Water-based lubricant and preparation method thereof

A technology of water-based lubricants and base rings, applied in the direction of lubricating compositions, chemical instruments and methods, additives, etc., can solve the problems of lack of raw materials, environmental pollution, poor wear resistance, etc., to improve performance and value, simple process, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

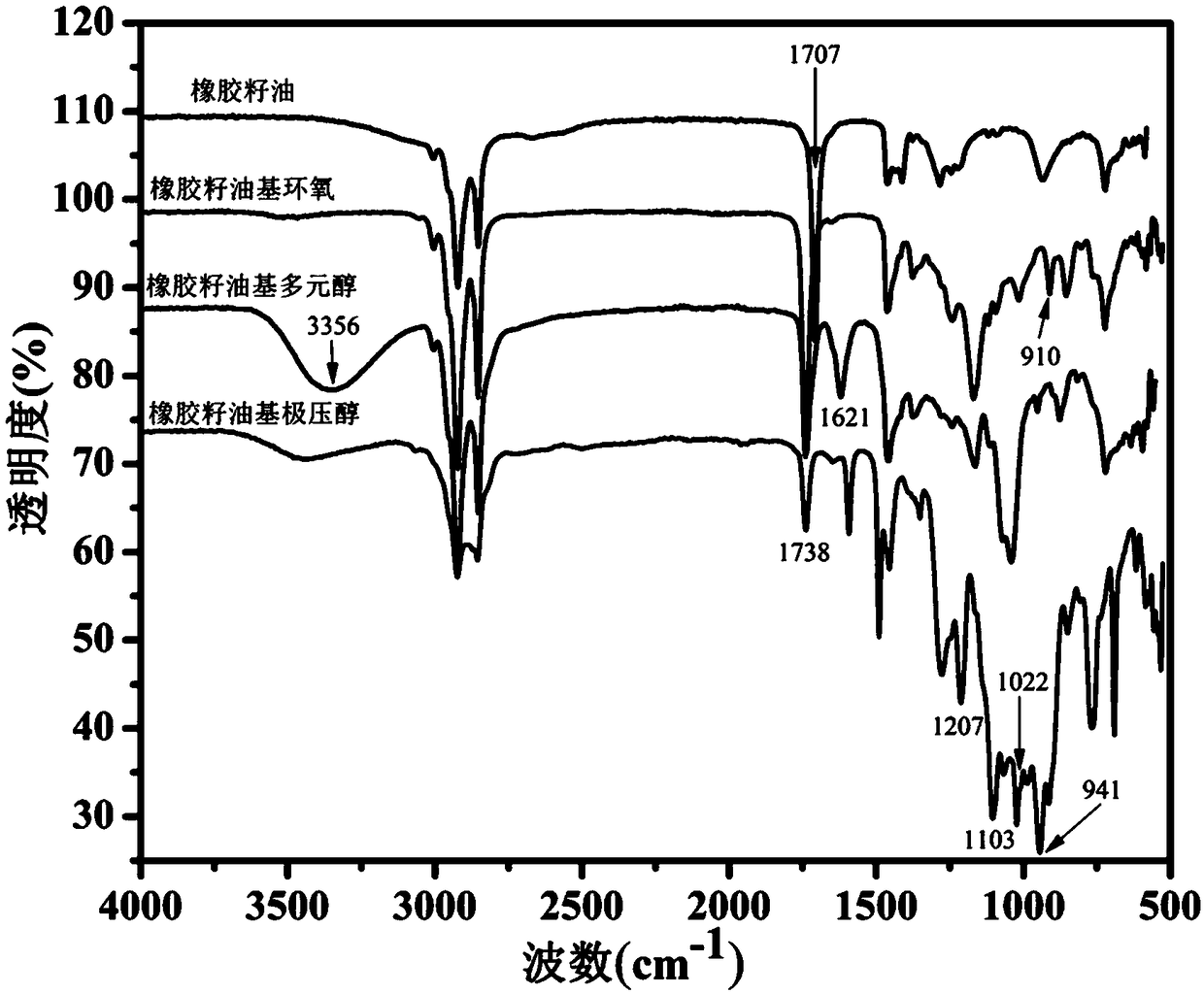

[0017] (1) Preparation of rubber seed oil-based epoxy

[0018] In a 500mL three-necked flask equipped with a heating mantle, a stirring device, and a thermometer, add 1mol of rubber seed oil, 10mol of epichlorohydrin, and 0.05% of the total mass of rubber seed oil and epichlorohydrin. Ammonium is used as a catalyst, the temperature is raised to 120°C, and the reaction takes 2 hours; at 50°C, under the action of 1mol sodium hydroxide and 10g calcium oxide, a ring-closing reaction occurs for 4 hours. Rubber seed oil based epoxy.

[0019] (2) Preparation of rubber seed oil-based polyol amine

[0020] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of rubber seed oil-based epoxy and 1 mol of diethanolamine obtained in step (1), and react at 90°C for 2 hours; then reduce the pressure to -0.1~-0.09MPa , distill off the solvent ethyl acetate to obtain rubber seed oil-based polyol amine;

[0021] (3) Preparation of rubber ...

Embodiment 2

[0027] (1) Preparation of rubber seed oil-based epoxy

[0028] In a 500mL three-necked flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of rubber seed oil, 8 mol of epichlorohydrin, and benzyl triethyl chloride, which accounts for 1% of the total mass of rubber seed oil and epichlorohydrin. Ammonium is used as a catalyst, the temperature is raised to 100°C, and the reaction is 3h; at 70°C, under the action of 1mol of sodium hydroxide and 10g of calcium oxide, a ring-closing reaction occurs for 3h, and the excess epichlorohydrin is obtained by filtering sodium chloride and distilling off excess epichlorohydrin under reduced pressure. Rubber seed oil based epoxy.

[0029] (2) Preparation of rubber seed oil-based polyol amine

[0030] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of rubber seed oil-based epoxy and 1 mol of diethanolamine obtained in step (1), and react at 70°C for ...

Embodiment 3

[0036] (1) Preparation of rubber seed oil-based epoxy

[0037] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1 mol of rubber seed oil, 6 mol of epichlorohydrin, and 2% benzyl triethyl chloride, which accounts for 2% of the total mass of rubber seed oil and epichlorohydrin. Ammonium is used as a catalyst, the temperature is raised to 110°C, and the reaction is 1 hour; at 60°C, under the action of 1mol of sodium hydroxide and 10g of calcium oxide, a ring-closing reaction occurs for 5 hours. Rubber seed oil based epoxy.

[0038] (2) Preparation of rubber seed oil-based polyol amine

[0039] In a 500mL three-neck flask equipped with a heating mantle, a stirring device, and a thermometer, add 1mol of rubber seed oil-based epoxy and 1mol of ethanolamine obtained in step (1), and react at 60°C for 5h; then reduce the pressure to -0.1~-0.09MPa, The solvent toluene is evaporated to obtain the rubber seed oil-based polyol amine; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum non-jamming load | aaaaa | aaaaa |

| Maximum non-jamming load | aaaaa | aaaaa |

| Maximum non-jamming load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com