CNT:SNC:PEDOT ternary water-based conductive ink and preparation method thereof

A conductive ink, water-based technology, used in inks, household appliances, applications, etc., can solve the problems of high price and easy oxidation, achieve excellent stability and conductivity, improve resource utilization, and improve the effect of sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

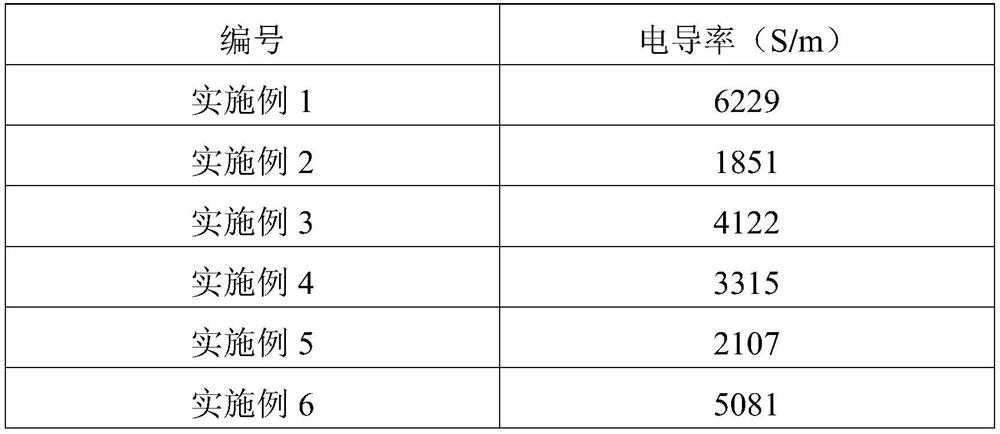

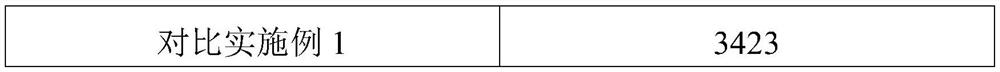

Examples

Embodiment 1

[0040] Add 5 g of pine wood pulp into 100 g of DMF solution in which 20 g of sulfamic acid is dissolved, react at 90° C. for 6 hours, separate the pine wood pulp from the reaction solution to obtain sulfated cellulose. The sulfated cellulose was added into water for shear dispersion for 40 minutes to obtain a sulfated nanocellulose aqueous dispersion (SNC aqueous dispersion).

[0041] Add 1.5g of CNT to 100g of SNC aqueous dispersion (1wt%), and make CNT:SNC dispersion by ultrasonic dispersion. Add 1.5g of EDOT monomer into the above CNT:SNC dispersion, stir and disperse for 1h. Then, 3.75 g of ammonium persulfate and 0.15 g of ferric chloride were added, and polymerized for 18 hours under a nitrogen atmosphere, and the polymerization temperature was 35° C. After the reaction is finished, the CNT:SNC:PEDOT ternary water-based conductive ink can be obtained.

Embodiment 2

[0043] Add 1 g of pine pulp into 100 g of DMF solution dissolved with 5 g of sulfamic acid, react at 70° C. for 2 hours, separate the pine pulp from the reaction solution to obtain sulfated cellulose. The sulfated cellulose was added into water for shear dispersion for 20 minutes to obtain a sulfated nanocellulose aqueous dispersion (SNC aqueous dispersion).

[0044]Add 0.5g of CNT into 100g of SNC aqueous dispersion (1wt%), and make CNT:SNC dispersion by ultrasonic dispersion. Add 0.5g of EDOT monomer into the above CNT:SNC dispersion liquid, stir and disperse for 1h. Then add 0.75g of ammonium persulfate and 0.025g of ferric chloride, and polymerize for 6 hours under nitrogen atmosphere, and the polymerization reaction temperature is 20°C. After the reaction is finished, the CNT:SNC:PEDOT ternary water-based conductive ink can be obtained.

Embodiment 3

[0046] Add 3 g of pine wood pulp into 100 g of DMF solution in which 10 g of sulfamic acid is dissolved, react at 80° C. for 4 hours, separate the pine wood pulp from the reaction solution to obtain sulfated cellulose. The sulfated cellulose was added into water for shear dispersion for 30 minutes to obtain a sulfated nanocellulose aqueous dispersion (SNC aqueous dispersion).

[0047] Add 1 g of CNT to 100 g of SNC aqueous dispersion (1 wt%), and make CNT:SNC dispersion by ultrasonic dispersion. Add 1 g of EDOT monomer into the above CNT:SNC dispersion, and stir to disperse for 1 h. Then add 2g of ammonium persulfate and 0.075g of ferric chloride, and polymerize for 12 hours under nitrogen atmosphere, and the polymerization temperature is 25°C. After the reaction is finished, the CNT:SNC:PEDOT ternary water-based conductive ink can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com