Surfacing flux-cored wire used for repairing hot-forging die

A technology of hot forging dies and flux-cored wires, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as insufficient crack resistance, achieve stable arc, small spatter, and meet repair needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

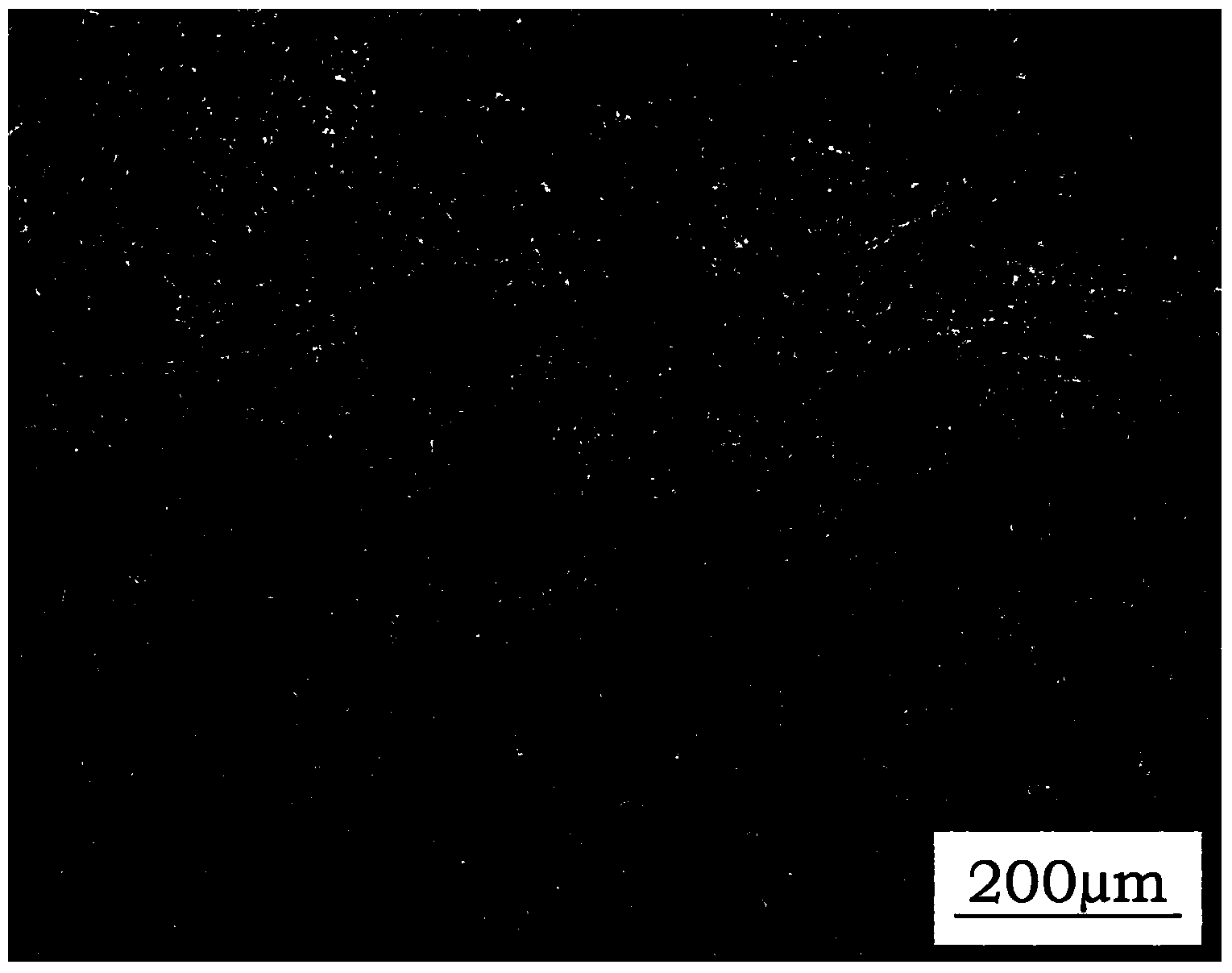

Image

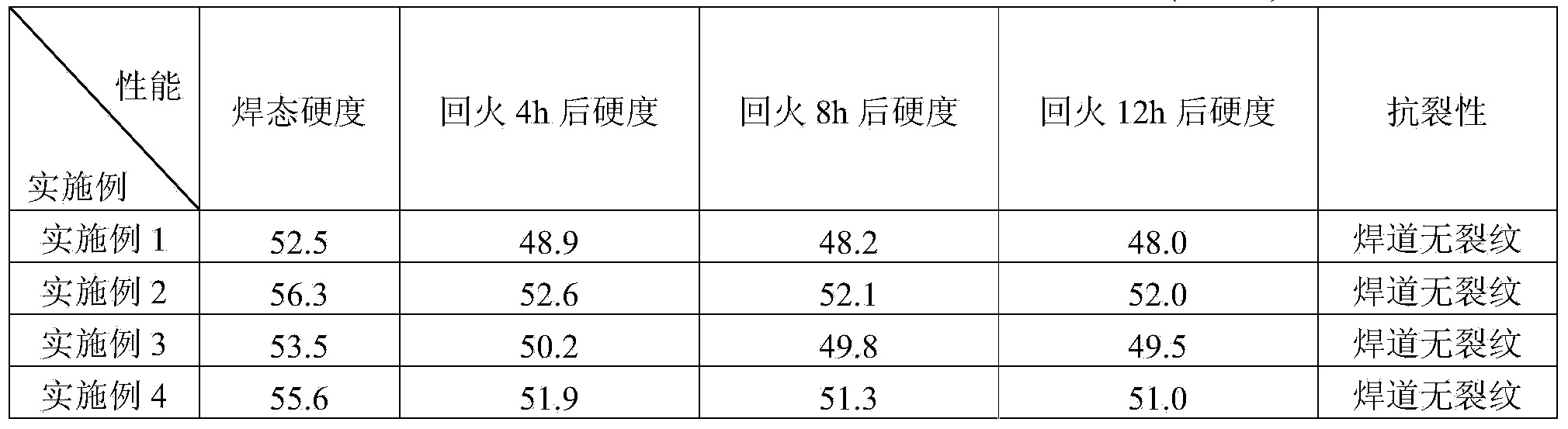

Examples

Embodiment 1

[0042]Take 500g of sodium fluoride, 750g of calcium fluoride, 500g of rutile, 430g of quartz, 430g of high-carbon ferrochrome, 2480g of pure chromium powder, 600g of pure nickel powder, 150g of ferrotungsten powder, 510g of electrolytic manganese, 2730g of ferromolybdenum powder, and ferrosilicon powder 610g, vanadium iron powder 140g, reduced iron powder 170g. Add the obtained flux-cored powder into the U-shaped steel strip groove with a filling rate of 30%, close the U-shaped groove to obtain a surfacing flux-cored wire with a diameter of 2.4mm, and prepare the surfacing layer according to the above-mentioned process, and the obtained The alloy composition in the deposited metal is: C: 0.05wt.%; Cr: 8.5wt.%; Ni: 1wt.%; W: 0.2wt.%; Mn: 0.8wt.%; Mo: 4.3wt.%; : 0.6wt.%; V: 0.25wt.%; Fe: balance.

Embodiment 2

[0044] Take 200g of sodium fluoride, 550g of calcium fluoride, 350g of rutile, 100g of quartz, 1320g of high carbon ferrochrome, 3830g of pure chromium powder, 1130g of pure nickel powder, 350g of tungsten iron powder, 250g of electrolytic manganese, 1470g of molybdenum iron powder, ferrosilicon powder 360g, 20g of vanadium iron powder, 70g of reduced iron powder. Add the obtained flux-cored powder into the U-shaped steel strip groove with a filling rate of 30%, close the U-shaped groove to obtain a surfacing flux-cored wire with a diameter of 2.4mm, and prepare the surfacing layer according to the above-mentioned process, and the obtained The alloy composition in the deposited metal is: C: 0.25wt.%; Cr: 13.5wt.%; Ni: 2.6wt.%; W: 1.2wt.%; Mn: 0.45wt.%; Mo: 2.5wt.%; Si: 0.1wt.%; V: 0.05wt.%; Fe: balance.

Embodiment 3

[0046] Take 600g of sodium fluoride, 500g of calcium fluoride, 550g of rutile, 500g of quartz, 530g of high-carbon ferrochrome, 2580g of pure chromium powder, 650g of pure nickel powder, 200g of ferrotungsten powder, 460g of electrolytic manganese, 2630g of ferromolybdenum powder, and ferrosilicon powder 560g, vanadium iron powder 130g, reduced iron powder 110g. Add the obtained flux-cored powder into the U-shaped steel strip groove with a filling rate of 30%, close the U-shaped groove to obtain a surfacing flux-cored wire with a diameter of 2.4mm, and prepare the surfacing layer according to the above-mentioned process, and the obtained The alloy composition in the deposited metal is: C: 0.1wt.%; Cr: 9wt.%; Ni: 1.6wt.%; W: 0.3wt.%; Mn: 0.65wt.%; Mo: 4.1wt.%; : 0.5wt.%; V: 0.2wt.%; Fe: balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com