A kind of production method of wool-like fabric

A production method and fabric technology, applied in textiles and papermaking, textiles, fabrics, etc., can solve the problems of poor shape retention, easy deformation, and high price, and achieve the effect of avoiding high price, strong environmental protection, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

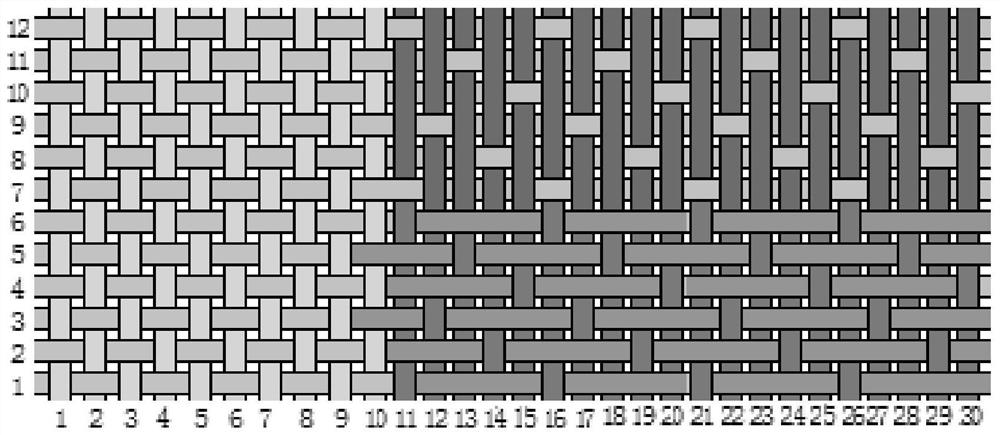

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] combine figure 1 Shown, a kind of manufacture method of wool-like fabric, manufacture method comprises the following steps: ①, take cupro ammonia fiber as the warp yarn of fabric for standby, the fineness specification of warp yarn is 120D / 70F, twist degree and twist direction specification are 800T / S ; ②, take cuproammonia fiber and modal fiber and form blended yarn by 50:50, as the weft yarn of the fabric for standby, the weft yarn is a single-ply yarn, and the fineness is 30 pounds; ③, adopt the loom to process step ① The warp yarns taken and the weft yarns taken in step ② are interwoven in warp and weft, and the fabric after interweaving is a dobby structure in which plain weave and combined weave alternately circulate.

[0019] Specifically, the plain weave spans 10 warp yarns, and the combined weave spans 20 warp yarns. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com