Sweep ultrasonic preparation method for collagen-chitosan compound film of tuna skin

A technology of frequency-sweeping ultrasound and collagen, which is applied in the direction of flexible coverings, packaging, wrapping paper, etc., can solve the problem of insignificant improvement in mechanical properties, achieve the effects of broadening research directions, simple process operation, and favorable comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

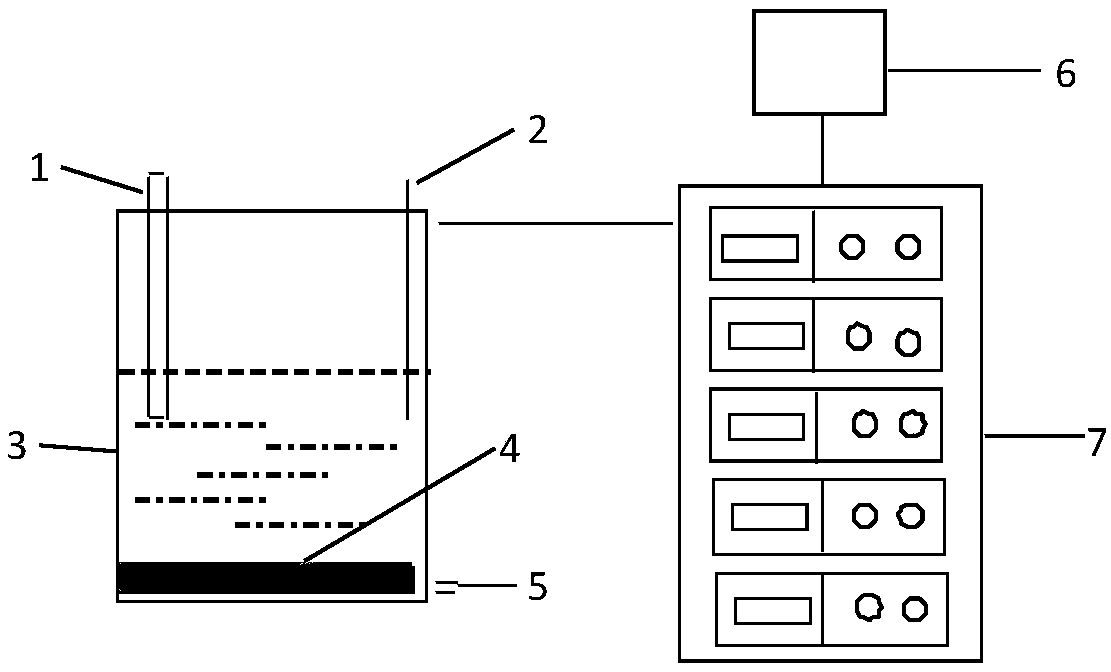

Method used

Image

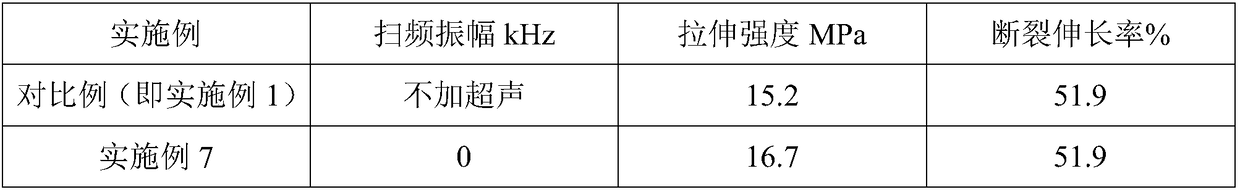

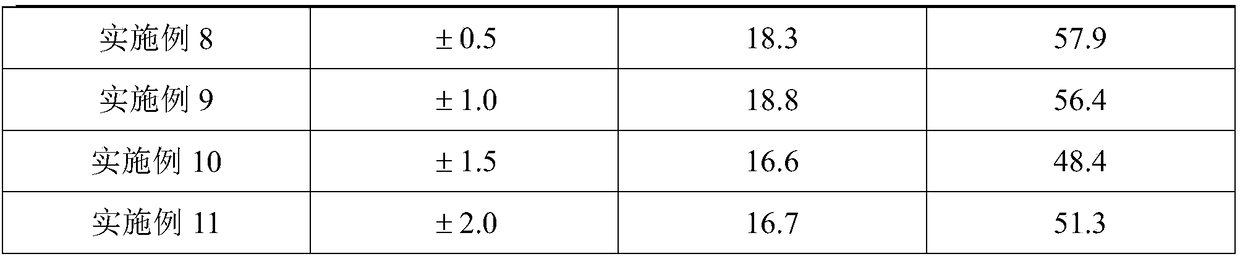

Examples

Embodiment 1

[0029] The preparation method of the tuna skin collagen-chitosan composite membrane without sonication is carried out according to the following steps:

[0030] (1) Weigh a certain amount of collagen in a beaker, prepare a 2g / 100mL collagen solution with distilled water, dissolve in a water bath at 50°C for 30 minutes, and filter with suction to obtain a pure collagen solution. Weigh a certain mass of chitosan into a beaker, add 2% (V / V) glacial acetic acid to make a 2g / 100mL chitosan solution, dissolve in a water bath at 50°C for 30min, and let stand overnight. Mix collagen and chitosan solution at a mass ratio of 1:4, add 25% (total solute mass ratio) glycerin as a plasticizer, stir at 20°C for 10 minutes and mix to obtain a mixed solution.

[0031] (2) The mixed solution in step (1) was cross-linked in a water bath at 55° C. for 1 hour to obtain a non-ultrasonic composite membrane solution.

[0032] (3) Spread the non-ultrasonic composite membrane solution obtained in step...

Embodiment 2

[0041] The preparation method of the tuna skin collagen-chitosan composite membrane that different frequency sweeping periods are processed, carries out according to the following steps:

[0042] (1) Weigh a certain amount of collagen in a beaker, prepare a 2g / 100mL collagen solution with distilled water, dissolve in a water bath at 50°C for 30 minutes, and filter with suction to obtain a pure collagen solution. Weigh a certain mass of chitosan into a beaker, add 2% (V / V) glacial acetic acid to make a 2g / 100mL chitosan solution, dissolve in a water bath at 50°C for 30min, and let stand overnight. Mix collagen and chitosan solution at a mass ratio of 1:4, add 25% (total solute mass ratio) glycerin as a plasticizer, stir at 20°C for 10 minutes and mix to obtain a mixed solution.

[0043] (2) The mixed solution in step (1) was subjected to frequency-sweep ultrasonic treatment at 55°C, and the ultrasonic treatment parameters were: frequency 28kHz; power density 100W / L; frequency s...

Embodiment 3

[0053] The sweep period of the ultrasonic treatment is 100ms, and the rest of the steps are the same as in Example 2; the specific results of tensile strength and elongation at break are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com