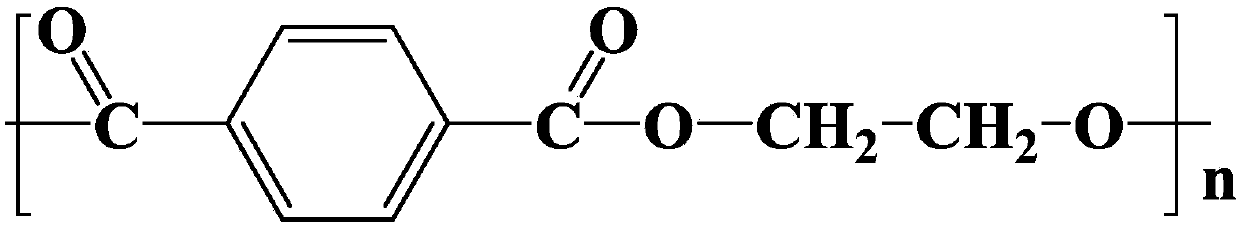

Method for preparing metal organic framework material from PET (polyethylene terephthalate) waste materials

A metal organic framework and waste technology, applied in the field of materials, can solve the problems of limited number of repeated recycling, poor performance, and many impurities in recycled plastics, and achieve the effect of broadening the research direction and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

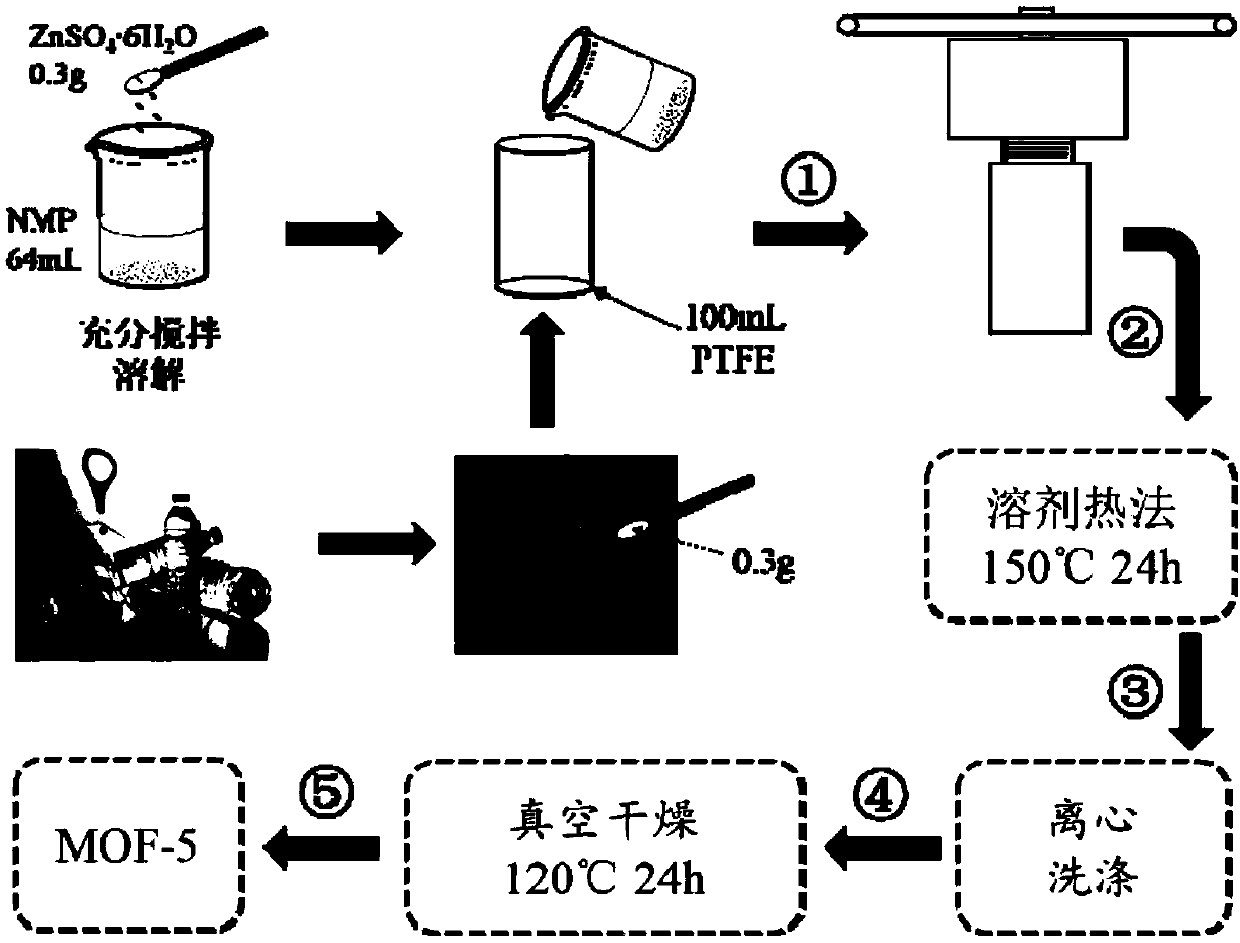

[0015] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

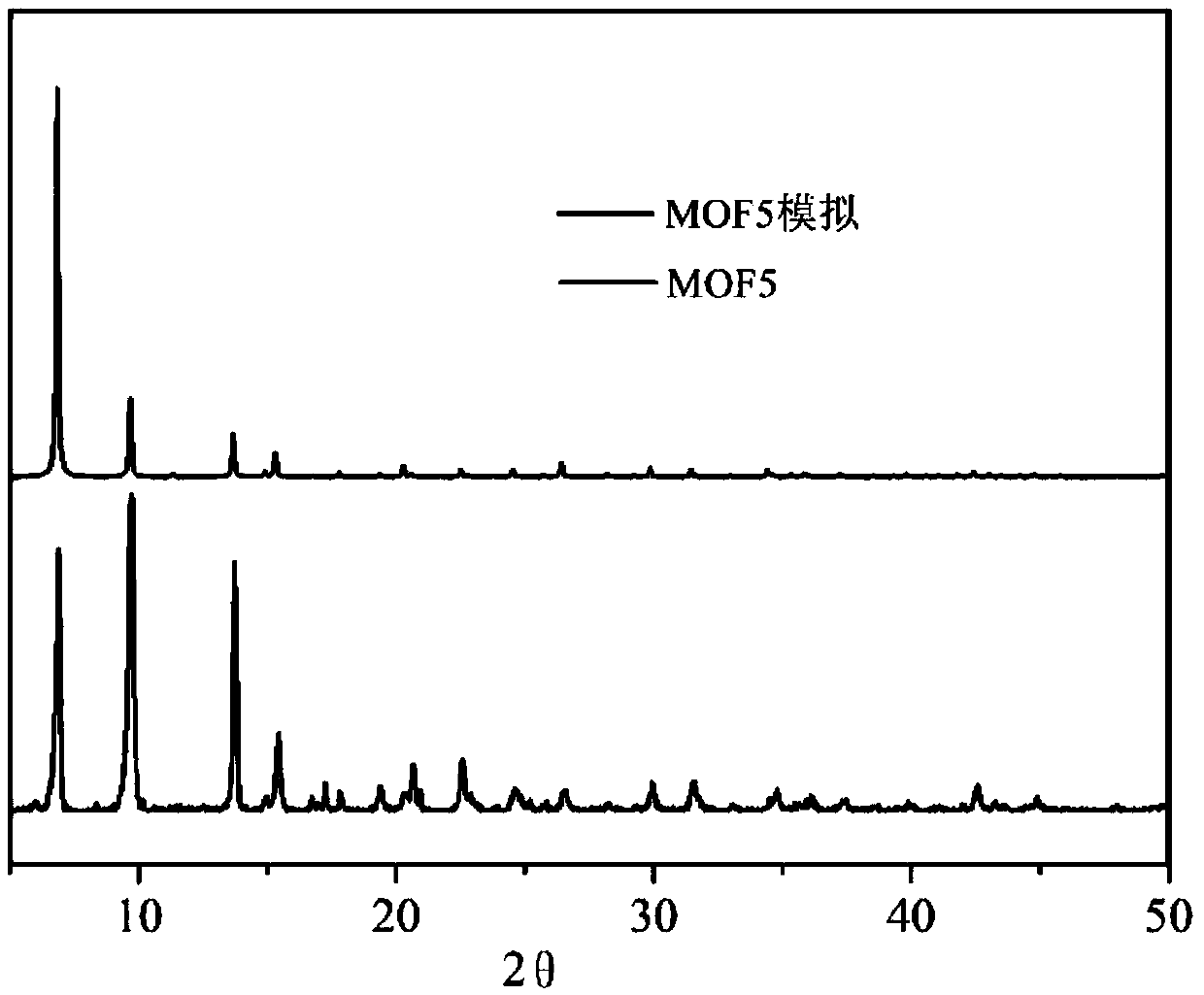

[0016] First weigh 0.3g zinc nitrate (Zn(NO 3 ) 2 ·6H 2 O) Add it to 64 milliliters of N-methylpyrrolidone (NMP) solvent, stir well at room temperature to make it dissolve completely, then transfer the solution to a polytetrafluoroethylene liner with a volume of 100 mL for subsequent use. Take a discarded plastic bottle, cut it into pieces, weigh 0.3g and add it to the polytetrafluoroethylene liner, then pack the polytetrafluoroethylene liner tightly in the hydrothermal reaction kettle, and put the packaged hydrothermal reaction kettle Heat at 150°C for 24 hours in a blast drying oven. After the reaction is completed, the reactor is cooled to room temperature, centrifuged and washed three times with NMP and methanol to remove excess reactants, and finally the obtained sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com