Interior coating for can and preparation method of interior coating

A technology of coating and polyester, which is applied in the field of can coating coating and its preparation, which can solve the problems of general discount, difficult to cure film layer, time-consuming and laborious formulation design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, carry out the preparation of polyester:

[0032] Put 52kg of neopentyl glycol, 63kg of ethylene glycol, 112kg of terephthalic acid, 33kg of isophthalic acid, 21kg of sebacic acid, and 100g of tetrabutyl titanate into the reaction kettle. Replace the air with nitrogen, stir and raise the temperature to 220~240°C for reaction. The acid value is less than 30mg KOH / g as the end point. After the reaction is over, raise the temperature to 240~260°C, polycondensate and stir for 30 minutes under vacuum conditions, add 5kg of trimellitic anhydride, continue stirring, and after reaching the predetermined viscosity, fill it with nitrogen to eliminate the vacuum, and extrude Discharge.

[0033] The obtained polyester had an intrinsic viscosity I.V. of 0.36, a glass transition temperature Tg of 45°C, an acid value A.V. of 20 mgKOH / g, and a hydroxyl value OH.V. of 12 mgKOH / g.

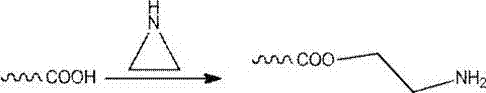

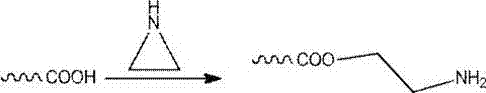

[0034] Stir to dissolve the resin in 150kg of 150# solvent, add 2kg of aziridine, and keep for 30m...

Embodiment 2

[0036] First, carry out the preparation of polyester:

[0037] Put 62kg of neopentyl glycol, 55kg of ethylene glycol, 99kg of terephthalic acid, 51kg of isophthalic acid, 18kg of sebacic acid, and 120g of tetrabutyl titanate into the reaction kettle. Replace the air with nitrogen, stir and raise the temperature to 220~240°C for reaction. The acid value is less than 30mg KOH / g as the end point. After the reaction is over, raise the temperature to 240~260°C, polycondensate and stir for 30 minutes under vacuum conditions, add 3kg of pyromellitic anhydride, continue stirring, and after reaching the predetermined viscosity, fill it with nitrogen to eliminate Vacuum, extrude and discharge.

[0038] The obtained polyester had an intrinsic viscosity I.V. of 0.42, a glass transition temperature Tg of 50°C, an acid value A.V. of 35 mgKOH / g, and a hydroxyl value OH.V. of 8 mgKOH / g.

[0039] Stir to dissolve the resin in 100kg of DBE solvent, add 3.5kg of propyleneimine, and keep for 30...

Embodiment 3

[0041] First, carry out the preparation of polyester:

[0042] Put 72kg of neopentyl glycol, 49kg of ethylene glycol, 83kg of terephthalic acid, 49.8kg of isophthalic acid, 40.4kg of sebacic acid, and 90g of tetrabutyl titanate into the reaction kettle. Replace the air with nitrogen, stir and raise the temperature to 220~240°C for reaction. The acid value is less than 30mg KOH / g as the end point. After the reaction is over, heat up to 240~260°C, polycondensate and stir for 30 minutes under vacuum conditions, add 4kg of pyromellitic anhydride, continue stirring, and fill nitrogen to eliminate Vacuum, extrude and discharge.

[0043] The obtained polyester had an intrinsic viscosity I.V. of 0.3, a glass transition temperature Tg of 40°C, an acid value A.V. of 40 mgKOH / g, and a hydroxyl value OH.V. of 20 mgKOH / g.

[0044] Stir to dissolve the resin in 200kg of DBE solvent, add 5kg of aziridine, and keep for 30min. Add 70kg of phenolic resin (Cytec PR565) and 30kg of amino resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com