A method for preparing gradient coatings by laser cladding to repair cold rolls

A technology of laser cladding and gradient coating, which is applied in the direction of coating, metal material coating process, etc., can solve the problems of shedding, low bonding strength, high carbon content, etc., to meet the needs of repair, high comprehensive mechanical properties, tissue dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

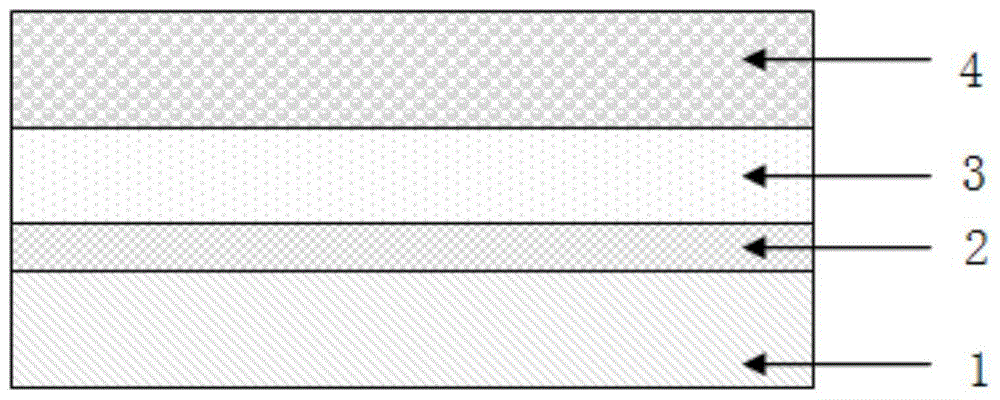

Method used

Image

Examples

Embodiment example 1

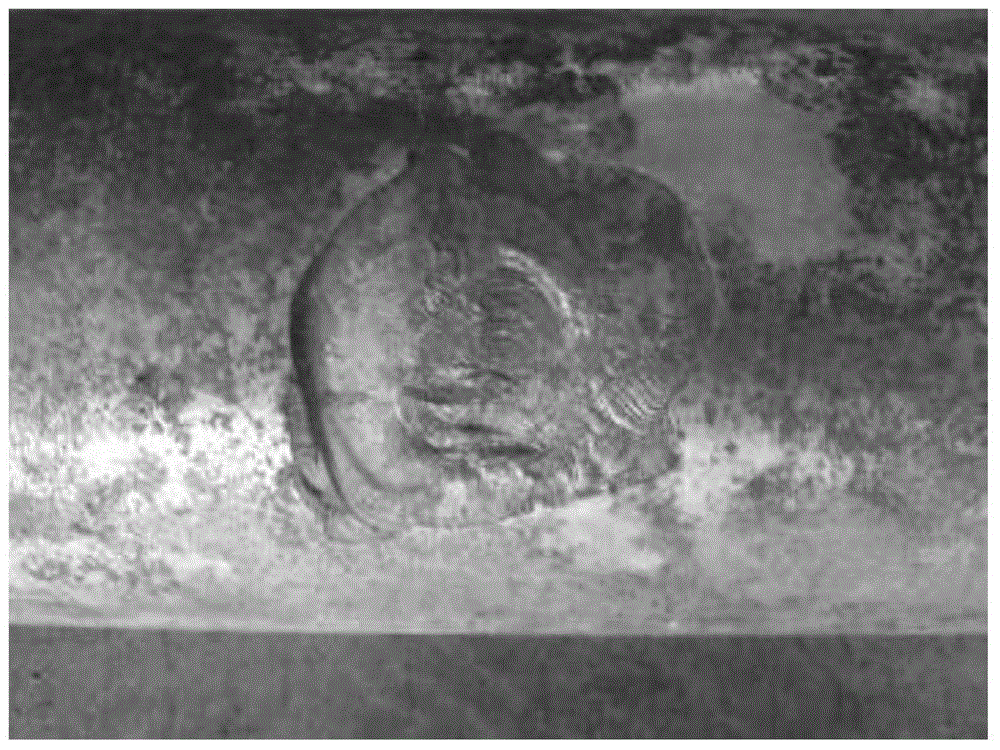

[0031] Implementation Case 1: Surface Repair of Steel Strip Cold Roll

[0032] The material of the roll is Cr12MoV alloy, which has fine grains, good hardenability, high hardness, strength and toughness after quenching and tempering, and small quenching deformation. It is widely used in the manufacture of cold rolls. The effect of repairing with traditional surfacing welding is poor, and the service life is less than 10 hours.

[0033] The technology of the present invention is implemented in this field, and the roll is repaired by laser cladding, and the implementation process is as follows:

[0034] (1) Grinding the area to be repaired of the steel strip cold roll, and then sandblasting to further roughen and purify the surface of the substrate;

[0035] (2) Prepare the first layer of solder powder, using pure gold powder, manganese powder, nickel powder, zinc powder, chromium powder, mixed according to mass ratio 55.0:12.0:8.0:24.0:1.0, mixed by ball mill for 50 minutes, a...

Embodiment 2

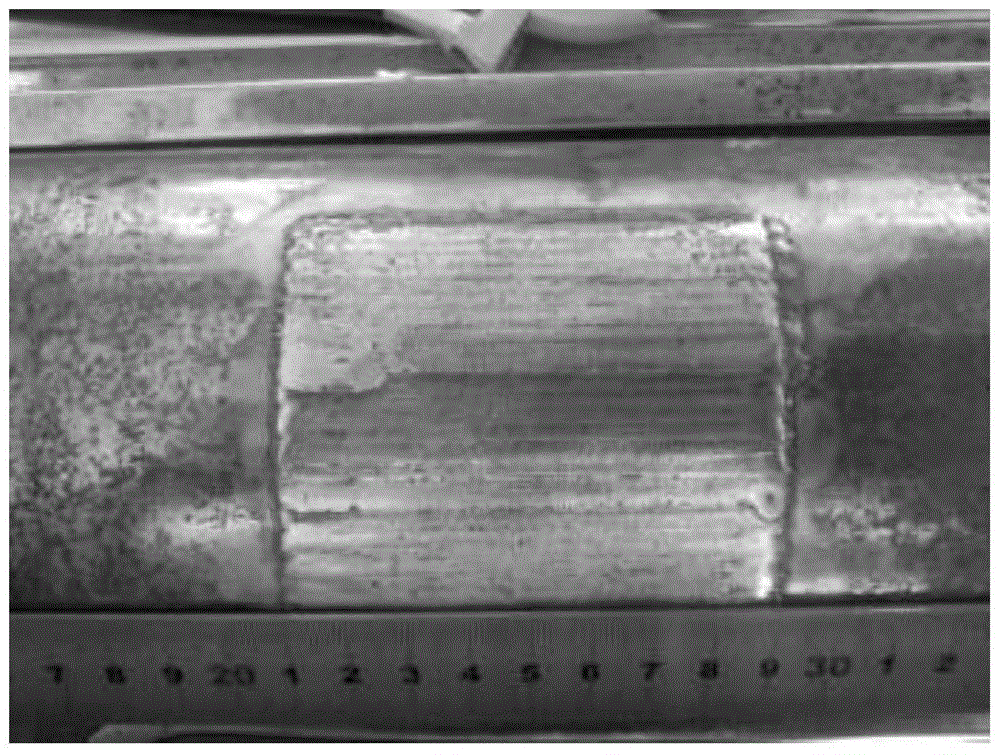

[0042] Embodiment 2: Preparation of cladding layer on the surface of wire roll

[0043] The material of the roll is H13 alloy. This steel has high hardenability and thermal cracking resistance, good wear resistance, relatively weakened toughness, good heat resistance, and excellent comprehensive mechanical properties at higher temperatures. performance and high stability against tempering. It can be used in the manufacture of cold rolls, and the service life after surfacing welding is only 3 to 5 hours. Utilize the technology of the present invention to carry out laser cladding repair to this roll, the implementation process is as follows:

[0044] (1) Grinding the area of the wire roll to be repaired, and then sandblasting to further roughen and purify the surface of the substrate;

[0045] (2) Prepare the first layer of solder powder, using pure gold powder, manganese powder, nickel powder, zinc powder, chromium powder, mixed according to mass ratio 55.0:12.0:8.0:24.0:1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com