A kind of lipoic acid modified ethyl cellulose film and preparation method thereof

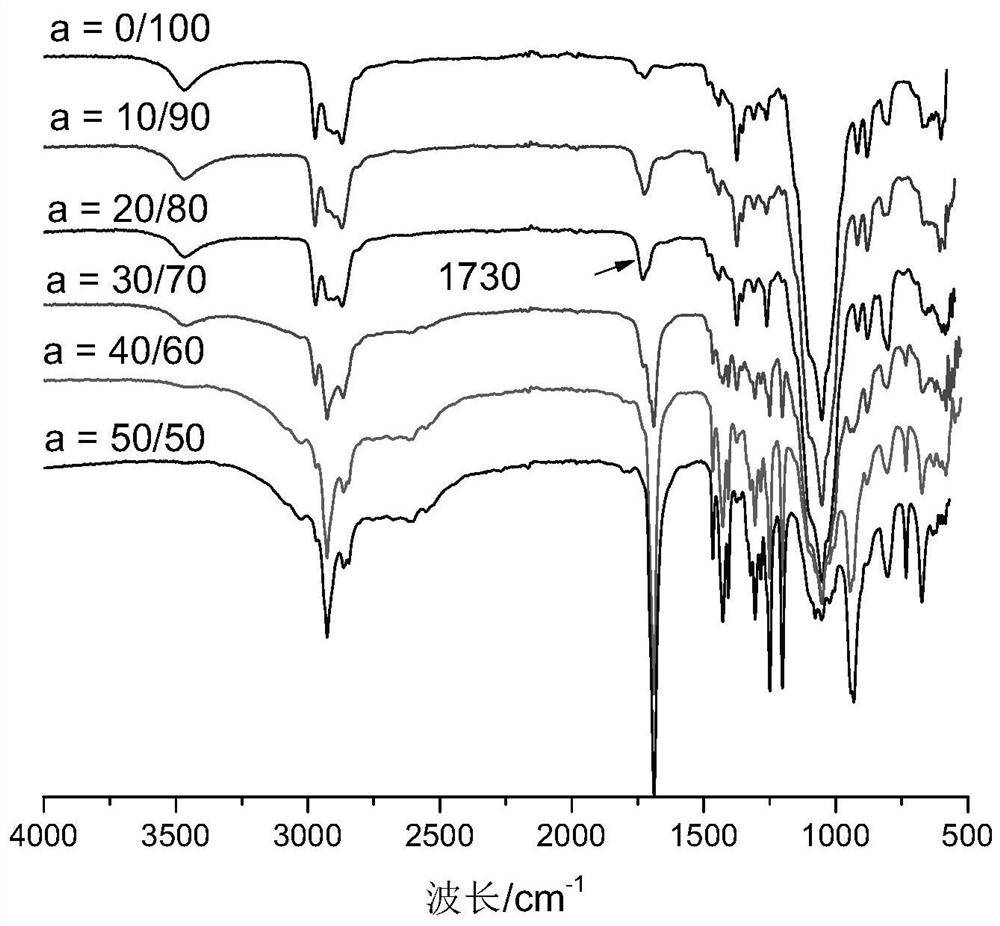

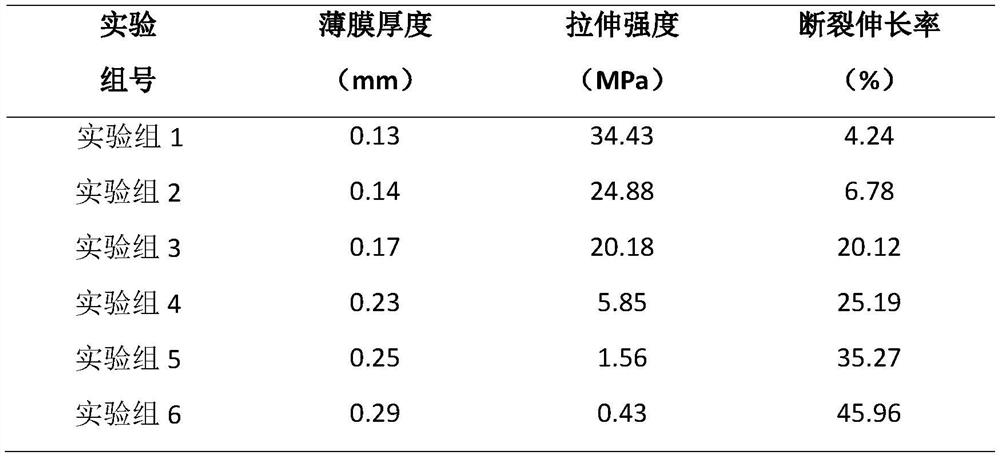

A technology of ethyl cellulose and lipoic acid, applied in the field of materials, can solve the problems of brittleness and poor flexibility of pure ethyl cellulose film, and achieve the effect of improving performance and value, improving flexibility and broadening application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The first step, weighed ethyl cellulose was added to the reaction vessel, the mass ratio of ethyl cellulose / glacial acetic acid 7: amount of glacial acetic acid was added to 100, and then the reaction temperature was raised to 72 deg.] C, stirring was continued for 2 hours, until the ethyl cellulose was completely dissolved in glacial acetic acid, cooled to room temperature, to obtain a mass fraction of 6.5% ethyl cellulose solution; the second step, the mass fraction of 6.5% ethyl cellulose solution poured into a mold, and then placed in an oven at 120 deg.] C so that the deposition 2h, to give pure ethyl cellulose film.

Embodiment 2

[0016] The first step, weighed ethyl cellulose was added to the reaction vessel, the mass ratio of ethyl cellulose / glacial acetic acid 7: amount of glacial acetic acid was added to 100, and then the reaction temperature was raised to 72 deg.] C, stirring was continued for 2 hours, until the ethyl cellulose was completely dissolved in glacial acetic acid, cooled to room temperature, to obtain a mass fraction of 6.5% ethyl cellulose solution; the second step, weighed and placed in a reaction flask amount of lipoic acid, wherein , lipoic acid and ethylcellulose mass ratio of 10 / 90, followed by addition of glacial acetic acid, the temperature was raised to 80 deg.] C was stirred for 0.5h, until completely dissolved in glacial acetic acid lipoic acid, lipoic acid solution can be obtained; step , accounting for the lipoic acid and lipoic acid content was 0.1% by mass of a polymerization inhibitor fraction were added to 6.5% ethyl cellulose solution was stirred at 80 ℃ 0.5h, cooled to ...

Embodiment 3

[0018] The first step, weighed ethyl cellulose was added to the reaction vessel, the mass ratio of ethyl cellulose / glacial acetic acid 7: amount of glacial acetic acid was added to 100, and then the reaction temperature was raised to 73 ℃, stirring was continued for 2.5 hours, until the ethyl cellulose was completely dissolved in glacial acetic acid, cooled to room temperature, to obtain a mass fraction of 6.5% ethyl cellulose solution; the second step, weighed and placed in a reaction flask amount of lipoic acid, wherein , lipoic acid and ethylcellulose mass ratio of 20 / 80, followed by addition of glacial acetic acid, the temperature was raised to 83 deg.] C IH stirring, until completely dissolved in glacial acetic acid lipoic acid, lipoic acid solution can be obtained; the third step, solution of lipoic acid and lipoic acid accounted for 0.2% of the mass fraction of the polymerization inhibitor were added to the mass fraction of 6.5% ethyl cellulose solution was stirred at 83 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com