ladle lining repair gunning mix comprises the following components in percentage by weight: 45-60% of brown fused alumina particle, 10-20% of silicon carbide particle, 1-5% of kyanite powder, 1-5% of Gangxi earth, 1-10% of active alpha-Al2O3 powder, 1-7% of silicon micropowder, 1-5% of metallic silicon powder, 0-5% of ball pitch, 0-5% of amorphous graphite and 2-10% of pure calcium aluminate cement. The raw materials are weighed according to the particle sizes and proportions and uniformly mixed in a mixer. The torpedo ladle lining repair gunning mix has favorable refractoriness, oxidation resistance and slag iron permeation and corrosion resistance at the torpedo ladle service temperature of 1400-1530 DEG C.

Owner:SHOUGANG CORPORATION

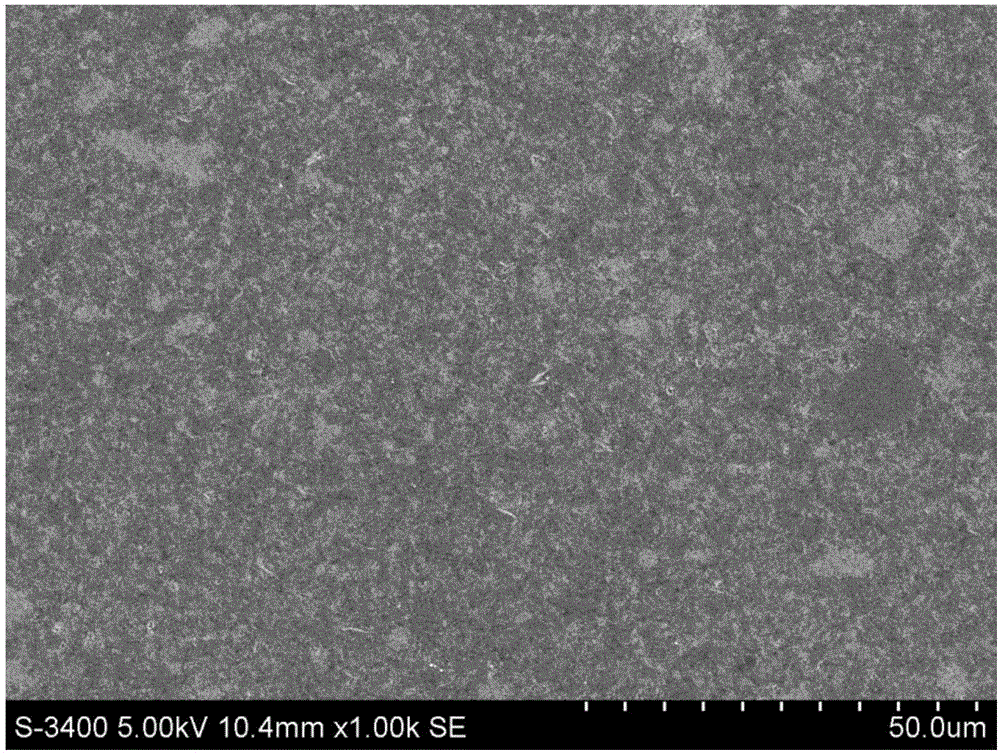

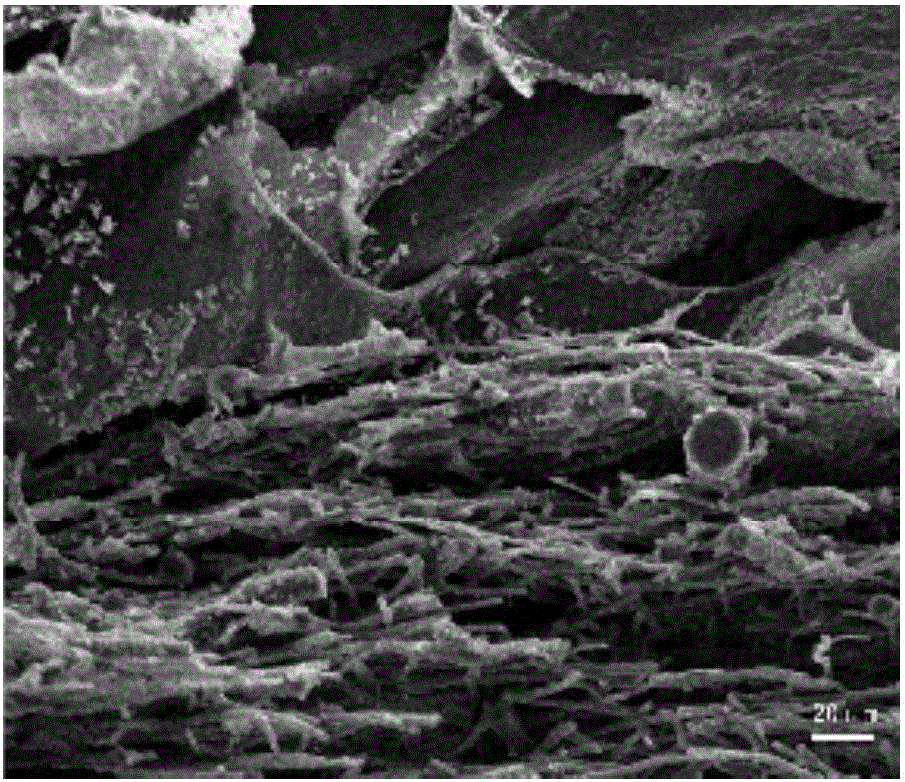

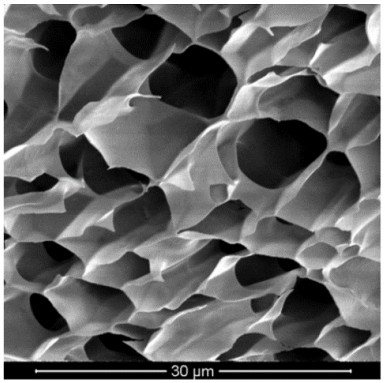

Bionic tissue based on acellular matrix-cell-three-dimensional fiber network and preparation method of bionic tissue

ActiveCN105944143AGood biocompatibilityPromote degradationProsthesisAcellular matrixNetwork structure

The invention relates to bionic tissue based on an acellular matrix-cell-three-dimensional fiber network and a preparation method of the bionic tissue. The bionic tissue based on the acellular matrix-cell-three-dimensional fiber network at least comprises composite acellular matrix hydrogel and epithelial cells. The composite acellular matrix hydrogel adopts a three-dimensional fiber network material good in biocompatibility as a framework. The three-dimensional fiber network material good in biocompatibility is a network structure material formed by winding fibers good in biocompatibility. The bionic tissue based on the acellular matrix-cell-three-dimensional fiber network can carry out simulation according to the tissue and organ structures, has good application prospects in tissue engineering, and can be widely applied to the field of biomedicine.

Owner:DONGHUA UNIV

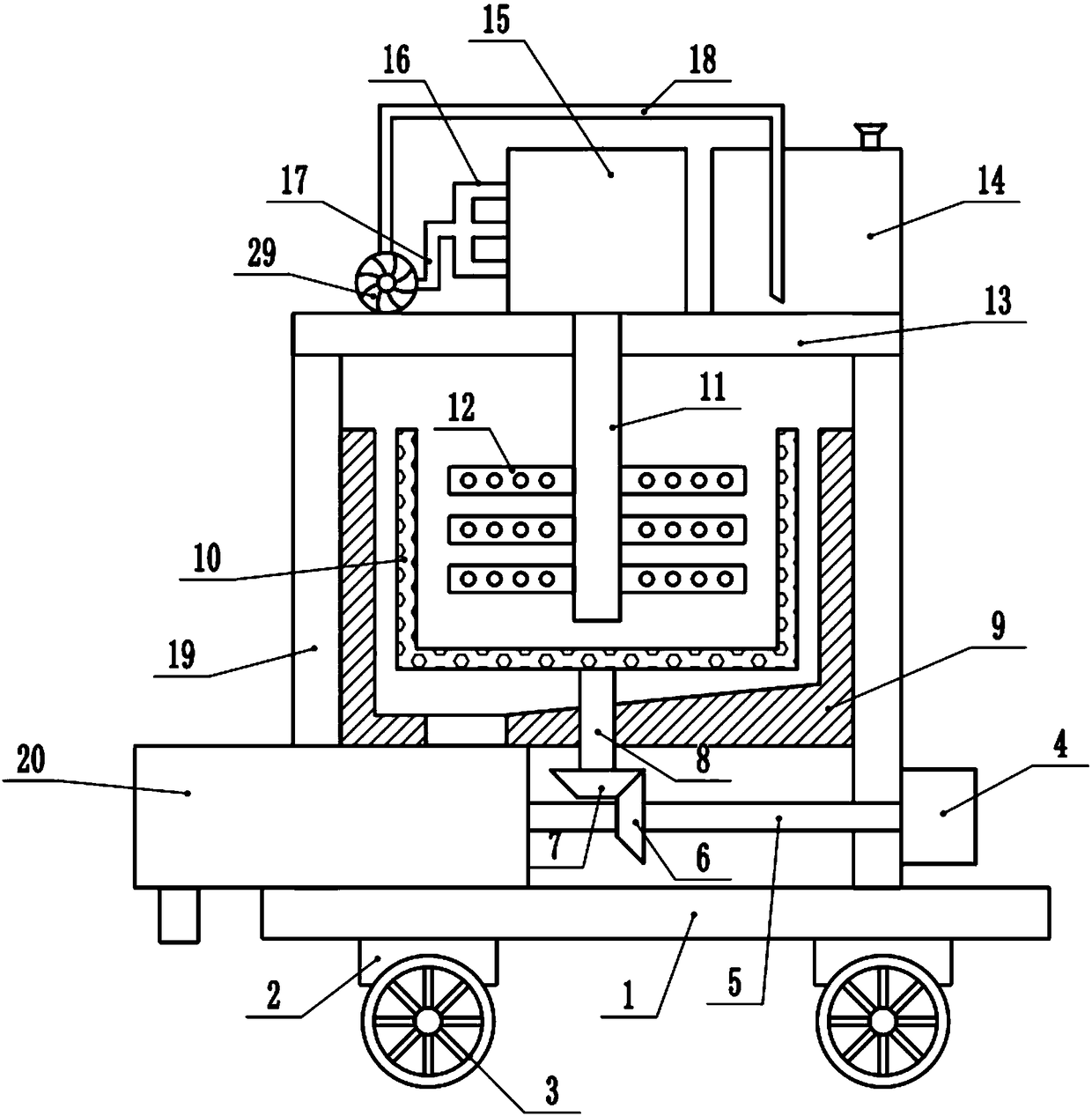

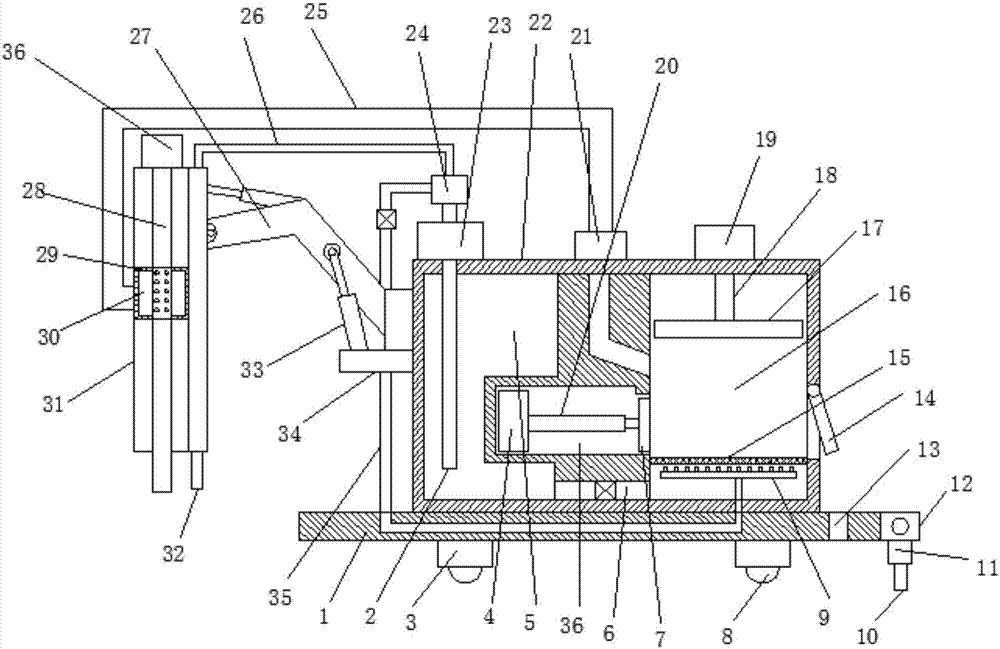

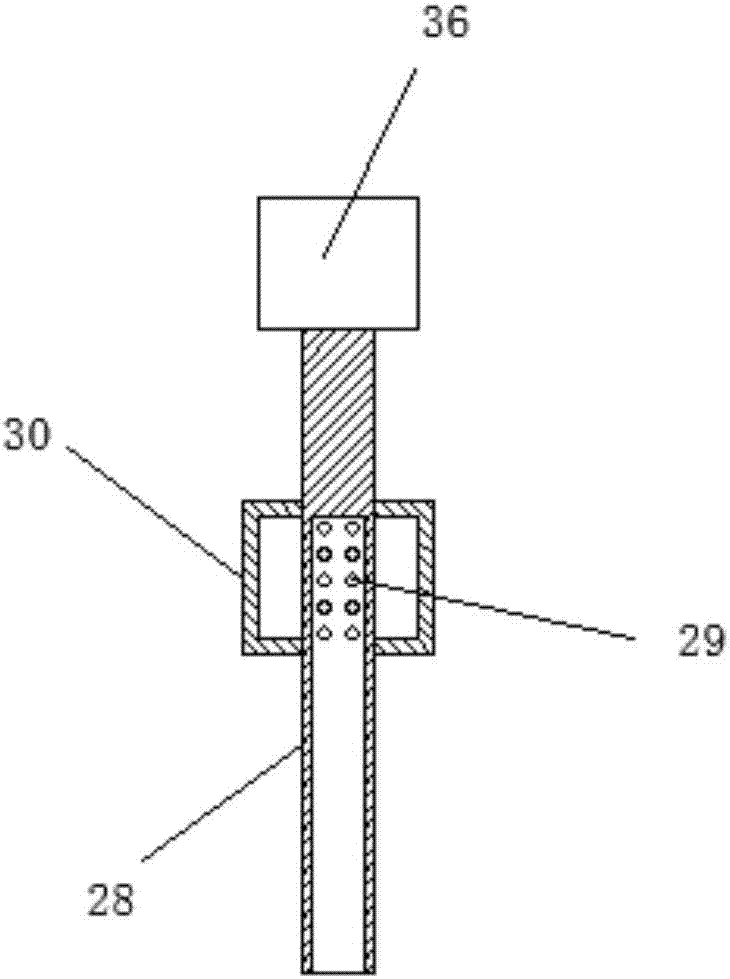

Environment-friendly contaminated soil off-site control device

ActiveCN109127708AImprove repair effectReasonable structureContaminated soil reclamationGear wheelAgricultural engineering

The invention discloses an environment-friendly contaminated soil off-site control device which comprises a traveling base. Supporting frames are mounted on two sides of the upper end of the travelingbase, a repairing cylinder is mounted between middles of the supporting frames, a top frame is mounted at the upper ends of the supporting frames, a power box is mounted in the middle of the upper end of the top frame, a chemical tank is mounted on the right side of the upper end of the top frame, a power shaft is mounted in the power box, power blades are uniformly arranged at the upper end of the power shaft positioned in the power box, the lower end of the power shaft penetrates the top frame and is connected with stirring blades, a rotating cylinder is arranged in the repairing cylinder,a rotating shaft is connected in the middle of the low end of the rotating cylinder, a first gear is connected at the lower end of the rotating shaft, a second gear is connected at the lower end of the first gear, a rotating shaft is mounted in the middle of the second gear, and a drying cylinder is mounted on the left side of the upper end of the traveling base. According to the device, a liquidrepair agent and a solid repair agent are mixed and stirred in a divided manner, the repair effects of the contaminated soil are improved, the repaired soil is dried and secondly mixed, and the repairquality of the soil is further improved.

Owner:HEBEI HUAQING ENVIRONMENTAL TECH GRP CO LTD

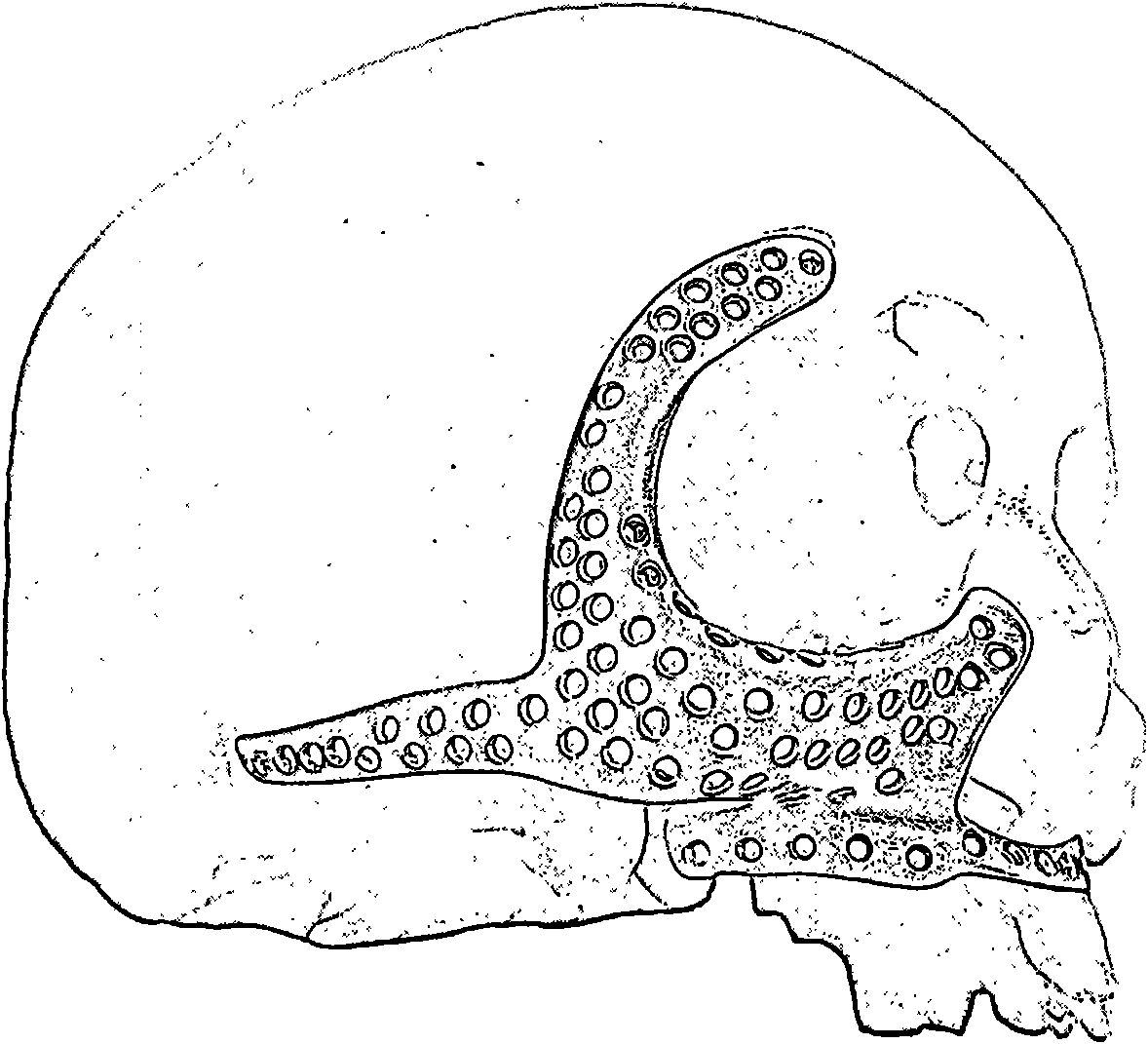

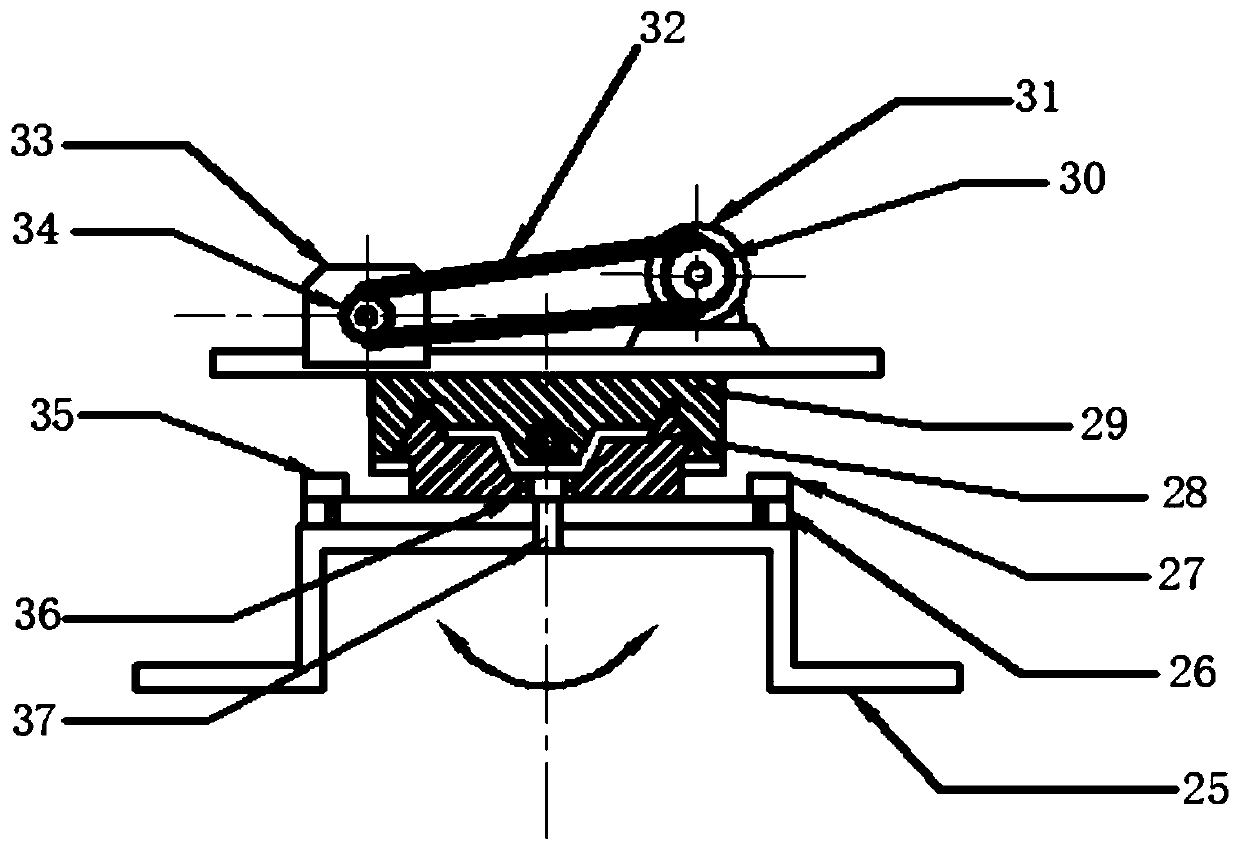

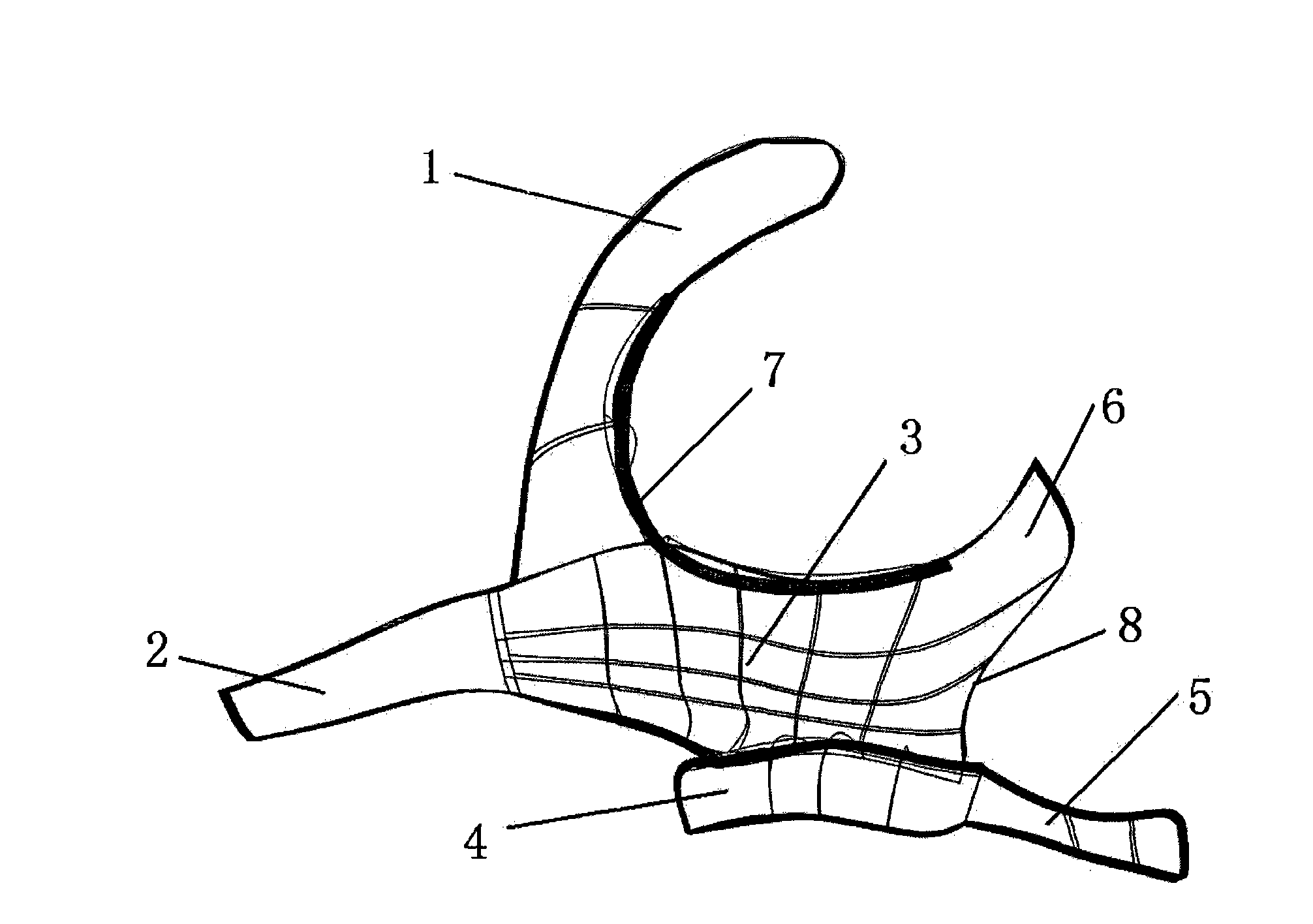

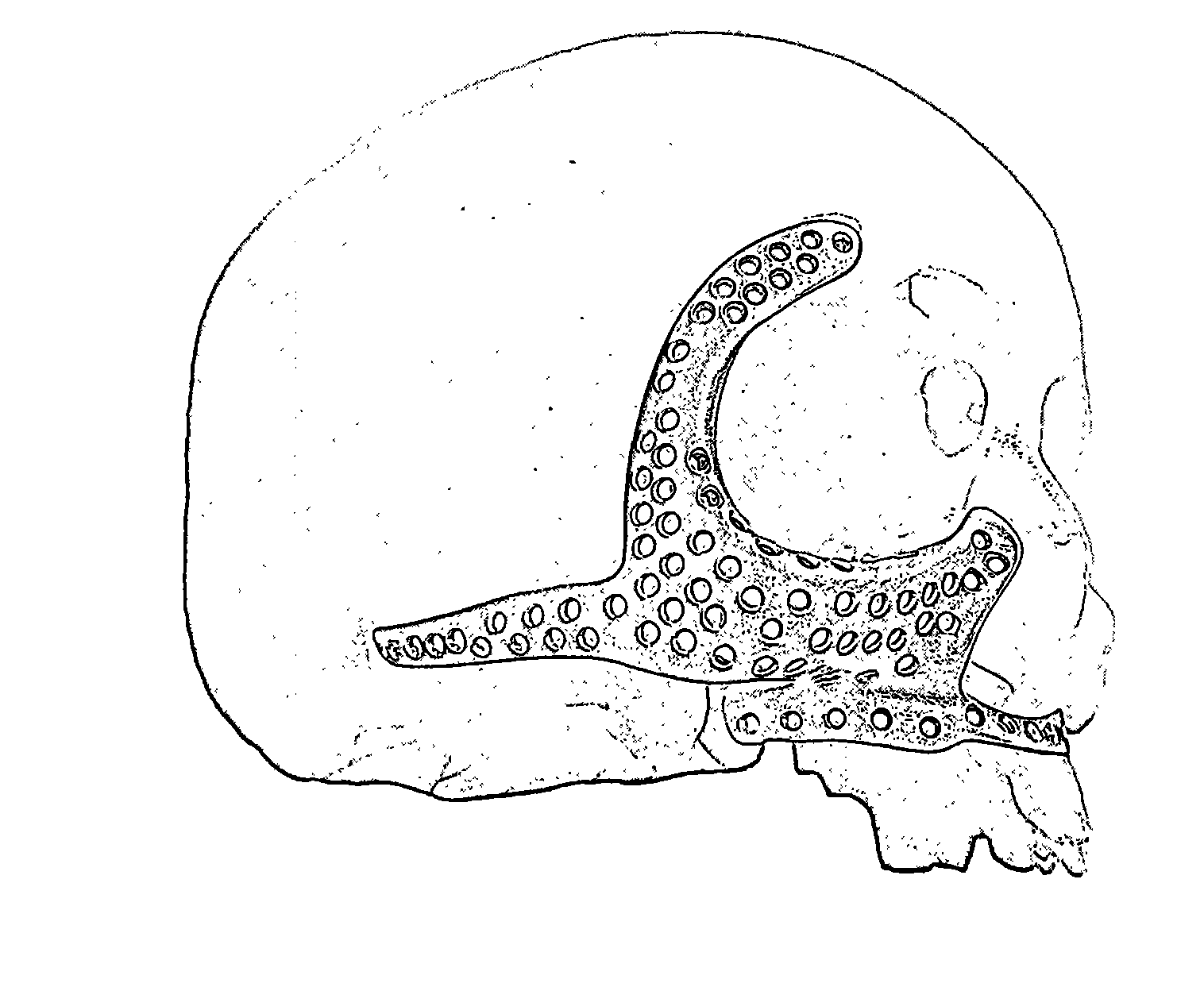

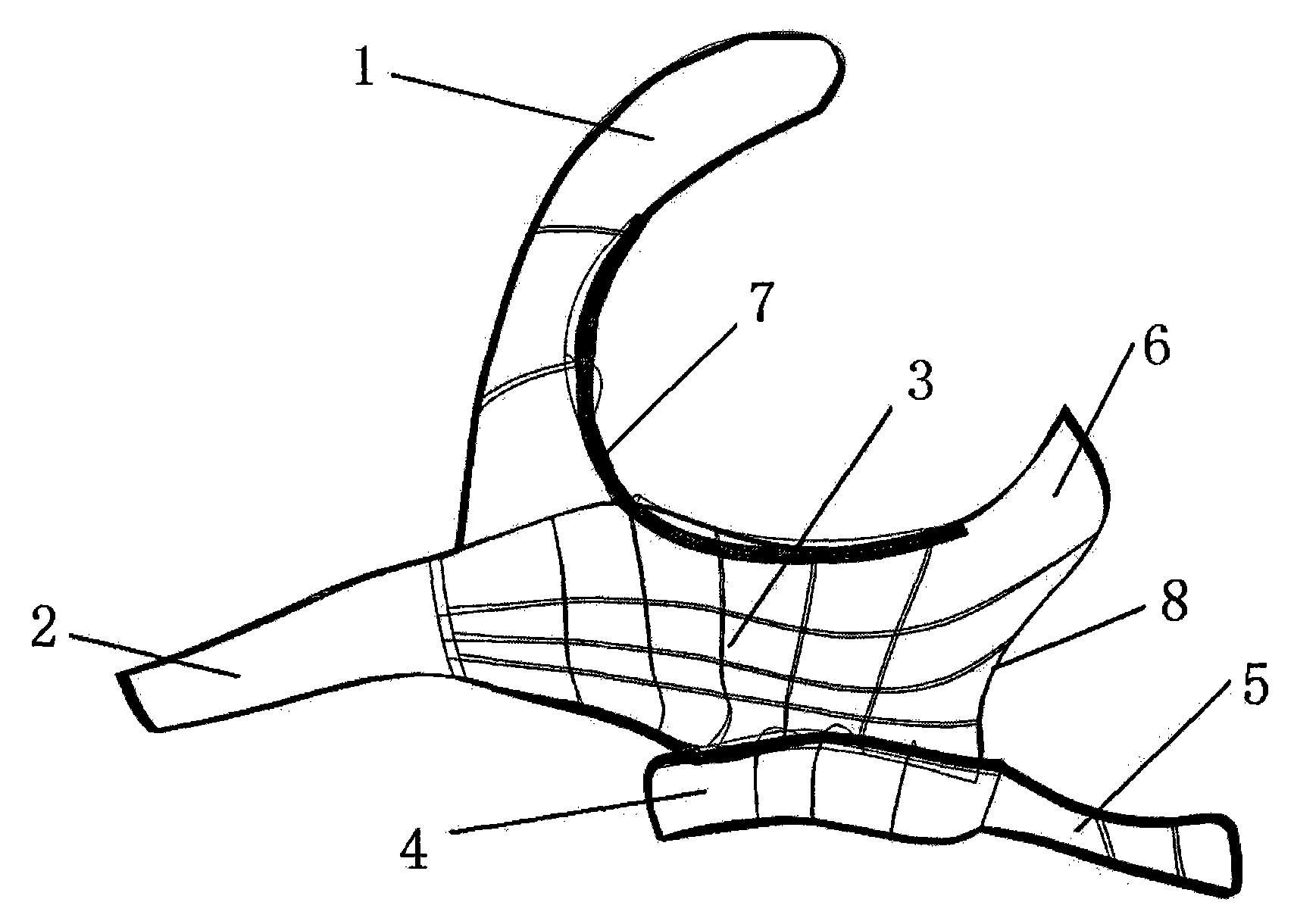

Integral repair stent of eye sockets, cheekbones and maxillary bone and manufacturing method thereof

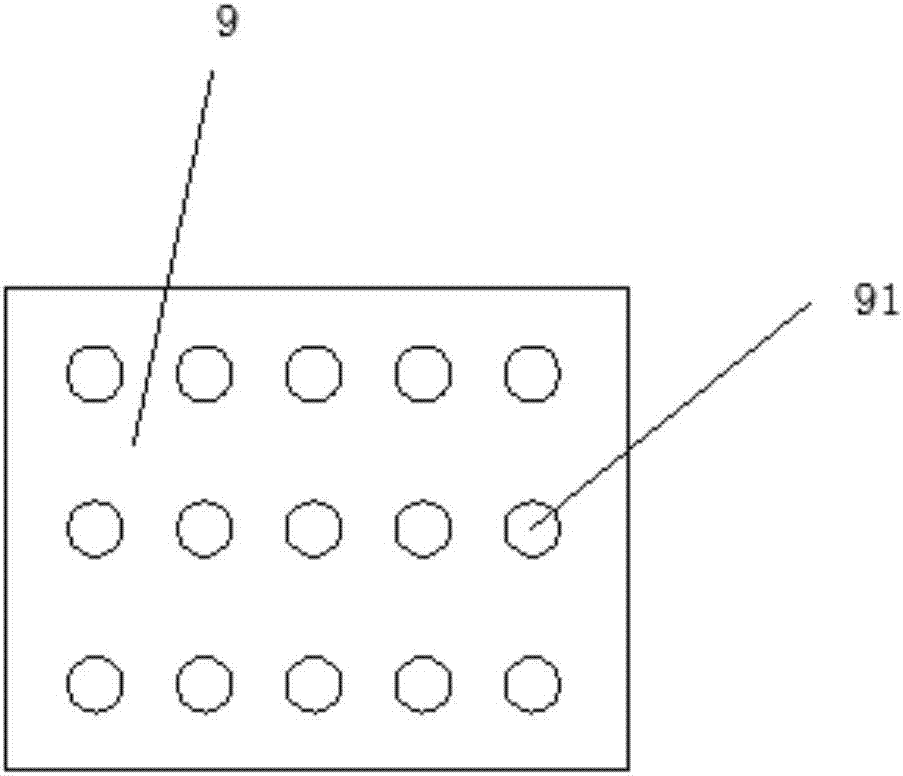

The invention relates to an integral repair stent of eye sockets, cheekbones and a maxillary bone and a manufacturing method thereof, and the integral repair stent can meet the repair needs when the eye sockets, the cheekbones and the maxillary bone all have defects. The integral repair stent is characterized in that the integral repair stent comprises a stent body which combines the shapes of theeye sockets, the shapes of the cheekbones and the shape of the maxillary bone, the stent body comprises a cheekbone repair area, a temporal arcade repair area of the cheekbones is extended from the left side of the cheekbone repair area, the right side of the cheekbone repair area is a piriform aperture shape repair area and is extended for forming a piriform aperture connecting area, a plantingtrough is distributed at the bottom of the cheekbone repair area, a piriform aperture bottom fixing area is extended from the right side of the planting trough, an eye socket outer edge repair area isupward extended from an eye socket shape repair area arranged at the upper edge of the cheekbone repair area; and the eye socket outer edge repair area, the piriform aperture bottom fixing area, thepiriform aperture connecting area and the temporal arcade repair area of the cheekbones all have sunk hole array structures.

Owner:北京吉马飞科技发展有限公司

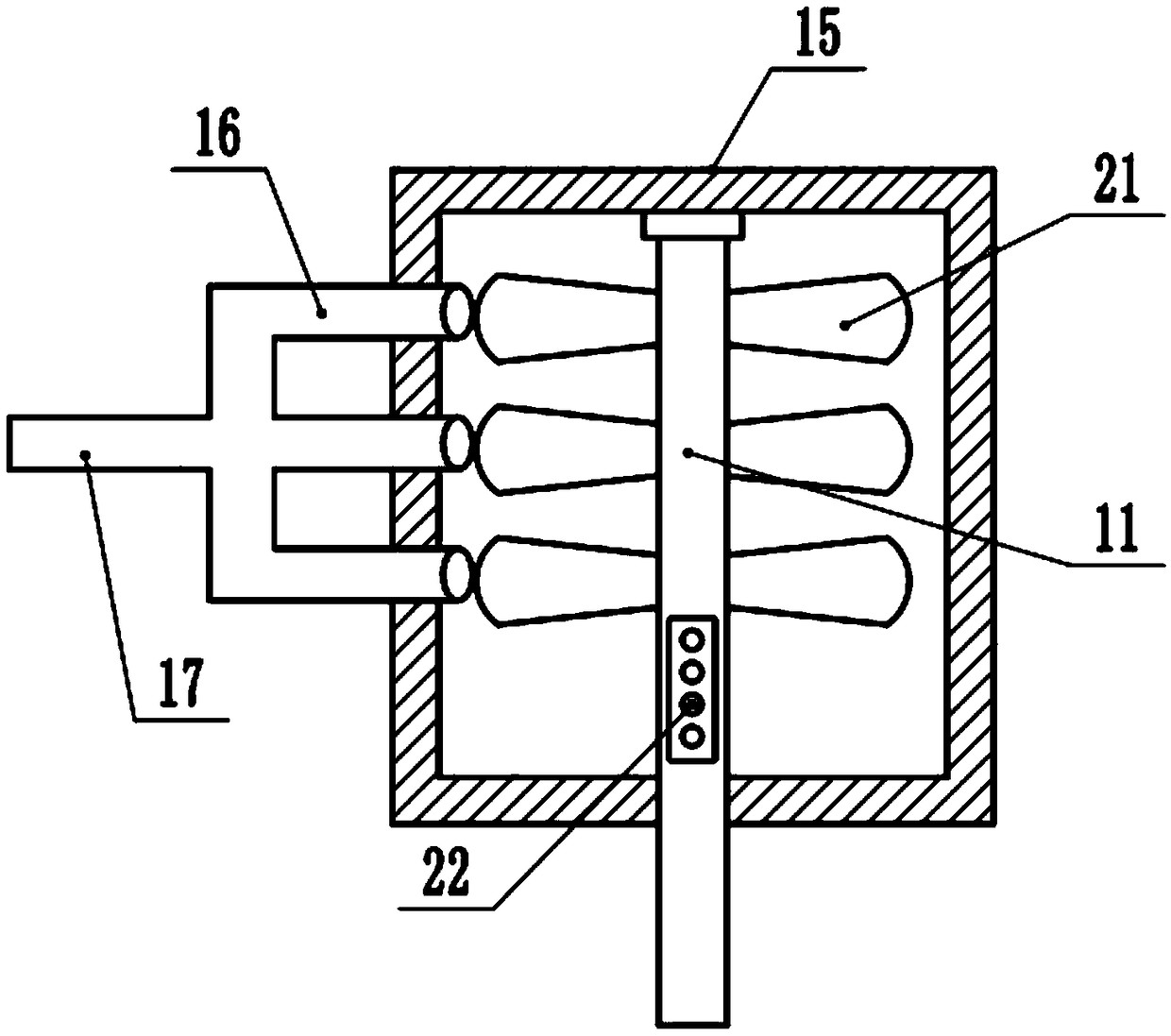

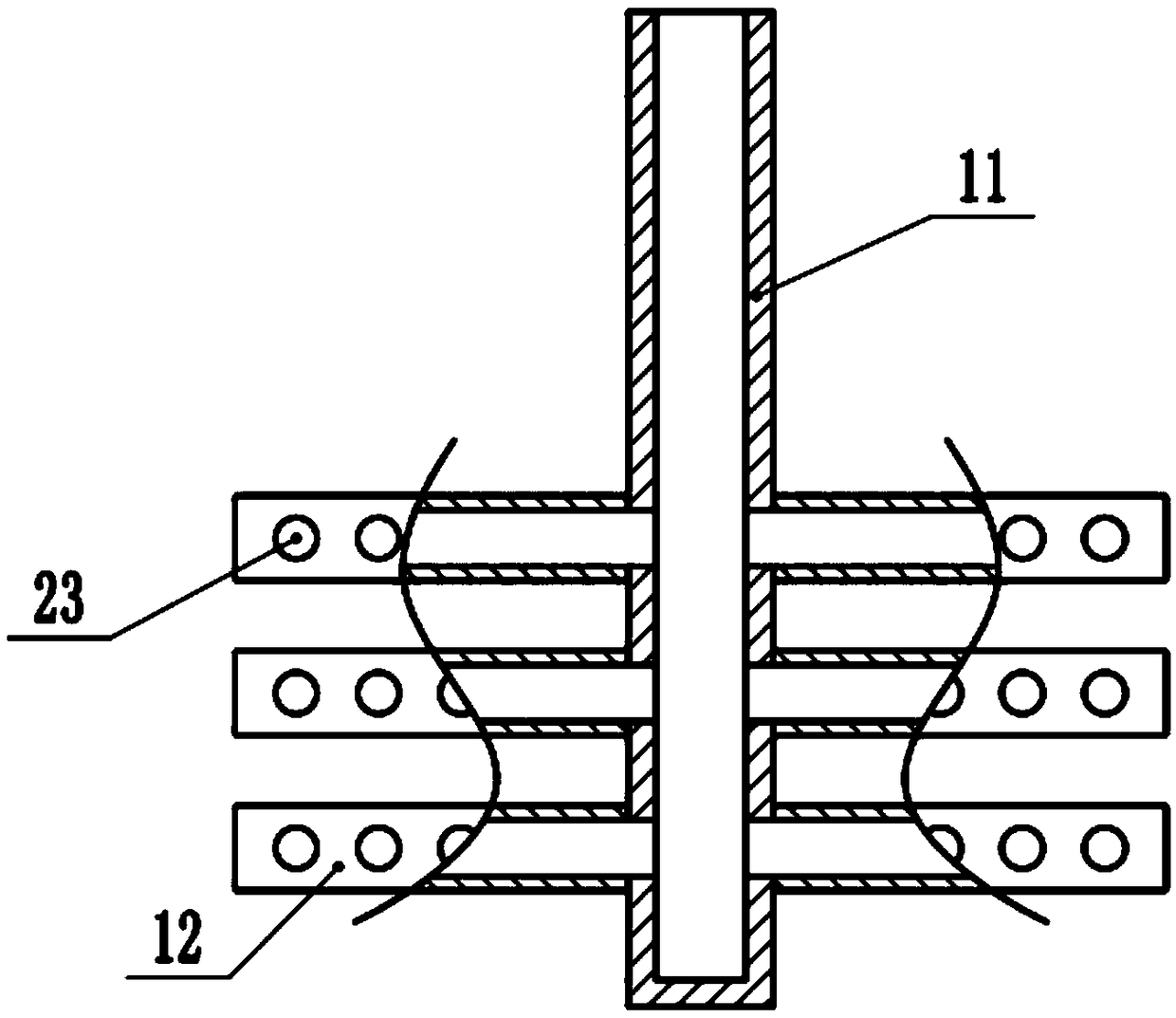

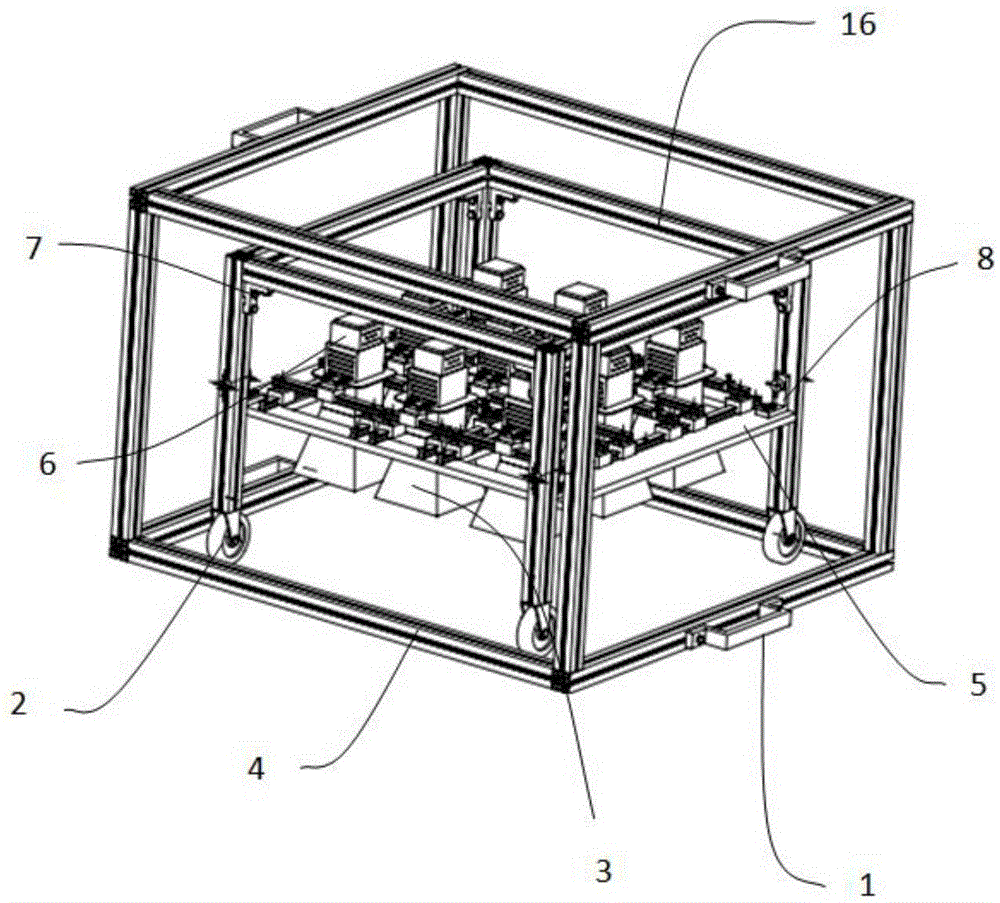

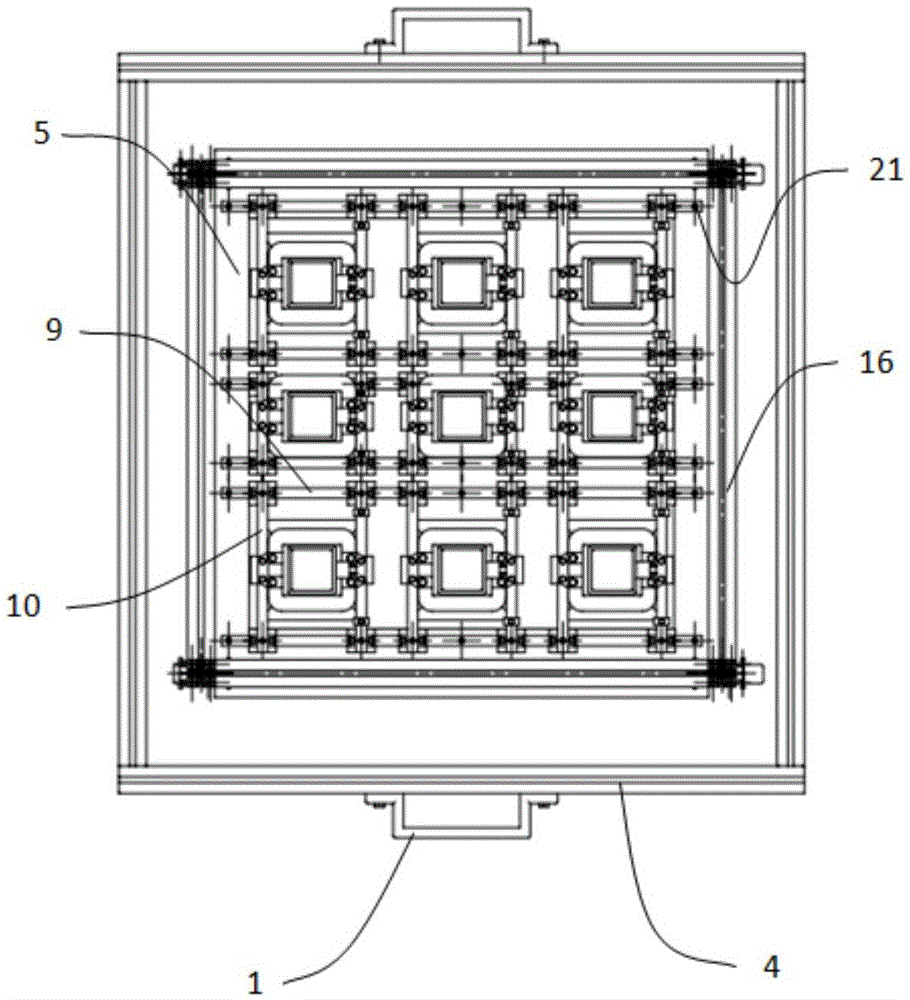

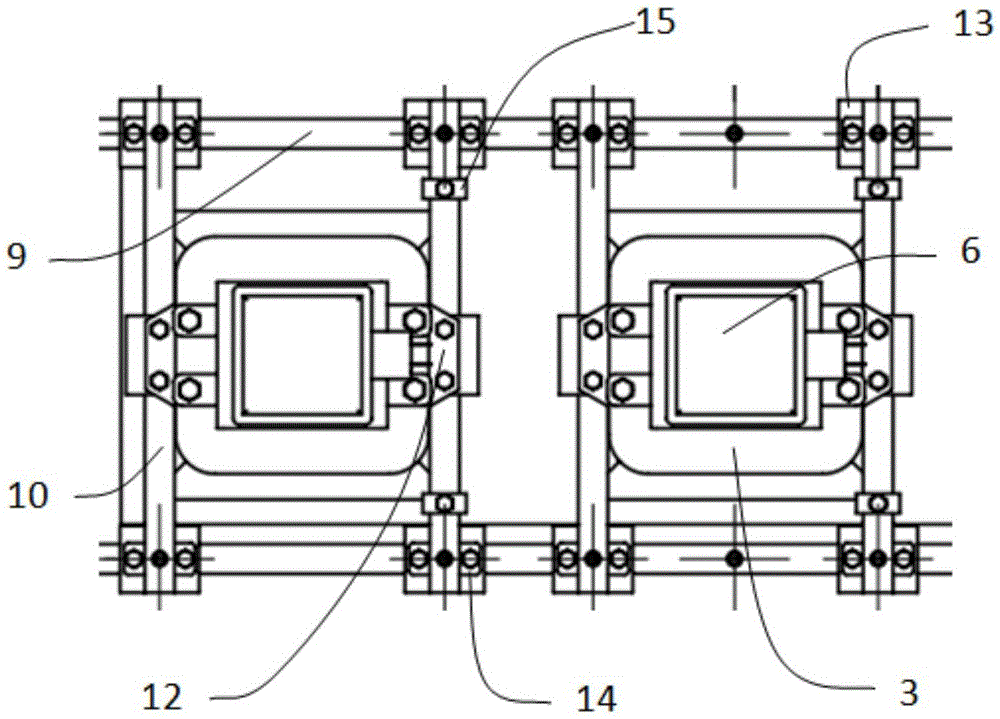

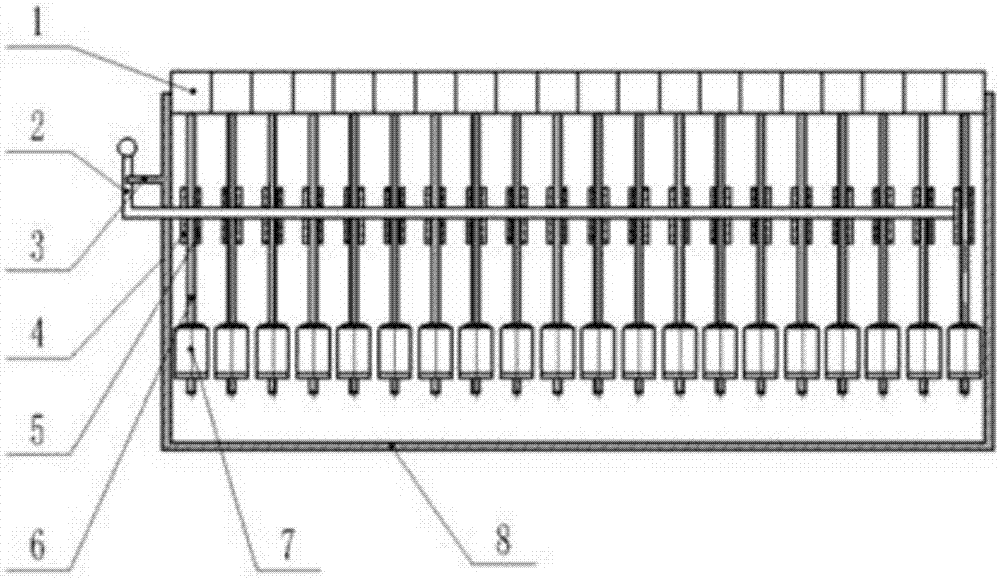

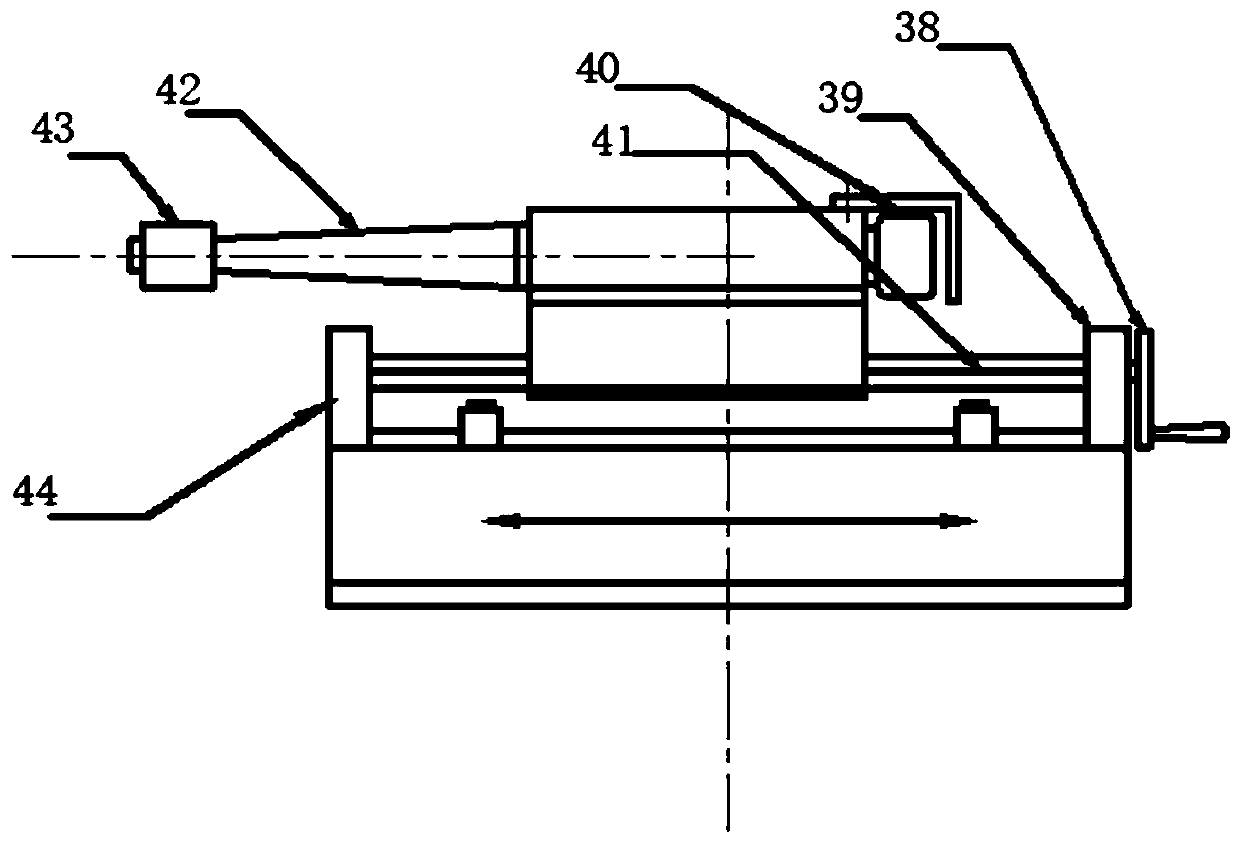

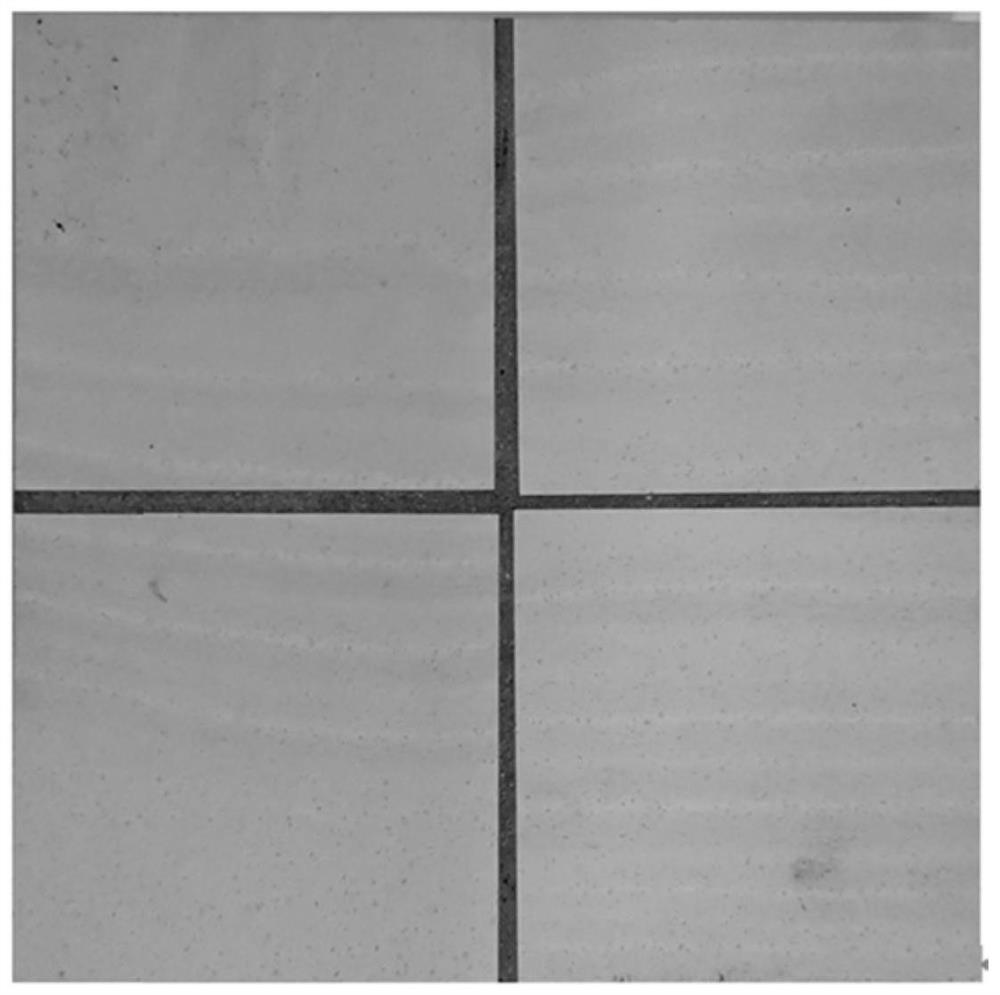

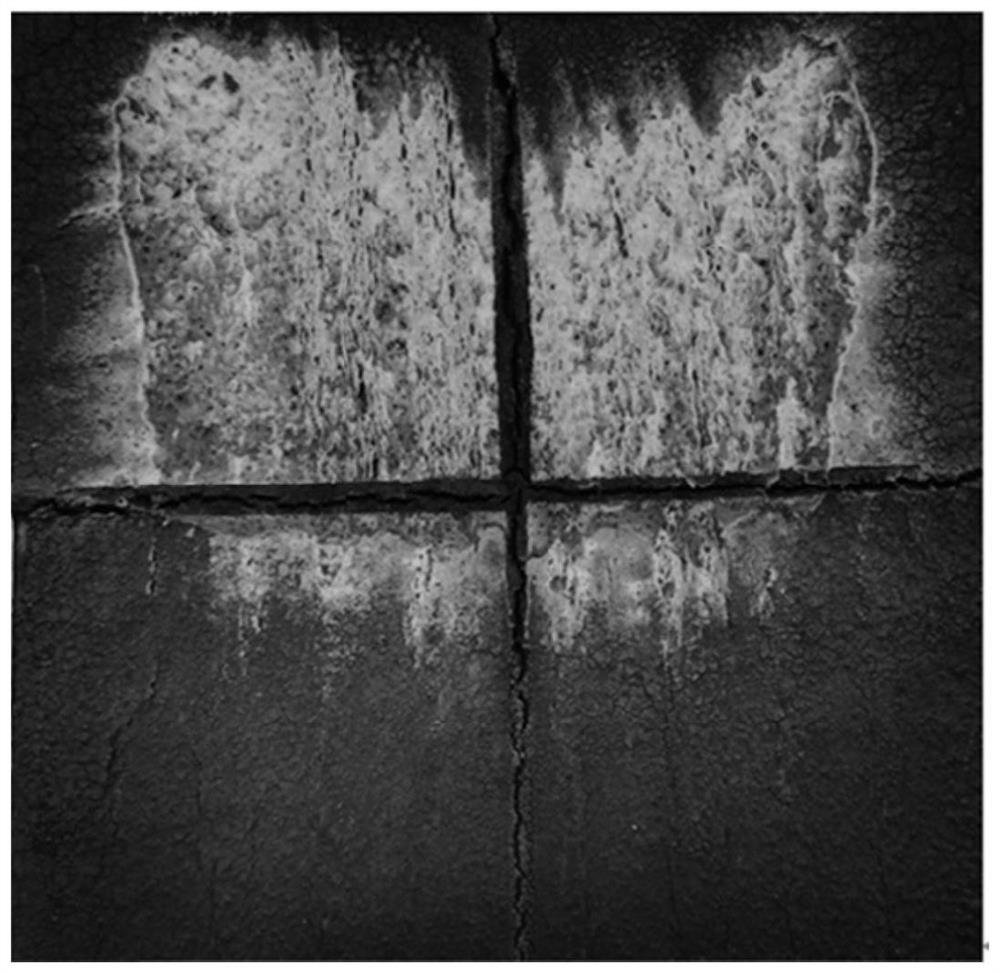

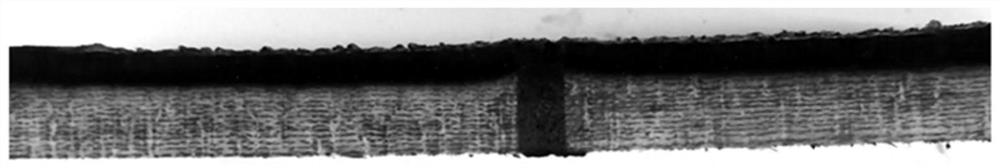

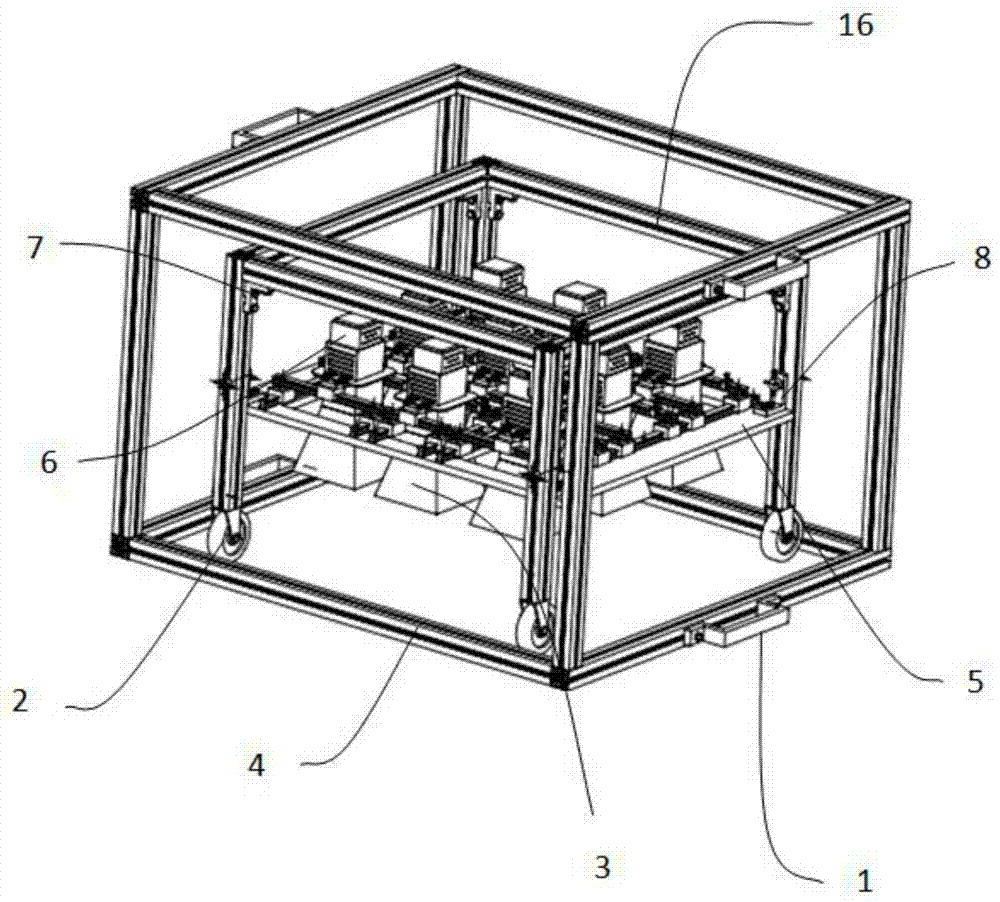

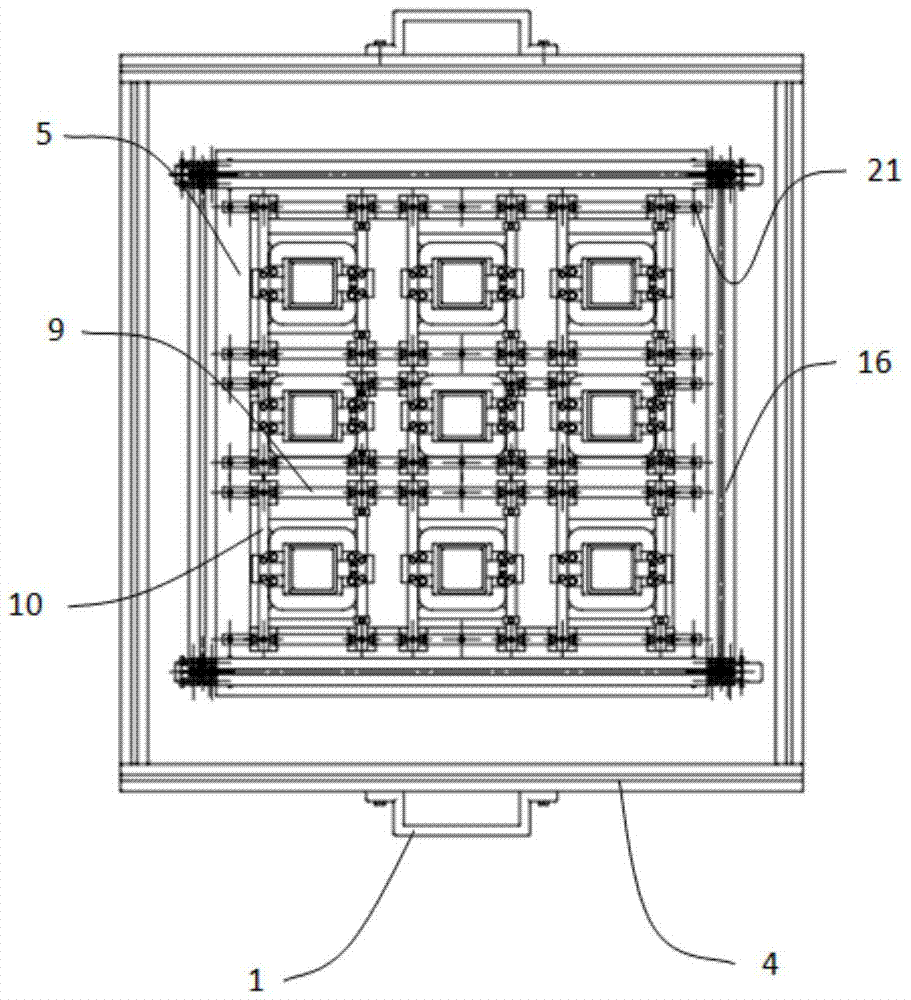

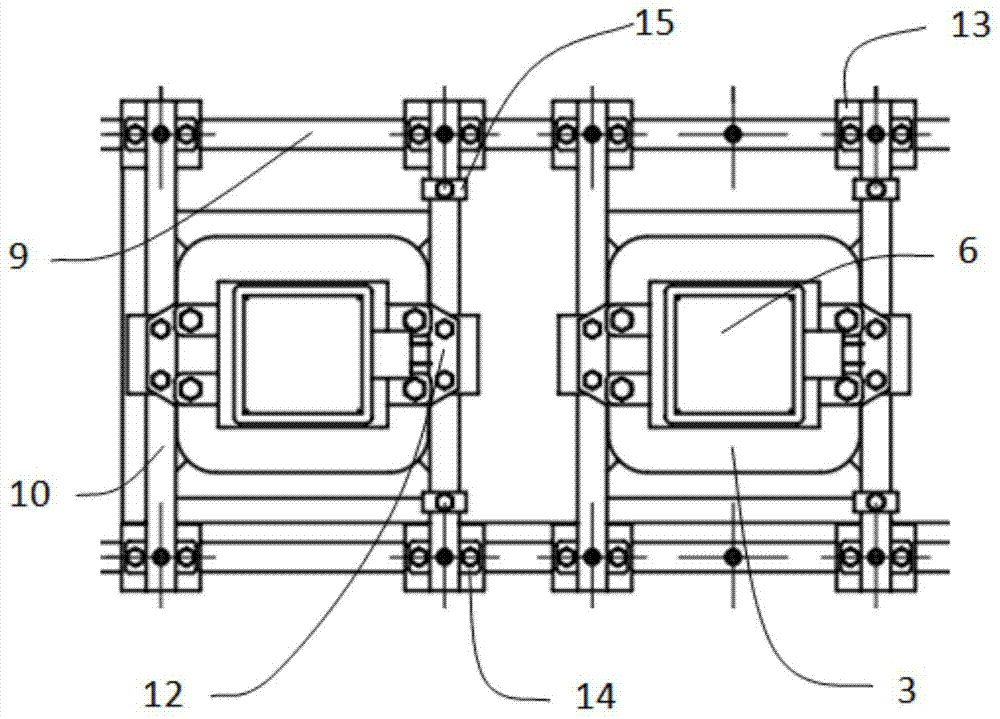

Adjustable bituminous pavement microwave heat regeneration test device

ActiveCN105544369ASolve the problem of not heating to the expected temperatureSolve correlation problemsRoads maintainenceMicrowaveEngineering

The invention discloses an adjustable bituminous pavement microwave heat regeneration test device which comprises a bearing device and an outer framework connected with the bearing device. The bearing device is provided with a microwave heating device and at least one transverse and longitudinal movement adjusting device used for adjusting the microwave heating device to transversely and longitudinal move in the plane where the bearing device is located. The microwave heating device can be adjusted in the transverse and longitudinal directions, the height of the microwave heating device can be adjusted, the device can adapt to damaged bituminous pavements of different heating areas, different heights and irregular heights, and repair requirements in actual life are met. The regeneration test device is simple in structure, complete in function and convenient to operate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Collagen film with 3D micro-patterns, and preparation method and application thereof

The invention belongs to the field of biomedical materials, and discloses a collagen film with 3D micro-patterns as well as a preparation method and application thereof. The collagen film with the 3Dmicro-patterns is prepared by the following steps: forming 3D micro-patterns on a silicon wafer by adopting a photolithography technology by using a mask with 3D micro-patterns; pouring PDMS prepolymers onto the silicon wafer so as to be subjected to cross-linking and curing, thereby obtaining a PDMS base with the 3D micro-patterns; dissolving collagen in an acidic solution, adding water, and carrying out uniform stirring so as to obtain a collagen solution; adding a cross-linking agent into the collagen solution so as to be subjected to cross-linking, thereby obtaining cross-linking reactionproducts; and then, removing bubbles from the cross-linking reaction products, pouring the bubble-removed cross-linking reaction products onto the PDMS base, carrying out air-drying so as to have a film formed, and carrying out stripping so as to obtain the collagen film with the 3D micro-patterns. The preparation technology of the collagen film with the 3D micro-patterns is simple in processes and relatively low in cost; and the prepared film combines advantages of collagen and patterned surface, thereby having good physicochemical properties and biocompatibility. The collagen film with the 3D micro-patterns can be used in corneal tissue engineering so as to induce corneal tissue regeneration; moreover, the collagen film with the 3D micro-patterns is capable of performing regulation on corneal cell behavior, thereby forming a structure similar to native tissues.

Owner:SOUTH CHINA UNIV OF TECH

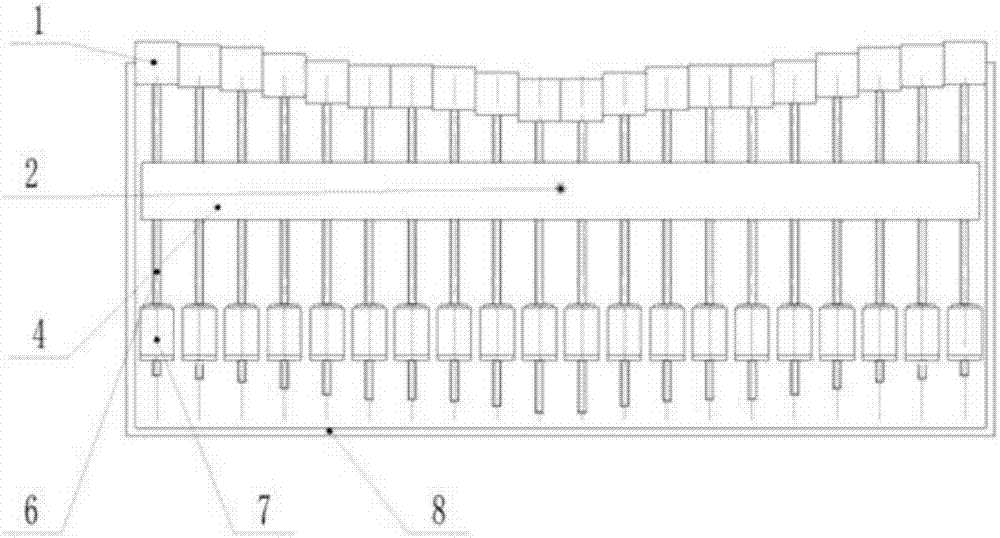

Matrix type adjustable sheet metal deformation device

A matrix type adjustable sheet metal deformation device comprises a shell, operating blocks, screw rods, motors and clamping devices; the shell is a box body and the top of the shell is open; a plurality of motors are arranged above a bottom plate in the shell uniformly and fixedly; the screw rods are arranged on the motors; the motors rotate to drive the screw rod to do up-and-down reciprocatingmotion; the screw rods vertically face towards the opening direction of the shell; the operating blocks are fixedly arranged at the top ends of the screw rods; a plurality of operating blocks are arranged in parallel to form a matrix which completely cover the top opening of the shell; and clamping devices are arranged on the screw rods. The motor rotate to drive the operating blocks to move and the matrix at the top of the shell is converted by different shapes, so that the sheet metal repairing requirement is met; and a control unit controls rotation of the motors, so that the precision is high, the sheet metal repairing effect is good and the problem that time and labor are consumed through purely manual repairing is solved.

Owner:CHANGAN UNIV

Injectable hydrogel dressing based on polyphenol-gallium ion coordination as well as preparation method and application of injectable hydrogel dressing

PendingCN114191605AGood flexibilityGood tissue adhesionPharmaceutical delivery mechanismBandagesChemistryBiomedical engineering

The invention particularly relates to an injectable hydrogel dressing based on polyphenol-gallium ion coordination as well as a preparation method and application of the injectable hydrogel dressing. The hydrogel compound dressing is prepared from the following raw materials in percentage by mass: 3-30% of an antibacterial high-molecular compound, 3-30% of a natural polyphenol compound, 3-30% of an inorganic gallium compound and deionized water. The hydrogel auxiliary material has good injectable performance, antibacterial performance, hemostatic performance and antioxidant effect, and can significantly improve the wound healing effect in a mouse full-thickness skin wound simulation model.

Owner:FUZHOU UNIVERSITY

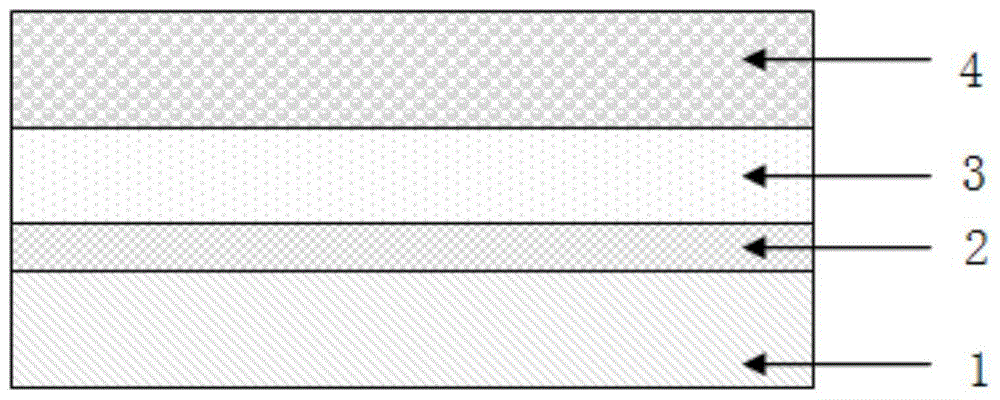

A method for preparing gradient coatings by laser cladding to repair cold rolls

ActiveCN104404510BImprove toughnessHigh bonding strengthMetallic material coating processesSand blastingOptoelectronics

The invention relates to a method for restoring a cold roll through preparing a gradient coating via laser cladding. The method comprises the following steps: 1) carrying out polishing, cleaning and sand blasting on the to-be-restored area of the cold roll; 2) paving a brazing flux on the surface of the to-be-restored area of the cold roll, paving brazing filler metal powder on the brazing flux and preparing a first transition layer through a high-temperature heating manner; 3) pacing transition material powder on the surface of the first transition layer and preparing a second transition layer through laser cladding; 4) paving alloy powder on the surface of the second transition layer and preparing a third gradient layer through laser cladding. The method starts with the structural design of a cladding layer, and the cladding layer is designed into an alloy gradient layer with a multilayer structure, so that the problem that the cold roll is easy to crack, relatively low in bonding strength and easy to fall off after the restoration is solved.

Owner:九江中科神光科技有限公司

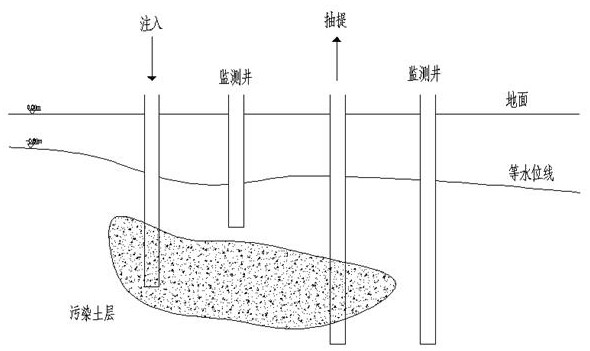

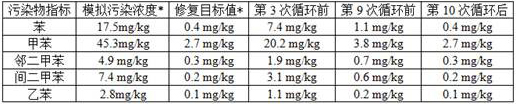

In-situ chemical oxidation remediation method for soil contaminated by benzene series

InactiveCN112387771ASave repair input costIncreased redox potentialContaminated soil reclamationOrganic fertilisersContaminated soilsPollutant

The invention relates to an in-situ chemical oxidation remediation method for soil contaminated by benzene series. The method comprises the following steps: injecting a soil remediation agent, carrying out ex-situ treatment after extraction and conducting periodic monitoring. After the injected soil remediation agent is in full contact with pollutants adsorbed on soil particles in a contaminated soil layer under the action of underground water runoff, permeation and hydraulic gradient, the pollutants are degraded into low-molecular simple organic matters by utilizing relatively high oxidation-reduction potential of the soil remediation agent, so the in-situ chemical oxidation remediation method for the soil contaminated by benzene series is realized.

Owner:NANJING GW ENVIRONMENT ENG

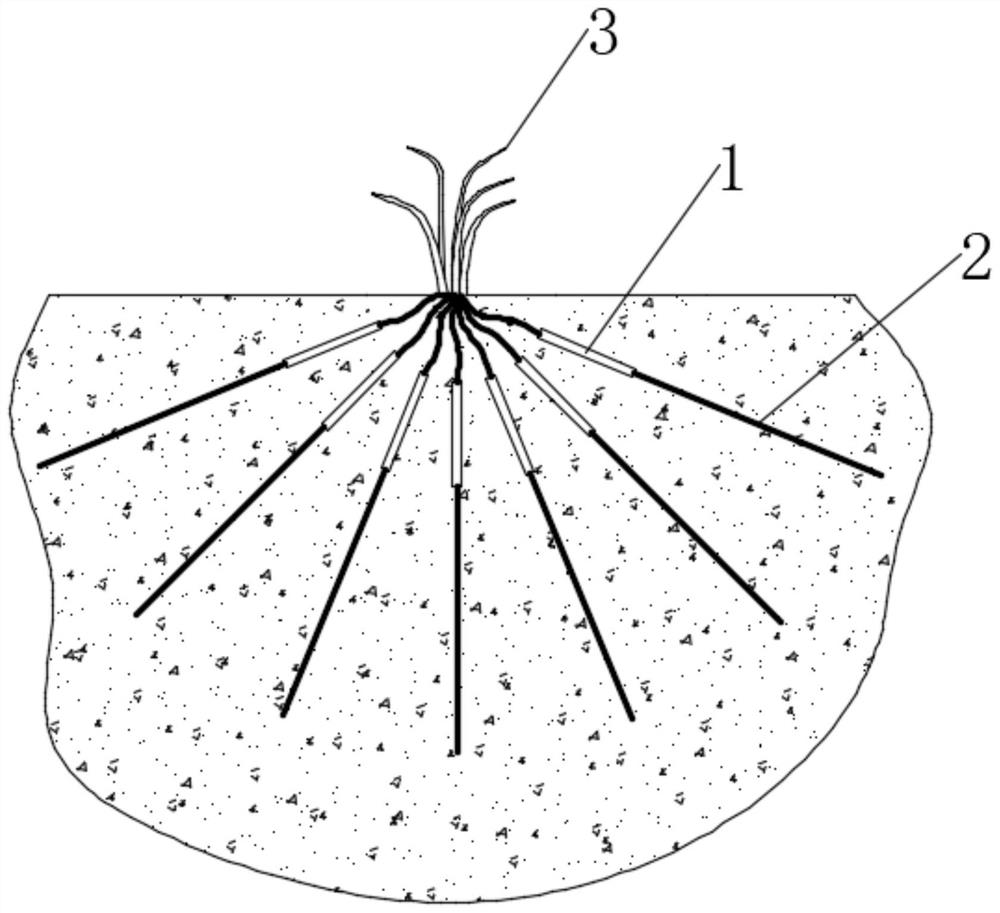

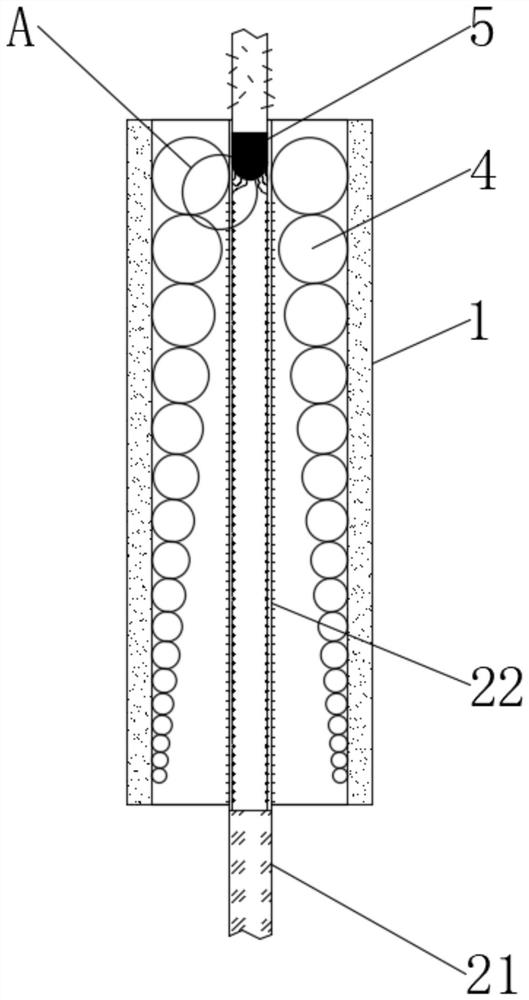

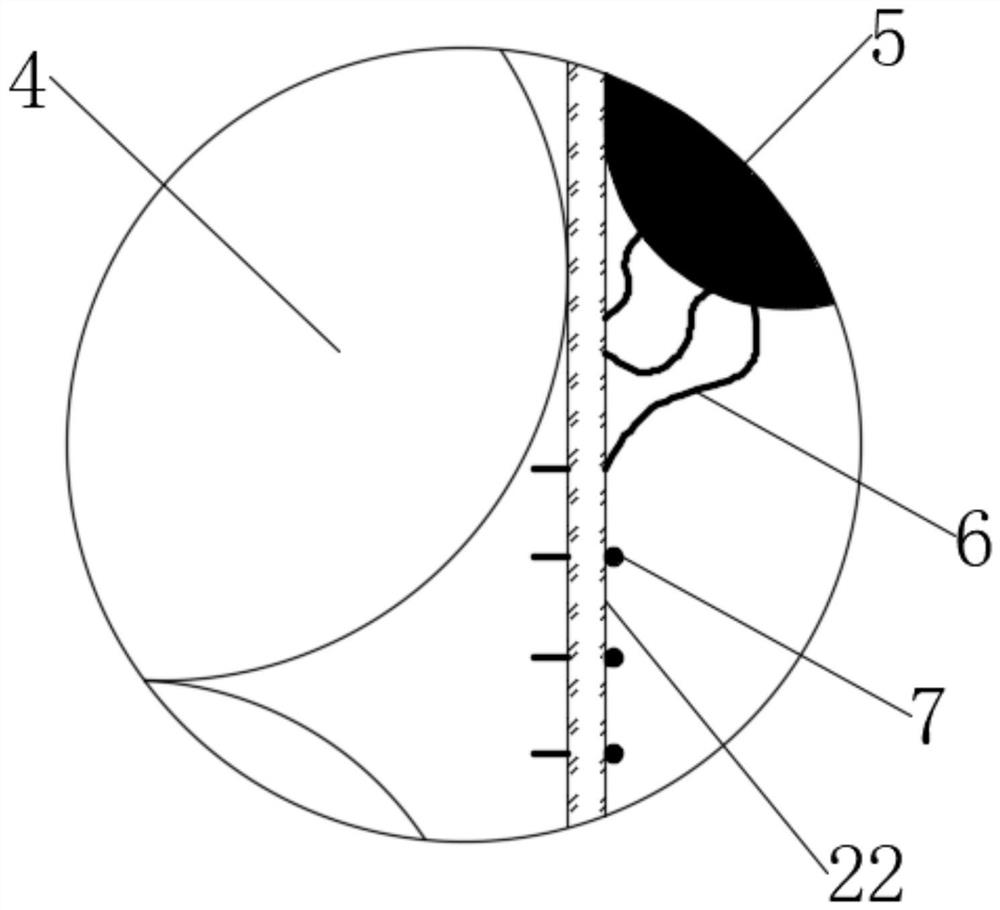

Heavy metal contaminated soil continuous root type combined remediation method

InactiveCN111872109AImprove capture efficiencyPlay an auxiliary role in repairingContaminated soil reclamationFiberMicroorganism

The invention discloses a heavy metal contaminated soil continuous root type combined remediation method, belongs to the technical field of soil remediation, and can realize continuous connection of root systems of heavy metal hyperaccumulation plants through combination of continuous biological isolation tubes and continuous fiber dummy roots to meet remediation requirements of large-scale deep contaminated soil. The method comprises the following steps: absorbing moisture deep in soil by taking the continuous fiber dummy roots as root systems, forcing the moisture to carry heavy metal ions to transfer to the continuous fiber dummy roots, performing complementary remediation based on the combined action of microorganisms in the continuous fiber dummy roots and heavy metal hyperaccumulation plants, and isolating the growth of the microorganisms by utilizing the continuous fiber dummy roots. According to the method, the continuous fiber dummy root and the continuous biological isolationtube can adapt to the growth of the root system of the heavy metal hyperaccumulation plant, provide nutrients required by the growth of the microorganisms and the heavy metal hyperaccumulation plantin real time, and promote the effect of combined remediation.

Owner:达小莉

Method for repairing size of casing spigot by supersonically spraying NiCrFeMn coating

InactiveCN108220864AHigh bonding strengthImprove stabilityMolten spray coatingKeroseneMaterials science

The invention relates to a method for repairing the size of a part, in particular to a method for repairing the size of a casing spigot by supersonically spraying a NiCrFeMn coating. The method comprises the following steps of 1, carrying out sand blowing treatment on the casing spigot; 2, performing oil removal treatment on the casing spigot; 3, carrying out protection on the part, which does notneed to be subjected to spraying repair, of the casing spigot before sand blowing; 4, carrying out sand blowing treatment on the area, which needs to be repaired in size, of the casing spigot, wherein 50-60 mesh magnesia sand is adopted, and sand blowing pressure is 0.2-0.5 MPa; and 5, supersonically spraying the NiCrFeMn coating on the area, which needs to be repaired, of the casing spigot, wherein the specific parameters are as follows that a kerosene flow rate is 2.5-5.5 L / min, an oxygen flow rate is 800-1200 L / min, a powder feeding rate is 75-80 g / min, spraying distance ranges from 120 mmto 240 mm and a spraying angle ranges from 60 degrees to 65 degrees. According to the method, a repaired part meets the assembling requirements, part reproduction cost is saved, and the production cost is reduced.

Owner:新锐咨询(辽宁)有限公司

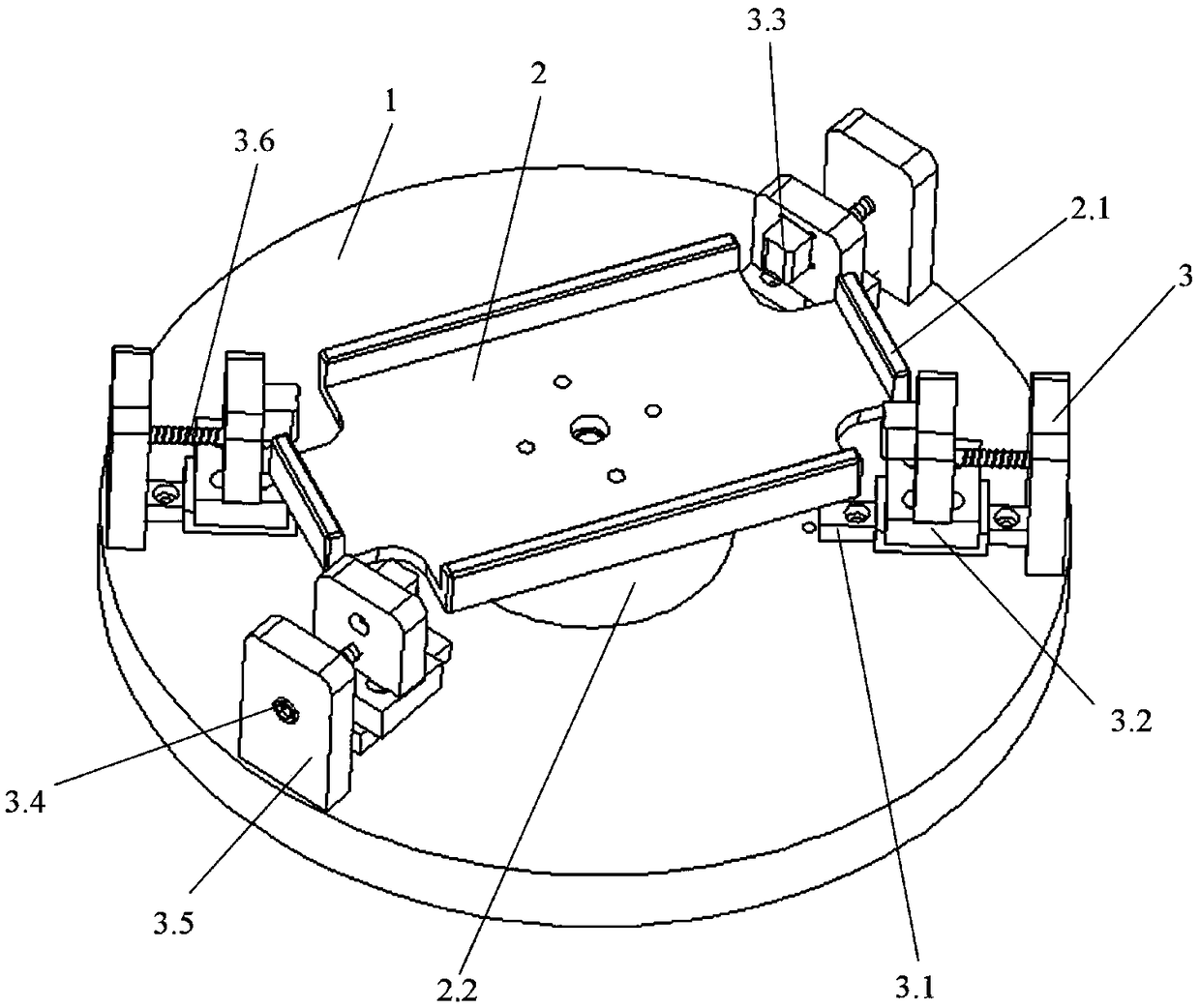

R corner too large size repairing device

ActiveCN109333227AImprove stabilityFull energy savingEdge grinding machinesGrinding work supportsDiagonalEngineering

The invention provides an R corner too large size repairing device. The R corner too large size repairing device comprises a base plate and further comprises a product fixing assembly and a grinding wheel grinding assembly which are arranged on the base plate. The product fixing assembly comprises a product containing groove and a rotation disc which are arranged up and down and fixedly connected,and notches are formed in the four R corner positions of the product containing groove. The grinding wheel grinding assembly comprises at least two grinding wheel grinding pieces arranged at the twoR corner notches in the diagonal line direction of the product containing groove. Each grinding wheel grinding piece comprises a sliding rail, a sliding piece arranged on the sliding rail in a slidingmanner, a grinding wheel and a movable connecting piece, wherein the sliding rail is horizontally arranged on the base plate and is arranged towards the corresponding R corner notch in the length direction, the grinding wheel is arranged on the side, close to the corresponding R corner notch, of the sliding piece, and the movable connecting piece is used for adjusting the grinding thickness of the grinding wheel and making the grinding wheel tightly pressed on the corresponding product R corner. By means of the R corner too large size repairing device, the two R corners, in the diagonal linedirection, of a product can be repaired at the same time, repairing of R corners of multiple products can be achieved as well, and the qualification rate reaches up to 100%.

Owner:LENS TECH CHANGSHA

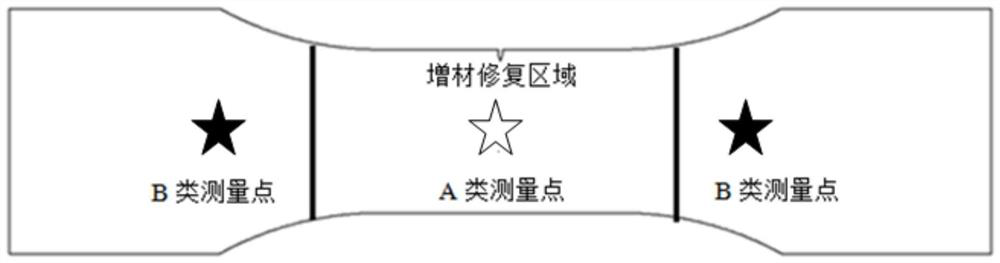

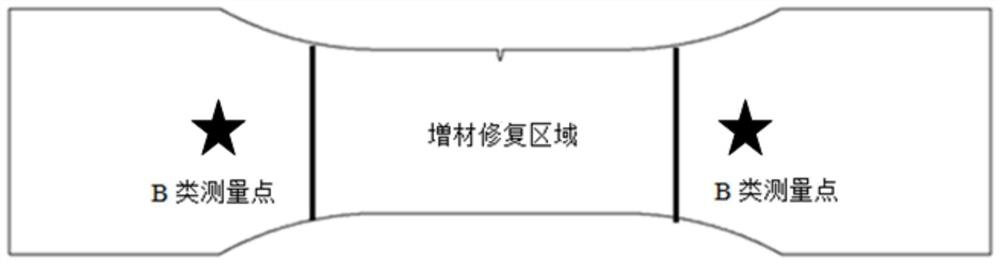

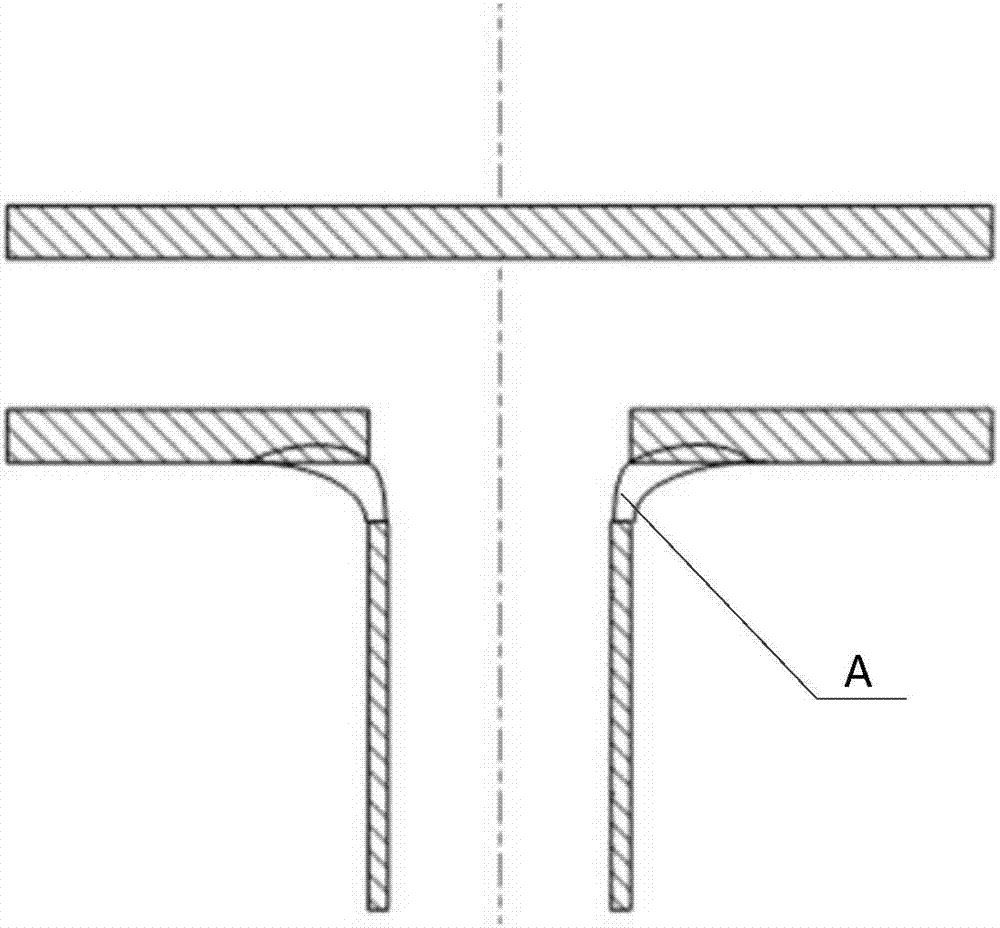

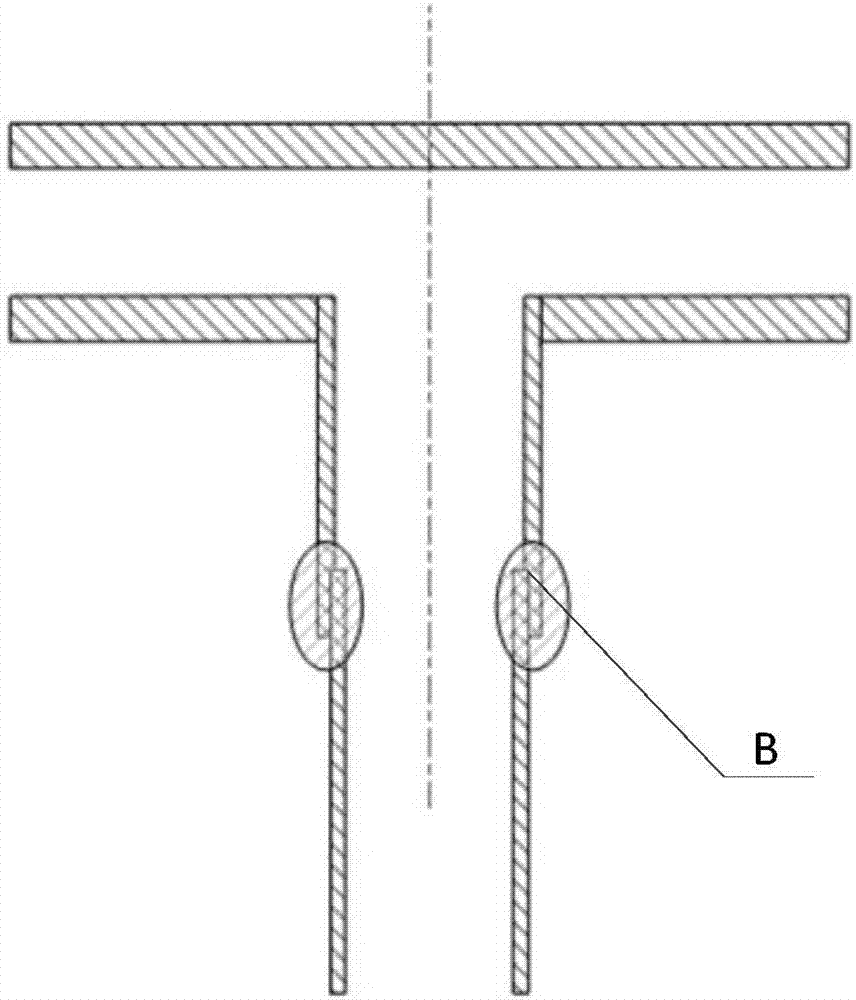

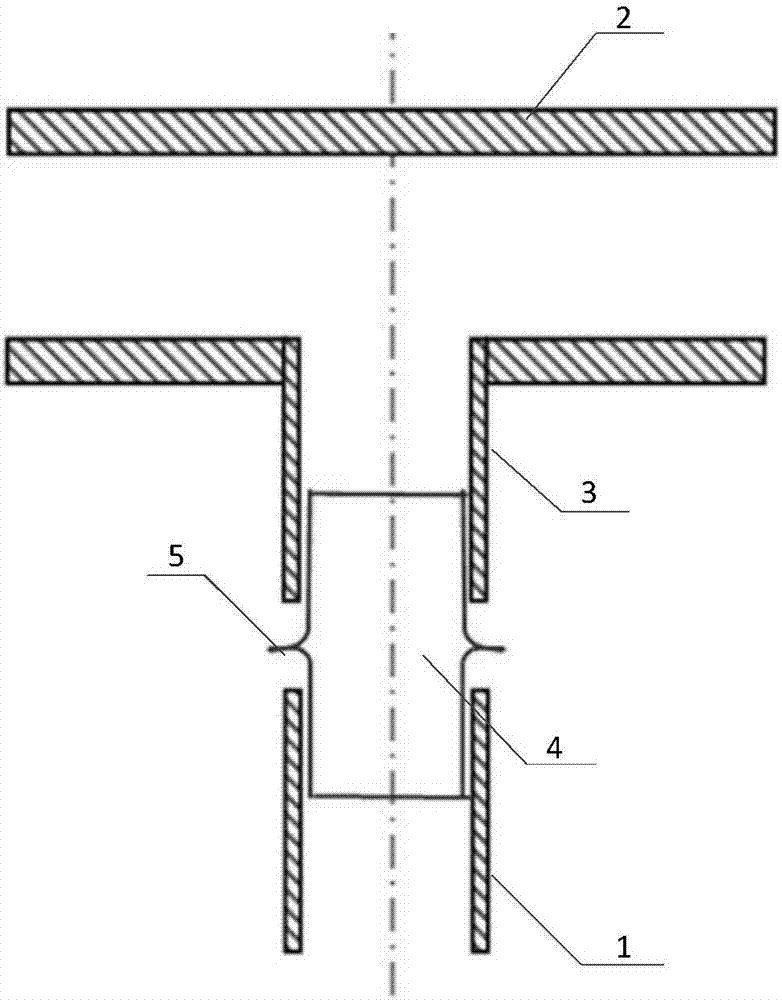

Aluminum alloy structure temperature control method for high-speed jet additive repair

PendingCN112518157AMeet repair needsAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesTemperature controlJet flow

The invention belongs to the field of additive repair, and particularly relates to an aluminum alloy structure temperature control method for high-speed jet additive repair. The method comprises the steps that firstly, a to-be-repaired part is obtained, an A-type measuring point and a B-type measuring point are selected on the part, a first temperature sensor is arranged at the A-type measuring point, and a second temperature sensor is arranged at the B-type measuring point; secondly, the alarm threshold of the first temperature sensor is set as a first alarm threshold, and the alarm thresholdof the second temperature sensor is set as a second alarm threshold; and thirdly, high-speed jet additive repair operation is conducted on the part, and when the first temperature sensor or the second temperature sensor gives an alarm, the high-speed jet additive repair operation is stopped immediately; and when a measured value of the first sensor reaches first preset temperature and a measuredvalue of the second sensor reaches second preset temperature, high-speed jet additive repair operation is conducted on the part again, and the current step is repeated unitl high-speed jet additive repair is completed.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

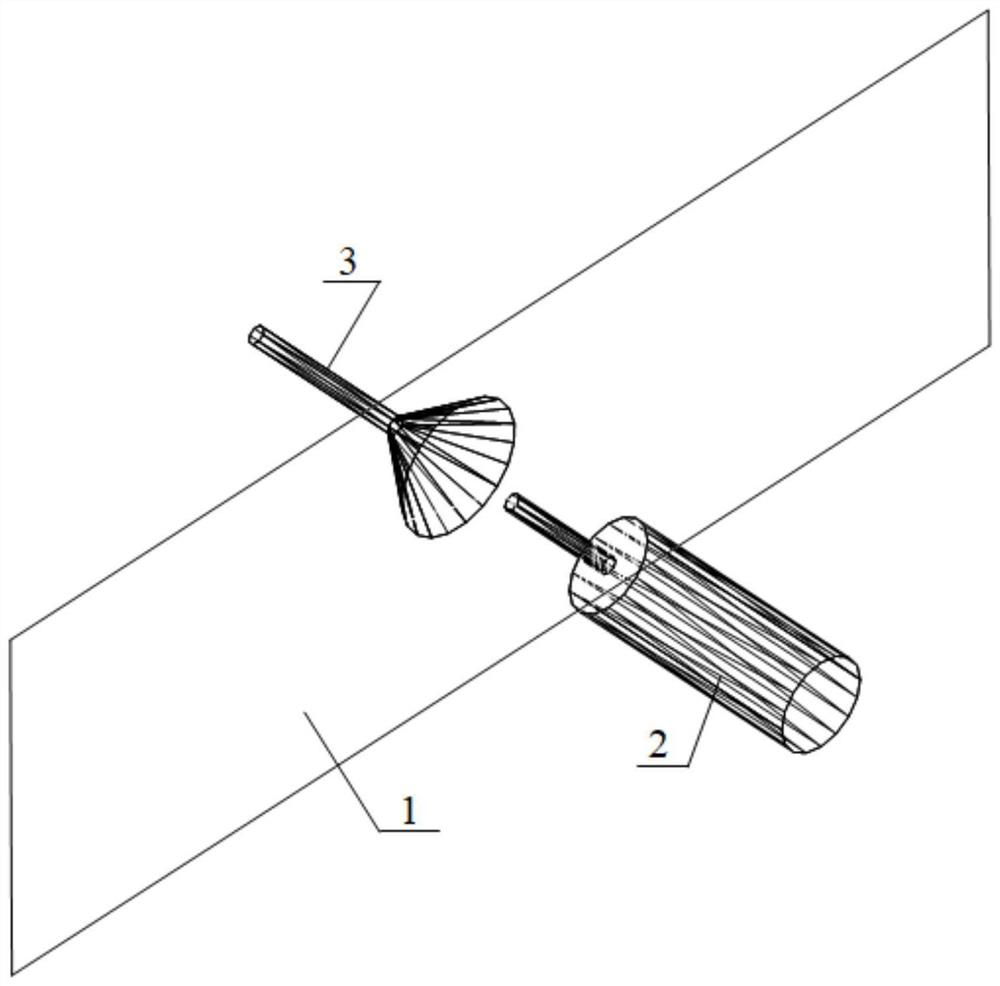

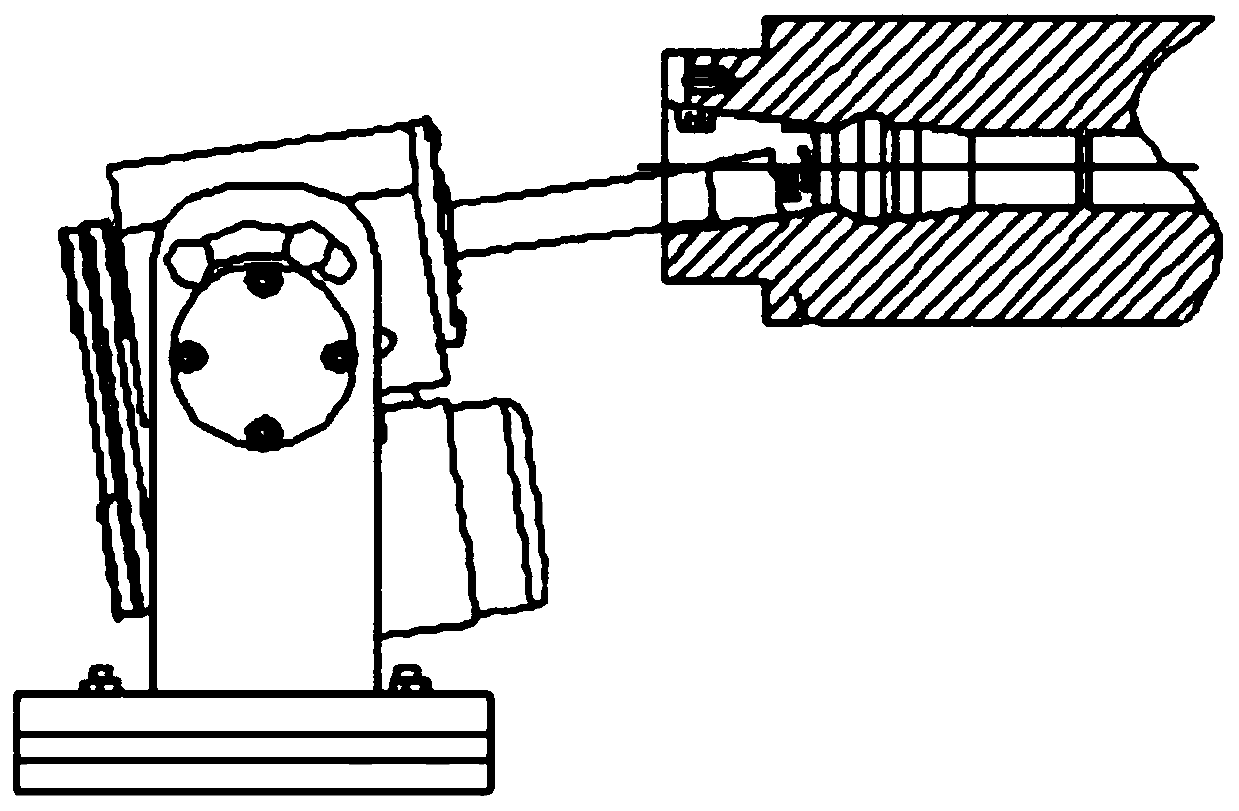

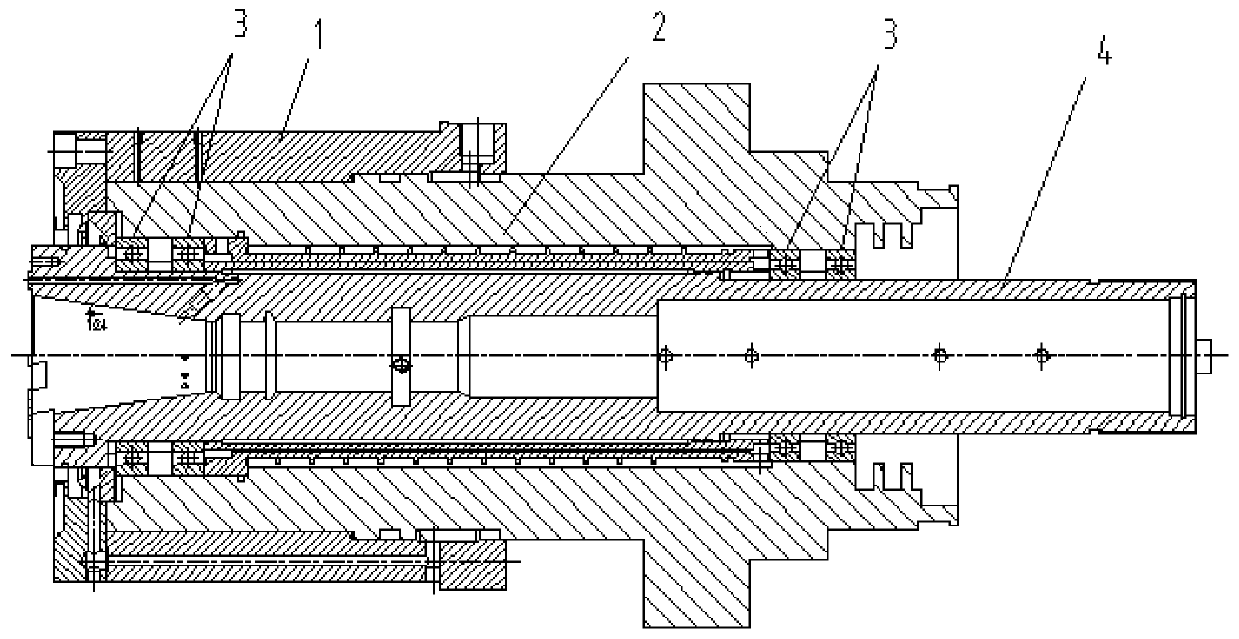

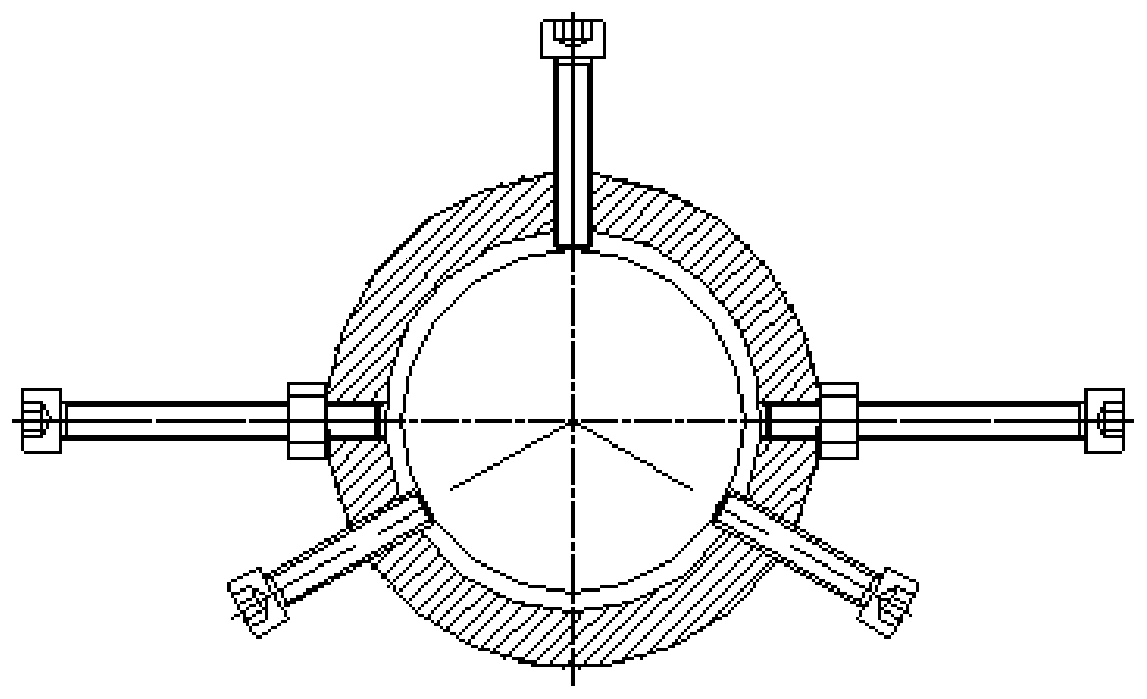

Method for repairing spindle taper hole through autogenous grinding device

ActiveCN110712074AEnsure repair accuracyAvoid excessive grindingGrinding carriagesRevolution surface grinding machinesNumerical controlTransmission belt

The invention discloses a method for repairing a spindle taper hole through an autogenous grinding device, and belongs to the technical field of machine tool maintaining. The method is mainly used forrepairing work of benchmark losses caused by serious numerical control machine tool spindle taper hole damage. The method is suitable for maintaining of the benchmark losses caused by numerical control machine tool spindle taper hole damage. The structure is simple, stability is good, through machine tool feeding, precise control over each time of grinding amount can be achieved, excessive grinding of the spindle taper hole can be avoided, the maintaining cost is greatly reduced, and the spindle taper hole repairing quality is improved. A base, a guide rail bottom plate, a bearing, a rotationshaft, a guide rail, a feeding drag plate, a screw, a screw support and a hand wheel are included, the motor drives a driving belt wheel to rotate, a transmission belt winds around the driving belt wheel and a driven belt wheel, the hand wheel drives the screw to rotate, the guide rail and the feeding drag plate have a fit structure, and relatively axially move, and the method comprises the stepsof using of an autogenous grinder, machine tool precision detection and grinding wheel grinding path performing.

Owner:INNER MONGOLIA FIRST MACHINERY GRP +1

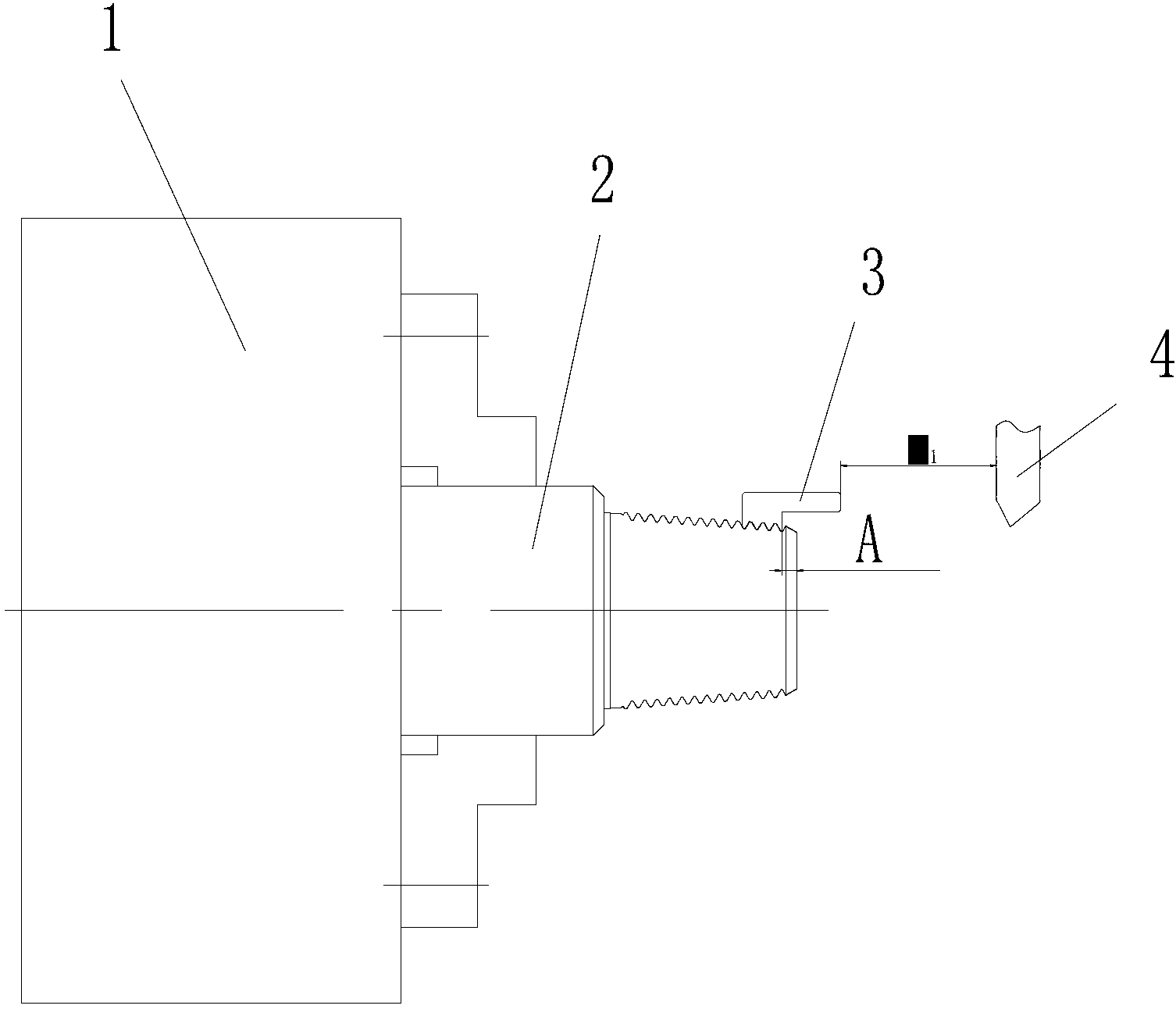

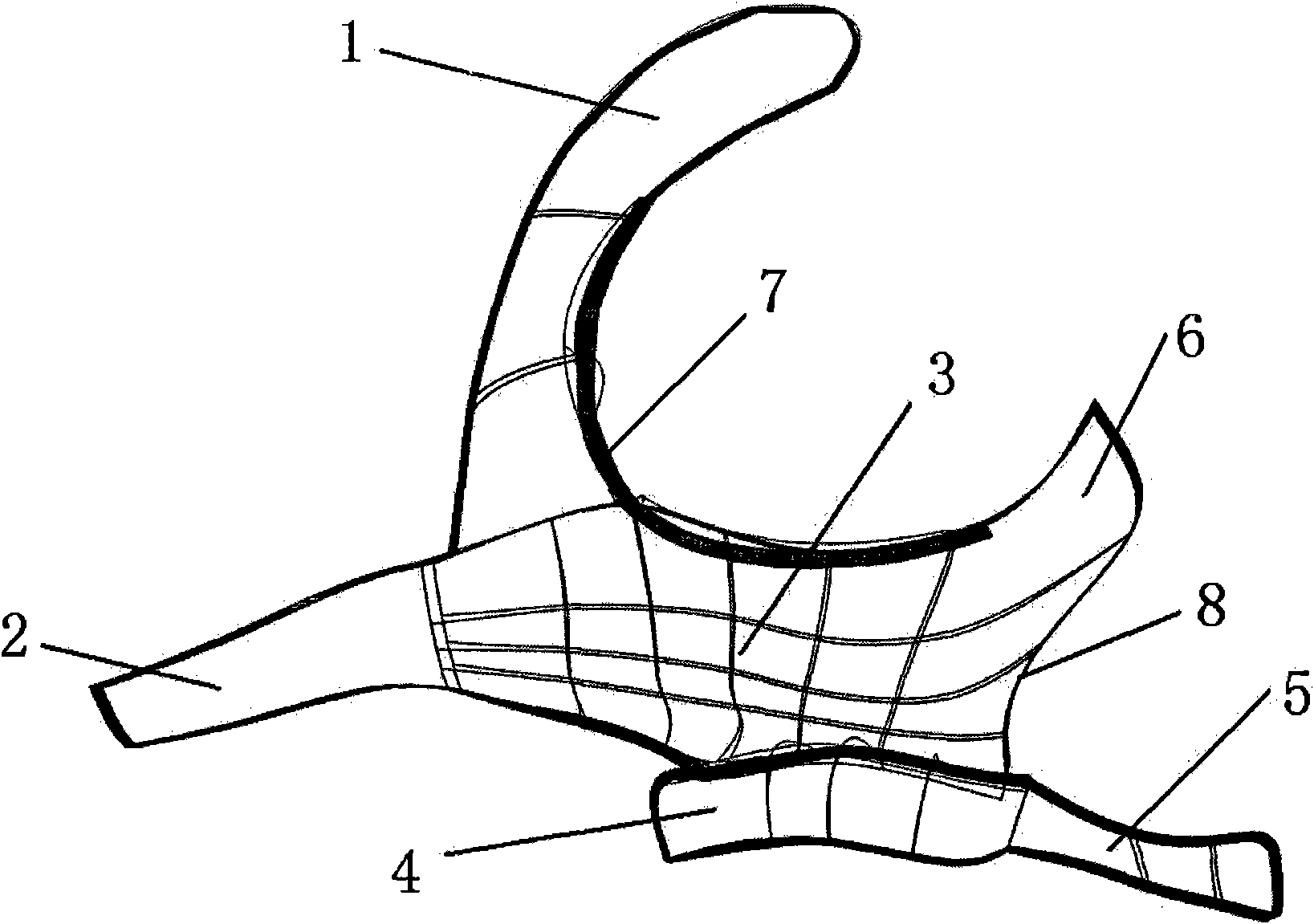

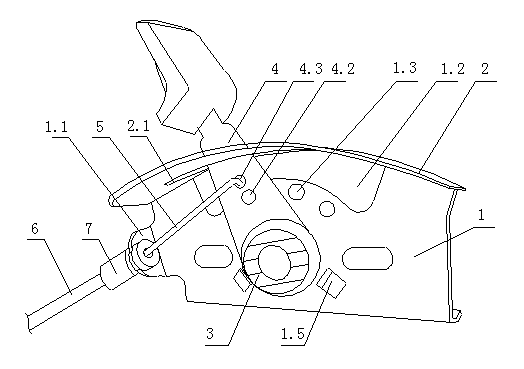

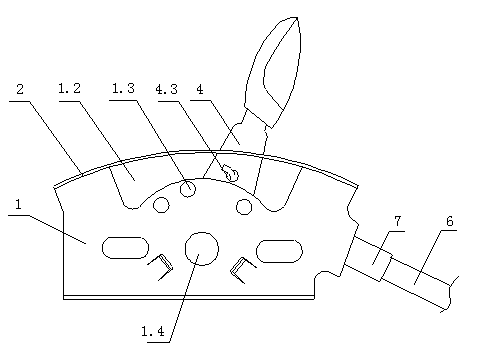

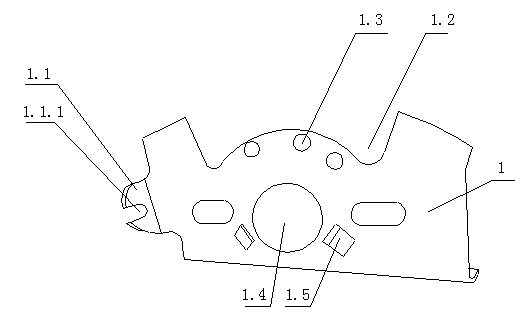

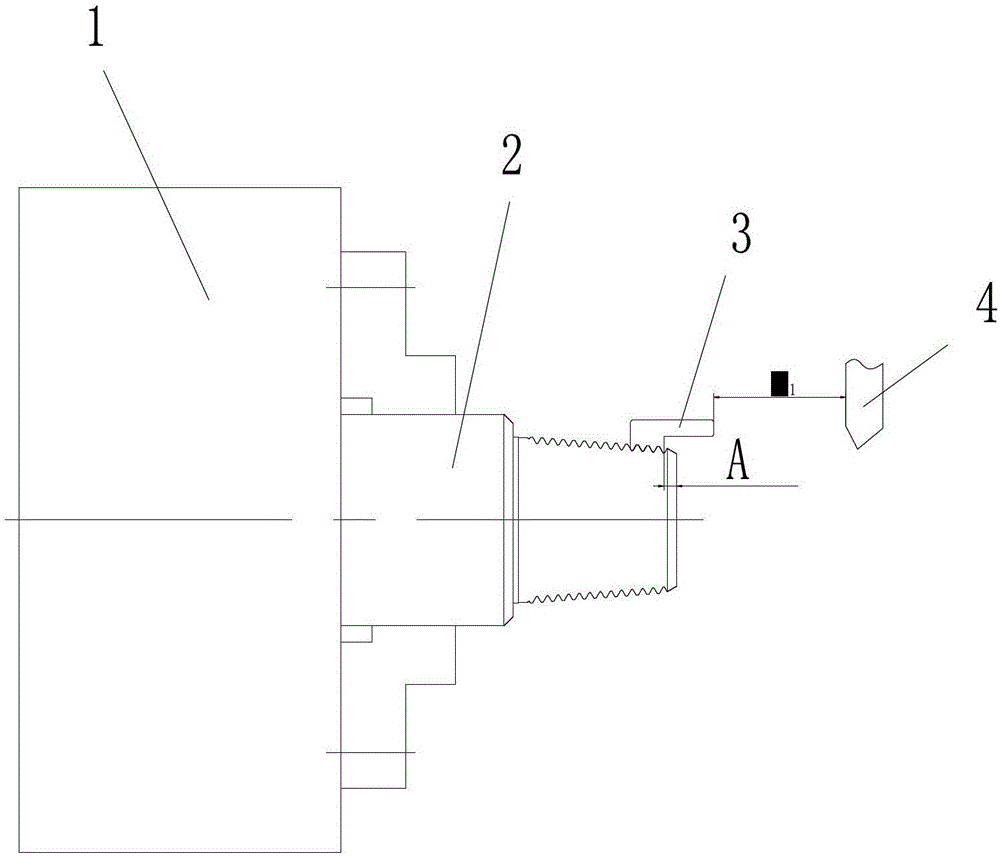

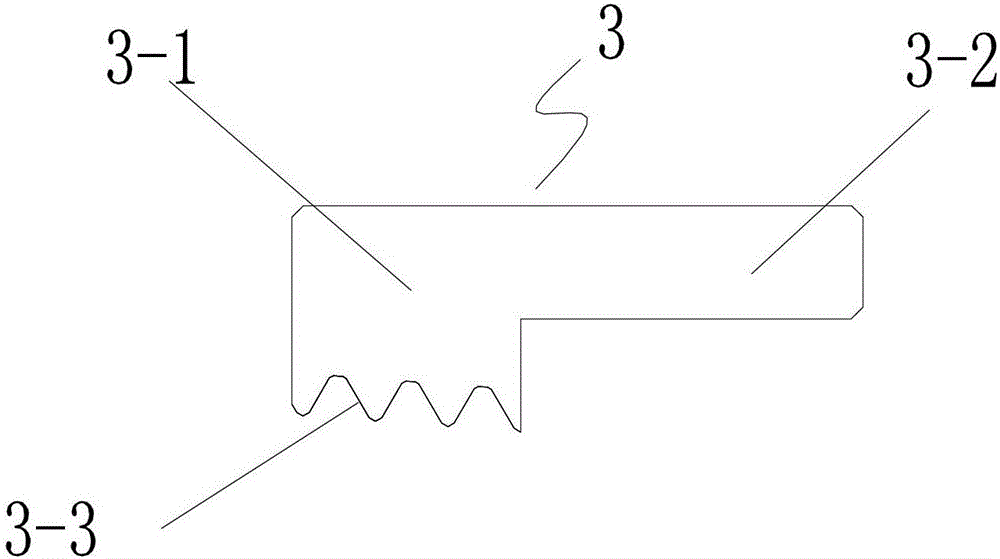

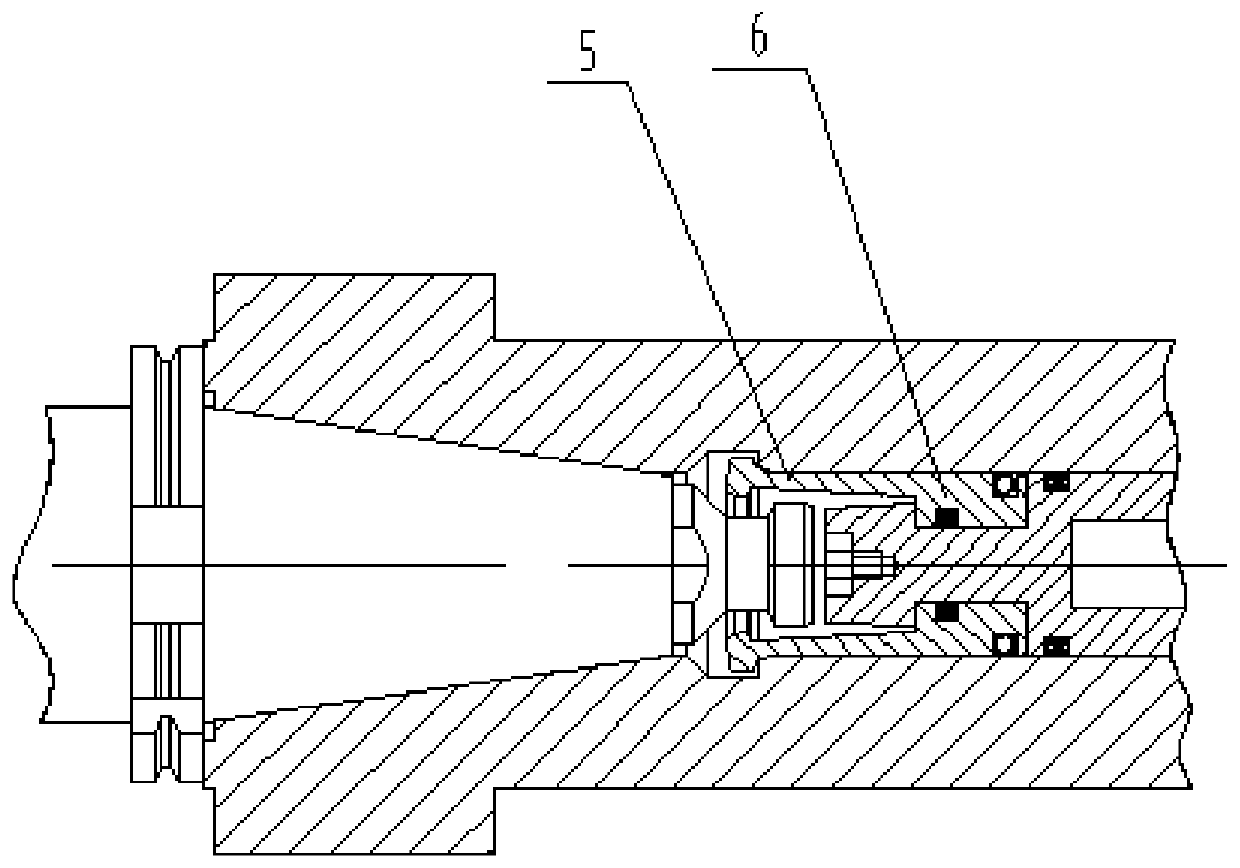

Control cable component for gear adjustable mower

InactiveCN102840038ANot easy to wear or corrodeNot easy to jump gearHarvestersEngine controllersMowerWrench

The invention relates to a control cable component for a gear adjustable mower, and belongs to the technical field of agricultural machinery. The control cable component for the gear adjustable mower is characterized by comprising a support (1), a top cover (2), a pin shaft (3), a wrench (4), a control cable (5), a steel wire protective pipe (6) and a sleeve head (7). The control cable component for the gear adjustable mower has the advantages as follows: as a fixed through hole is formed in the support and the fixed through hole is matched with a projection on the wrench to adjust the gear of an accelerator, the projection and the fixed through hole are very tightly matched with each other, so that the gear of the mower is uneasy to skip during vibratory working; the accelerator gear can be adjusted, and different accelerator sizes can meet requirements for trimming lawns of different types; and as a sleeve skin is arranged on the steel wire protective pipe, uneasiness for the steel wire protective pipe to be worn or corroded in the working process is guaranteed.

Owner:李士清

Remediation and restoration device for full-automatic efficient soil remediation

InactiveCN107409519AReasonable structureInnovative designSoil lifting machinesHydraulic cylinderRestoration device

The invention discloses a full-automatic high-efficiency soil treatment repairing and restoring device, which comprises a support seat, a device body is connected to the middle part of the upper end of the support seat, the left end of the device body is a repairing liquid chamber, and a liquid inlet pipe is arranged inside the repairing liquid chamber, and the liquid inlet pipe The upper end is connected with a suction pump, the upper end of the suction pump is connected with a two-way valve, the left end of the two-way valve is connected with a repair tube, the end of the repair tube is connected with a flushing plate, the upper end of the two-way valve is connected with a suction tube, and the middle of the device body is provided with a pushing chamber. The left end of the push chamber is equipped with an electric telescopic cylinder, the right end of the electric telescopic cylinder is connected with an electric telescopic rod, the right end of the electric telescopic rod is connected with a push plate, the right end of the device body is provided with a filter chamber, and the upper end of the pressure chamber is connected with a filter plate. A filter press shaft is connected to the upper end of the filter press plate, a filter press hydraulic cylinder is connected to the upper end of the filter press shaft, and a filter plate is arranged in the bottom middle of the filter press chamber. The invention realizes the continuous and fully automatic restoration of the soil, and at the same time realizes the restoration of the soil after restoration, and has strong practicability.

Owner:李小婷

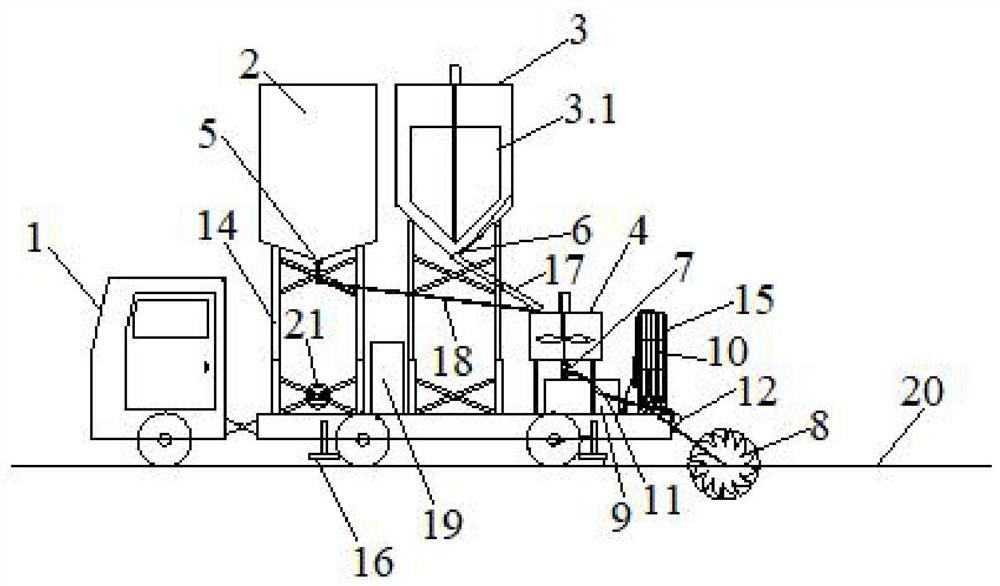

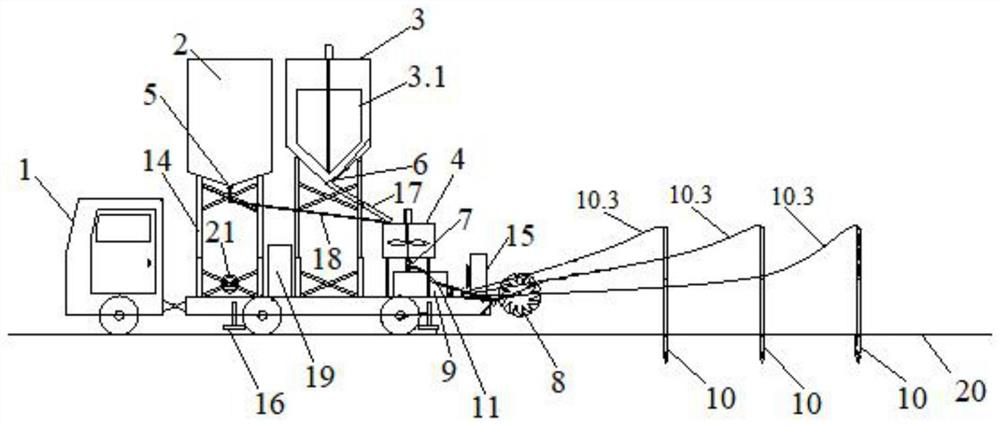

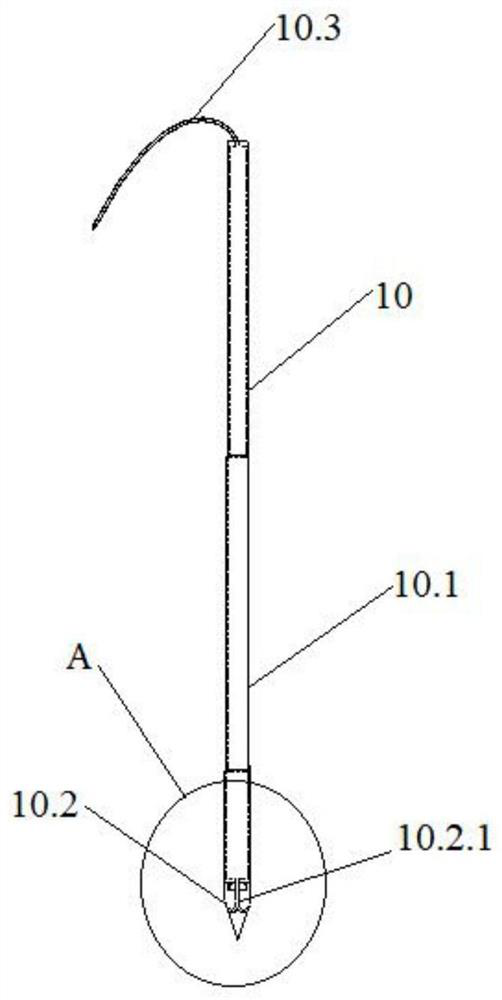

An integrated device for soil in situ remediation

ActiveCN113020240BGood restorativeAvoid wastingContaminated soil reclamationSoil scienceIn situ remediation

The invention provides an integrated device for soil in-situ restoration, which includes a moving mechanism, a shallow soil restoration unit, a deep soil restoration unit, and a liquid medicament silo, a solid medicament powder silo, and a medicament mixing unit arranged on the moving mechanism. Mechanism and power control assembly; the liquid medicament silo communicates with the medicament mixing mechanism, and the solid medicament powder silo communicates with the medicament mixing mechanism; the shallow soil remediation unit includes a soil turning component and a medicament splitting spray assembly; the deep soil remediation The unit includes a booster pump and a plurality of spin medicament injection needles, the spin medicament injection needles include a spin spray head, and the spin spray head includes an even number of nozzles, for the projection of any two opposing nozzles on a vertical plane It is W-shaped, and the projection on the horizontal plane is S-shaped. The invention can realize integrated restoration of shallow soil and deep soil and improves restoration efficiency.

Owner:中铝环保生态技术(湖南)有限公司

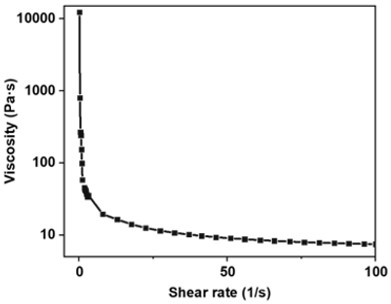

Adhesive filler for splicing light porous composite material and preparation method of adhesive filler

ActiveCN112300748ASatisfy assembly glueMeet Gap FillingNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberPtru catalyst

The invention provides an adhesive filler for splicing a light porous composite material and a preparation method of the adhesive filler. The adhesive filler is obtained by the following steps: weighing 100 parts by mass of hydroxyl-terminated polysiloxane, and putting the hydroxyl-terminated polysiloxane into a mixing container; weighing 0-30 parts by mass of white carbon black, 10-40 parts by mass of chopped fibers, 10-50 parts by mass of hollow spheres, 5-15 parts by mass of an antioxidant filler and 0-30 parts by mass of a diluent, putting the above weighed materials into the mixing container, and conducting physical stirring and mixing at room temperature; and weighing 3-10 parts by mass of a cross-linking agent and 0.5-2 parts by mass of a catalyst, adding the cross-linking agent andthe catalyst into the mixed material, and continuously conducting stirring to be used for splicing the light porous composite material. The adhesive filler has good chemical and physical adaptabilitywith a low-density composite material matrix, and meanwhile, has the characteristics of high-temperature ablation resistance, oxidation resistance, high-temperature sealing, low density and low thermal conductivity, and meets the requirements of splicing, bonding, gap filling and repairing of the light porous composite material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Repair method of oil drill pipe thread

ActiveCN103231200BImprove processing efficiencyMaster quicklyAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention relates to a repairing method of the threads of an oil drill pipe. The method comprises determining a thread start, carrying out automatic repair according to the thread start through a thread processing program, revising the thread repairing amount; and numerically controlling the thread repairing. Particularly, the method comprises the following steps: mounting a drill pipe joint to be repaired on a numerical control machine tool, utilizing a thread start searcher to determine the thread start Z1; inputting the thread start Z1 into a parameter #500, and the machine tool programs a special processing macroprogram to automatically compute out the start position of the threads; and setting a repairing amount #502 according to the actual damage amount of the drill pipe. By setting the parameters above, a thread cutter can be guaranteed to perform the repairing processing along the track of the original threads. Compared with a traditional thread repairing method, the repairing method of the threads of the oil drill pipe has the advantage that only a simple thread start searcher is required. An operator of an ordinary technical level can master the operation of the method within a short time. And due to the utilization of the numerical control machine tool, the processing efficiency is high, the quality is stable and no positioning is needed.

Owner:TIANJIN DEHUA GASOLINEEUM EQUIP MFG

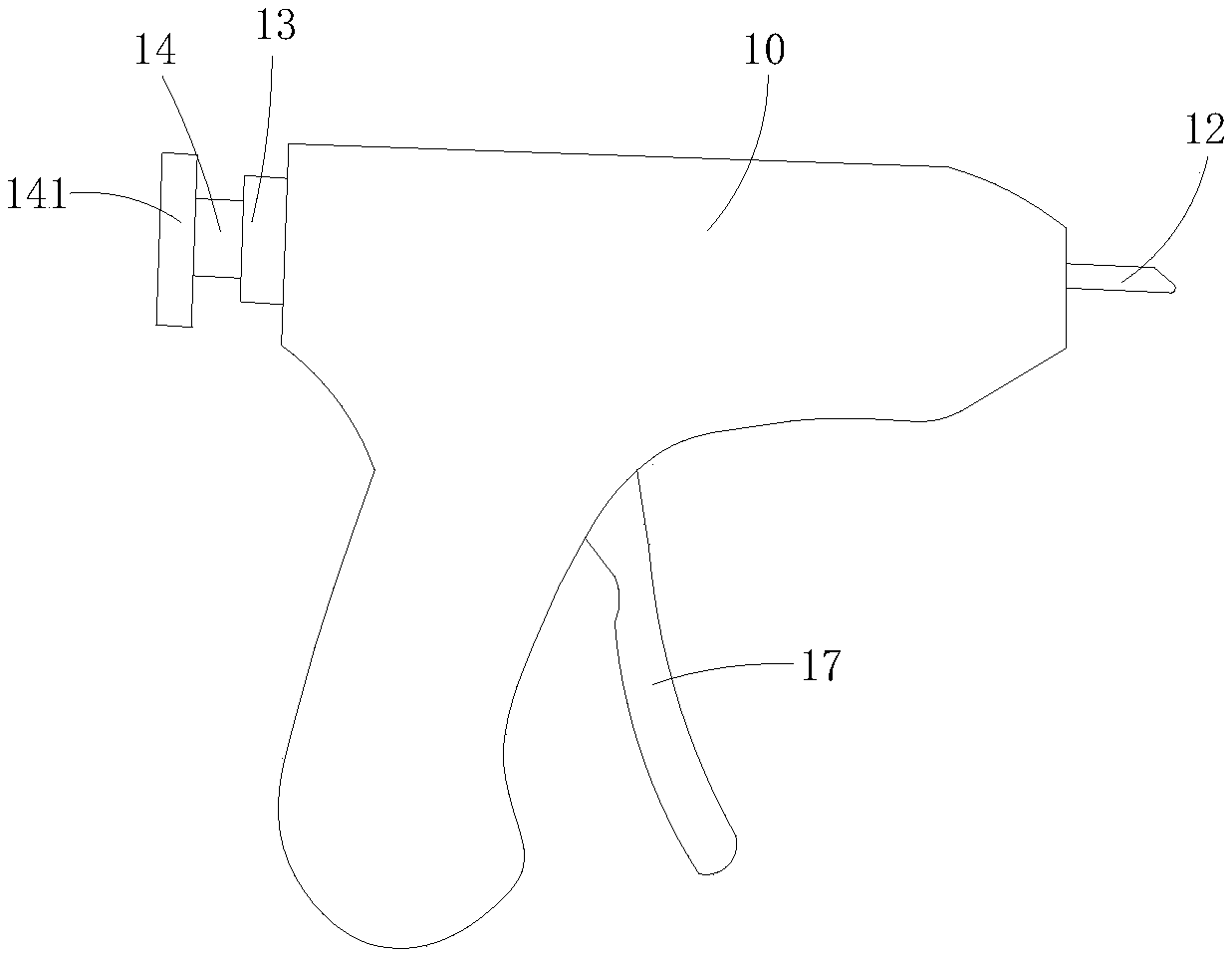

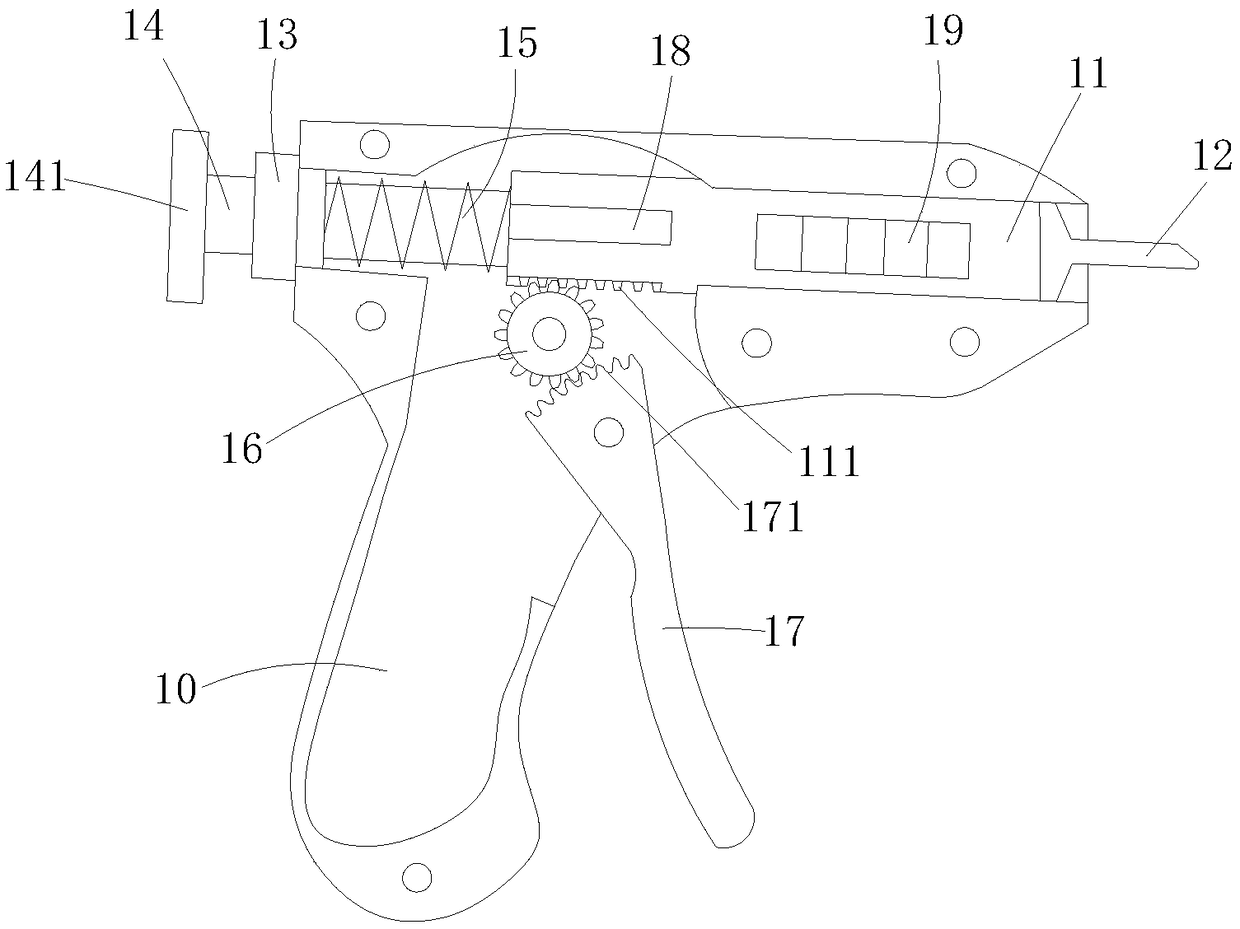

Dismantling-free tire repair gun for automobile vacuum tire

The invention discloses a dismantling-free tire repair gun for an automobile vacuum tire. The dismantling-free tire repair gun comprises a gun body and a gun tube; the gun tube is arranged in the gunbody; a limiting end face for limiting the gun tube from sliding out is arranged in the gun body; the dismantling-free tire repair gun further comprises a glue injection needle tube, a positioning screw cap, a push rod, a return spring, a gear and a trigger; a discharge cavity is formed in the gun tube; the glue injection needle tube is screwed to the end part of the gun tube; the push rod is inserted into the gun tube; the positioning screw cap is screwed with the gun body; an external thread of the push rod is screwed with an internal thread of the positioning screw cap; the front end part of the push rod has a push block; the return spring is inserted outside the push rod; one end of the return spring resists against the end face of the gun tube, and the other end of the return spring resists against the positioning screw cap; the trigger is pivoted onto the gun body through a pin shaft, and the end part of the trigger has a driving toothed rack; a gear is pivoted into the gun body;a driven toothed rack is arranged on the gun tube; one side of the gear meshes with the driving toothed rack, and the other side of the gear meshes with the driven toothed rack. The dismantling-freetire repair gun disclosed by the invention has the advantages that the tire is not required to be dismantled, and the tire repair gun is convenient and labor-saving and cannot cause secondary damage to the tire.

Owner:梅胜旺

An adjustable experimental device for microwave thermal regeneration of asphalt pavement

ActiveCN105544369BSolve the problem of not heating to the expected temperatureSolve correlation problemsRoads maintainenceMicrowaveEngineering

The invention discloses an adjustable bituminous pavement microwave heat regeneration test device which comprises a bearing device and an outer framework connected with the bearing device. The bearing device is provided with a microwave heating device and at least one transverse and longitudinal movement adjusting device used for adjusting the microwave heating device to transversely and longitudinal move in the plane where the bearing device is located. The microwave heating device can be adjusted in the transverse and longitudinal directions, the height of the microwave heating device can be adjusted, the device can adapt to damaged bituminous pavements of different heating areas, different heights and irregular heights, and repair requirements in actual life are met. The regeneration test device is simple in structure, complete in function and convenient to operate.

Owner:ANHUI POLYTECHNIC UNIV

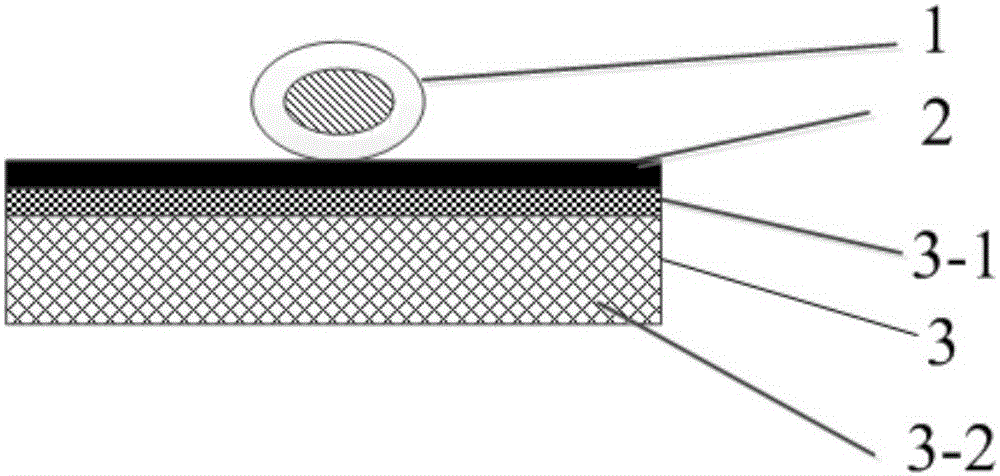

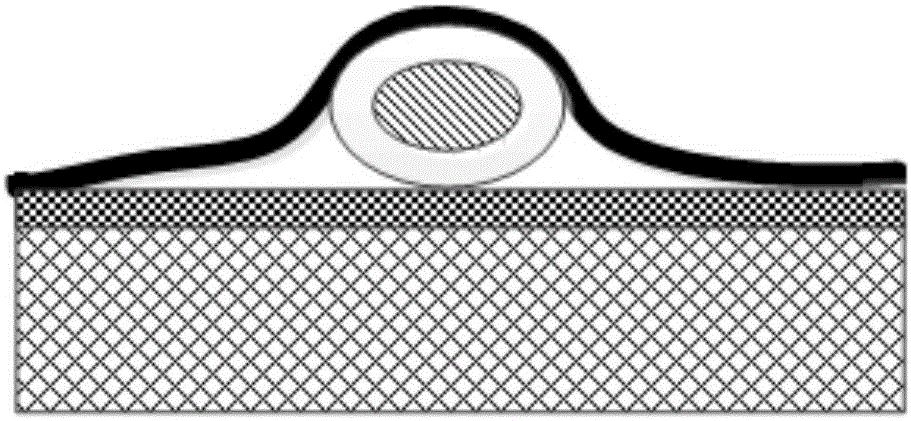

Preparation method of integrated fiber post core for oral cavity

PendingCN113367813AReduce dental restoration costsMeet repair needsAdditive manufacturing apparatusTooth crownsMilling cutterResin matrix

The invention relates to a preparation method of an integrated fiber post core for an oral cavity. The preparation method comprises preparation of short quartz fibers, preparation of a light-cured resin matrix and preparation of a light-cured resin matrix and short quartz fiber suspension, and further comprises the following steps: 1) obtaining three-dimensional data; 2) designing a personalized integrated fiber post core in an emulated manner; 3) making a 3D-print emulated post core file; and 4) manufacturing the personalized integrated fiber post core. According to the method, the personalized integrated fiber post core with high degree of adaptation with a shape of a root canal can be quickly and accurately obtained, a resin adhesive layer is thin and uniform after adhesion, the adhesion area and micro leakage are effectively reduced, the long-term stability of repair is improved, and the requirements on oral cavity repair are better met. Compared with a CAD / CAM (computer-aided design / computer-aided manufacturing) method for manufacturing the integrated fiber post core, the method has the advantages that the precision is high, the adaptation degree is high, the loss of a milling cutter is avoided, raw materials are only mixed for later use during preparation, the corresponding consumption of the raw materials can be adjusted as required, a large number of raw materials are saved, and the oral repair cost of a patient is remarkably reduced.

Owner:华中科技大学协和深圳医院

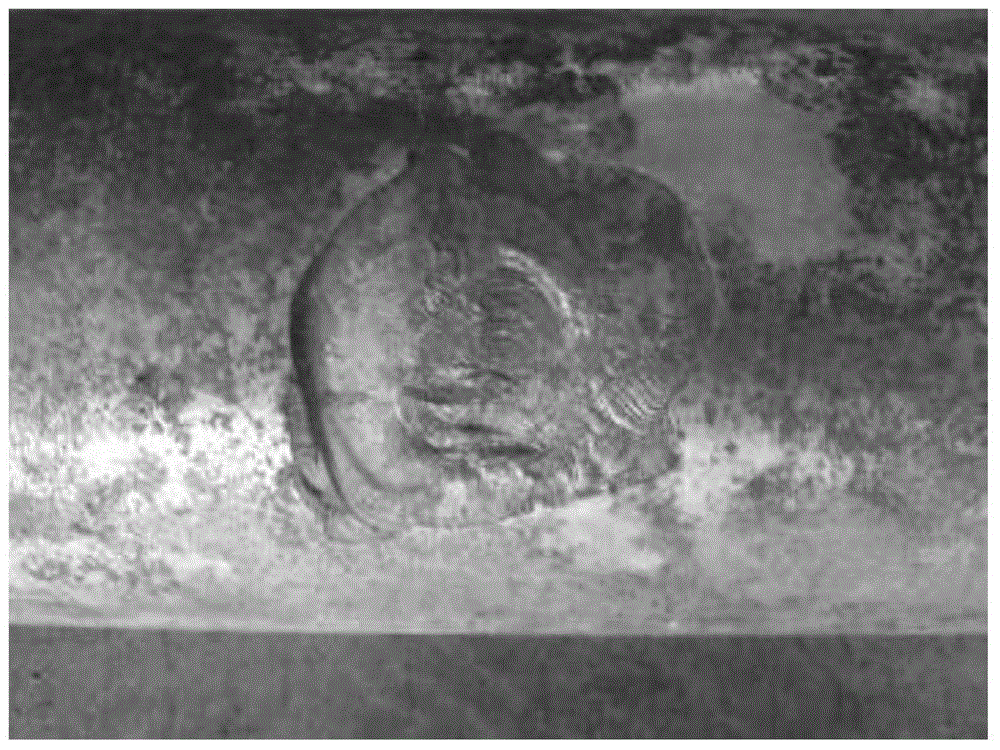

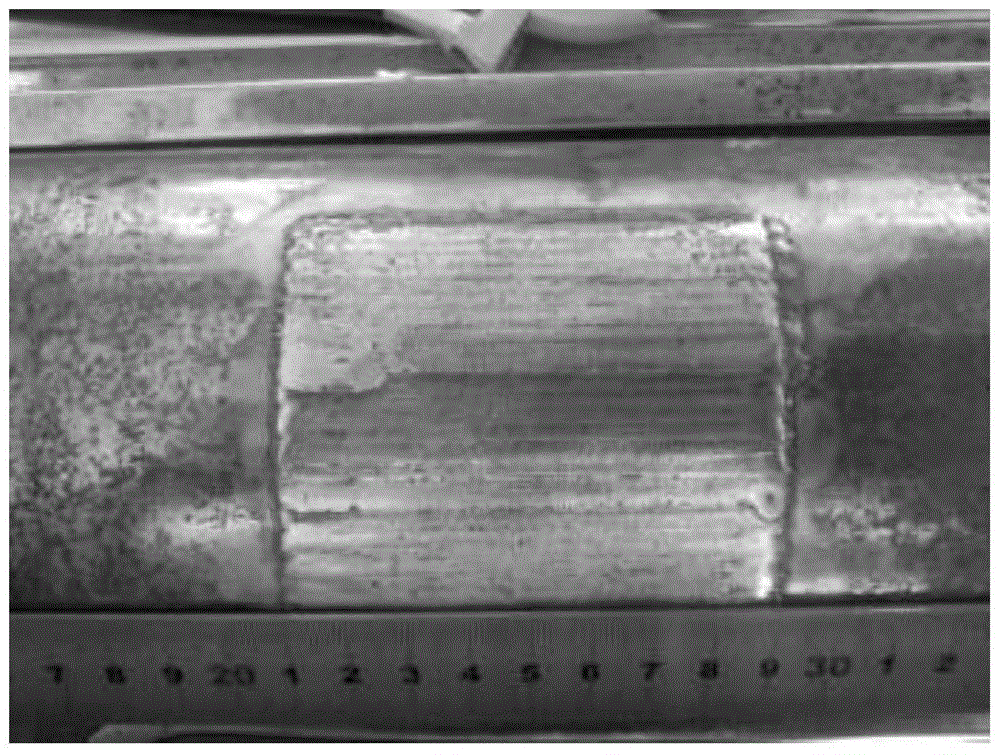

A surfacing flux-cored wire for hot forging die repair

InactiveCN103862194BImprove crack resistanceNo crackArc welding apparatusWelding/cutting media/materialsCrack resistanceHigh carbon

The invention discloses a surfacing flux-cored wire used for repairing a hot-forging die and belongs to the technical field of welding materials. Flux-cored powder is wrapped by adopting a carbon steel belt, and comprises the following substances in mass percentage content: 2-6 percent of sodium fluoride, 5-8 percent of calcium fluoride, 3-5.5 percent of rutile, 1-5 percent of quartz, 4.3-13.2 percent of high-carbon ferrochrome, 24.8-38.3 percent of pure chromium powder, 6-11.3 percent of nickel powder, 1.5-3.5 percent of Fe-W powder, 2.5-5.1 percent of electrolytic manganese, 14.7-27.3 percent of Fe-Mo powder, 3.6-6.1 percent of ferrosilicon powder, 0.2-1.4 percent of ferrovanadium powder and the balance of reduced iron powder. The filling rate of the flux-cored wire is 20-35 percent. Compared with traditional materials, the surfacing flux-cored wire disclosed by the invention has the advantages that (1) the thermal stability and the thermal fatigue resistance are very good, and the hardness range is 48-52HRC; (2) surfacing metal is high in crack resistance, so that preheating before welding or immediate heat treatment after welding is not needed; (3) the surfacing manufacturability is good, and the appearance of a weld is attractive.

Owner:BEIJING UNIV OF TECH

A method for repairing the inner taper hole of the main shaft of the machining center

ActiveCN106695241BSolve the positioning accuracyImprove restoration qualityPolishingStructural engineering

Owner:CHINA FIRST AUTOMOBILE

Integral repair stent of eye sockets, cheekbones and maxillary bone and manufacturing method thereof

The invention relates to an integral repair stent of eye sockets, cheekbones and a maxillary bone and a manufacturing method thereof, and the integral repair stent can meet the repair needs when the eye sockets, the cheekbones and the maxillary bone all have defects. The integral repair stent is characterized in that the integral repair stent comprises a stent body which combines the shapes of the eye sockets, the shapes of the cheekbones and the shape of the maxillary bone, the stent body comprises a cheekbone repair area, a temporal arcade repair area of the cheekbones is extended from the left side of the cheekbone repair area, the right side of the cheekbone repair area is a piriform aperture shape repair area and is extended for forming a piriform aperture connecting area, a plantingtrough is distributed at the bottom of the cheekbone repair area, a piriform aperture bottom fixing area is extended from the right side of the planting trough, an eye socket outer edge repair area is upward extended from an eye socket shape repair area arranged at the upper edge of the cheekbone repair area; and the eye socket outer edge repair area, the piriform aperture bottom fixing area, thepiriform aperture connecting area and the temporal arcade repair area of the cheekbones all have sunk hole array structures.

Owner:北京吉马飞科技发展有限公司

Novel structure and machining technique of capillary pipe mesh grating

PendingCN107218834AGuaranteed patencyHigh strengthHeat exchanger fasteningTubular elementsButt weldingCapillary Tubing

The invention discloses a novel structure of a capillary pipe mesh grating. The novel structure of the capillary pipe mesh grating comprises a plurality of capillary pipes and main pipes, wherein the main pipes are arranged oppositely so as to connect the capillary pipes into the capillary pipe mesh grating; and connecting parts matched with the capillary pipes are arranged on the main pipes correspondingly and connected with the capillary pipes through first metal hollow pipes, and thus a capillary pipe mesh grating body is formed. According to the novel structure of the capillary pipe mesh grating, the connecting parts provided with branch structures are arranged on the prefabricated main pipes and combined with the capillary pipes through the first metal hollow pipes, so that an existing socket welding way is converted into a butt welding way; in addition, by additionally arranging the hollow pipes, it is ensured that a water flow channel is unblocked after welding, and the strength of the welded parts of the capillary pipes is improved to a certain extent through the hollow pipes; and the welding process can be completed through small equipment. The invention further provides a machining method of the capillary pipe mesh grating.

Owner:膜纳柯工业科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com