Repair method of oil drill pipe thread

A technology of oil drill pipe and repair method, applied in the field of mechanical processing, can solve the problems of low processing efficiency, material waste, unstable processing accuracy, etc., and achieve the effect of high processing efficiency, low investment and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

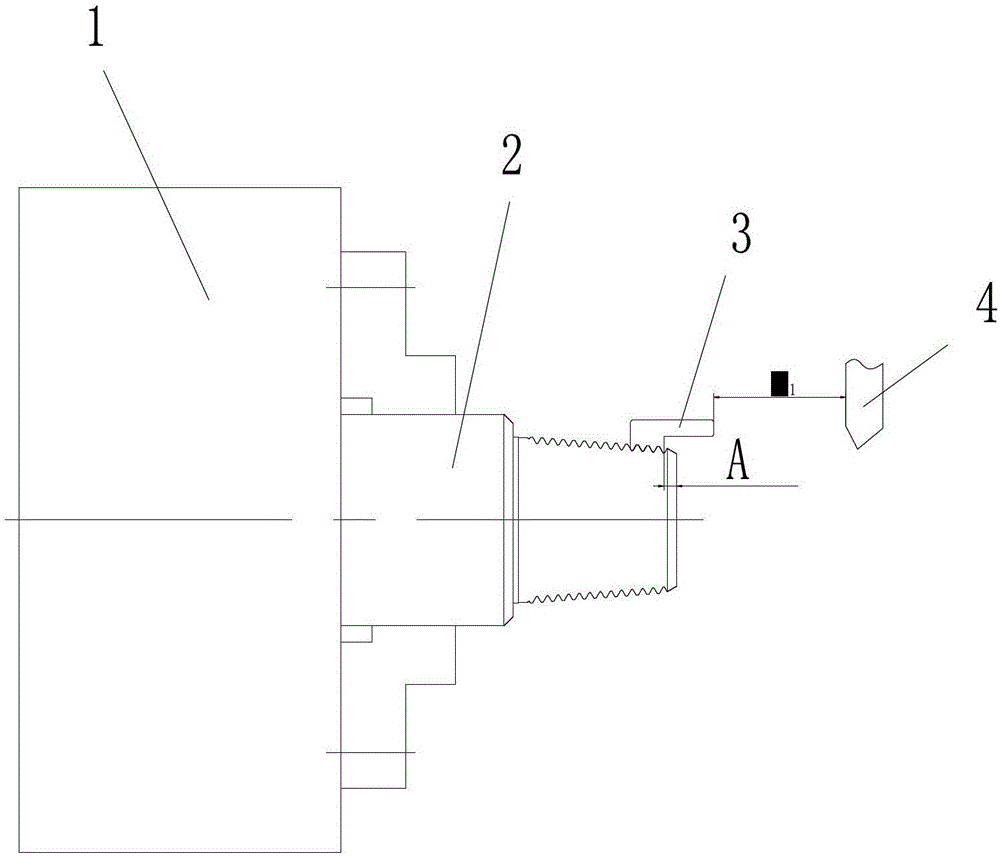

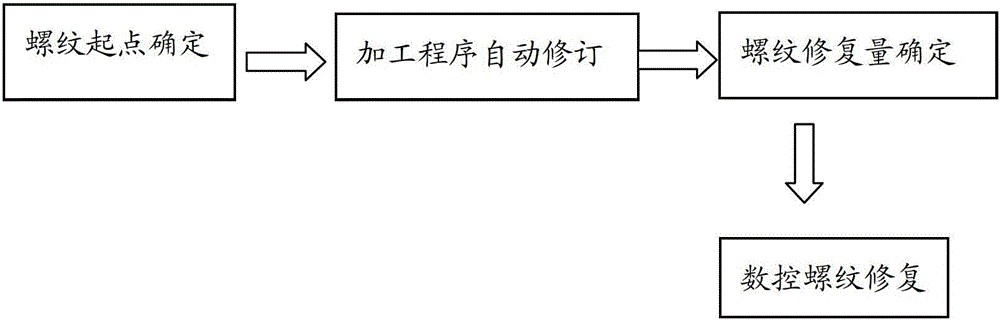

[0046] See the accompanying drawings for details of the embodiment, a method for repairing the thread of an oil drill pipe, the thread starting point is determined, the thread processing program is automatically revised according to the thread starting point, the thread repair amount is revised, and the numerical control thread is repaired. The specific steps are as follows:

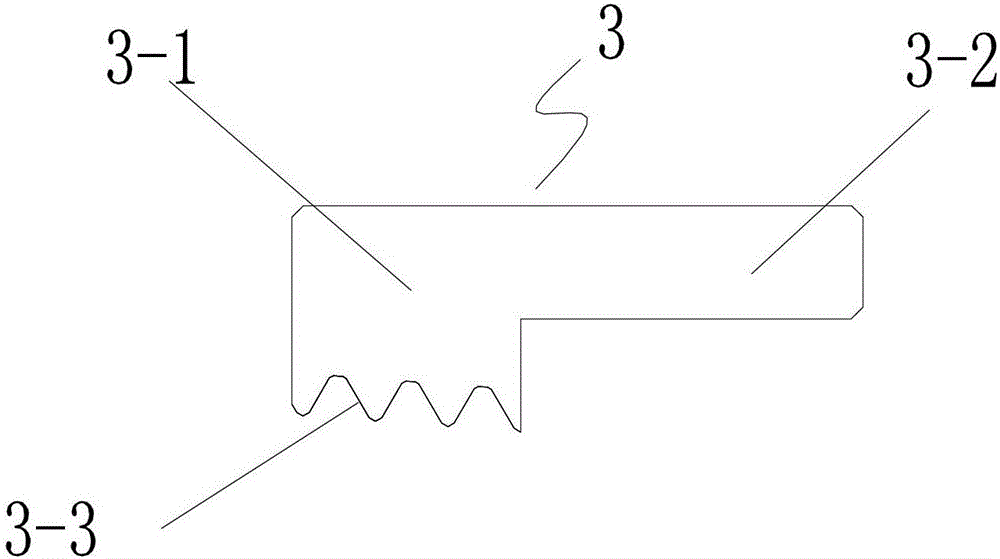

[0047] (1) Fix the drill pipe joint 2 to be repaired on the CNC lathe 1, and use the thread starting point finder 3 to determine the thread starting point Z1 of the drill pipe joint;

[0048] (2) Input the thread starting point Z1 into parameter #500, and the machine tool will compile a special machining macro program according to this repair method to automatically calculate the starting point of the thread;

[0049] (3) Set the repair amount A (#502) according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com