Lipoic acid-modified ethyl cellulose film and preparation method thereof

A technology of ethyl cellulose and lipoic acid, which is applied in the field of materials, can solve the problems of pure ethyl cellulose film such as brittleness and poor flexibility, and achieve the effect of improving performance and value, improving flexibility and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

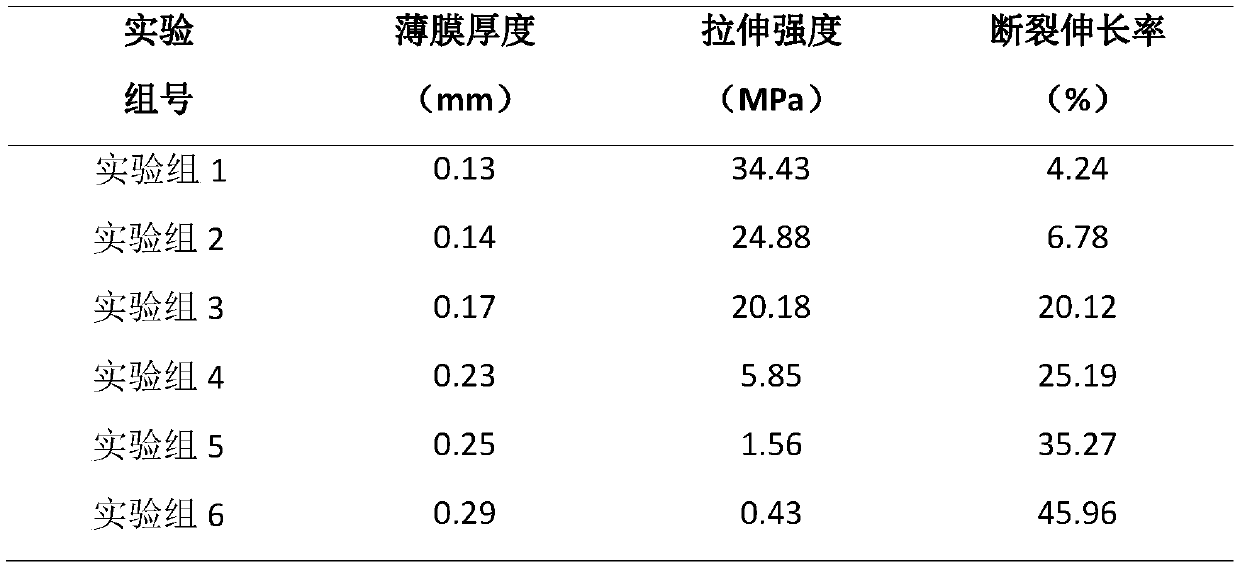

Embodiment 1

[0014] The first step is to weigh ethyl cellulose and add it to the reaction vessel, add a certain amount of glacial acetic acid according to the mass ratio of ethyl cellulose / glacial acetic acid as 7:100, then raise the reaction temperature to 72°C and keep stirring for 2 Hour, until ethyl cellulose is completely dissolved in glacial acetic acid, cool to room temperature, can obtain the ethyl cellulose solution that mass fraction is 6.5%; The second step, the mass fraction is 6.5% ethyl cellulose solution Pour it into a mold, and then put it in an oven at 120°C for 2 hours to form a film to obtain a pure ethyl cellulose film.

Embodiment 2

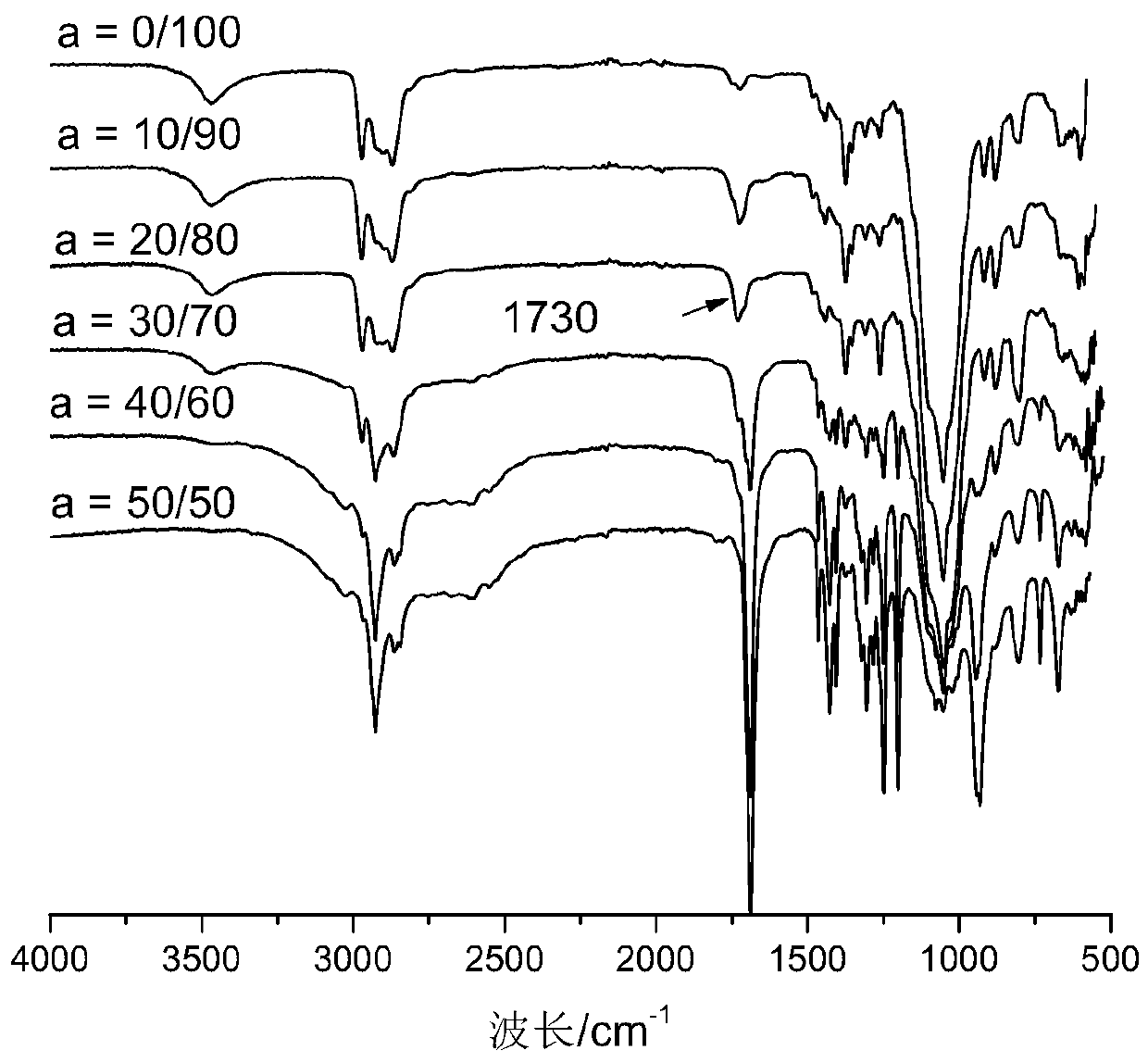

[0016] The first step is to weigh ethyl cellulose and add it to the reaction vessel, add a certain amount of glacial acetic acid according to the mass ratio of ethyl cellulose / glacial acetic acid as 7:100, then raise the reaction temperature to 72°C and keep stirring for 2 Hour, until ethyl cellulose is completely dissolved in glacial acetic acid, is cooled to room temperature, can obtain the ethyl cellulose solution that mass fraction is 6.5%; The second step, takes by weighing quantitative lipoic acid and places reaction bottle, wherein , the mass ratio of lipoic acid and ethyl cellulose is 10 / 90, then add glacial acetic acid, raise the temperature to 80°C and stir for 0.5h until lipoic acid is completely dissolved in glacial acetic acid to obtain lipoic acid solution; the third step Add lipoic acid solution and 0.1% inhibitor of lipoic acid mass fraction to ethyl cellulose solution with a mass fraction of 6.5%, stir at 80°C for 0.5h, cool to room temperature, and pour into a...

Embodiment 3

[0018] The first step is to weigh ethyl cellulose and add it to the reaction vessel, add a certain amount of glacial acetic acid according to the mass ratio of ethyl cellulose / glacial acetic acid as 7:100, then raise the reaction temperature to 73°C and keep stirring for 2.5 Hour, until ethyl cellulose is completely dissolved in glacial acetic acid, is cooled to room temperature, can obtain the ethyl cellulose solution that mass fraction is 6.5%; The second step, takes by weighing quantitative lipoic acid and places reaction bottle, wherein , the mass ratio of lipoic acid and ethyl cellulose is 20 / 80, then add glacial acetic acid, raise the temperature to 83° C. and stir for 1 h until lipoic acid is completely dissolved in glacial acetic acid to obtain lipoic acid solution; the third step, The lipoic acid solution and the 0.2% polymerization inhibitor accounting for the lipoic acid mass fraction were added to the ethyl cellulose solution with a mass fraction of 6.5%, stirred at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com