Patents

Literature

34results about How to "Broaden research direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic cathode material for sodium ion battery

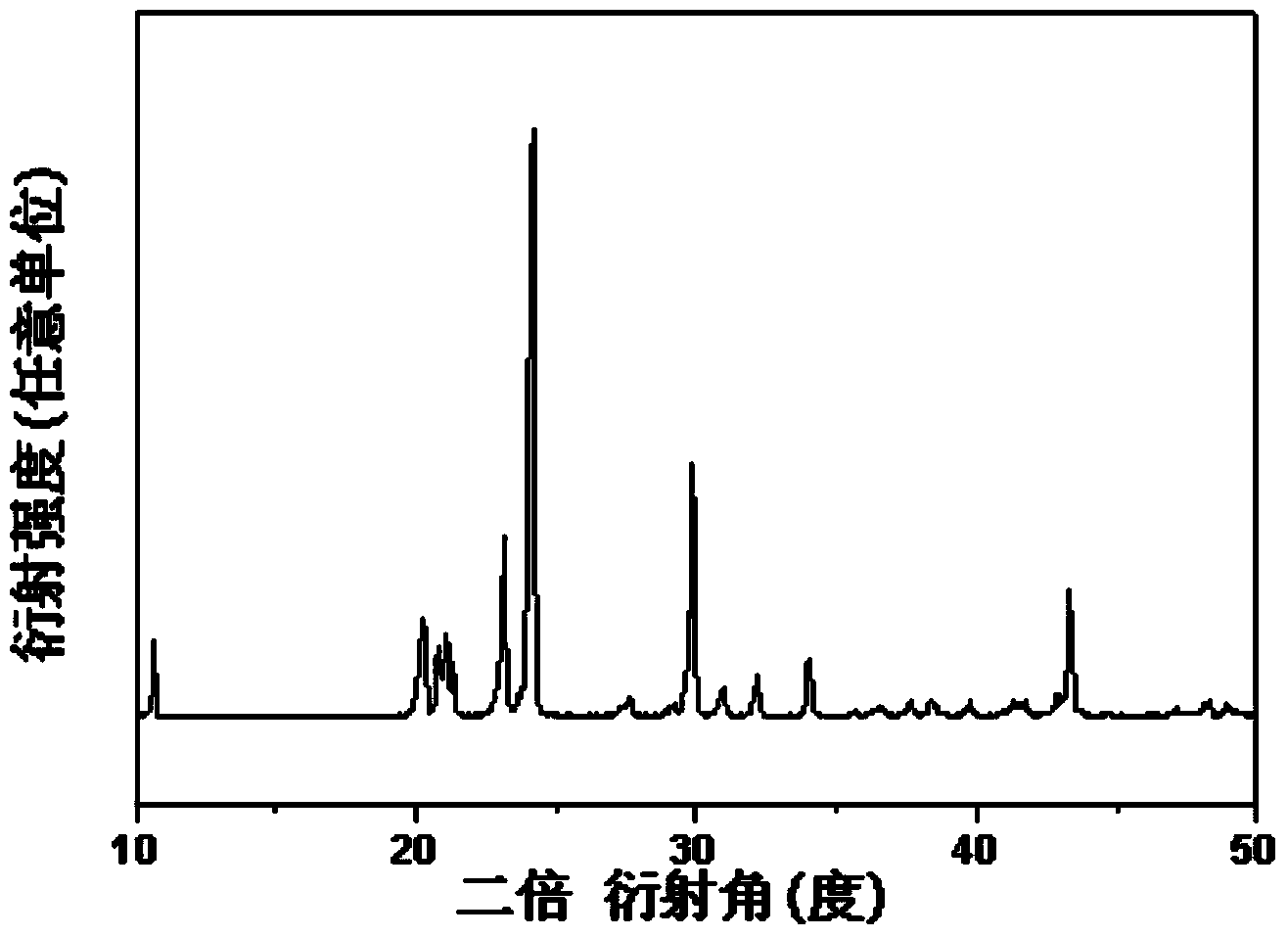

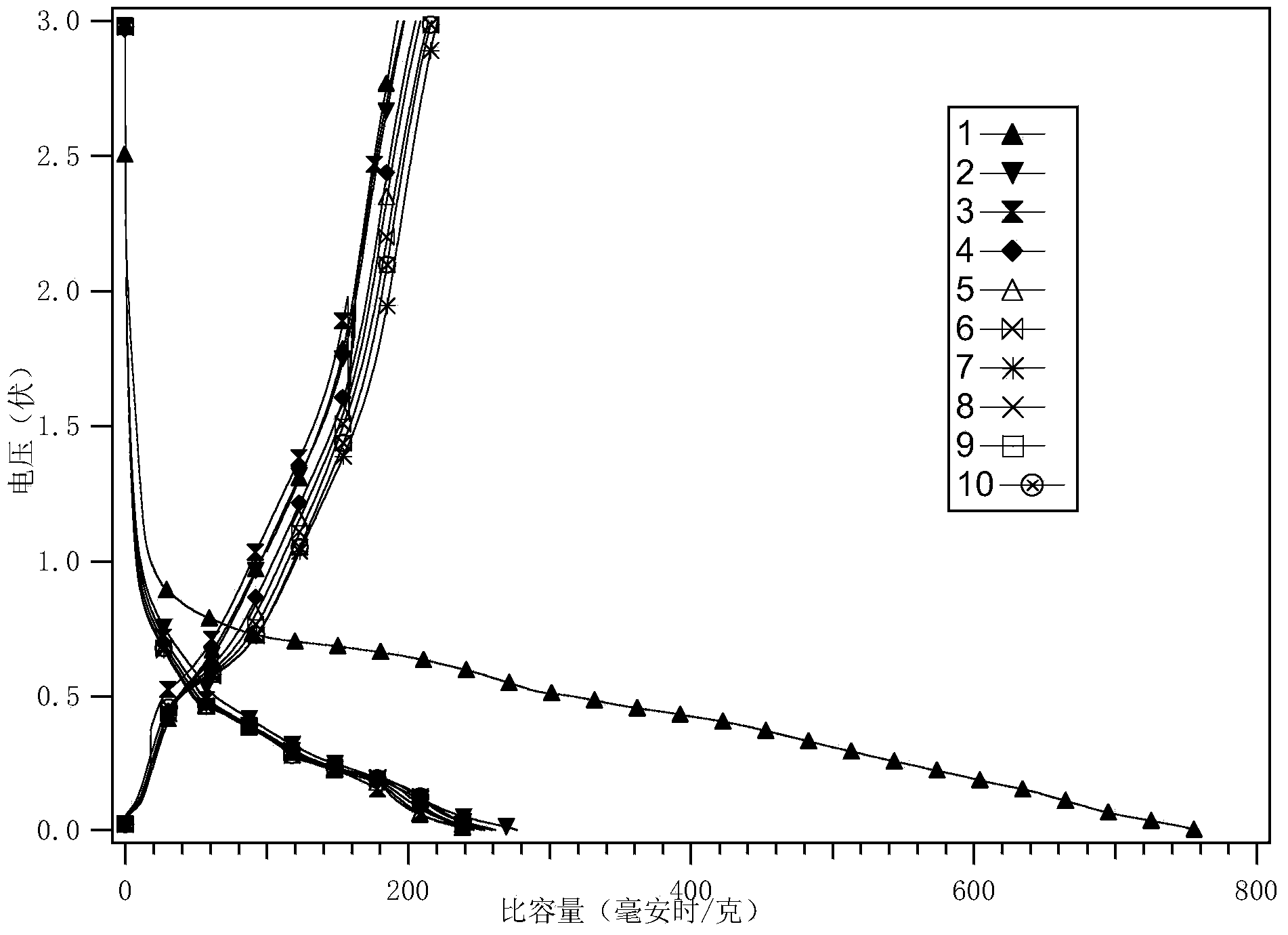

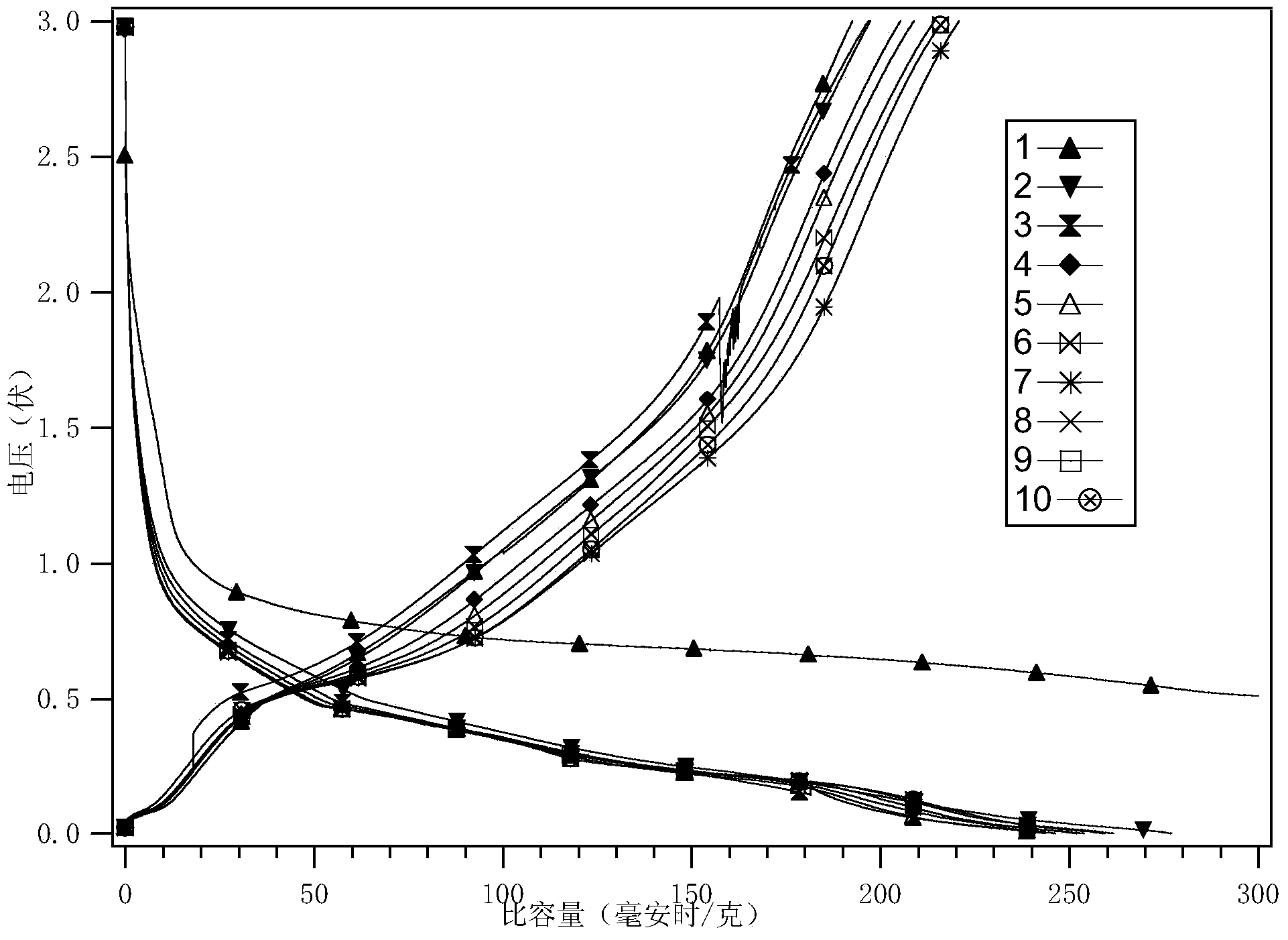

InactiveCN103456961AThe synthesis method is simpleReduce manufacturing costCell electrodesIonCharge and discharge

The invention discloses an organic cathode material for a sodium ion battery capable of being repeatedly charged and discharged, and belongs to the field of batteries. According to the organic cathode material for the sodium ion battery disclosed by the invention, an active substance of the organic cathode material is para-phthalate or a mixture of different para-phthalates; the chemical composition of the para-phthalate is C8H4O4.Rx, wherein R is Li, K, Rb, Cs, Mg, Ca, Sr, Ba, Ni, Cu, Sn, Fe, Zn, Cr, Al or Mn, and x is equal to 2 / 7, 1 / 3, 2 / 5, 1 / 2, 2 / 3, 1 or 2. The organic cathode material disclosed by the invention has low reaction potential, high quality specific capacity and excellent electrochemical cycle stability, and is simple in synthetic method and good in repeatability; the production cost is reduced, the requirement of sustainable development is met, and the organic cathode material has a wide application prospect in the field of sodium ion batteries.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

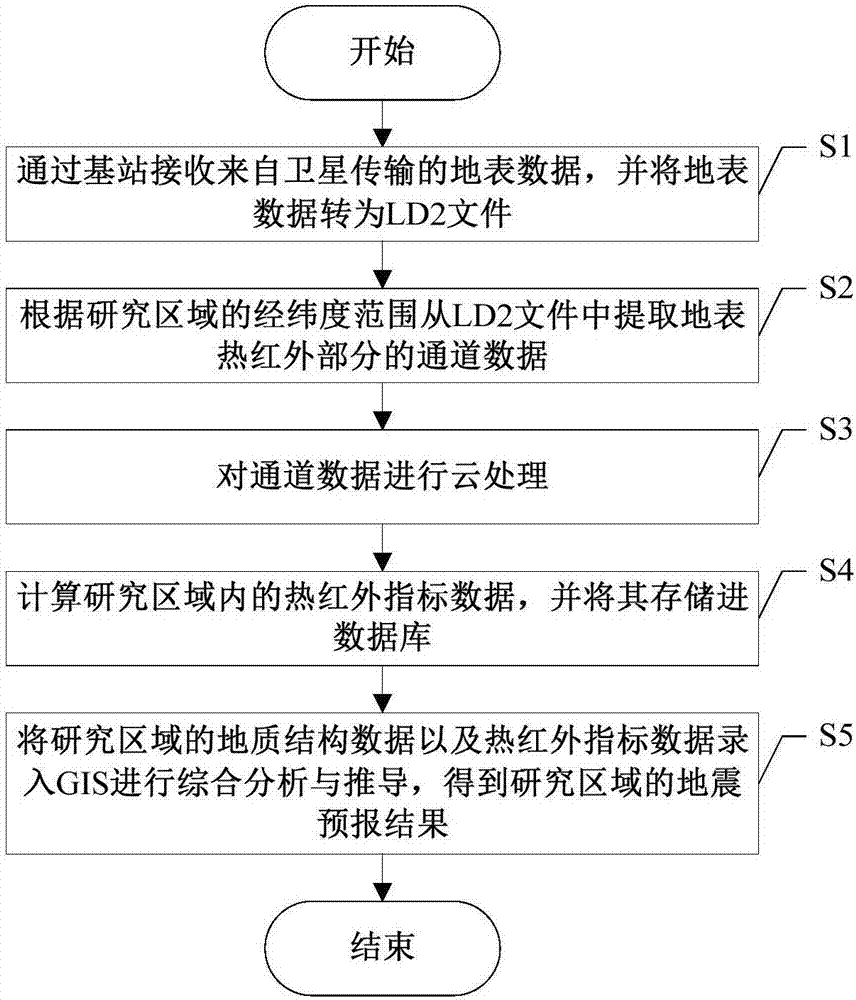

Earthquake precursor analysis method based on satellite thermal infrared data and GIS

InactiveCN107356969AWide variety of sourcesImprove stabilitySeismic signal processingEarthquake predictionAnalysis method

The invention discloses an earthquake precursor analysis method based on satellite thermal infrared data and a GIS. An earthquake prediction analysis is carried out by means of thermal infrared data +GIS, so that the accuracy is improved; the data for the analysis has the large source, so that the research effect is good. Besides, the research direction of the earthquake precursor is extended; and with the GIS way, all quantitative factor that may cause any influence on the earthquake occurrence are accommodated into spatial operation, so that the restriction of analysis of the geological factors and geological formation is eliminated.

Owner:四川易利数字城市科技有限公司

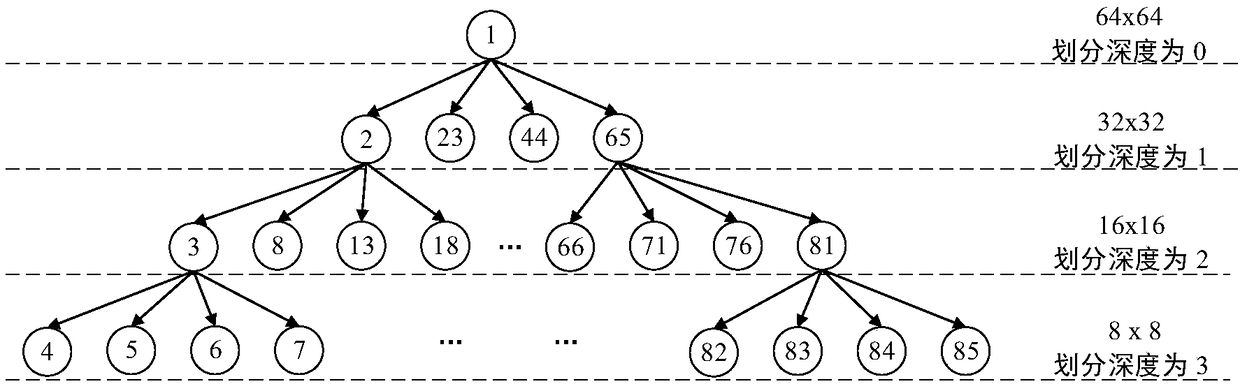

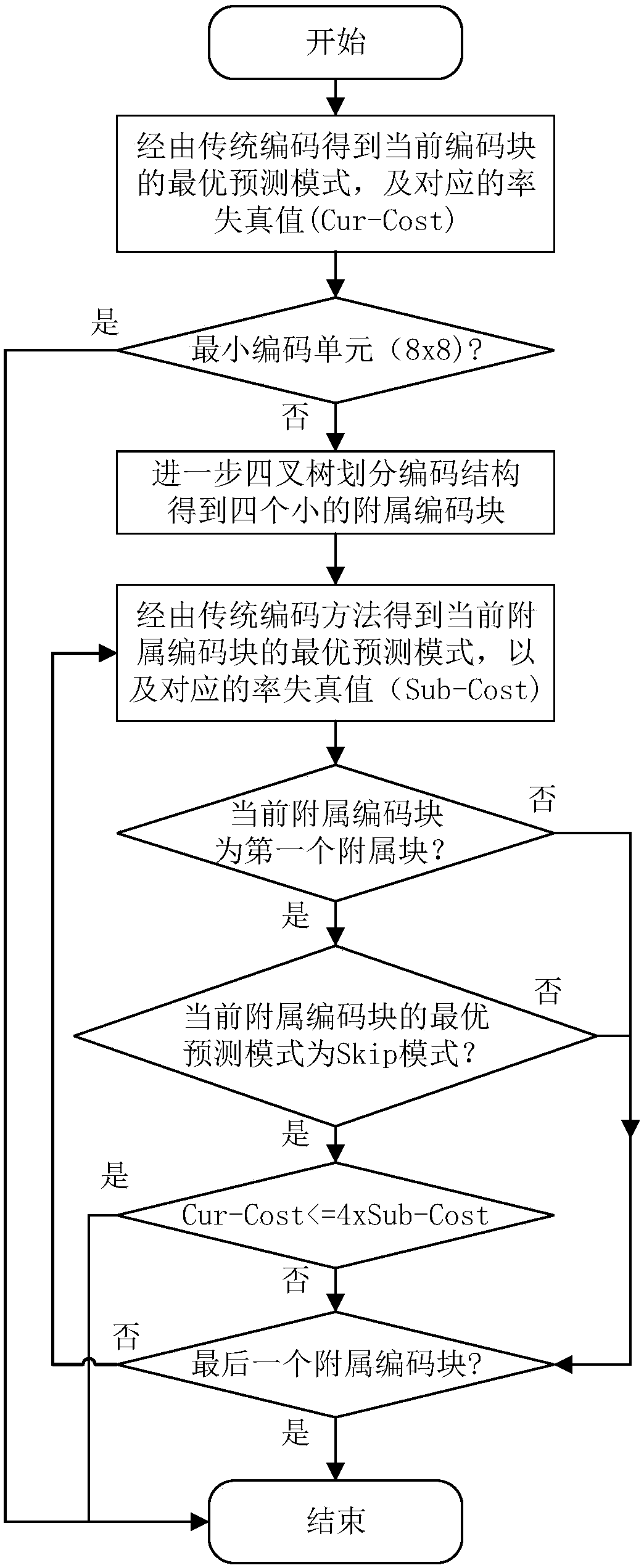

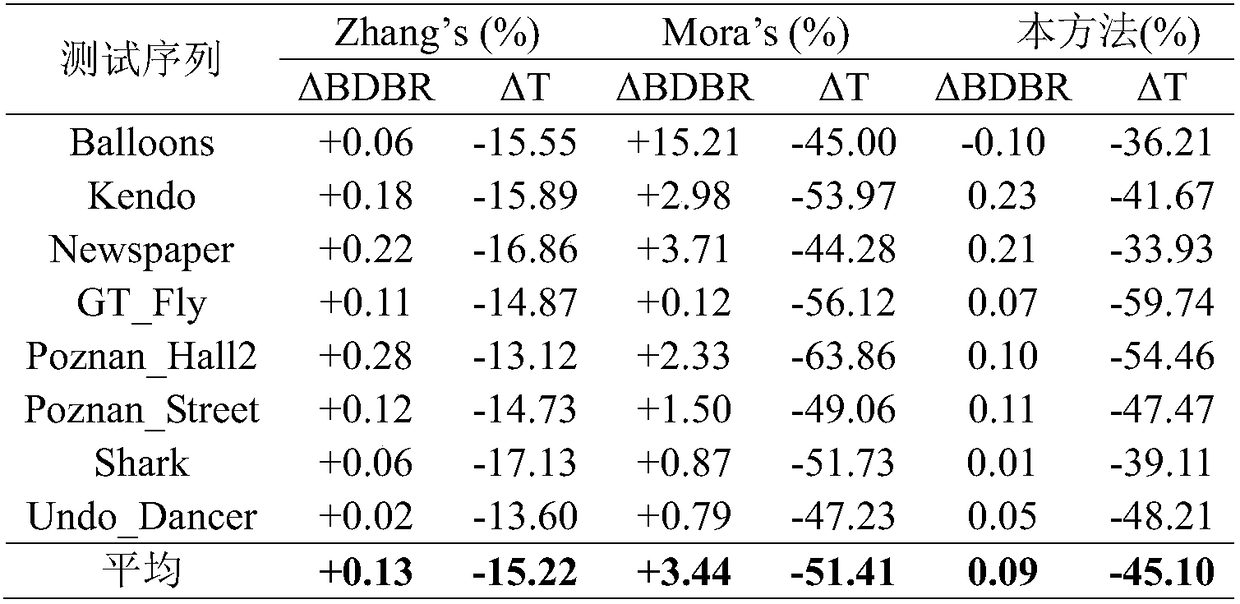

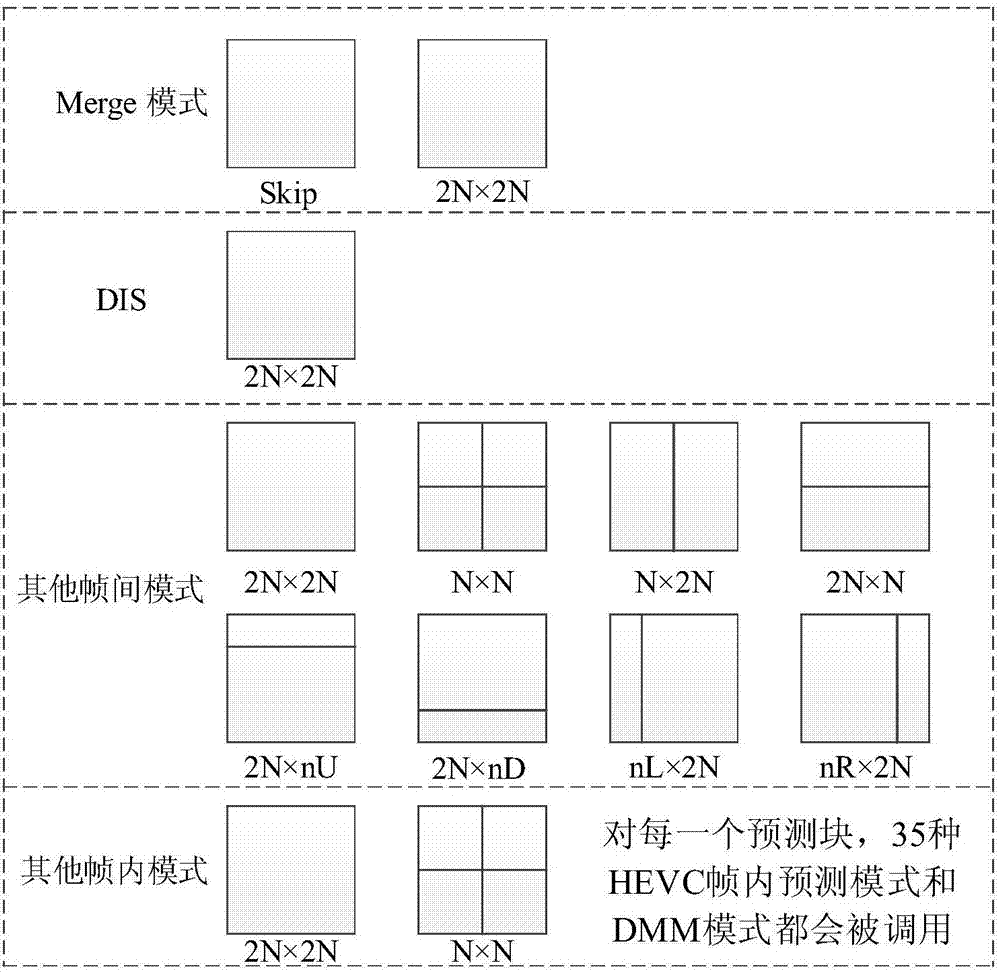

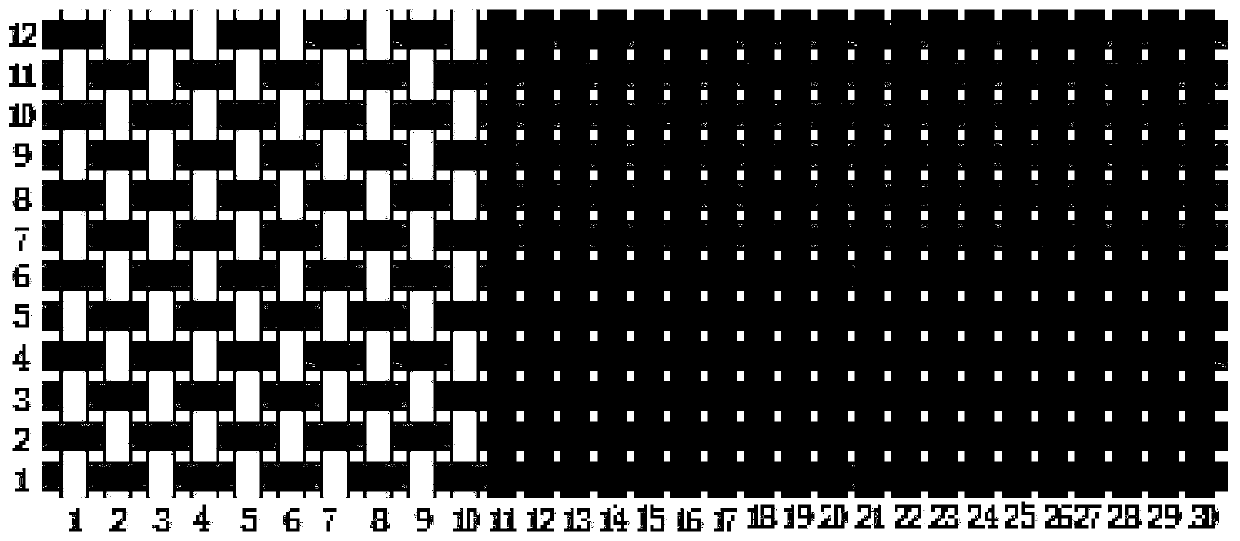

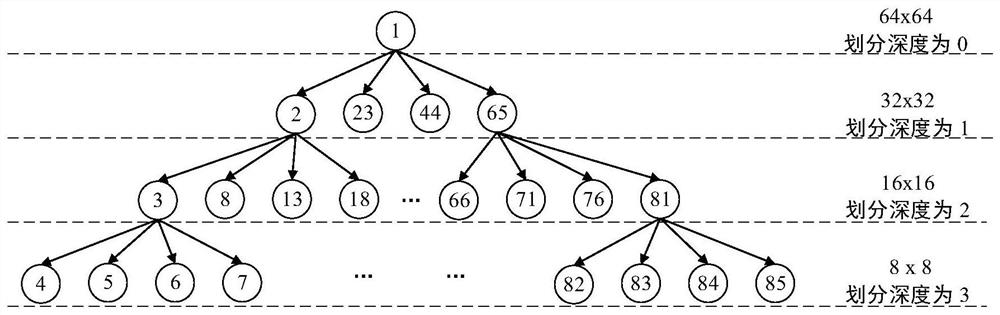

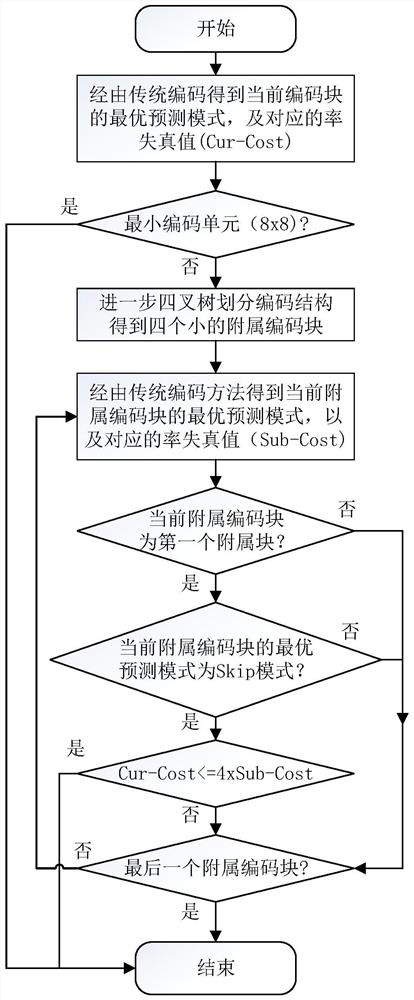

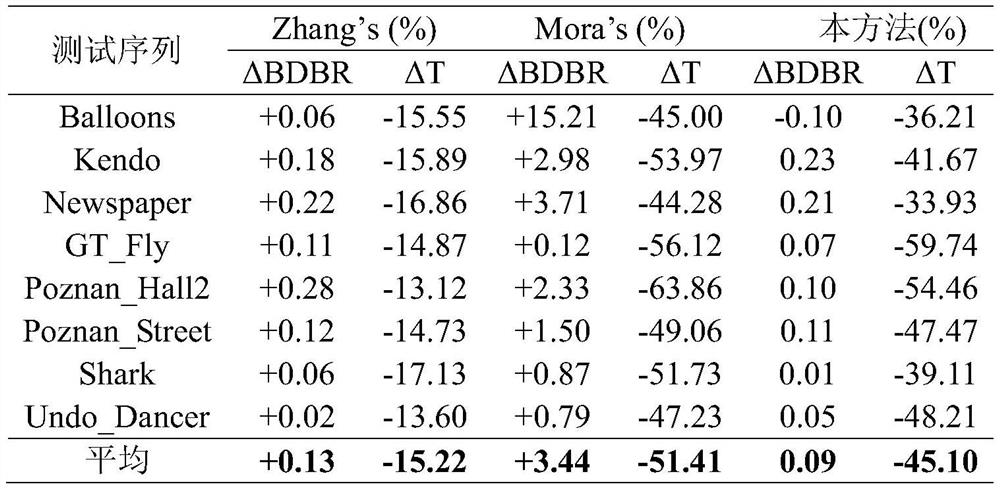

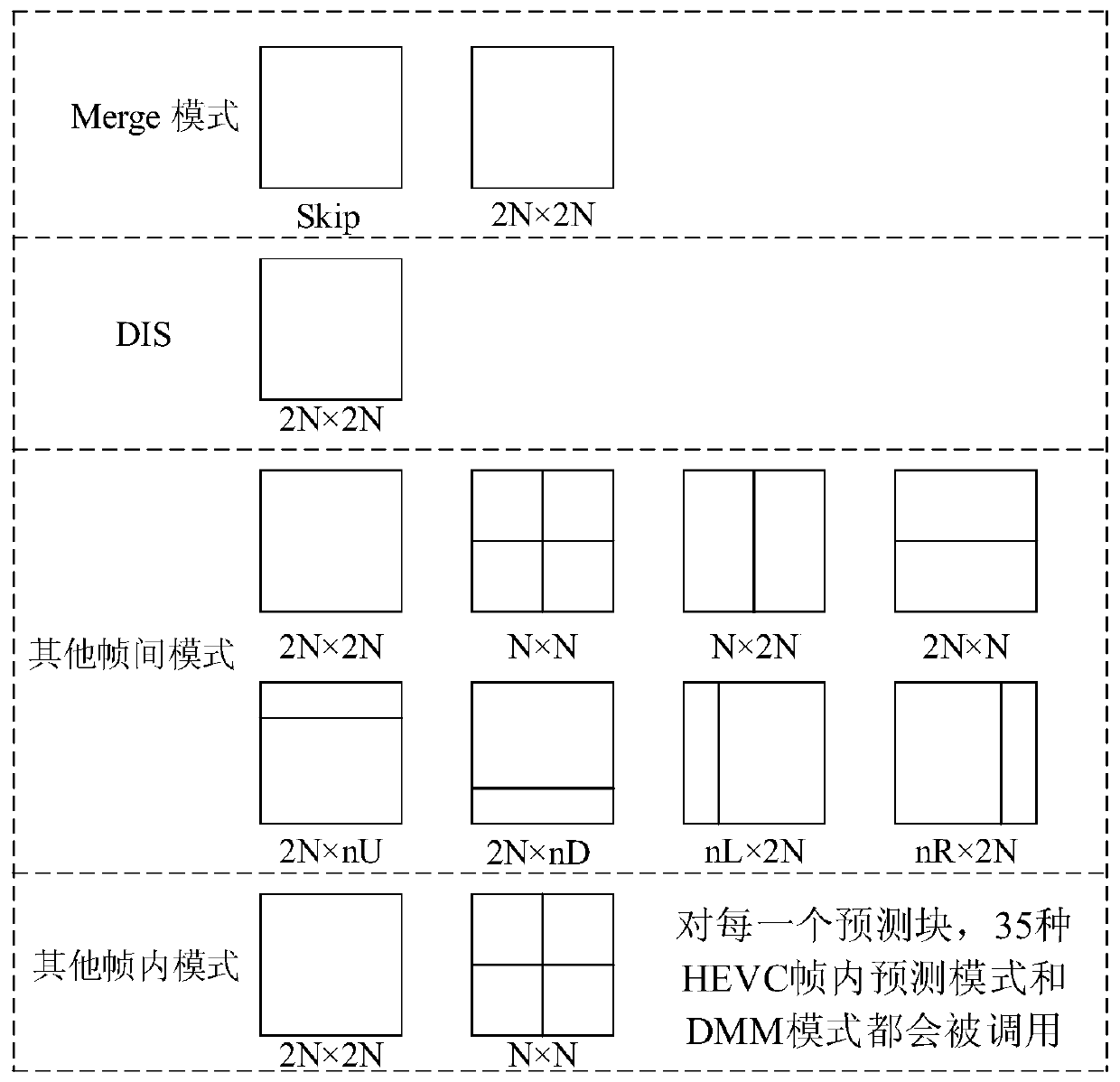

Quick decision method for 3D video depth image quad-tree encoding structure division

ActiveCN108347605AReduce complexityBroaden research directionDigital video signal modificationTree encodingRate distortion

The invention discloses a quick decision method for 3D video depth image quad-tree encoding structure division. The method comprises the following steps: firstly, obtaining the current encoding blockand an optimal prediction mode of the first small auxiliary encoding block thereof and a corresponding rate-distortion value through a traditional encoding method; and then judging whether the optimalmode of the first small auxiliary encoding block is the Skip mode, if the optimal mode is the Skip mode, further judging whether the rate-distortion value of the current encoding block is less than or equal to 4 times of the first small auxiliary encoding block rate-distortion value, if the rate-distortion value of the current encoding block is less than or equal to 4 times of the first small auxiliary encoding block rate-distortion value, terminating the current encoding block in advance to obtain the quad-tree encoding structure division. Through the quick decision method disclosed by the invention, the complexity of the intra-frame prediction encoding of the depth image is reduced, the encoding time required by the prediction is reduced, and the video quality of the final decoding endsynthetic visual angle is guaranteed.

Owner:NANJING UNIV OF SCI & TECH

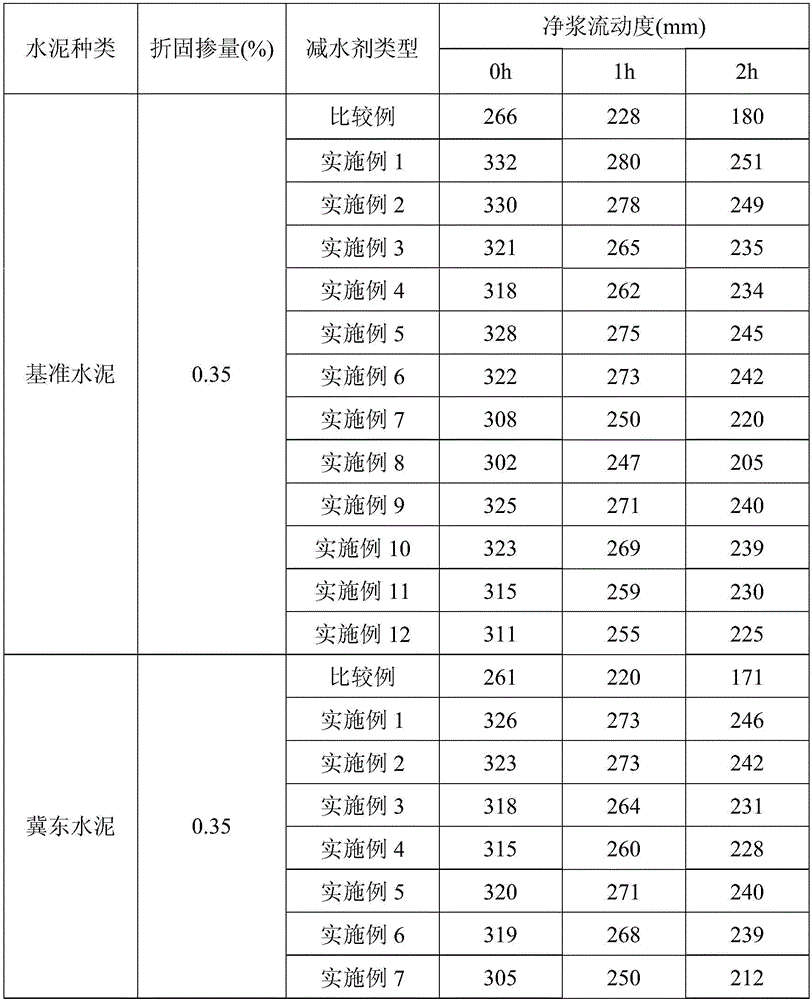

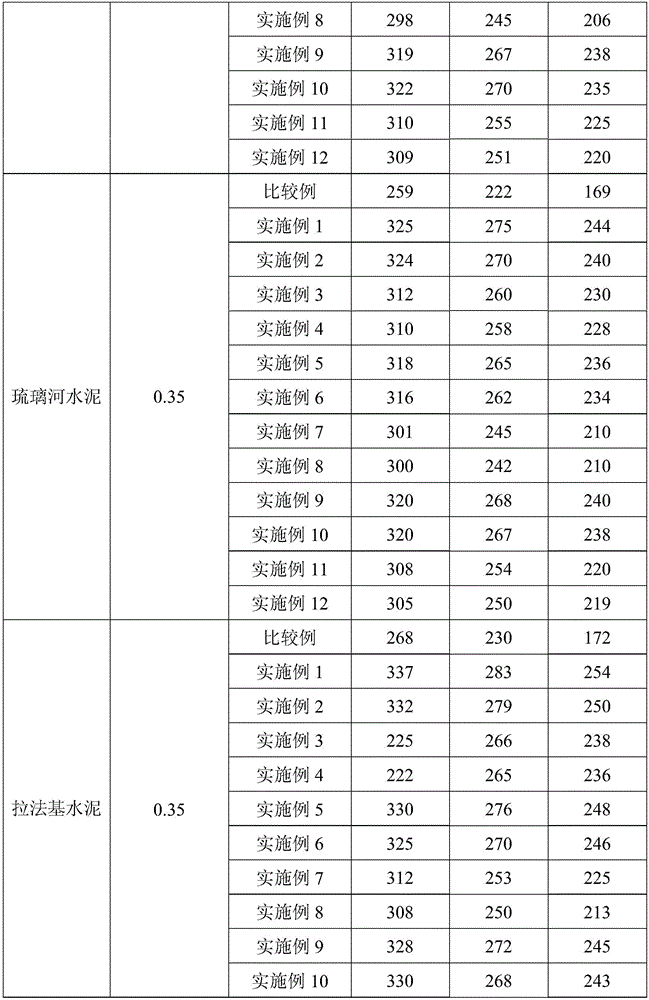

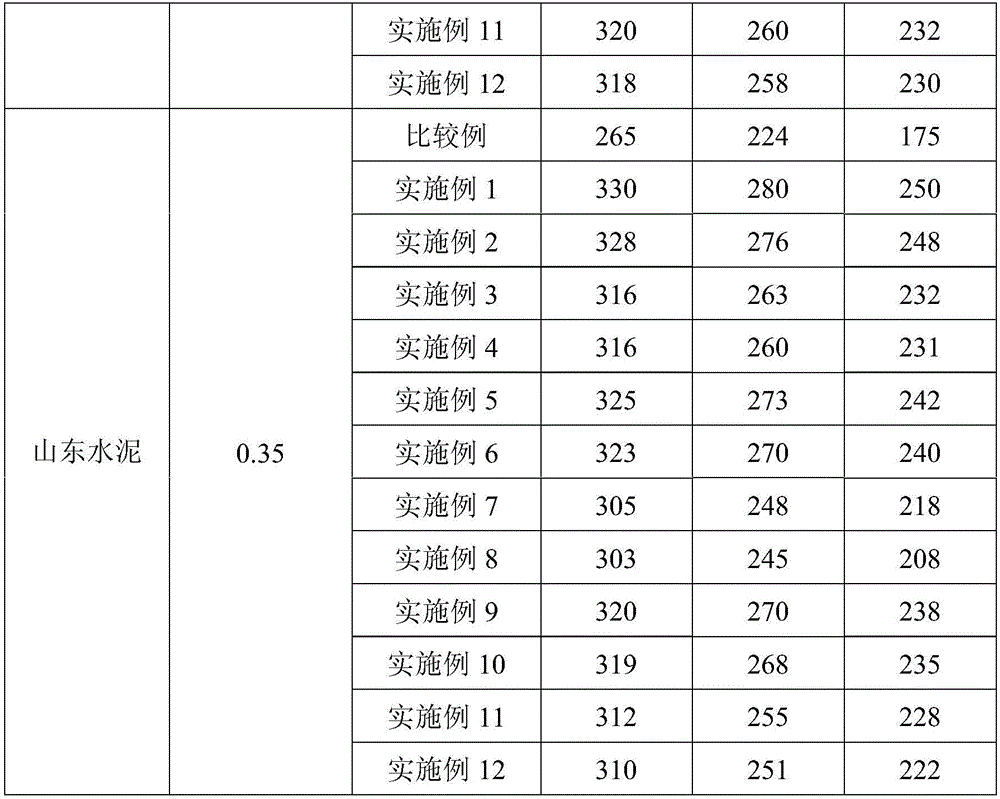

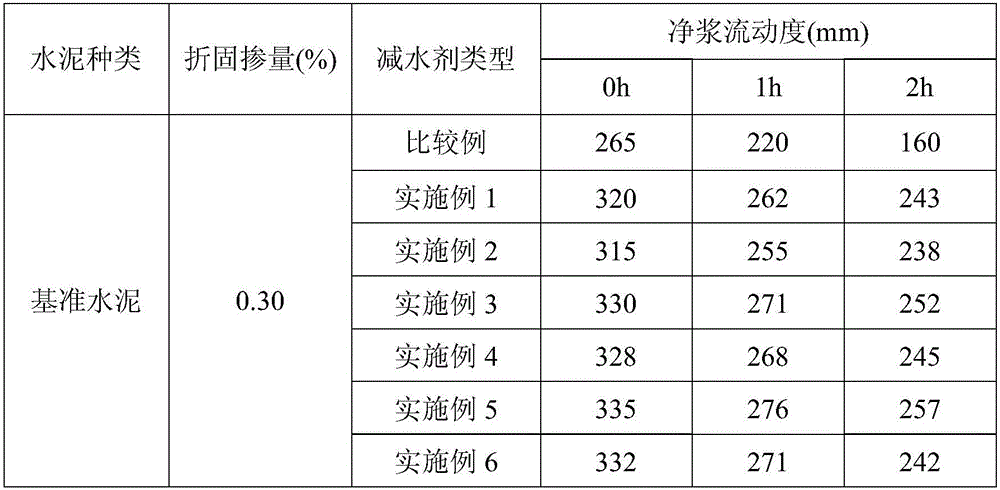

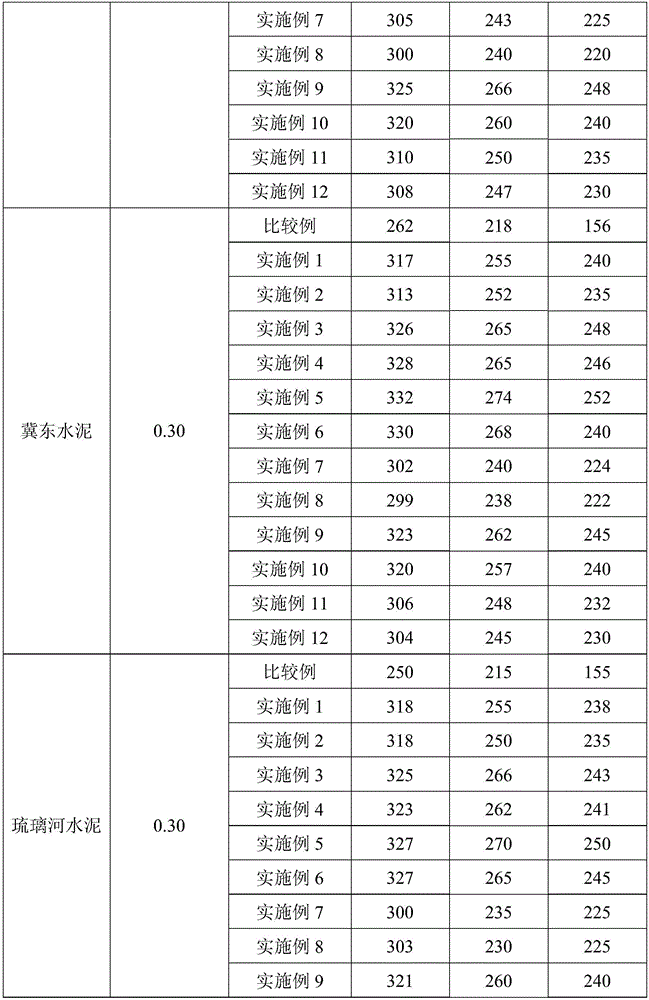

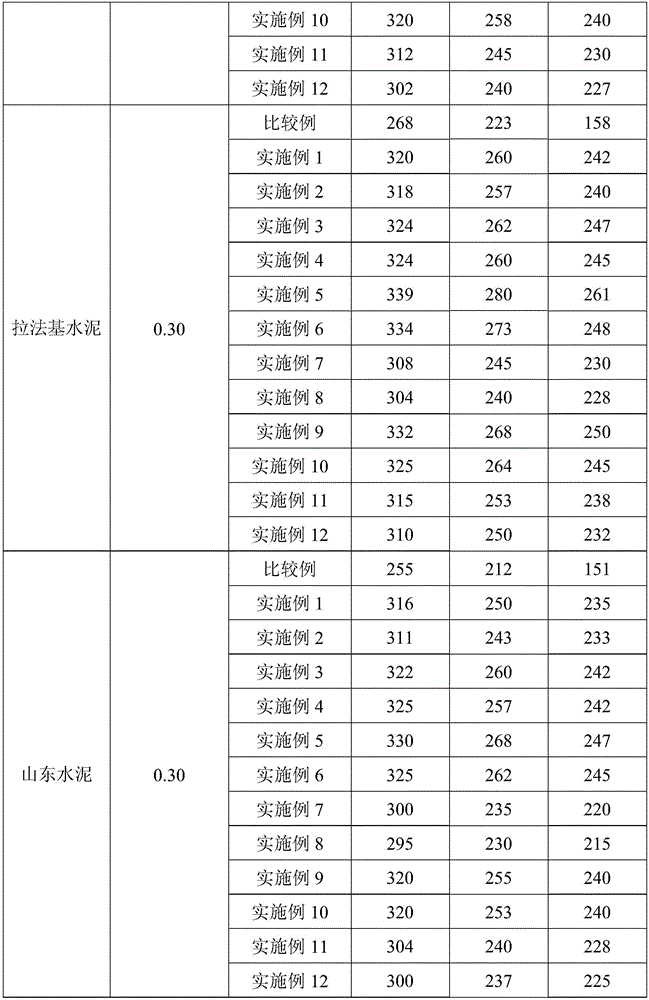

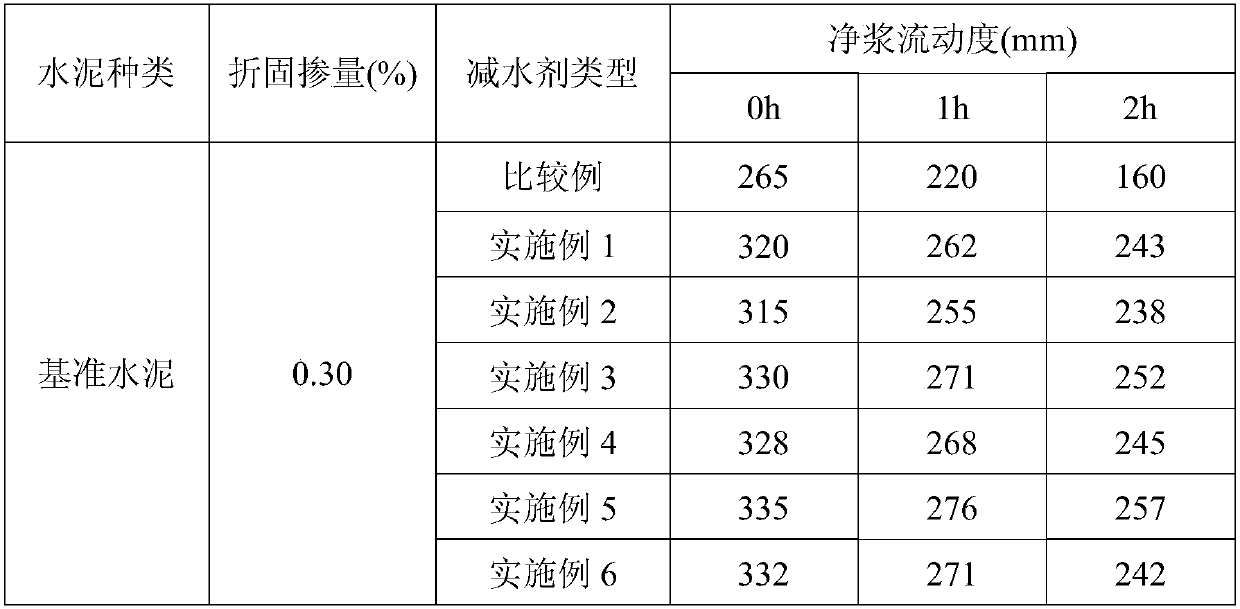

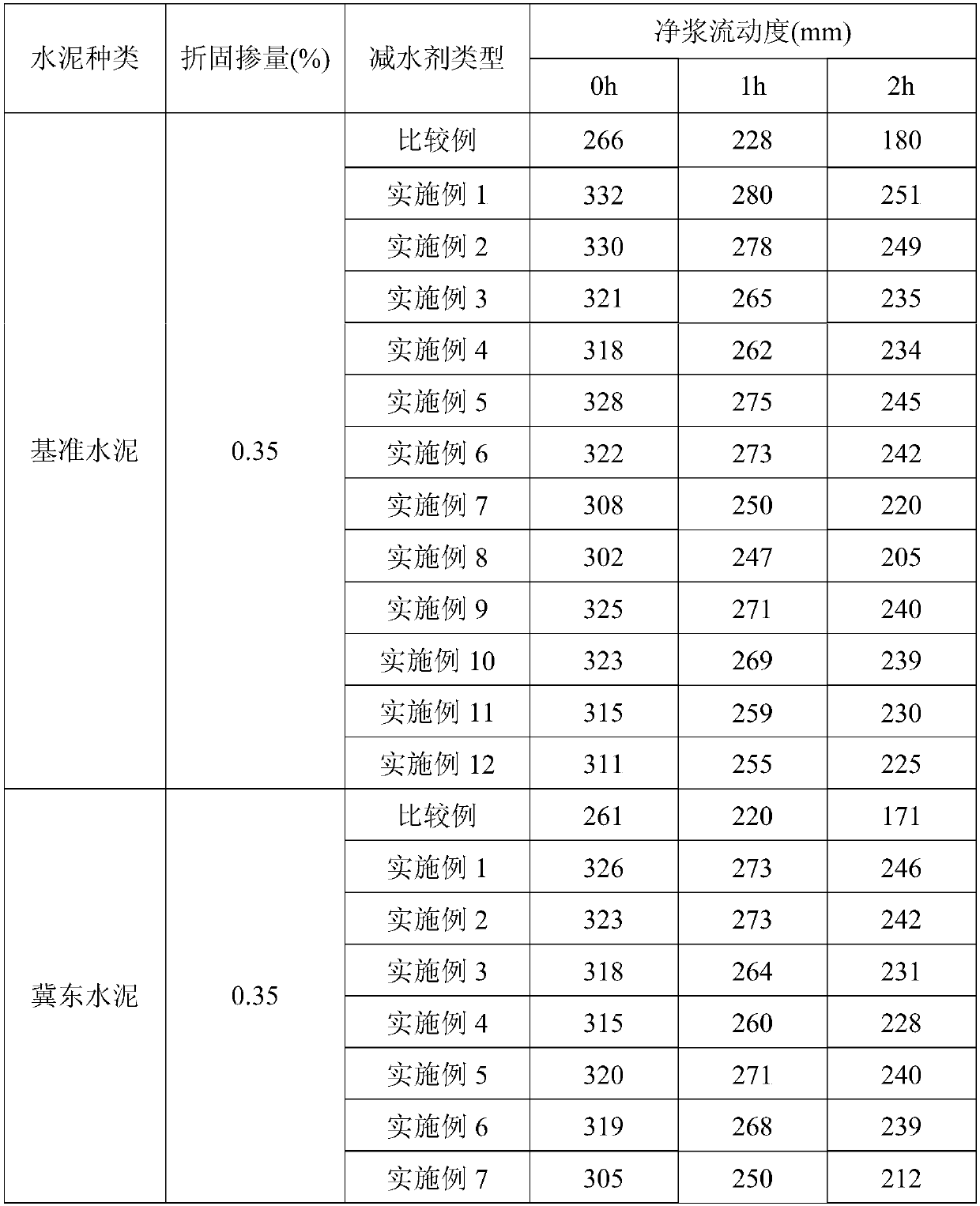

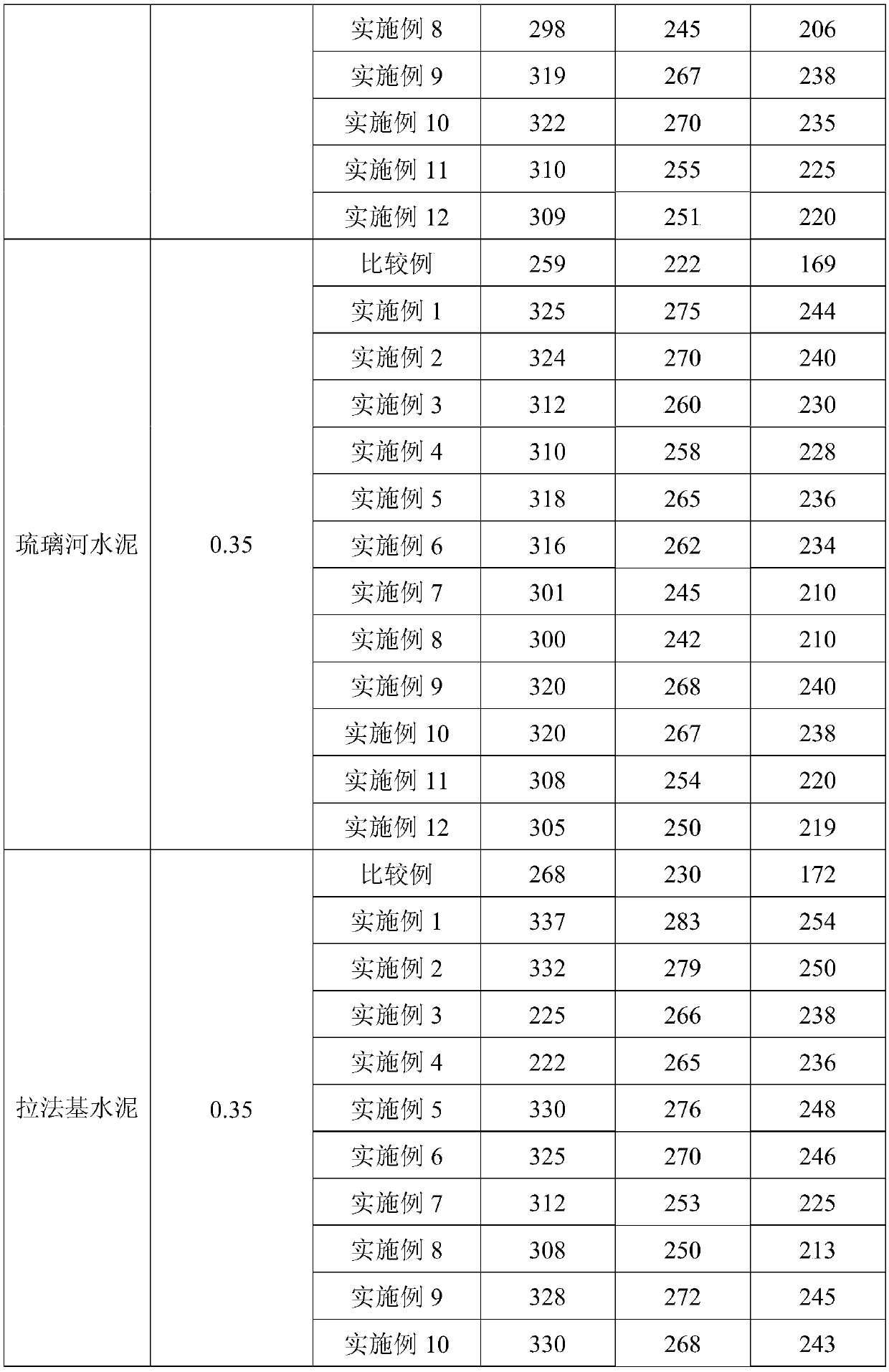

Method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with cationic side chain

ActiveCN106188557AThe polymerization process is mild and stableLess side effectsAlcoholPolyethylene glycol

Belonging to the field of dispersants, the invention provides a method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with a cationic side chain. The method consists of: employing an unsaturated carboxylic acid monomer, an unsaturated halogenated hydrocarbon monomer, an unsaturated cationic quaternary ammonium salt monomer, a polyethylene glycol compound and the like as the raw materials, firstly conducting main chain copolymerization, then polymerizing the cationic side chain, performing functionalization, and finally carrying out etherification grafting so as to synthesize the excellent performance high mud resistant polycarboxylic acid dispersant material with unsaturated halogenated hydrocarbon copolymerized and grafted with cationic side chain, i.e. taking unsaturated carboxylic acid and unsaturated halogenated hydrocarbon as the reactants, conducting free radical polymerization to obtain a carboxylic acid-halogenated hydrocarbon copolymer main chain, using high valence cerium salt-alcohol to initiate polymerization of an unsaturated cationic quaternary ammonium salt monomer so as to obtain a hydroxyl terminated cationic side chain, then modifying the hydroxyl terminated cationic side chain and the polyethylene glycol compound to obtain a functionalized side chain, and carrying out etherification grafting of the functionalized side chain on the carboxylic acid-halogenated hydrocarbon copolymer main chain. The method provided by the invention realizes high water reduction, slump loss resistance, high clay resistance and other multiple effects.

Owner:BEIJING UNIV OF TECH

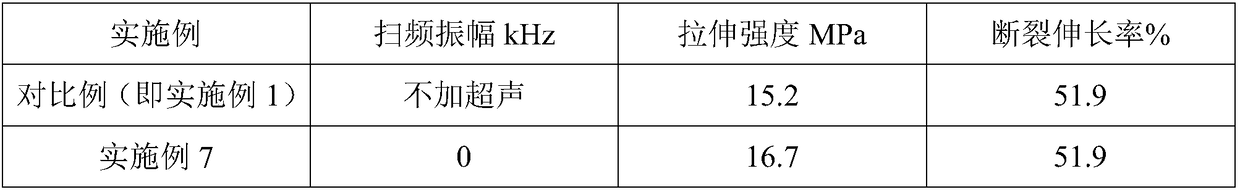

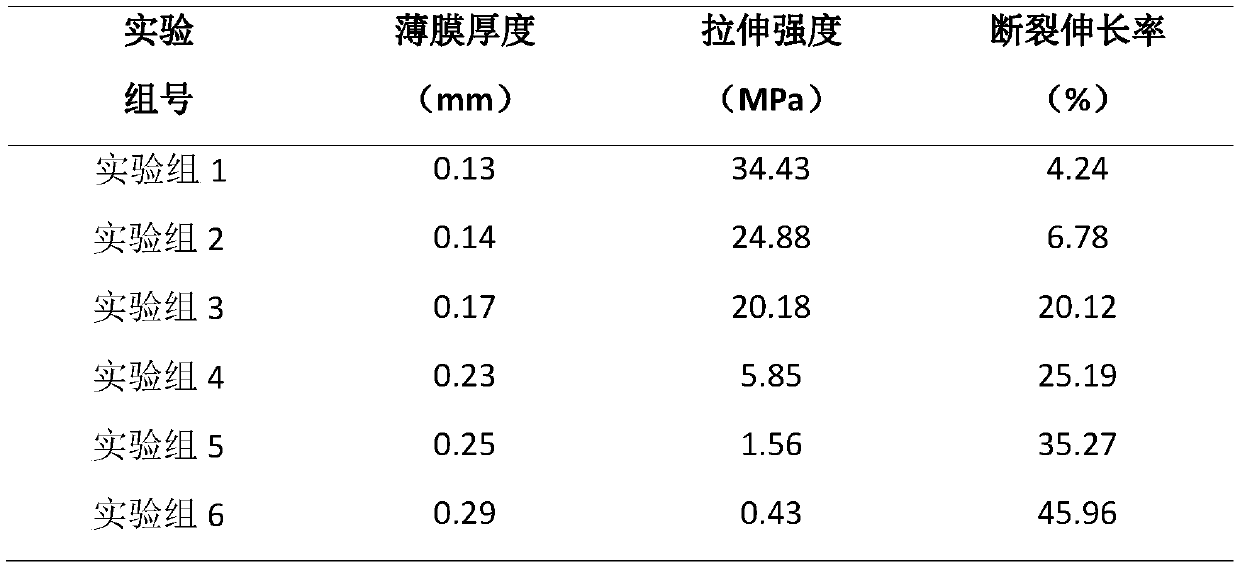

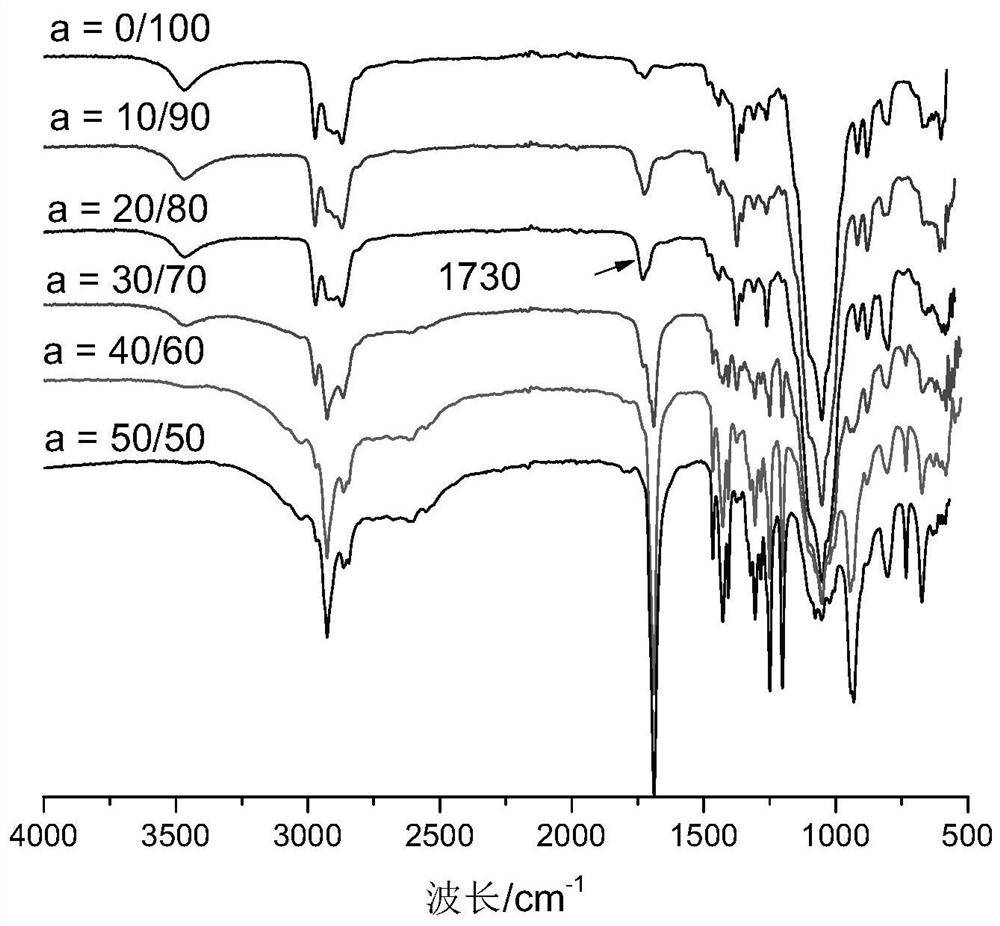

Sweep ultrasonic preparation method for collagen-chitosan compound film of tuna skin

InactiveCN109369972AIncrease added valueEfficient use ofFlexible coversWrappersMaterials preparationBiocompatibility Testing

The invention discloses a sweep ultrasonic preparation method for a collagen-chitosan compound film of tuna skin and belongs to the technical field of food packaging material preparation. The preparation method comprises the following steps: first, extracting enzyme soluble collagens from the tuna skin by using pepsase; and then preparing the collagen-chitosan edible compound film of the tuna skinassisted by sweep ultrasonic waves. The collagen-chitosan edible compound film of the tuna skin assisted by sweep ultrasonic waves is better in mechanical property compared with non-ultrasonic compound film, and the tensile strength and the elongation at break are obviously improved. The film is good in biocompatibility, degradable and good in preservation function. The main and auxiliary materials are edible substances which are safe and non-toxic, green and environment-friendly, sufficient in source and relatively low in cost. The invention provides certain technical parameters and theatrical guidance for developing a novel edible membrane material in food packaging industry in China.

Owner:JIANGSU UNIV

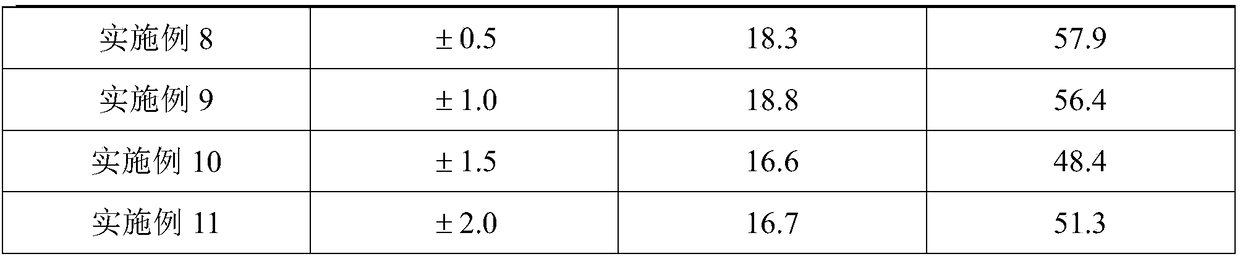

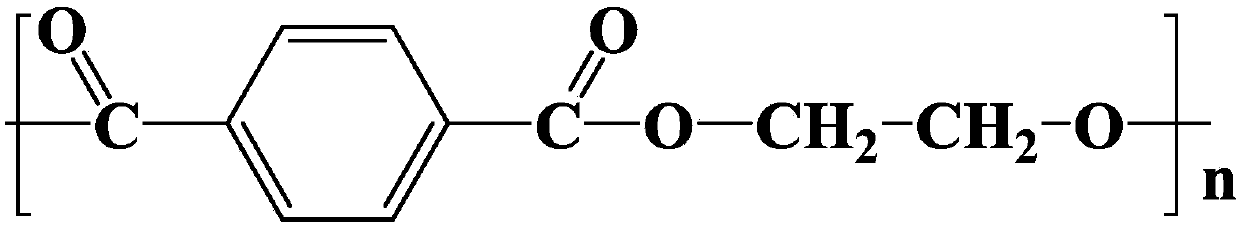

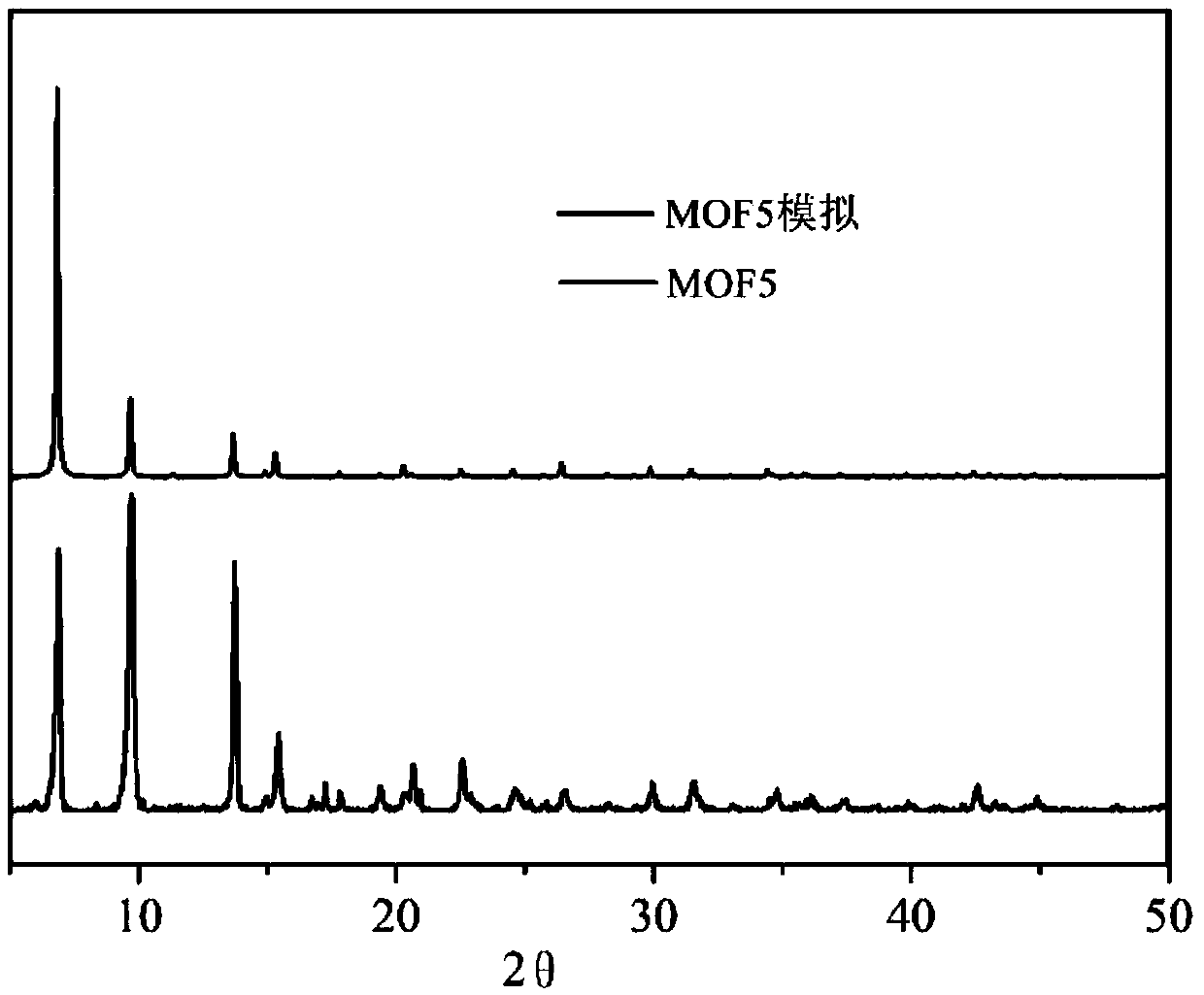

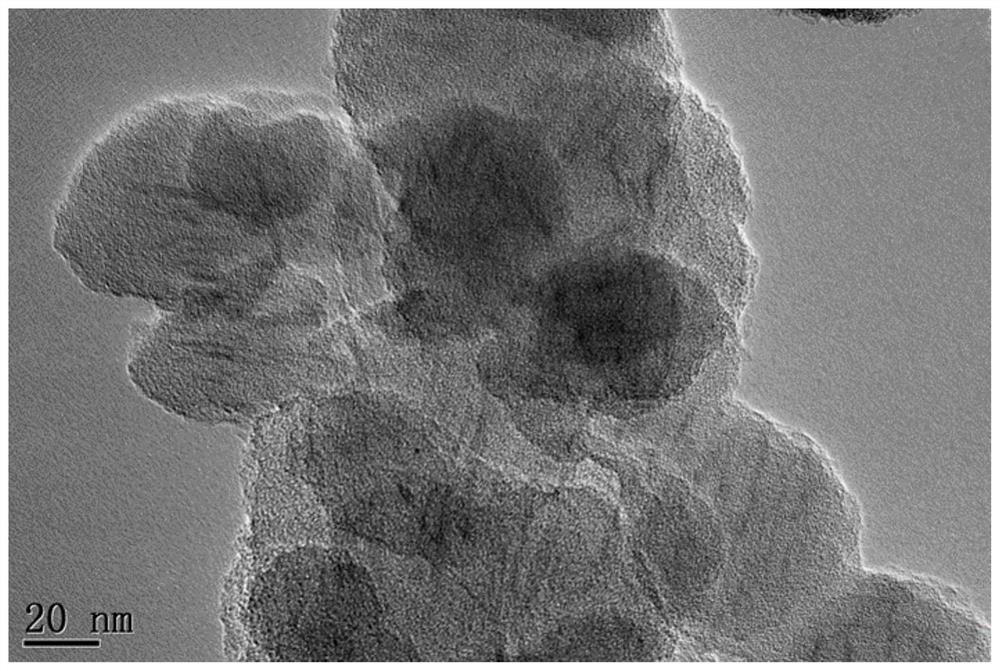

Method for preparing metal organic framework material from PET (polyethylene terephthalate) waste materials

InactiveCN108676174ABroaden research directionAchieve recyclingPolyethylene terephthalatePolyethylene terephthalate glycol

The invention provides a method for preparing a metal organic framework material from PET (polyethylene terephthalate) waste materials. Along with the fast development of human society, the resource lack and environment problems cause more and more attention of people, wherein the high efficiency resource recovery and utilization is a bridge for simultaneously solving the resource lack and environment problems. Plastic bottles are common waste materials in the life, and have the main ingredients of polyethylene terephthalate which has the chemical formula of COC6H4COOCH2CH2O, the English nameof polyethylene terephthalate and the abbreviation of PET. Experiments prove that the PET can be used for synthesizing metal-organic framework materials MOF-5; the metal-organic framework material canbe used in various fields. The method provides a method for realizing the high-efficiency PET recovery.

Owner:BEIJING UNIV OF TECH

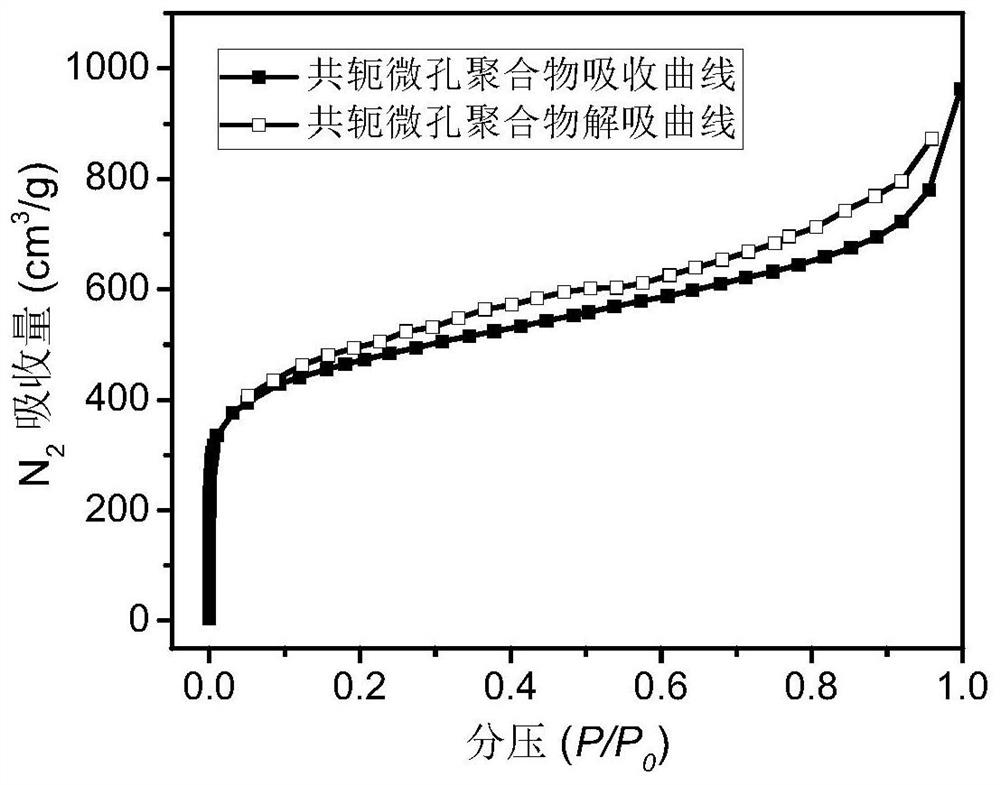

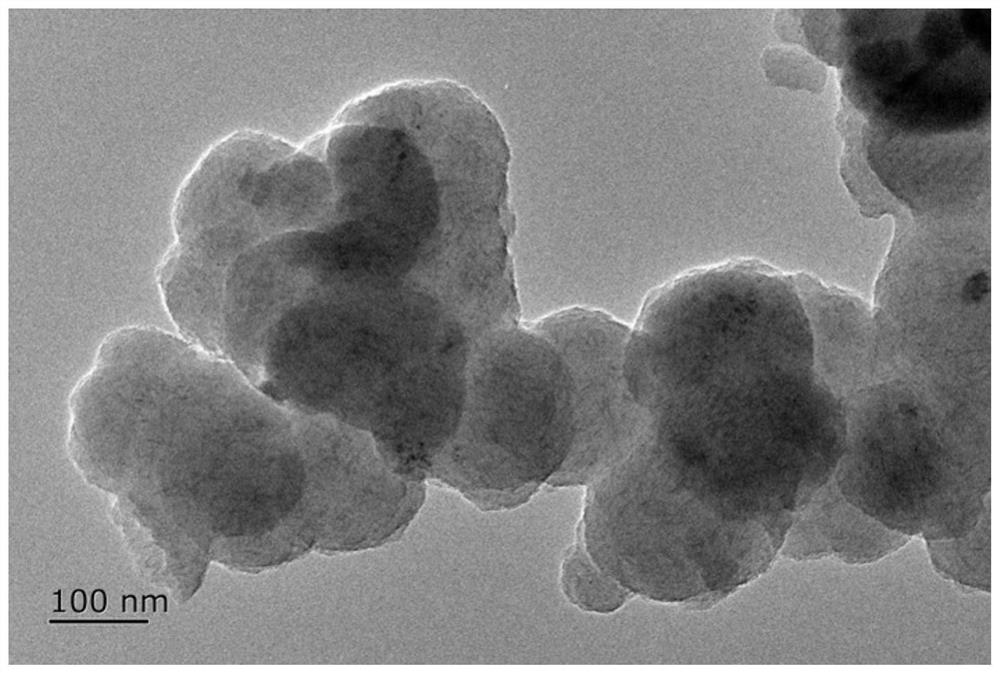

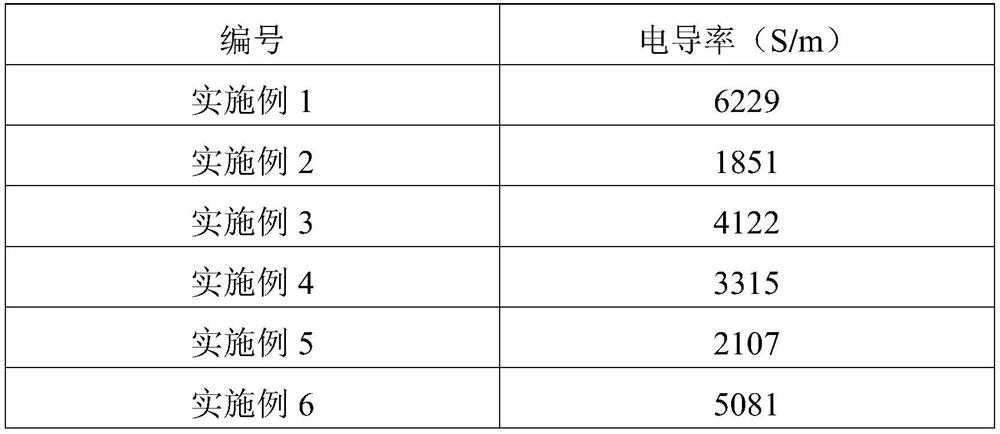

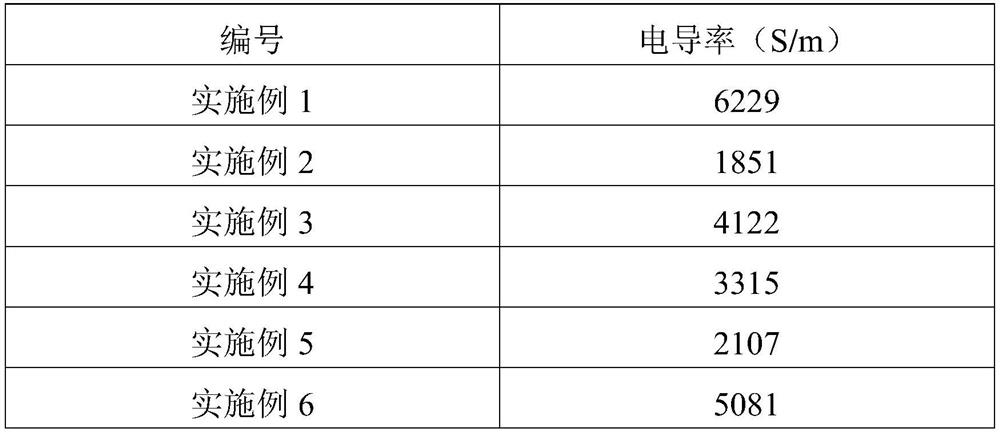

Conductive conjugated microporous polymer and preparation method thereof

PendingCN112679949ABroaden research directionSimple processMagnetic/electric field screeningMicroelectronicsPolymer chemistry

The invention discloses a conductive conjugated microporous polymer and a preparation method thereof, the conductive conjugated microporous polymer is composed of a conductive polymer and a conjugated microporous polymer, and the conductive polymer is distributed in nanopores of the conjugated microporous polymer. The conductive conjugated microporous polymer has adjustable conductivity and can be widely applied to the fields of electromagnetic wave absorption, microelectronics, conductive fillers, energy storage, catalysis, sensing and the like, and the preparation method is simple in process, low in cost and beneficial to large-scale preparation.

Owner:NANJING UNIV OF SCI & TECH

Lipoic acid-modified ethyl cellulose film and preparation method thereof

The invention discloses ipoic a lacid-modified ethyl cellulose film and a preparation method thereof. The preparation method comprises the following steps: step 1, weighing ethyl cellulose, adding theweighed ethyl cellulose into a reaction container, adding an organic solvent, carrying out heating and continuous stirring until the ethyl cellulose is completely dissolved, and performing cooling toroom temperature so as to obtain an ethyl cellulose solution; 2, weighing solid lipoic acid, adding the solid lipoic acid into another reaction container, and adding an organic solvent for dissolvingof the solid lipoic acid to obtain a lipoic acid solution; and 3, weighing a proper amount of the lipoic acid solution, the ethyl cellulose solution and a polymerization inhibitor, carrying out blending and stirring until the formed mixed solution is clear, pouring the mixed solution into a mold, and putting the mold into an oven to form a film. Compared with a pure ethyecellulose film, the filmprovided by the invention has the advantages that the mechanical properties of the film are greatly improved, and the application range of the ethyecellulose film can be widened. Besides, the film prepared by taking ethyl cellulose which is wide in source and renewable as a raw material and taking non-toxic and environment-friendly lipoic acid as a modifier has the advantages of excellent performance, water resistance, degradability and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

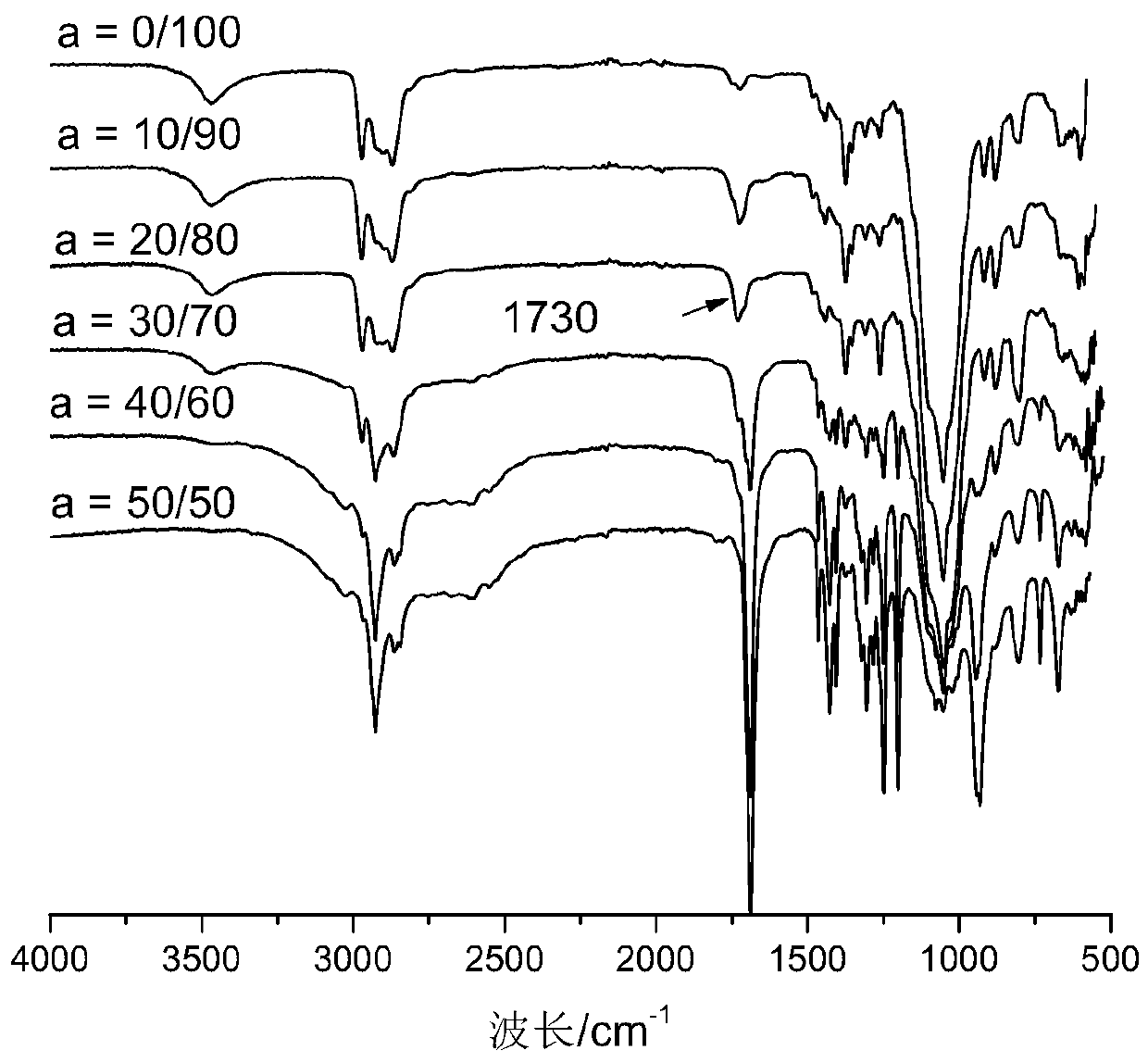

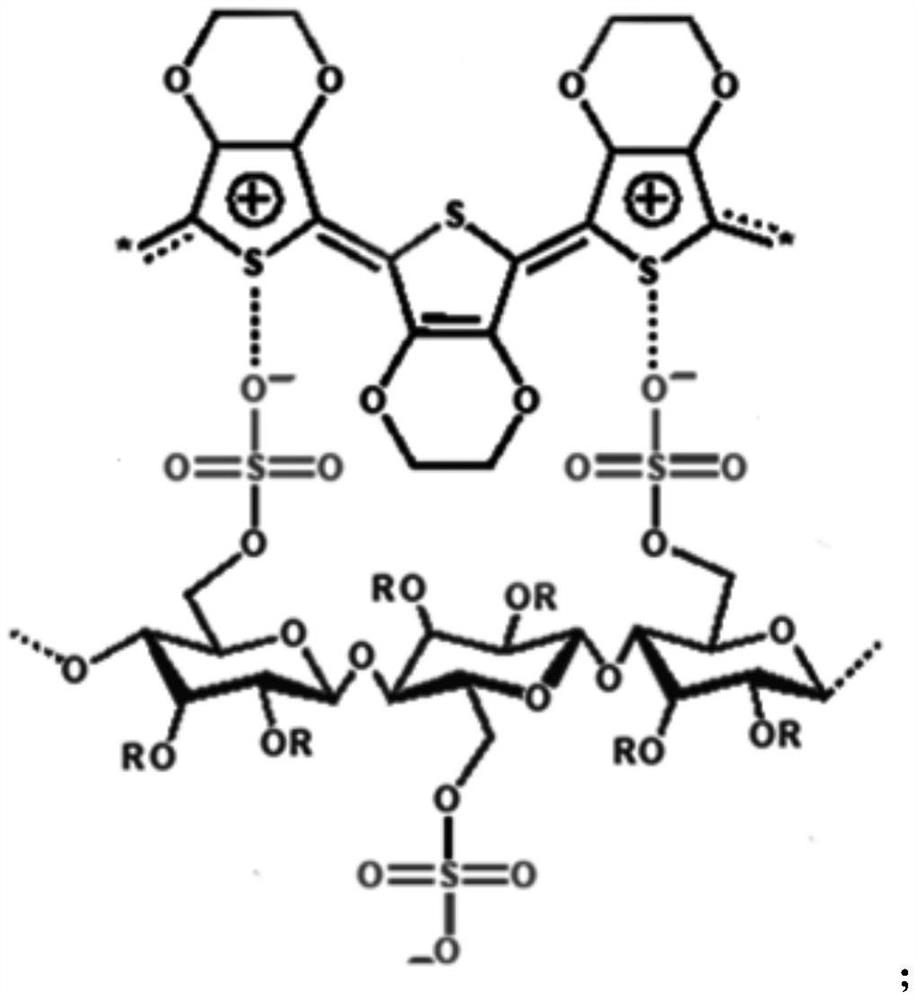

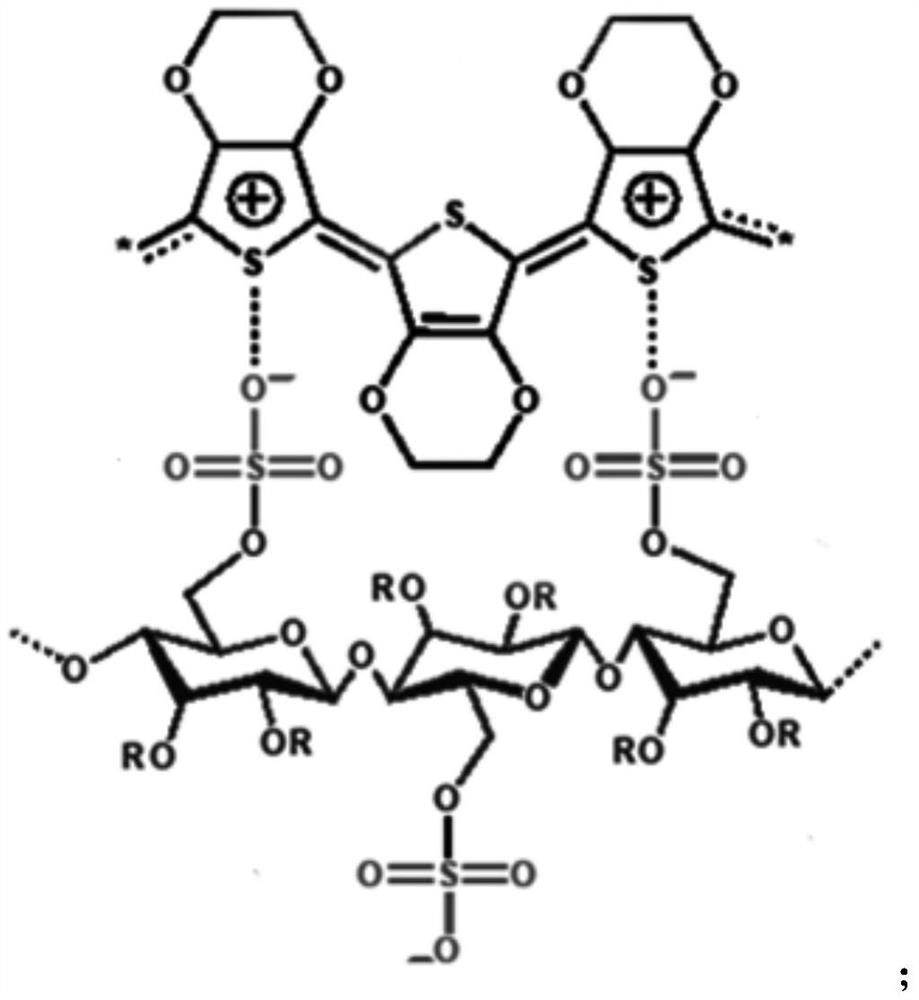

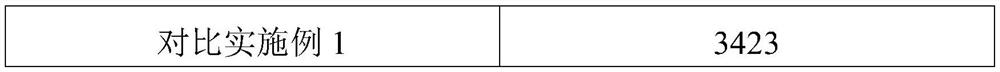

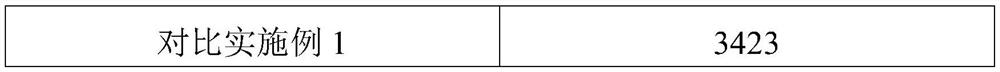

PEDOT:CS water dispersion system taking cellulose sulfate as template and preparation method of PEDOT:CS water dispersion system

The invention discloses a PEDOT:CS water dispersion system taking cellulose sulfate as a template and a preparation method of the PEDOT:CS water dispersion system. The method comprises the following steps: adding cellulose sulfate into water to obtain a cellulose sulfate aqueous solution, and then adding a monomer EDOT to obtain a mixed solution; and adding ammonium persulfate and ferric chlorideinto the mixed solution for polymerization reaction to obtain a PEDOT:CS water dispersion system taking cellulose sulfate as a template. On one hand, the invention provides the method for preparing cellulose sulfate, and provides the new PEDOT water dispersion system by replacing PSS with cellulose sulfate as a polymerization template of PEDOT. On the other hand, the prepared PEDOT:CS aqueous dispersion has good system stability, high PEDOT content and high conductivity, and has good application prospects in the fields of electrochromism, electromagnetic shielding, supercapacitors, electrochemical sensors and the like.

Owner:SOUTH CHINA UNIV OF TECH

Water-based lubricant and preparation method thereof

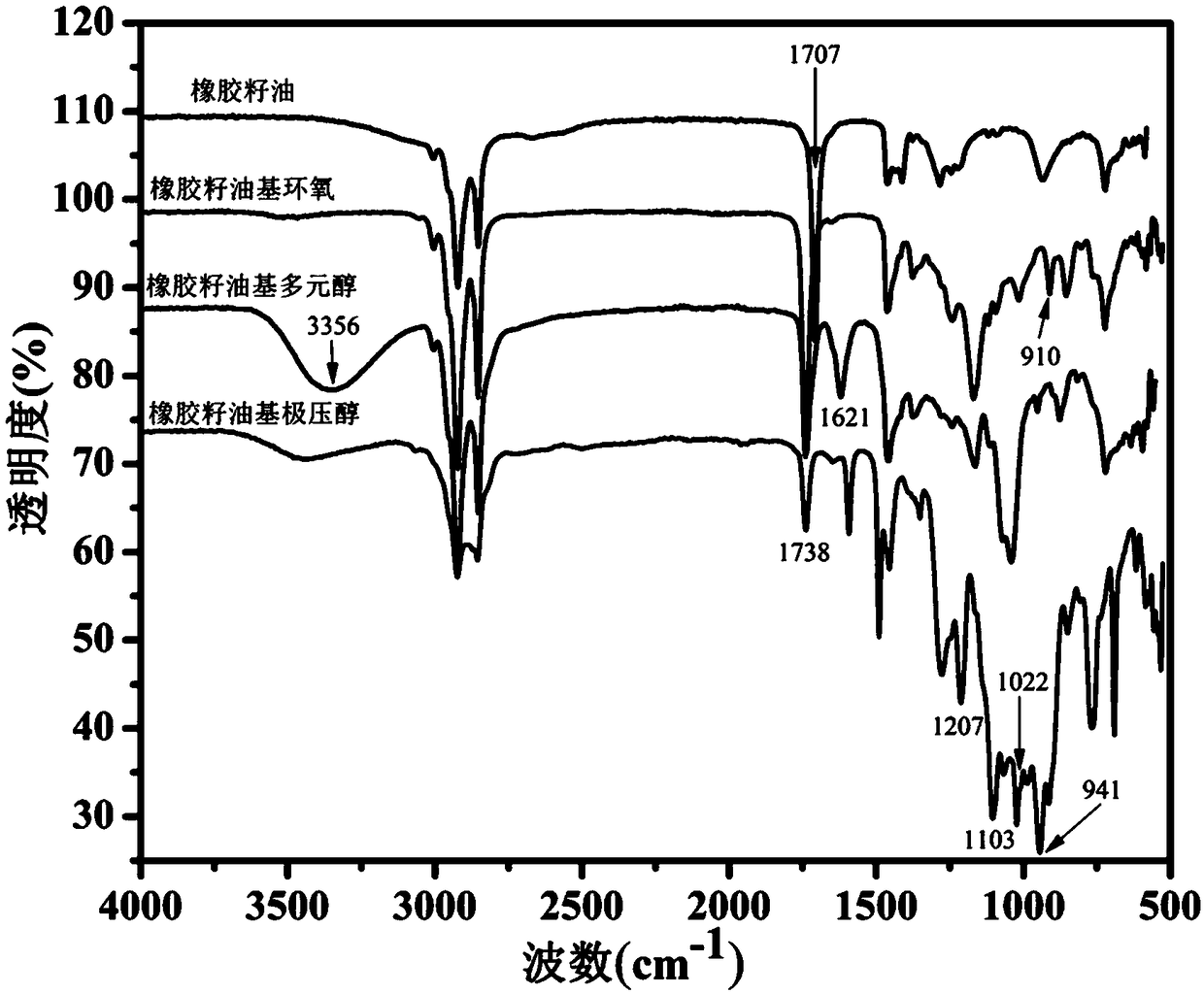

ActiveCN108624381AEnhance performance and valueMild reaction conditionsGroup 5/15 element organic compoundsAdditivesLubricationRubber seed oil

The invention discloses a water-based lubricant and a preparation method thereof. The preparation method comprises the following steps: carrying out an epoxy open-loop reaction on rubber seed oil andepoxy chloropropane; carrying out a closed-loop reaction on sodium hydroxide and calcium oxide so as to obtain rubber seed oil-based epoxy; carrying out an open-loop reaction on the rubber seed oil-based epoxy with an alkylol amine compound in an inert organic solvent so as to obtain rubber seed oil-based multi-element alkylol amine; carrying out an esterification reaction on an alcohol or alcoholether with the rubber seed oil-based multi-element alkylol amine and a phosphoryl chloride compound in an inert organic solvent so as to obtain a rubber seed oil-based extreme pressure alcohol or a rubber seed oil-based extreme pressure ether; dissolving the rubber seed oil-based extreme pressure alcohol or the rubber seed oil-based extreme pressure ether into a solution, thereby obtaining a stable green environmental-friendly water-based lubricant under the coactions of hydrogen bonds. The green environmental-friendly water-based lubricant prepared by using the method disclosed by the invention has multiple effects of lubrication, environment protection and extreme pressure wearing resistance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

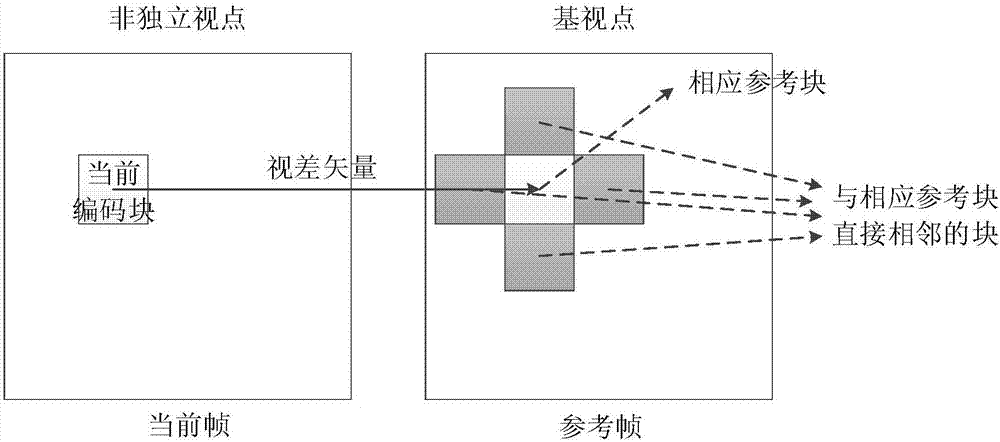

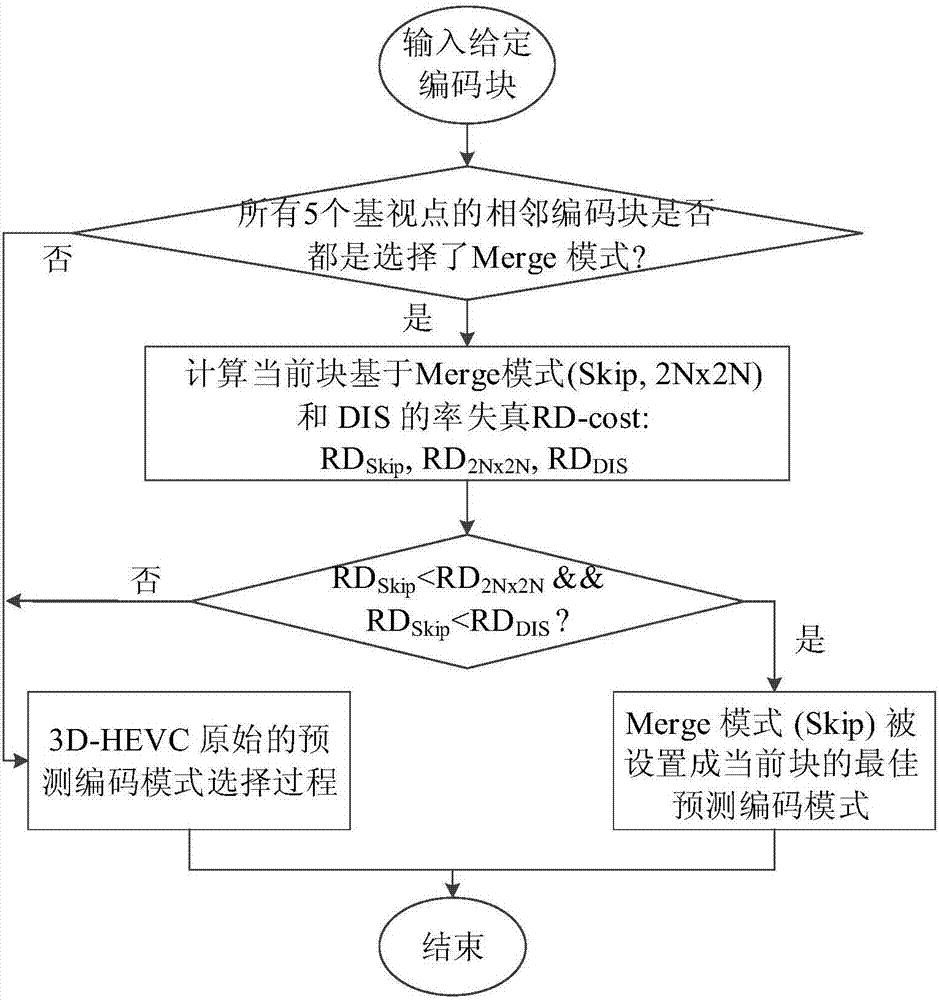

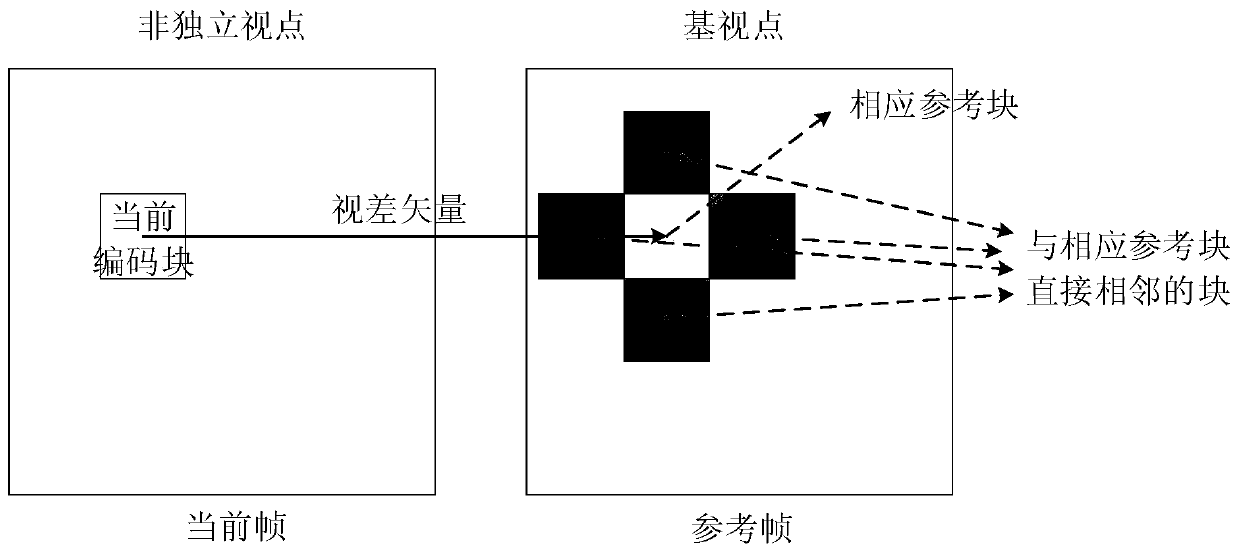

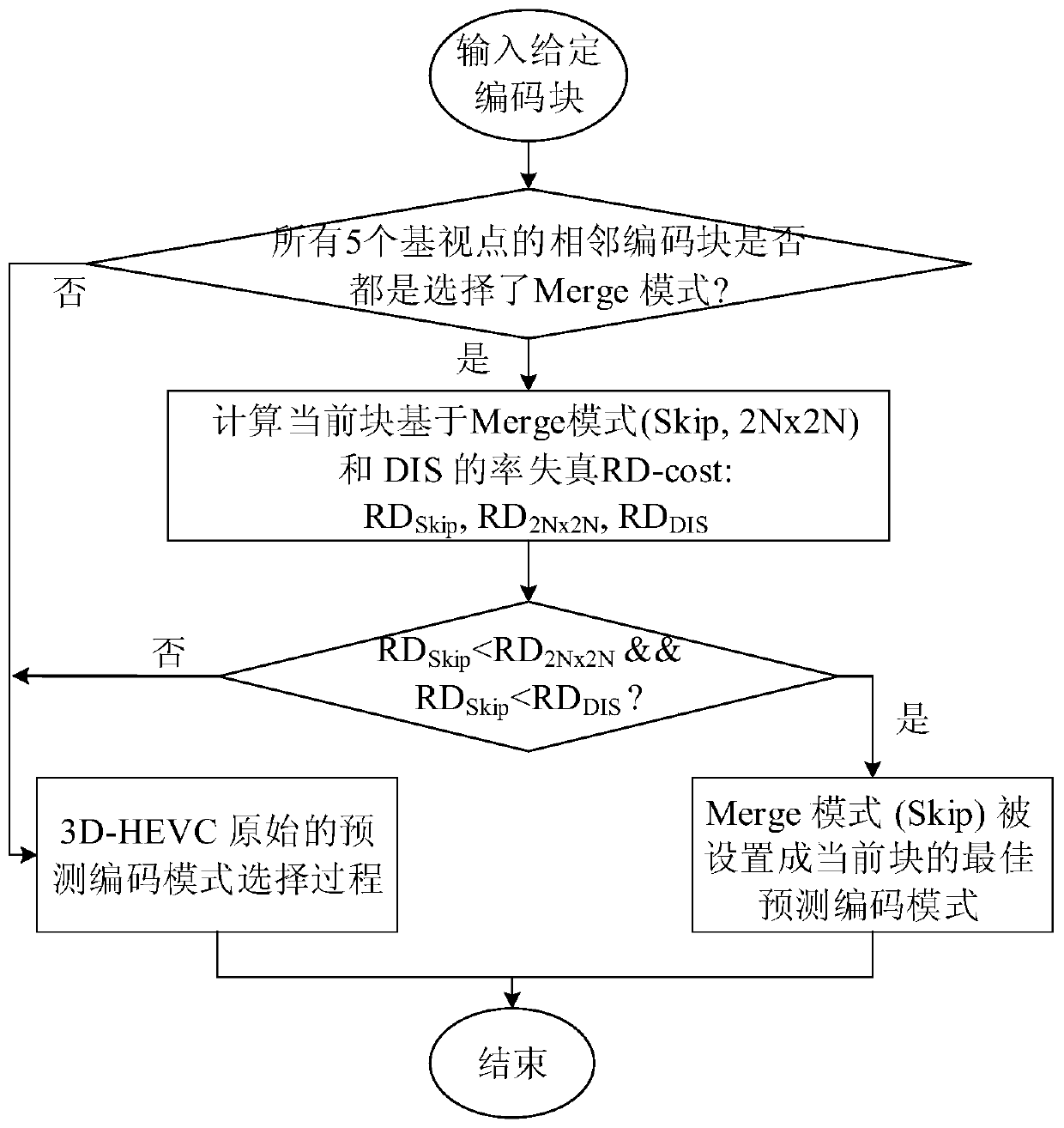

3D video depth image prediction mode selection method based on viewpoint correlation

ActiveCN107071479ABroaden research directionReduce coding complexityDigital video signal modificationCoding blockRound complexity

The invention discloses a 3D video depth image prediction mode selection method based on the viewpoint correlation. The method comprises the steps of: preliminarily judging the possibility that a current coding block selects the Skip mode by utilizing the viewpoint correlation at first; and then, for the coding block having high possibility, comparing the rate distortion RD-cost of the Skip mode with the rate distortion RD-cost of the 2N*2N Merge mode and the DIS mode, determining whether the current block selects the Skip mode or not, and ending a prediction mode selection process in advance. By means of the 3D video depth image prediction mode selection method based on the viewpoint correlation disclosed by the invention, the depth image prediction coding complexity can be reduced; the coding time required by prediction can be reduced; and furthermore, the video quality in the synthesis visual angle of the final decoding end can be ensured.

Owner:NANJING UNIV OF SCI & TECH

Method for synthesizing cationic polycarboxylate superplasticizer based on Hoffmann rearrangement reaction

The invention discloses a method for synthesizing a cationic polycarboxylate superplasticizer based on a Hoffmann rearrangement reaction, and belongs to the field of water reducing agents. Unsaturated amide monomers are modified into unsaturated isocyanate, meanwhile, an oxidation-reduction initiating system is formed by high-valence cerate and alcohol to initiate polymeric unsaturated cation quaternary ammonium salt monomers, a hydroxyl-terminated cation side chain is obtained, then isocyanate reacts with the hydroxyl-terminated cation side chain and polyethylene glycol monomethyl ether to obtain cationic macromonomers and polyether macromonomers, then the cationic macromonomers, the polyether macromonomers and small carboxylic acid monomers are subjected to free radical copolymerization, and the cationic polycarboxylate superplasticizer is obtained. Based on the Hoffmann rearrangement reaction principle, unsaturated amide modified amide reacts with the cation side chain and a polyether side chain, the macromonomers with different structures and different functions are designed and synthesized, and the novel pectinated polycarboxylate superplasticizer with polycarboxylic acid as a main chain and cations and polyether as the side chain is obtained finally. The synthesis process is continuous and easy to control, and multiple effects of excellent water reduction, collapse protection, clay resistance and the like are shown.

Owner:中铁一局集团工业贸易有限公司

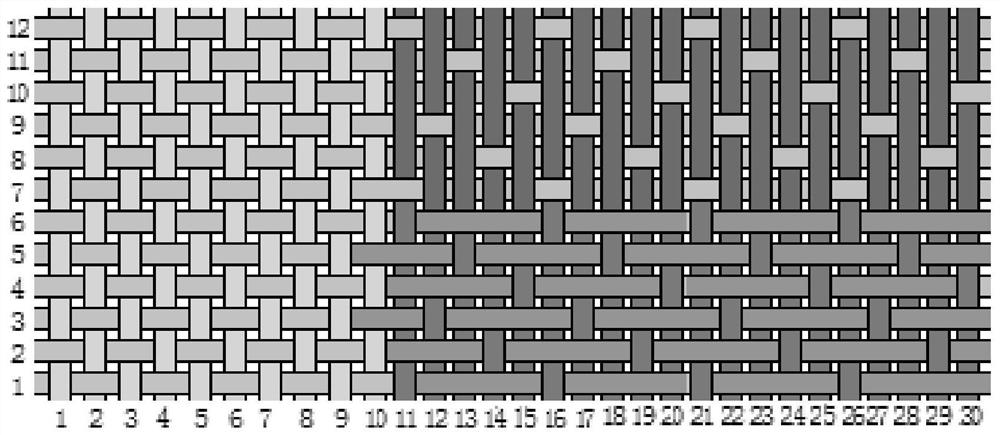

Making method of wool-like fabric

ActiveCN110257999AImprove qualityRealize comprehensive development applicationWoven fabricsEngineeringCopper

The invention relates to a making method of wool-like fabric. The making method includes following steps: 1, taking copper ammonia fiber as warp of fabric for standby use; 2, using the copper ammonia fiber and modal fiber to form blended yarn according to a ratio of 50:50, and taking the blended yarn as weft for standby use; 3, adopting a loom to interweave the warp in the step 1 and the weft in the step 2, wherein fabric after being interwoven is of a small jacquard structure with plain weave and combined weave alternately circulated. Copper ammonia wool-like new products are studied to realize comprehensive development and application of the copper ammonia fiber, so that related study direction and application field are expanded. The wool-like fabric made by the method is excellent in quality and low in cost; textile fabric after being interwoven is highly wool-like in hand feeling and excellent in softness, comfort and drapability.

Owner:WUJIANG DEYI FASHIONS CLOTHS

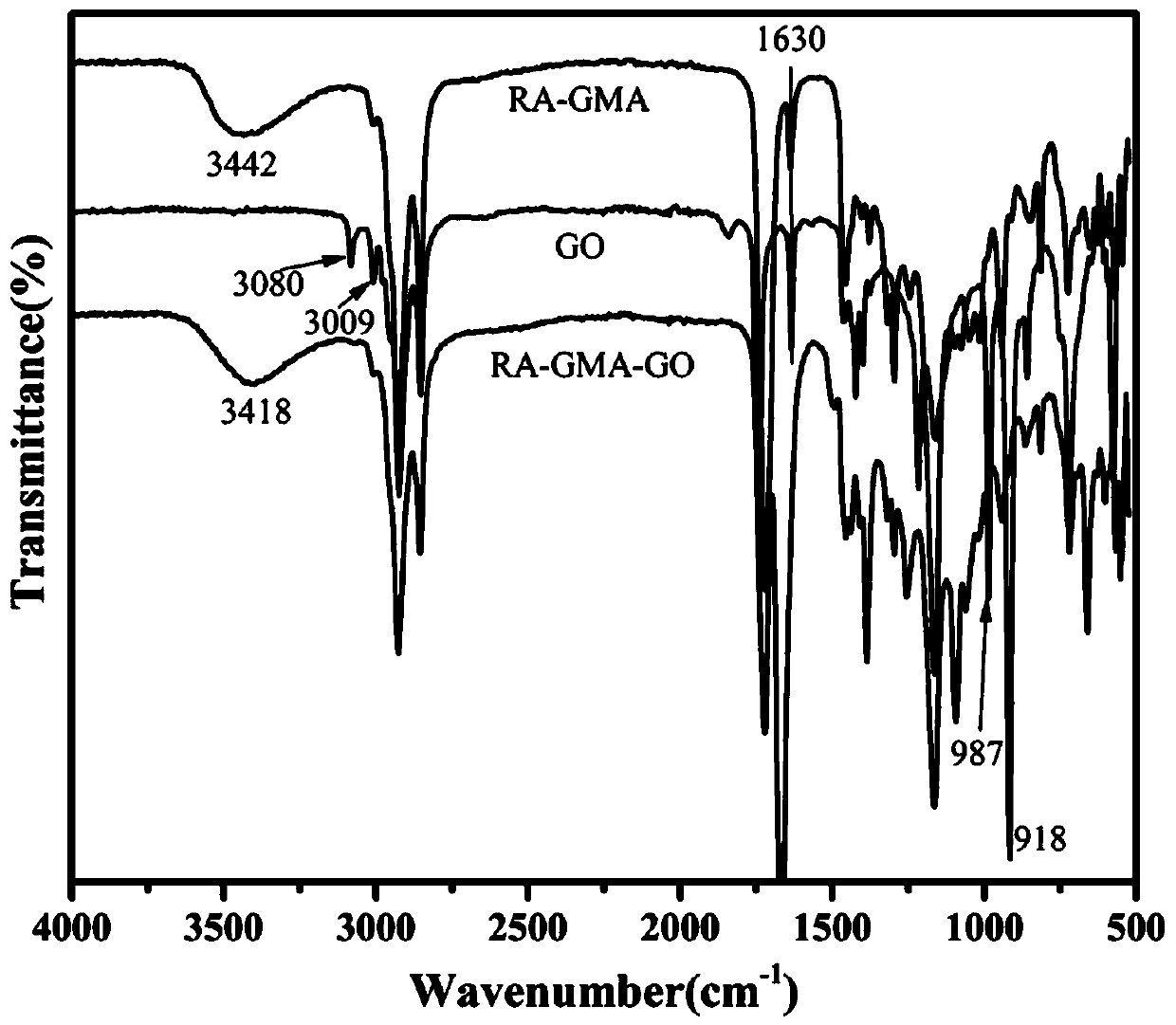

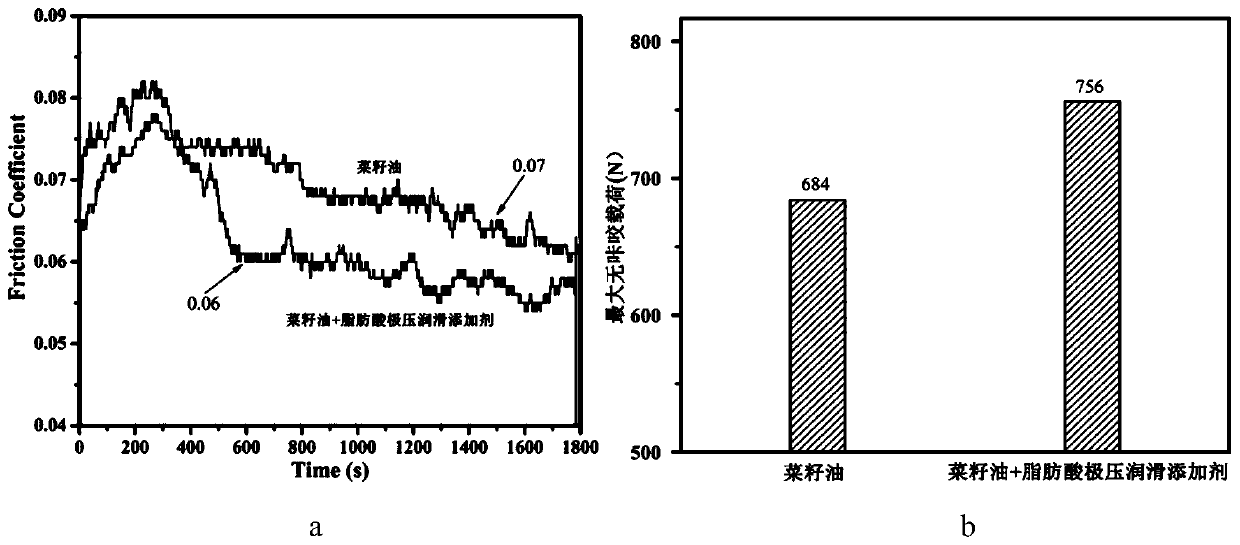

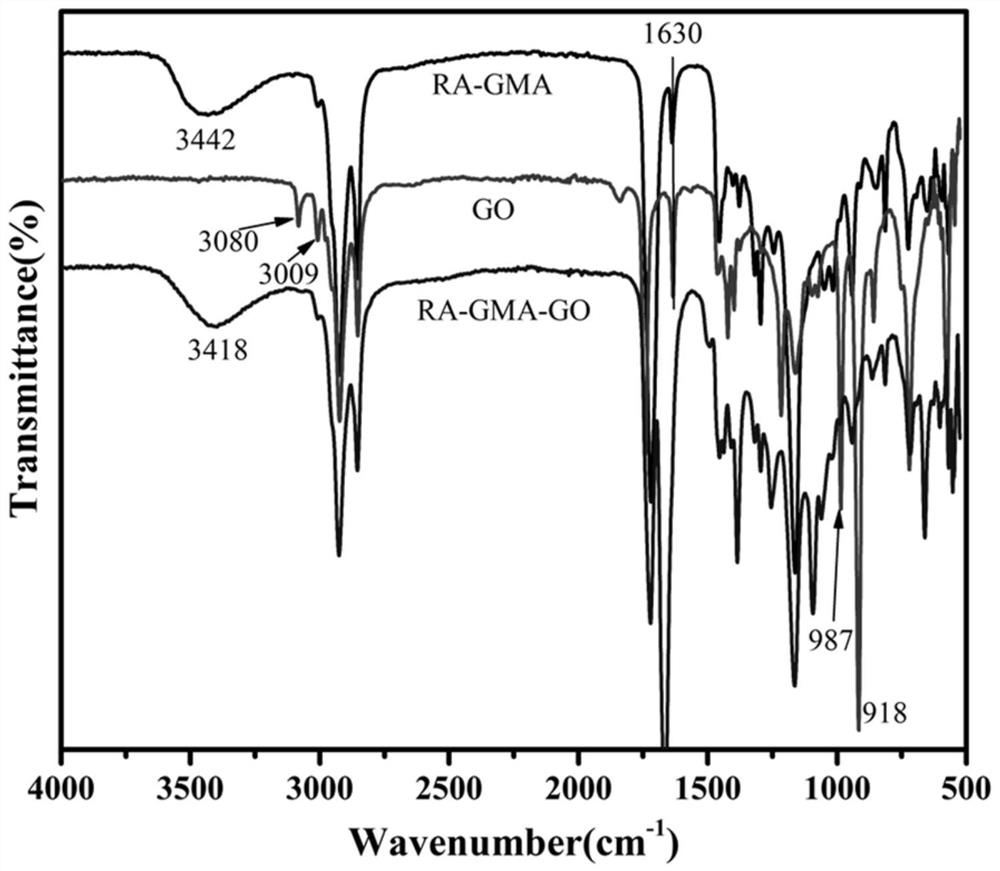

Bio-based extreme pressure lubricant and preparation method thereof

ActiveCN110964595AMild reaction conditionsSimple processLubricant compositionOrganic solventVegetable oil

The invention discloses a bio-based extreme pressure lubricant and a preparation method thereof. The preparation method comprises the following steps: step 1, mixing fatty acid, a compound containingterminal double bonds, a quaternary ammonium salt catalyst and hydroquinone, and reacting to obtain fatty acid containing terminal double bonds; step 2, carrying out polymerization reaction on the fatty acid containing the terminal double bond obtained in the step 1 and garlic oil in an inert organic solvent containing an initiator; and then evaporating under reduced pressure to remove the inert organic solvent to obtain a fatty acid-based extreme-pressure lubricating additive; and 3, dissolving the fatty acid-based extreme pressure lubricant additive obtained in the step 2 in vegetable oil toobtain the bio-based extreme pressure lubricant.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY +1

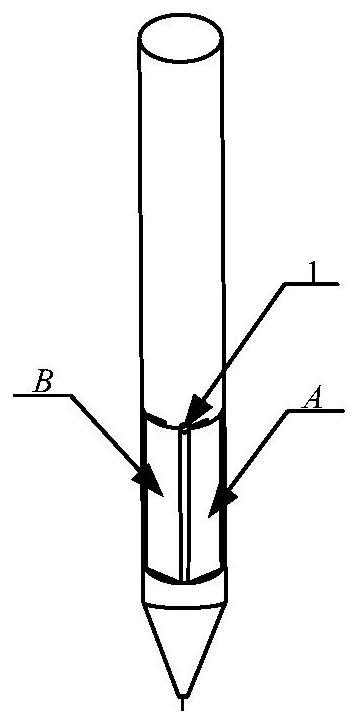

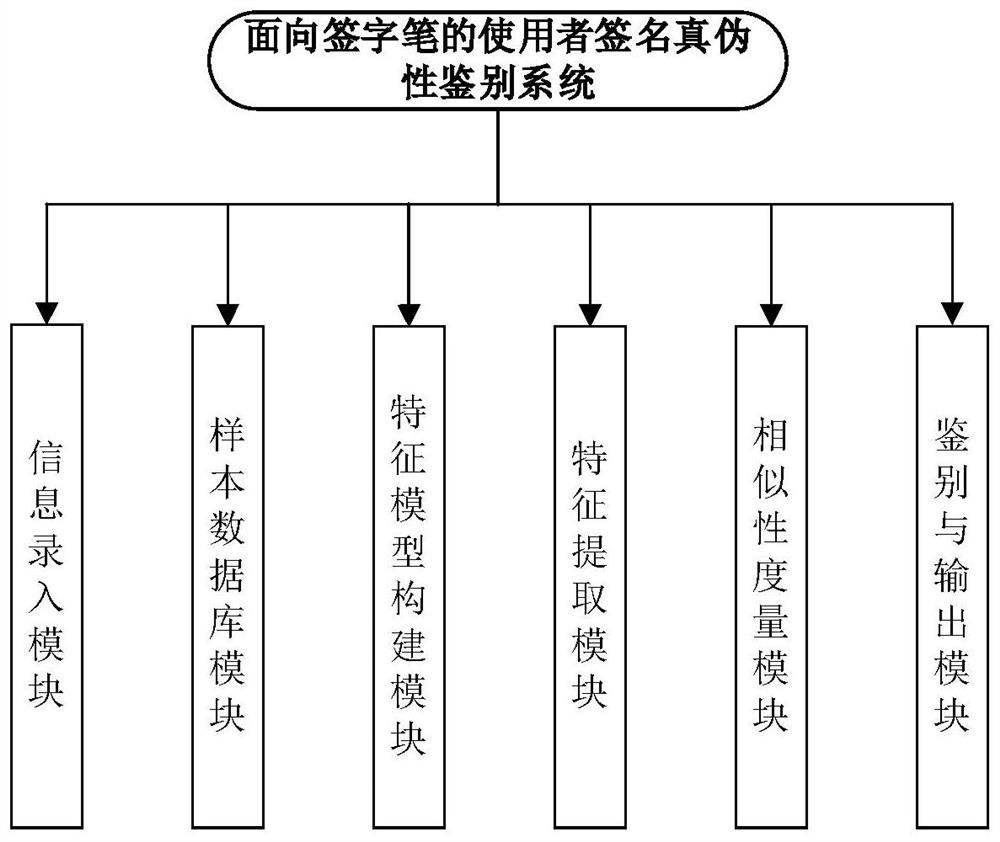

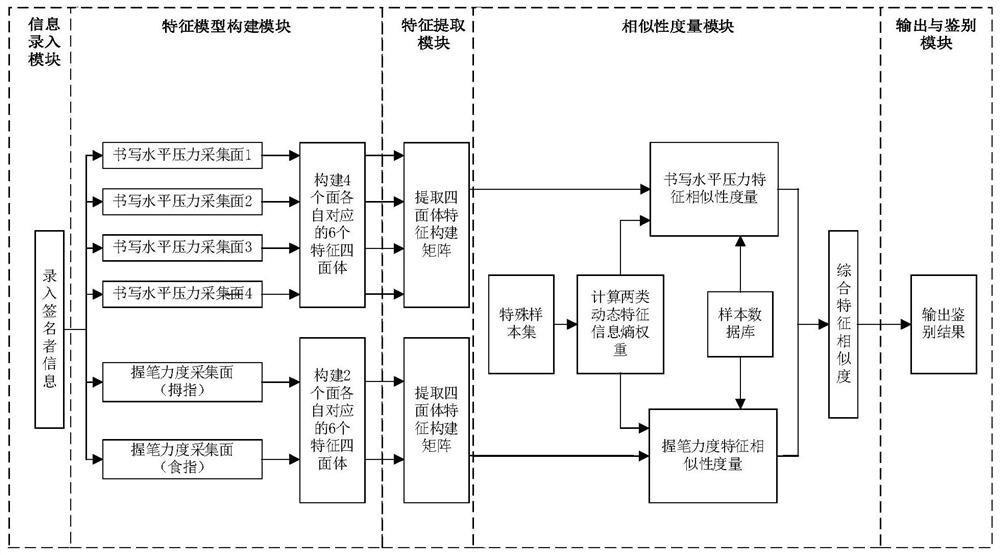

A signature authenticity identification system for signature pen

ActiveCN107657241BImprove accuracyImprove robustnessCharacter and pattern recognitionHandwritingFeature extraction

Owner:HOHAI UNIV CHANGZHOU

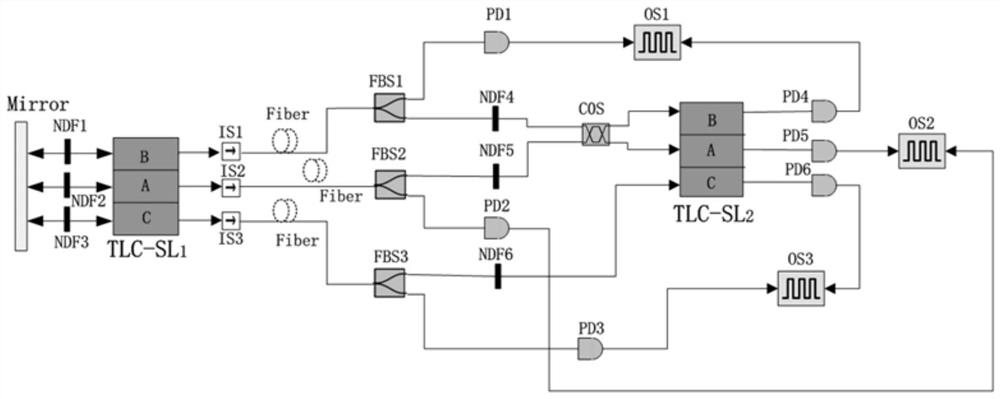

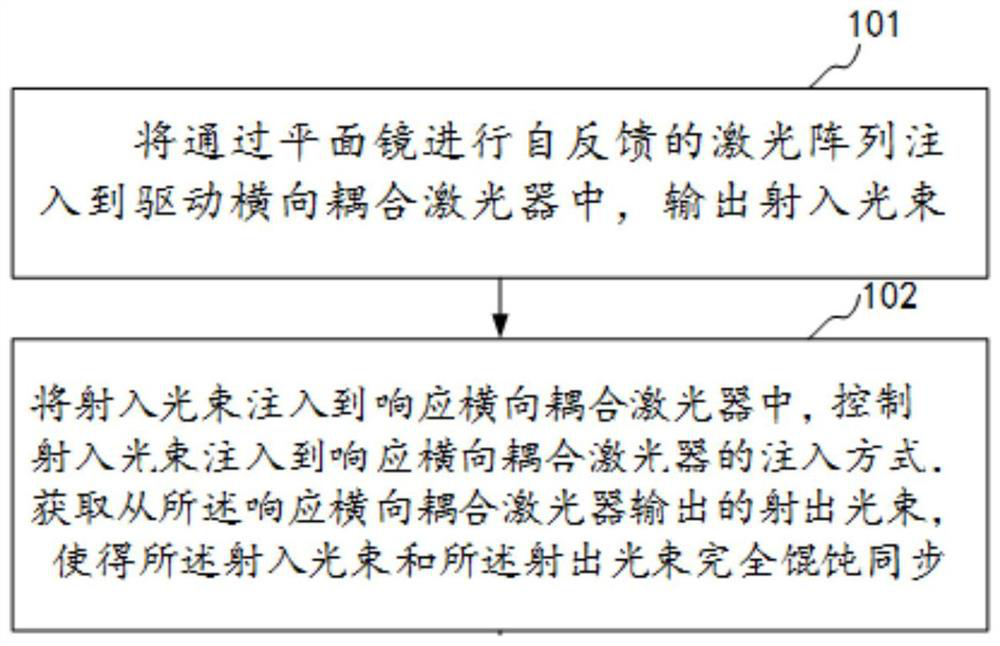

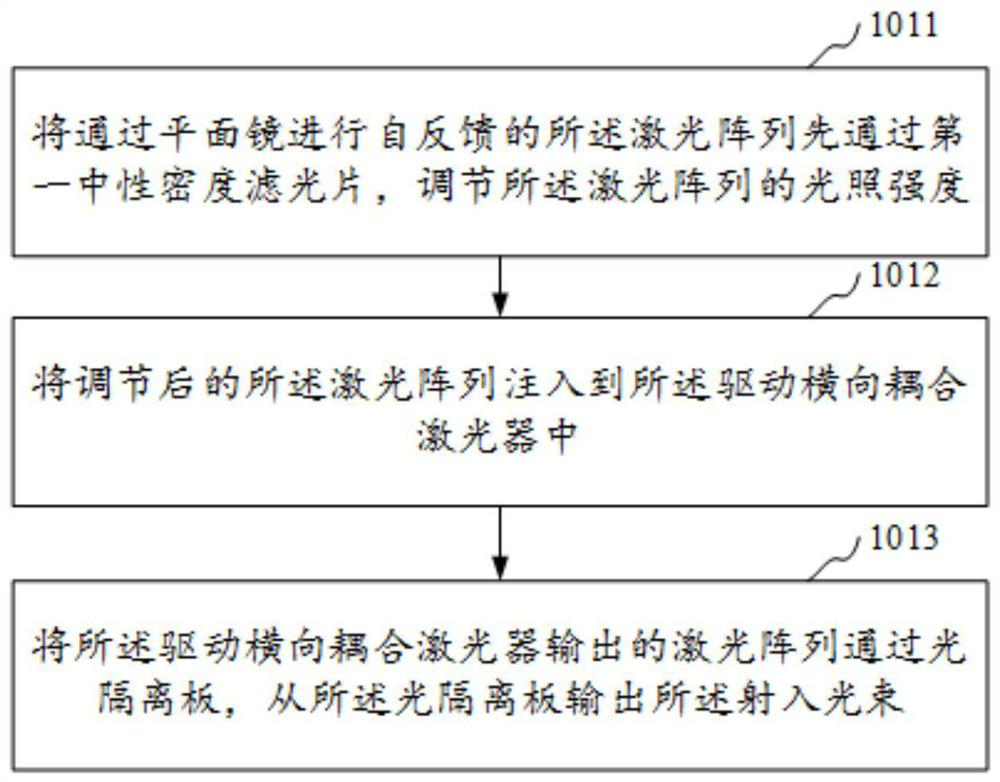

Light beam chaotic synchronous control method based on self-feedback transverse coupling laser

ActiveCN111969405AQuality improvementResearch Directions for Improving Chaotic Synchronous ControlLaser arrangementsLaser arrayPlane mirror

The invention relates to a light beam chaotic synchronization control method based on a self-feedback transverse coupling laser. The method comprises the steps of: injecting a laser array which carries out self-feedback through a plane mirror into a driving transverse coupling laser, and outputting an incident light beam; and injecting the incident light beam into a response transverse coupling laser, controlling an injection mode of injecting the incident light beam into the response transverse coupling laser, and obtaining an emergent light beam output from the response transverse coupling laser, so as to realize the completely chaotic synchronization of the incident light beam and the emergent light beam. By means of the method, the injection mode of injecting the incident light beam into the response transverse coupling laser is controlled, and high-quality complete chaotic synchronization control over all laser elements can be achieved for the driving transverse coupling laser under different self-feedback conditions.

Owner:WUYI UNIV

CNT:SNC:PEDOT ternary water-based conductive ink and preparation method thereof

ActiveCN112341865ABroaden research directionImprove resource utilizationInksAmmonium sulfateFlexible electronics

The invention discloses a CNT:SNC:PEDOT ternary water-based conductive ink and a preparation method thereof. The method comprises the following steps: adding carbon nanotubes into a sulfated nanocellulose aqueous dispersion, and conducting uniform dispersing to obtain a CNT:SNC dispersion; adding an EDOT monomer into the CNT:SNC dispersion, and conducting uniform stirring to obtain a mixed liquid;and adding ammonium persulfate and ferric chloride into the mixed solution, and carrying out polymerization reaction in an inert atmosphere to obtain the CNT:SNC:PEDOT ternary water-based conductiveink. The CNT:SNC:PEDOT ternary conductive ink has the advantages of being water-based, environment-friendly, good in stability, good in adhesive force, free of heating curing, high in universality andthe like. Meanwhile, due to the advantages of stable dispersion, high conductivity, excellent printing adaptability, excellent coating mechanical stability and the like, the conductive ink provided by the invention is expected to be applied to printing of various flexible electronic devices.

Owner:SOUTH CHINA UNIV OF TECH

A kind of lipoic acid modified ethyl cellulose film and preparation method thereof

A lipoic acid modified ethyl cellulose film and a preparation method thereof, the first step is to weigh ethyl cellulose in a reaction vessel, add an organic solvent, heat up and continue stirring until the ethyl cellulose is completely dissolved and then cooled to room temperature , can obtain ethyl cellulose solution; second step, weigh solid lipoic acid and join in reaction container, add organic solvent to dissolve, can obtain lipoic acid solution; The cellulose-based solution and the polymerization inhibitor are blended, stirred until the mixed solution is clear, poured into a mold, and put into an oven to form a film. Compared with the pure ethyl cellulose film, the membrane material of the invention has greatly improved mechanical properties and can broaden the application range of the ethyl cellulose film. In addition, the present invention uses the widely sourced and renewable ethyl cellulose as the raw material and the non-toxic and environment-friendly lipoic acid as the modifier, and the prepared film has excellent performance and has the advantages of water resistance and degradability.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

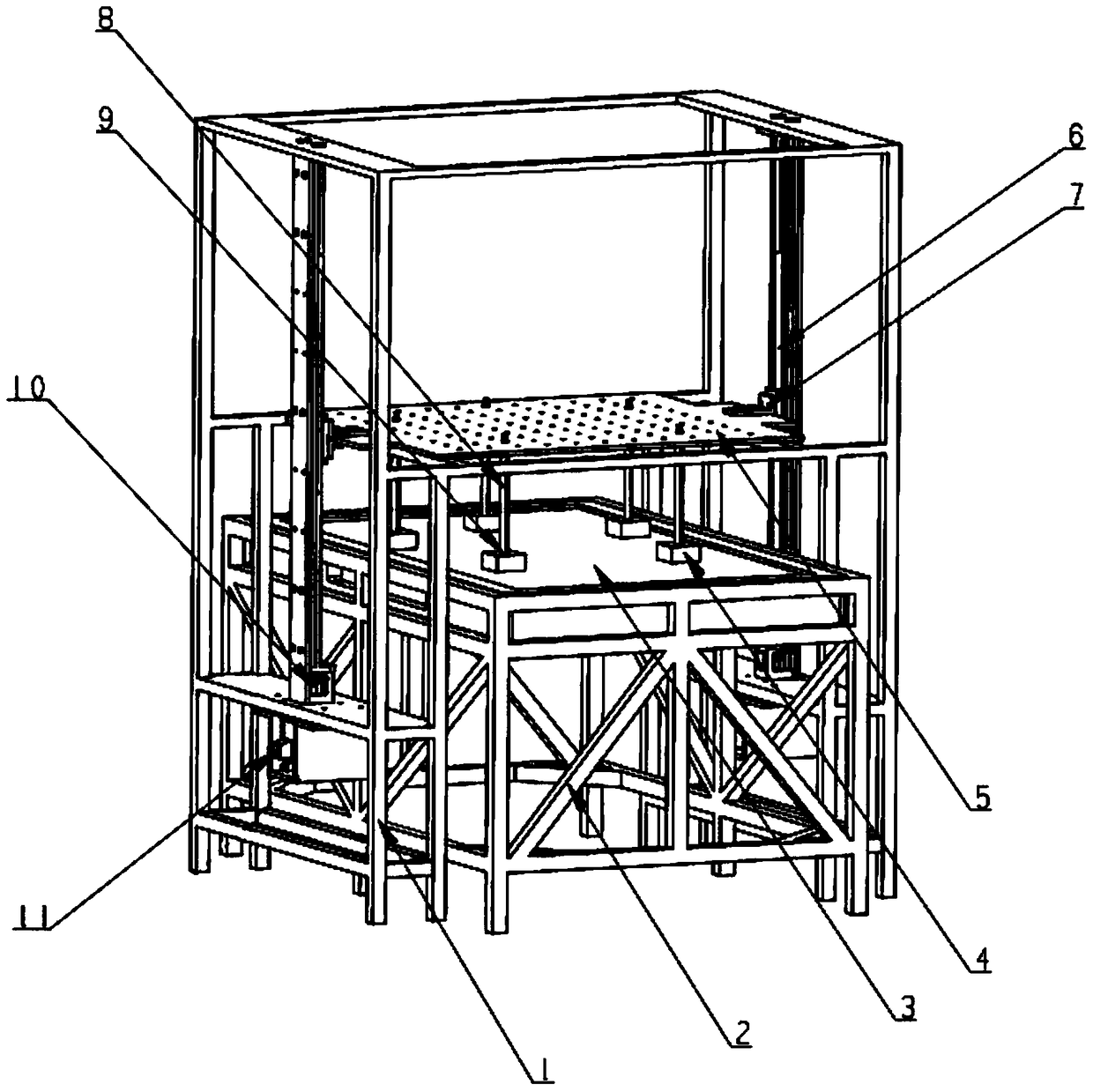

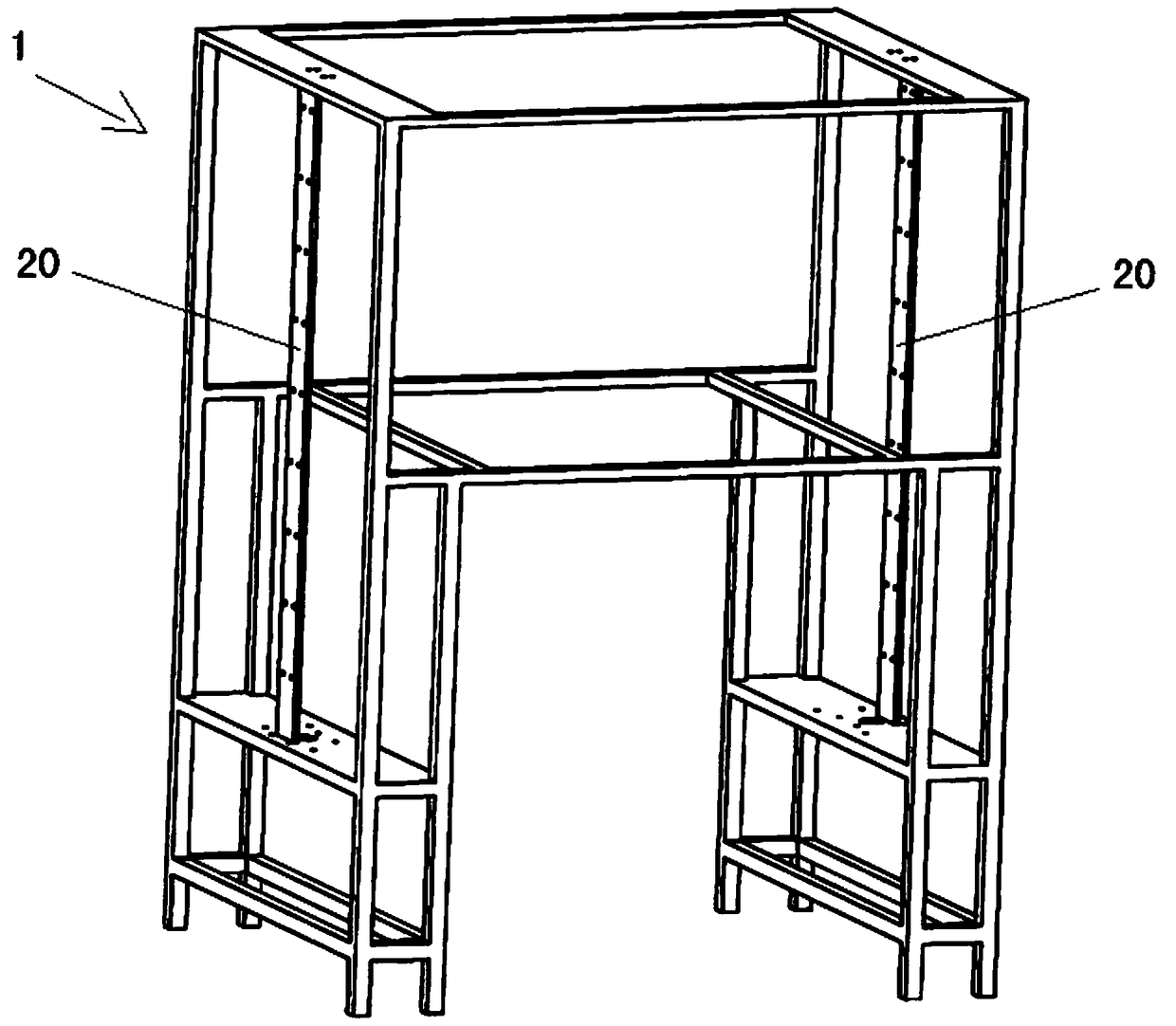

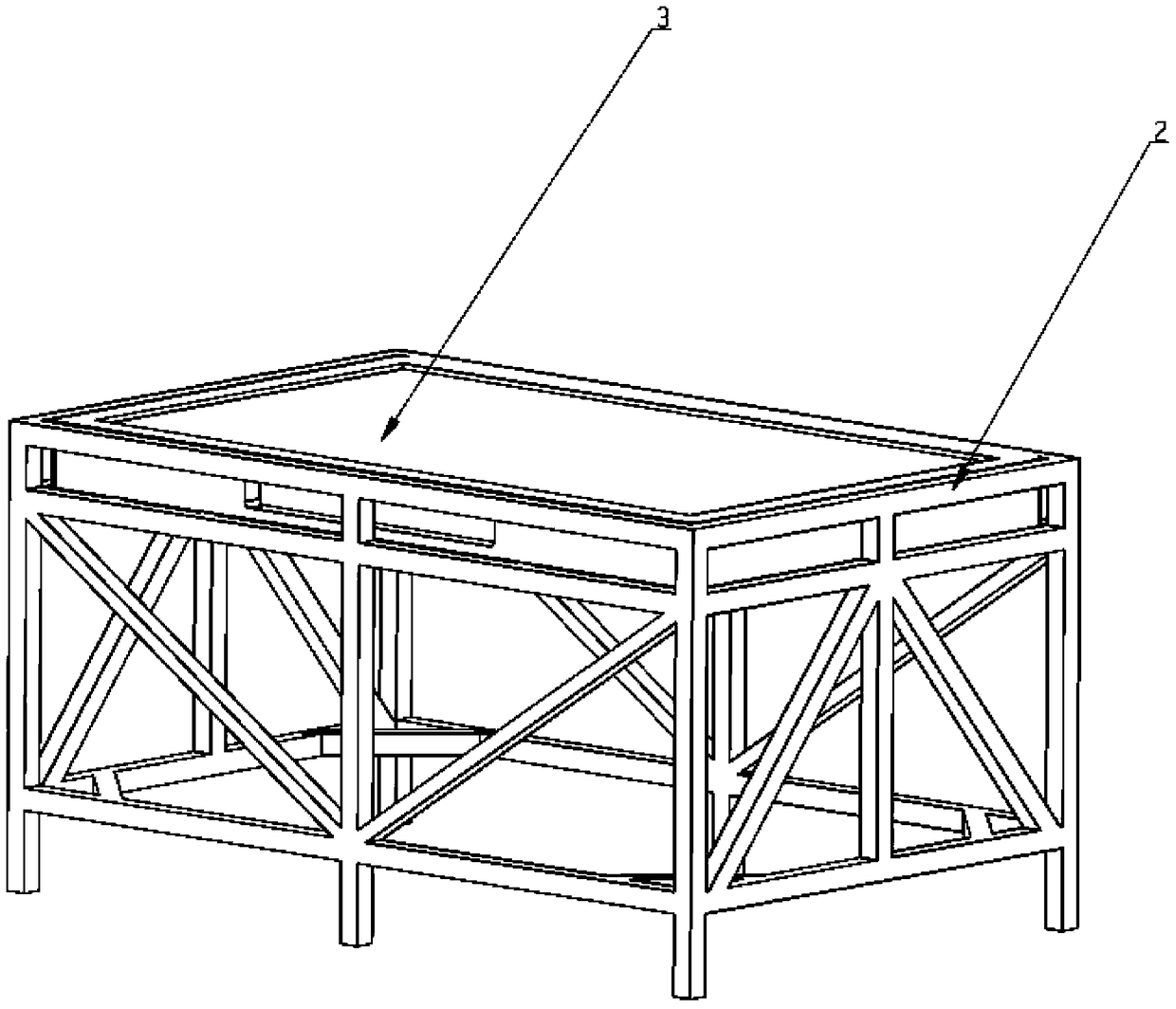

A Two-Dimensional Trajectory Tracking Mechanism for Moving Objects

The invention discloses a moving object two-dimensional trajectory tracking mechanism. The moving object two-dimensional trajectory tracking mechanism comprises a rack, a multi-point infrared acquisition device, a mechanical arm device and a driving device, wherein the multi-point infrared acquisition device is movably arranged at the lower part of the interior of the rack and is used for capturing the movement trajectories of a moving object, the mechanical arm device is fixedly arranged on the rack and is located above the multi-point infrared acquisition device in a lifting manner and is used for pressing the object on the multi-point infrared acquisition device, and the driving device is fixedly arranged on the rack and is used for driving the mechanical arm device. The moving object two-dimensional trajectory tracking mechanism of the invention has the advantages of simple operation, more accurate trajectory capture and high work efficiency.

Owner:GUANGXI UNIV

Method for Synthesizing Cationic Polycarboxylate Water Reducer Based on Hoffmann Rearrangement Reaction

The invention discloses a method for synthesizing a cationic polycarboxylate superplasticizer based on a Hoffmann rearrangement reaction, and belongs to the field of water reducing agents. Unsaturated amide monomers are modified into unsaturated isocyanate, meanwhile, an oxidation-reduction initiating system is formed by high-valence cerate and alcohol to initiate polymeric unsaturated cation quaternary ammonium salt monomers, a hydroxyl-terminated cation side chain is obtained, then isocyanate reacts with the hydroxyl-terminated cation side chain and polyethylene glycol monomethyl ether to obtain cationic macromonomers and polyether macromonomers, then the cationic macromonomers, the polyether macromonomers and small carboxylic acid monomers are subjected to free radical copolymerization, and the cationic polycarboxylate superplasticizer is obtained. Based on the Hoffmann rearrangement reaction principle, unsaturated amide modified amide reacts with the cation side chain and a polyether side chain, the macromonomers with different structures and different functions are designed and synthesized, and the novel pectinated polycarboxylate superplasticizer with polycarboxylic acid as a main chain and cations and polyether as the side chain is obtained finally. The synthesis process is continuous and easy to control, and multiple effects of excellent water reduction, collapse protection, clay resistance and the like are shown.

Owner:中铁一局集团工业贸易有限公司

Fast decision-making method for 3D video depth image quadtree coding structure division

ActiveCN108347605BReduce complexityBroaden research directionDigital video signal modificationCoding blockTheoretical computer science

The invention discloses a fast decision-making method for 3D video depth image quadtree coding structure division. The method is: first obtain the optimal prediction mode of the current coding block and its first small subsidiary coding block, and the corresponding rate-distortion value through the traditional coding method; then determine the optimal mode of the first small subsidiary coding block Whether it is Skip mode, if so, further judge whether the rate-distortion value of the current coding block is less than or equal to 4 times the rate-distortion value of the first small subsidiary coding block, if so, terminate the quadtree coding structure of the current coding block in advance divided. The present invention reduces the complexity of intra-frame predictive encoding of depth images, reduces the encoding time required for prediction, and ensures the video quality of the synthesized view at the final decoding end.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing high mud-resistant polycarboxylic acid dispersant by grafting cationic side chains by copolymerization of unsaturated halogenated hydrocarbons

ActiveCN106188557BThe polymerization process is mild and stableLess side effectsAlcoholPolyethylene glycol

Owner:BEIJING UNIV OF TECH

A kind of cnt:snc:pedot ternary water-based conductive ink and preparation method thereof

ActiveCN112341865BBroaden research directionImprove resource utilizationInksCarbon nanotubeFlexible electronics

Owner:SOUTH CHINA UNIV OF TECH

A kind of bio-based extreme pressure lubricant and preparation method thereof

ActiveCN110964595BMild reaction conditionsSimple processLubricant compositionPolymer scienceVegetable oil

A bio-based extreme pressure lubricant and a preparation method thereof. In the first step, a fatty acid, a compound containing a terminal double bond, a quaternary ammonium salt catalyst, and hydroquinone are mixed and reacted to obtain a fatty acid containing a terminal double bond; in the second step, the above The terminal double bond-containing fatty acid obtained in the first step and garlic oil are polymerized in an inert organic solvent containing an initiator; then the inert organic solvent is evaporated under reduced pressure to obtain a fatty acid-based extreme pressure lubrication additive; the third step is to use the obtained Fatty acid-based extreme pressure lubricant additives are dissolved in vegetable oil to obtain bio-based extreme pressure lubricants.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY +1

Medium and low temperature curing bio-based epoxy asphalt composite material and application thereof

InactiveCN113278297AGood flexibilityImprove toughnessBuilding insulationsLow temperature curingFirming agent

The invention relates to a medium and low temperature curing bio-based epoxy asphalt composite material and application thereof. The material is composed of a component A and a component B. The component A comprises the following components by mass: 15-40 parts of bisphenol A epoxy resin, 9.8-25 parts of modified epoxy resin, 4.5-10 parts of an epoxy diluent, 0.1-1 part of a curing accelerator, and 40-50 parts of petroleum asphalt. And the component B is a curing agent. The mass part ratio of the component A to the component B is 100: (50-70). The epoxy asphalt composite material prepared by the invention has the advantages of high strength, high toughness, medium and low temperature curing, strong compatibility, low energy consumption, low pollution, low cost, environmental protection and the like, and can be widely applied to road pavement of pavements and bridge floors.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

3D Video Depth Image Prediction Mode Selection Method Based on Viewpoint Correlation

ActiveCN107071479BBroaden research directionReduce coding complexityDigital video signal modificationPattern recognitionCoding block

The invention discloses a 3D video depth image prediction mode selection method based on the viewpoint correlation. The method comprises the steps of: preliminarily judging the possibility that a current coding block selects the Skip mode by utilizing the viewpoint correlation at first; and then, for the coding block having high possibility, comparing the rate distortion RD-cost of the Skip mode with the rate distortion RD-cost of the 2N*2N Merge mode and the DIS mode, determining whether the current block selects the Skip mode or not, and ending a prediction mode selection process in advance. By means of the 3D video depth image prediction mode selection method based on the viewpoint correlation disclosed by the invention, the depth image prediction coding complexity can be reduced; the coding time required by prediction can be reduced; and furthermore, the video quality in the synthesis visual angle of the final decoding end can be ensured.

Owner:NANJING UNIV OF SCI & TECH

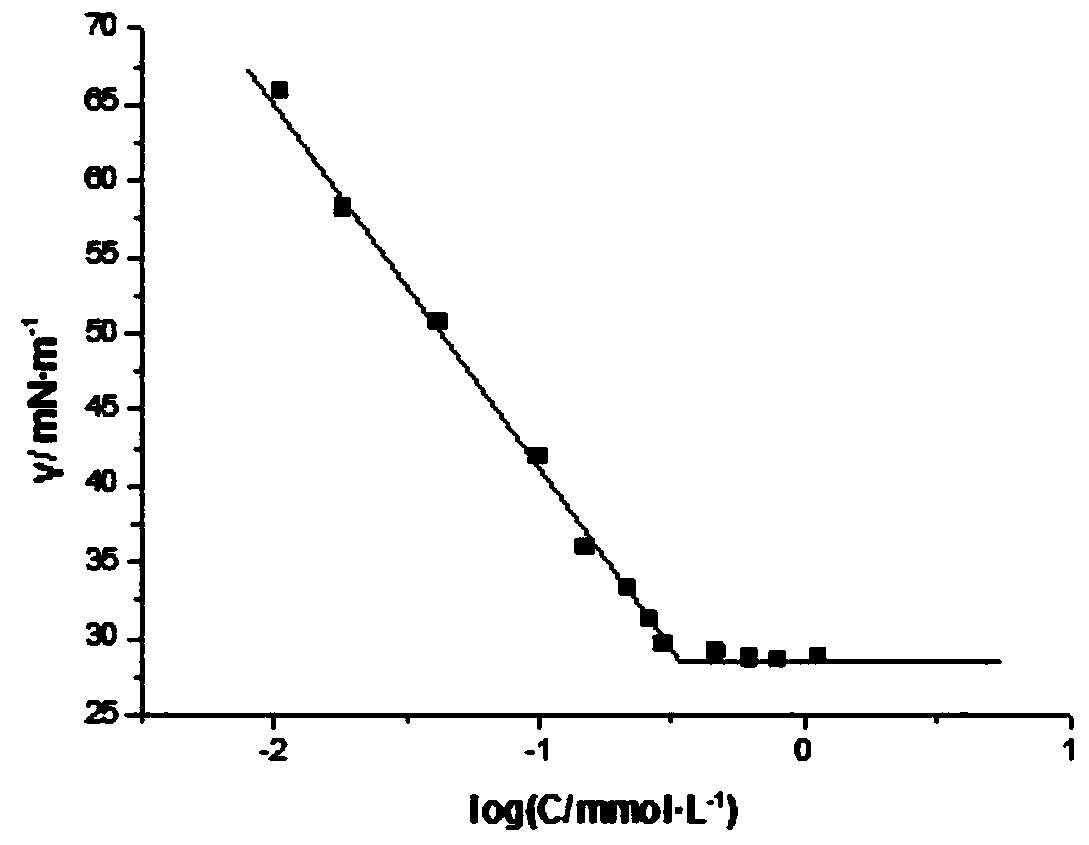

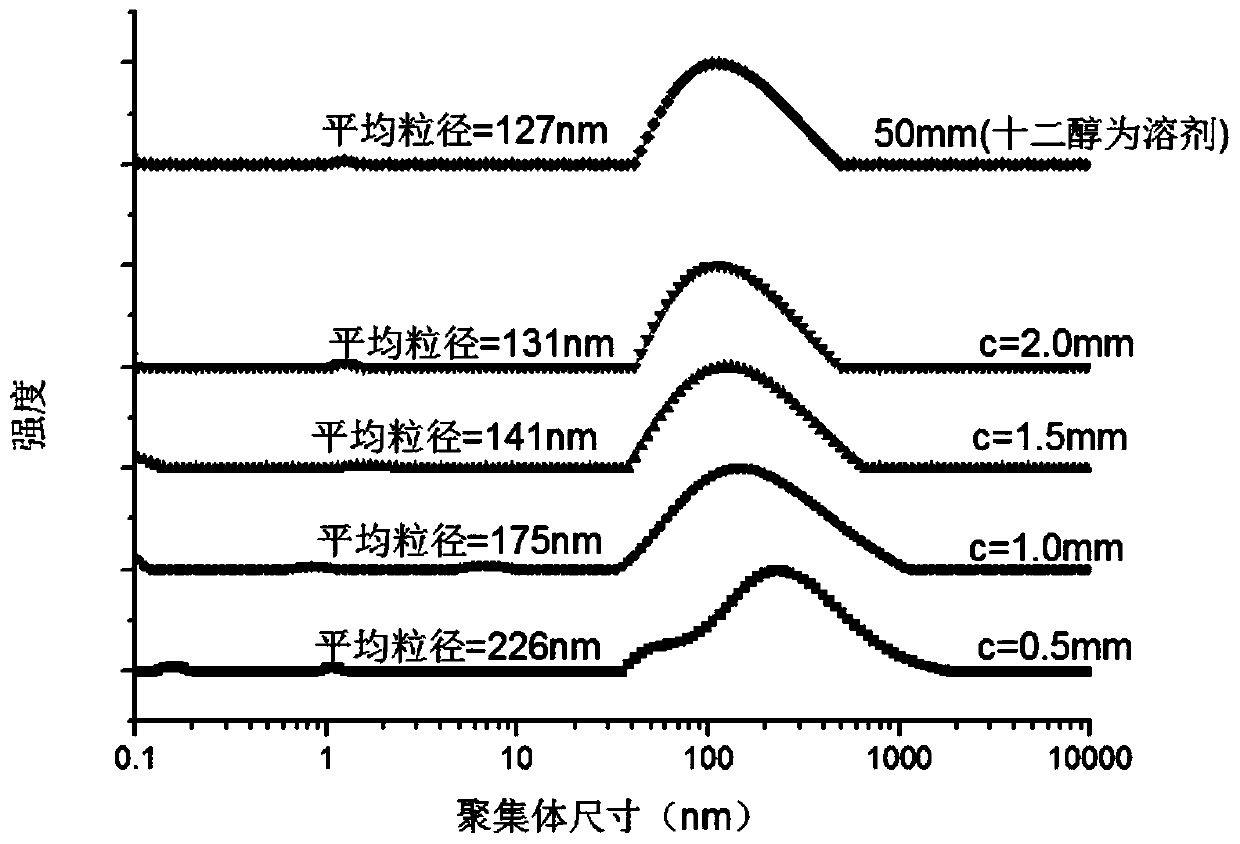

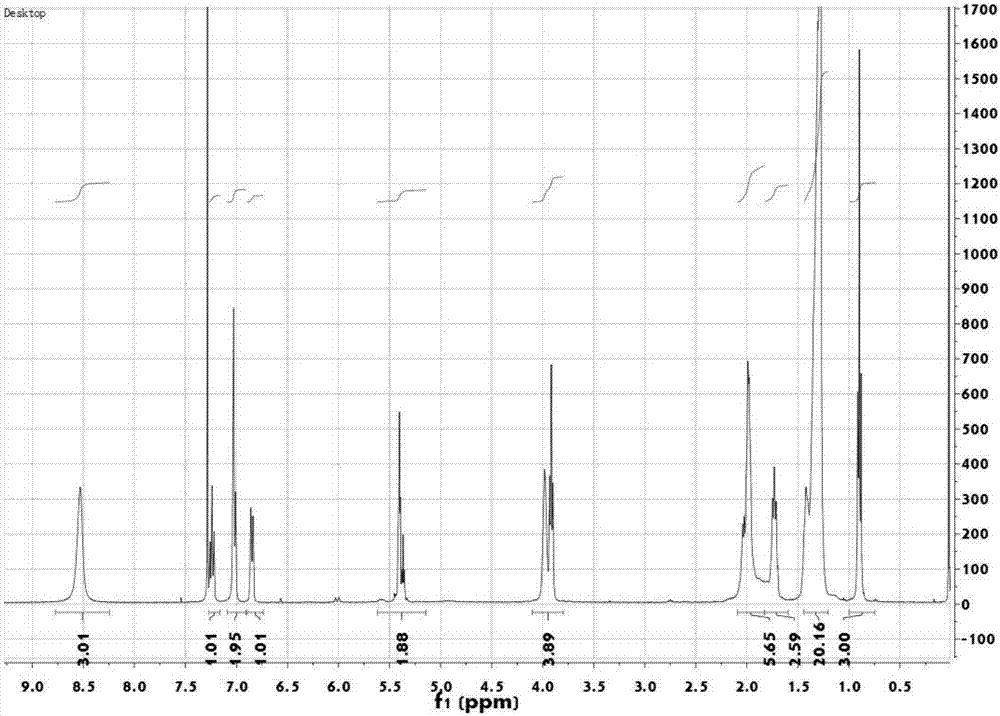

A kind of bio-based primary amine cationic surfactant and preparation method thereof

ActiveCN107879942BPromote degradationBroaden research directionOrganic compound preparationTransportation and packagingActive agentOleyl alcohol

The invention discloses a bio-based primary amine cationic surfactant and a preparation method thereof, belonging to the technical field of surfactant science and application. The synthesis of the surfactant of the present invention includes taking oleic acid and methanol as the starting raw materials to undergo esterification, reduction, and substitution in sequence to synthesize oleyl alcohol, and the substitution, substitution, reduction, and acidification reactions of oleyl alcohol and 3-hydroxybenzaldehyde to obtain the final Biobased primary amine cationic surfactant. The source of raw materials is wide, bio-renewable, green and environmentally friendly, and has high biodegradability. It enriches the types of bio-based surfactants that use renewable resources as raw materials, and can be widely used in the research of surfactant self-organization systems.

Owner:JIANGNAN UNIV

A kind of production method of wool-like fabric

ActiveCN110257999BImprove qualityRealize comprehensive development applicationWoven fabricsCuprammonium rayonPolymer science

Disclosed is a fabrication method for a wool-like fabric, the fabrication method comprising the following steps: (1) providing copper ammonia fiber to be used as the warp yarn of the fabric; (2) providing copper ammonia fiber and modal fiber and forming the same into a blended yarn at a 50:50 ratio to be used as the weft yarn of the fabric; and (3) interweaving, on a loom, the warp yarn provided in step (1) warpwise and the weft yarn provided in step (2) weftwise, the interwoven fabric having a dobby structure with alternating plain weave and combination weave. The fabrication method for a wool-like fabric according to the present invention provides a novel copper ammonia fiber wool-like product, achieving full development and application of copper ammonia fiber and broadening related research directions and application fields. The wool-like fabric formed by the fabrication method is cheap in price but superb in quality. The interwoven fabric has a handfeel very similar to wool, and is extremely soft, comfortable and drapable.

Owner:WUJIANG DEYI FASHIONS CLOTHS

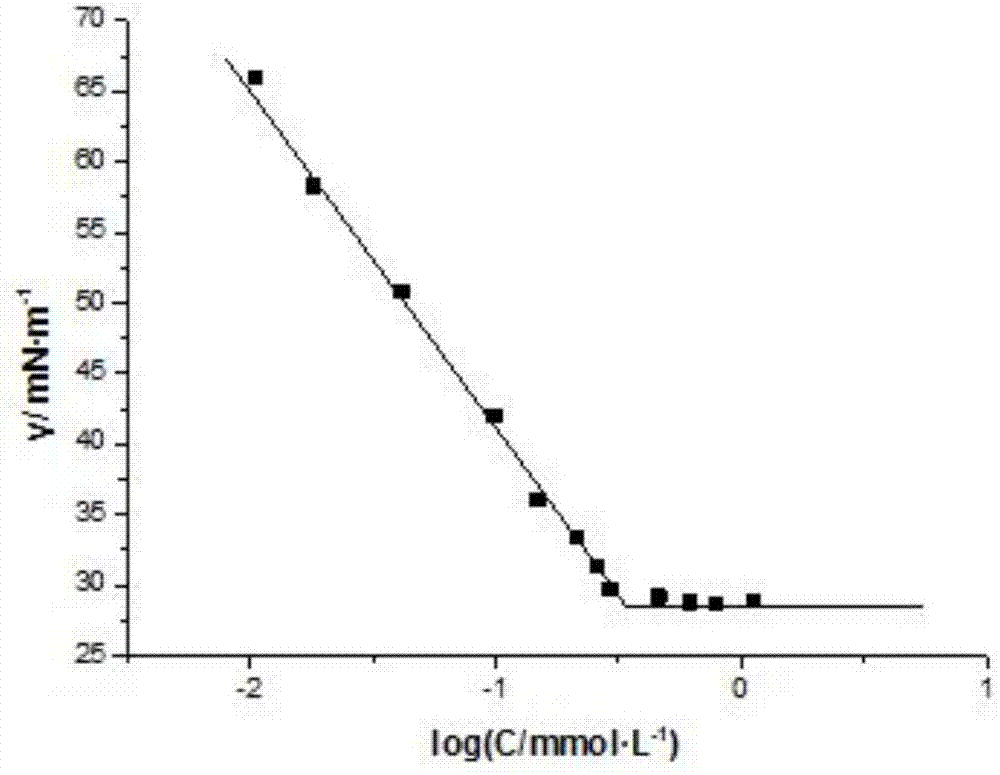

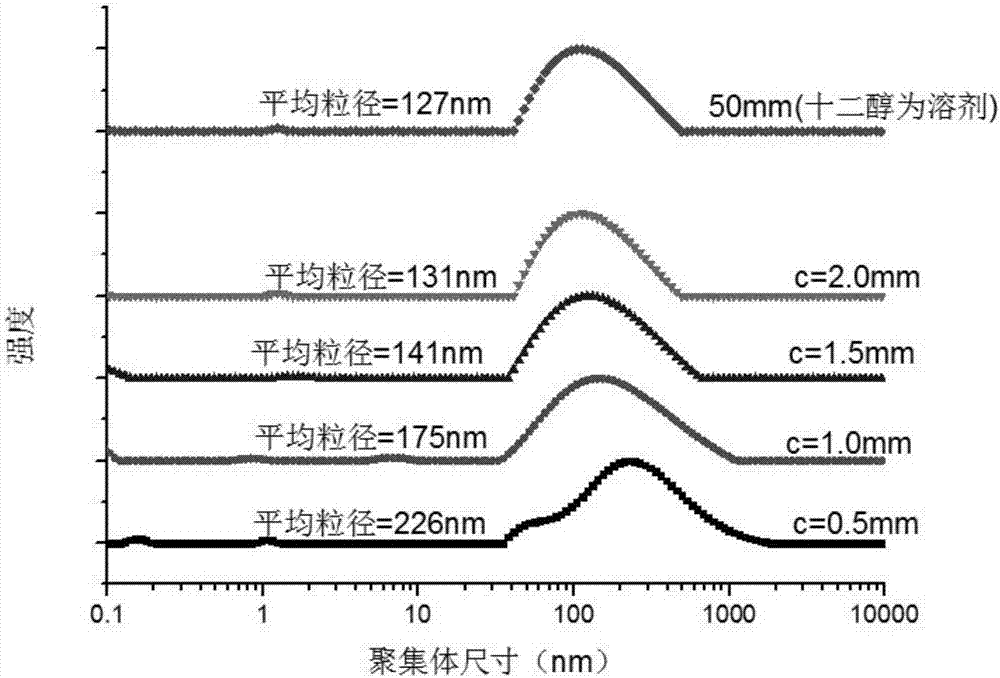

Bio-based primary amine cationic surfactant and preparation method thereof

ActiveCN107879942APromote degradationBroaden research directionOrganic compound preparationTransportation and packaging3-HydroxybenzaldehydeOleyl alcohol

The invention discloses a bio-based primary amine cationic surfactant and a preparation method thereof, and belongs to the technical field of surfactant science and application. The synthesis of the surfactant comprises the following steps that oleic acid and methyl alcohol are used as raw materials for sequentially carrying out esterification, reduction and substitution, so that oleyl alcohol issybthesized; substitution is carried out on the oleyl alcohol and 3-hydroxybenzaldehyde, and substitution, reduction, acidification reaction are carried out, so that the final bio-based primary aminecationic surfactant is obtained. The bio-based primary amine cationic surfactant has wide raw material sources, is biologically renewable, is green and environmentally friendly, and has high biodegradability, the types of biological-based surfactants with renewable resources as raw materials are enriched, and the bio-based primary amine cationic surfactant can be widely applied to research of a surfactant self-organizing system.

Owner:JIANGNAN UNIV

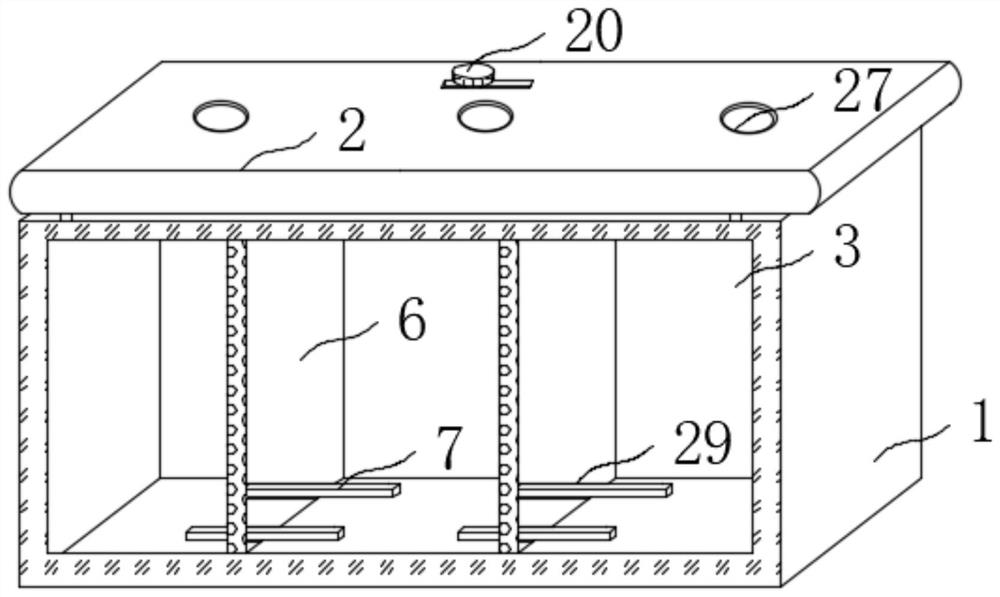

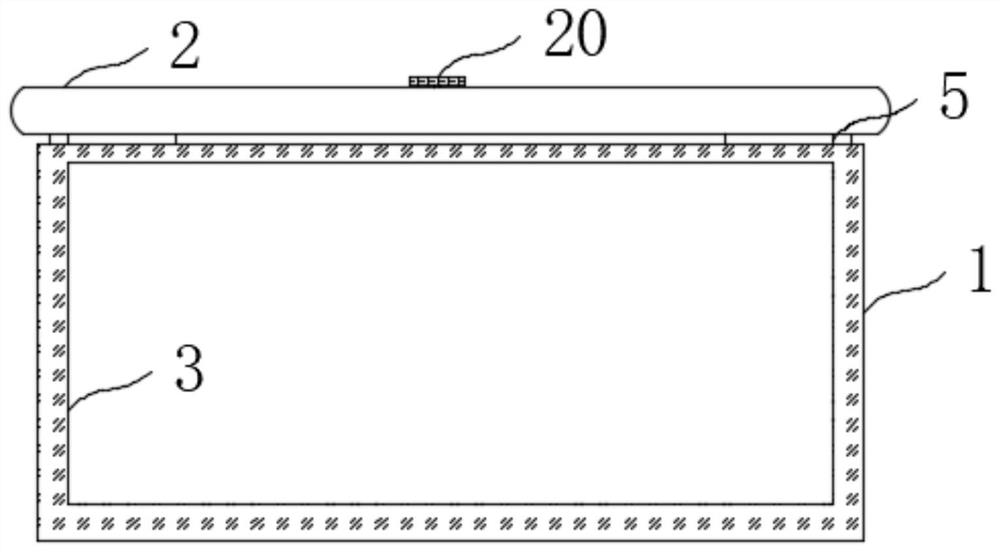

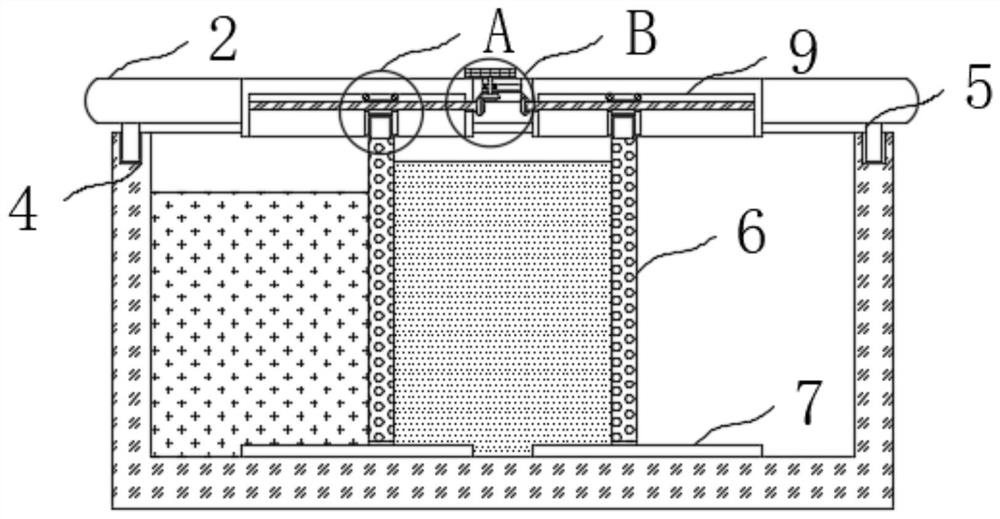

Cultivation device for researching growth state of wheat root system

PendingCN112753558AImprove research directionWide data coverageAgriculture gas emission reductionCultivating equipmentsEnvironmental geologyBotany

The invention discloses a cultivation device for researching the growth state of a wheat root system. The cultivation device comprises a culture box, a box cover is clamped on the culture box, two partition plates are arranged in the culture box, the culture box is sequentially divided into a water base cavity, a soil base cavity and a non-base cavity from left to right by the two partition plates, a plurality of planting holes are formed in the box cover, and the plurality of planting holes respectively correspond to the the water base cavity, the soil base cavity and the non-base cavity in position. The device has the advantages that three groups of contrast studies can be performed on wheat respectively, growth conditions of the wheat root system in different environments can be known more clearly, three groups of contrast study objects are in the same device, unified management is facilitated, and the sizes of growth spaces of the contrast study objects can be adjusted according to needs, so that the growth conditions of plants in different spaces can be researched, the research direction of the device is further improved, the coverage of obtained data is wider, and the accuracy is higher.

Owner:NANYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com