Graphene conductive ink and preparation method thereof

A technology of conductive ink and graphene, which is applied in ink, household utensils, applications, etc., can solve the problems of non-conductivity, easy sedimentation, poor conductivity, etc., and achieve flexibility, resistance to bending, strong adhesion, and excellent physical properties. The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

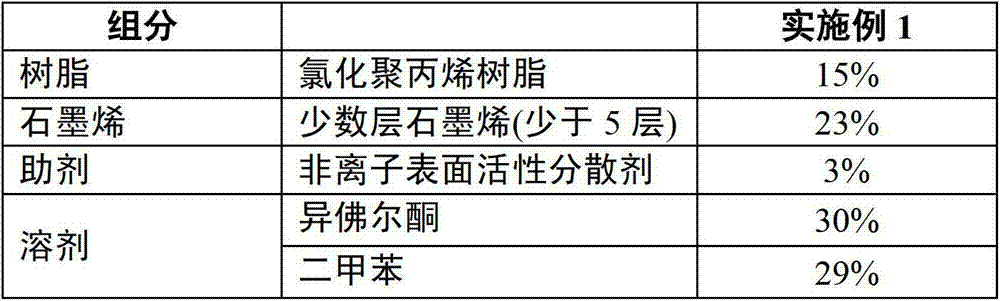

[0042] According to the following table, put the resin and solvent in the dispersion tank, keep the temperature below 40°C, and stir at 500rpm to completely dissolve the resin to obtain a resin solution.

[0043] Add graphene and additives to the resin solution, mix evenly, transfer to a sand mill, grind for 6 hours, and use a scraper fineness meter to test the fineness of the conductive ink until the fineness of the ink is less than 10 μm, that is, the graphene conductive ink is prepared.

[0044]

[0045] The graphene conductive ink prepared in Example 1 uses a small number of layers of graphene as a filler. Due to the two-layered structure of graphene, the threshold for forming a conductive path is low, and the resistivity is 0.36Ω·cm in the case of 23% filling. Chlorinated polypropylene resin with thermoplastic resin has strong adhesion to polypropylene and polyethylene, and has good adhesion to paper, PET and other materials; use isophorone and xylene as solvents to adj...

Embodiment 2

[0048] Disperse each component according to the preparation method described in Example 1 to obtain graphene conductive ink. The conductivity of the graphene conductive ink prepared in Example 2 reaches 0.021Ω·cm.

[0049] The conductive ink prepared in Example 2 reduces the cost due to the use of multi-layer graphene, and at the same time adds a polyurethane derivative wetting agent to improve the compatibility between the graphene and the resin.

Embodiment 3

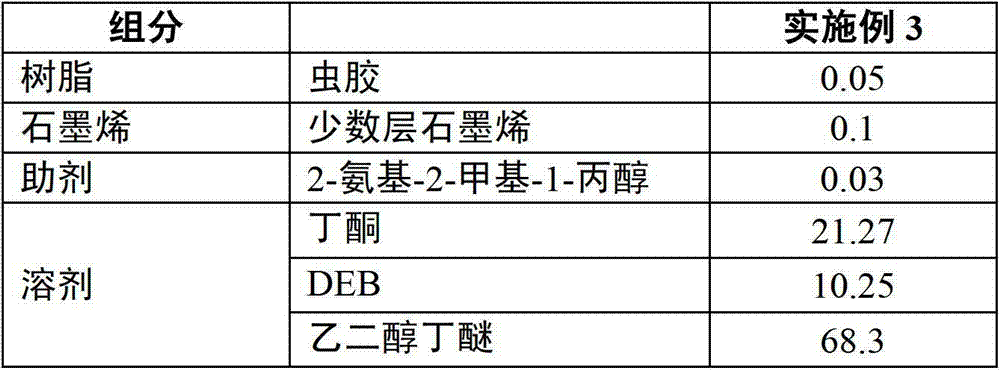

[0051]

[0052] Disperse each component according to the preparation method described in Example 1 to obtain graphene conductive ink.

[0053] The sheet resistance of the graphene conductive ink prepared in Example 3 is 29Ω·cm.

[0054] The graphene conductive ink prepared in embodiment 3 adopts shellac. 2-Amino-2-methyl-1-propanol adjusted the compatibility between graphene and solvent, and adjusted the relative content of graphene and solvent at the same time. The prepared ink is characterized by low solid content and low viscosity, suitable for For some special applications such as spraying, printing, spin coating, etc., it can be used to prepare some nanometer ultra-thin conductive films, thin film resistors, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com