Method for preparing high mud-resistant polycarboxylic acid dispersant by grafting cationic side chains by copolymerization of unsaturated halogenated hydrocarbons

A technology of unsaturated and halogenated hydrocarbons, applied in the field of high mud-resistant dispersants, to achieve the effect of broadening research directions and design ideas, broad application prospects, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

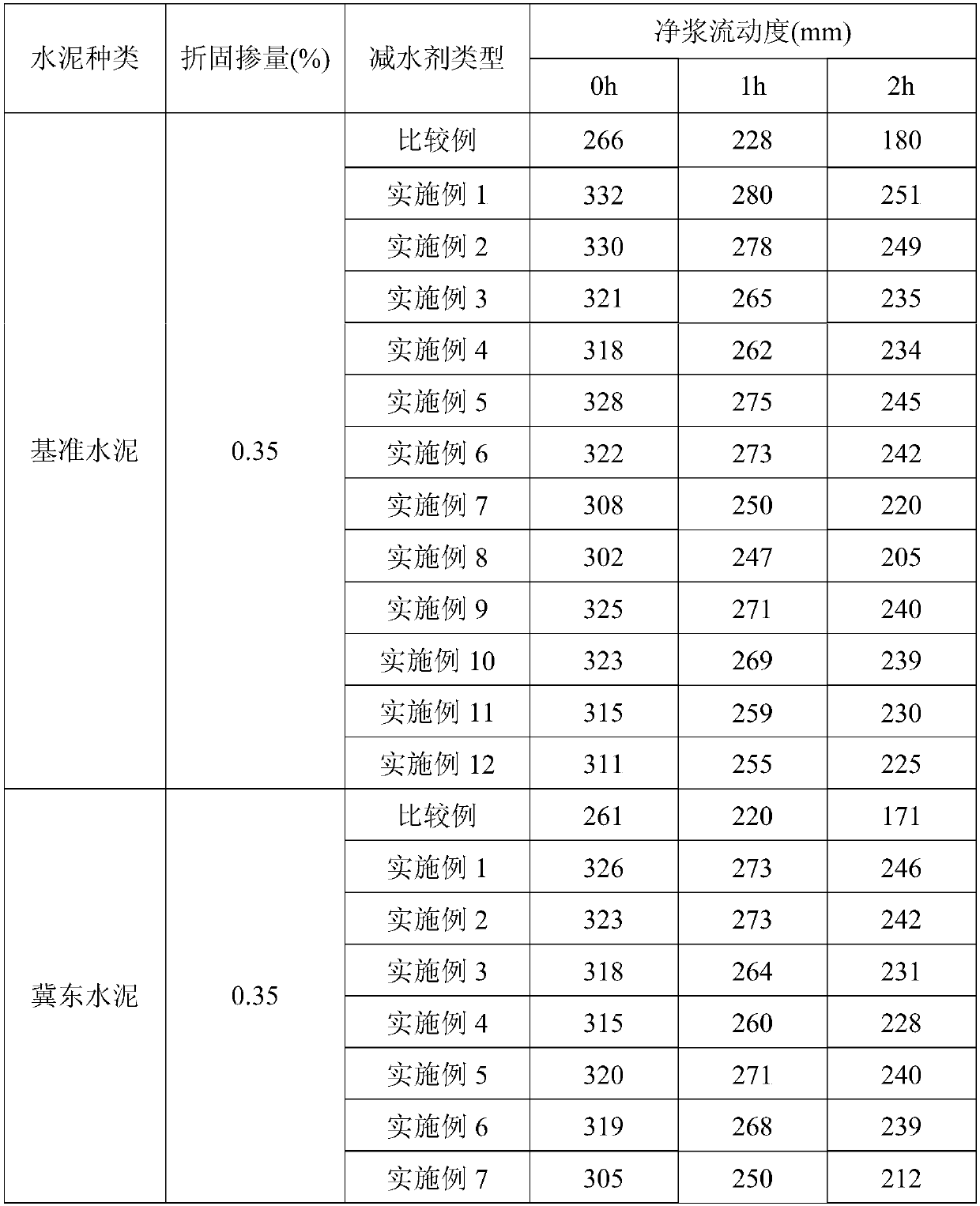

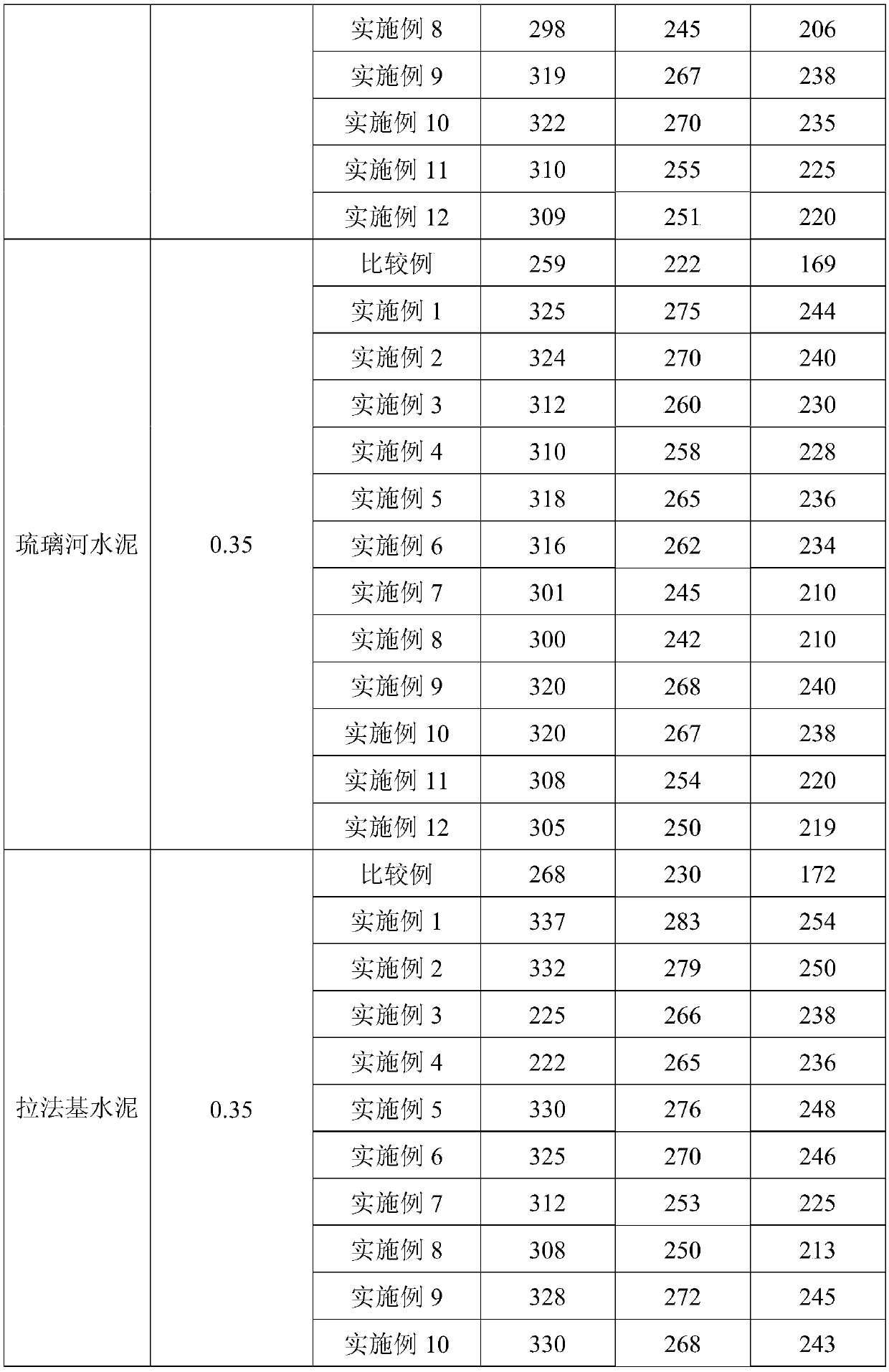

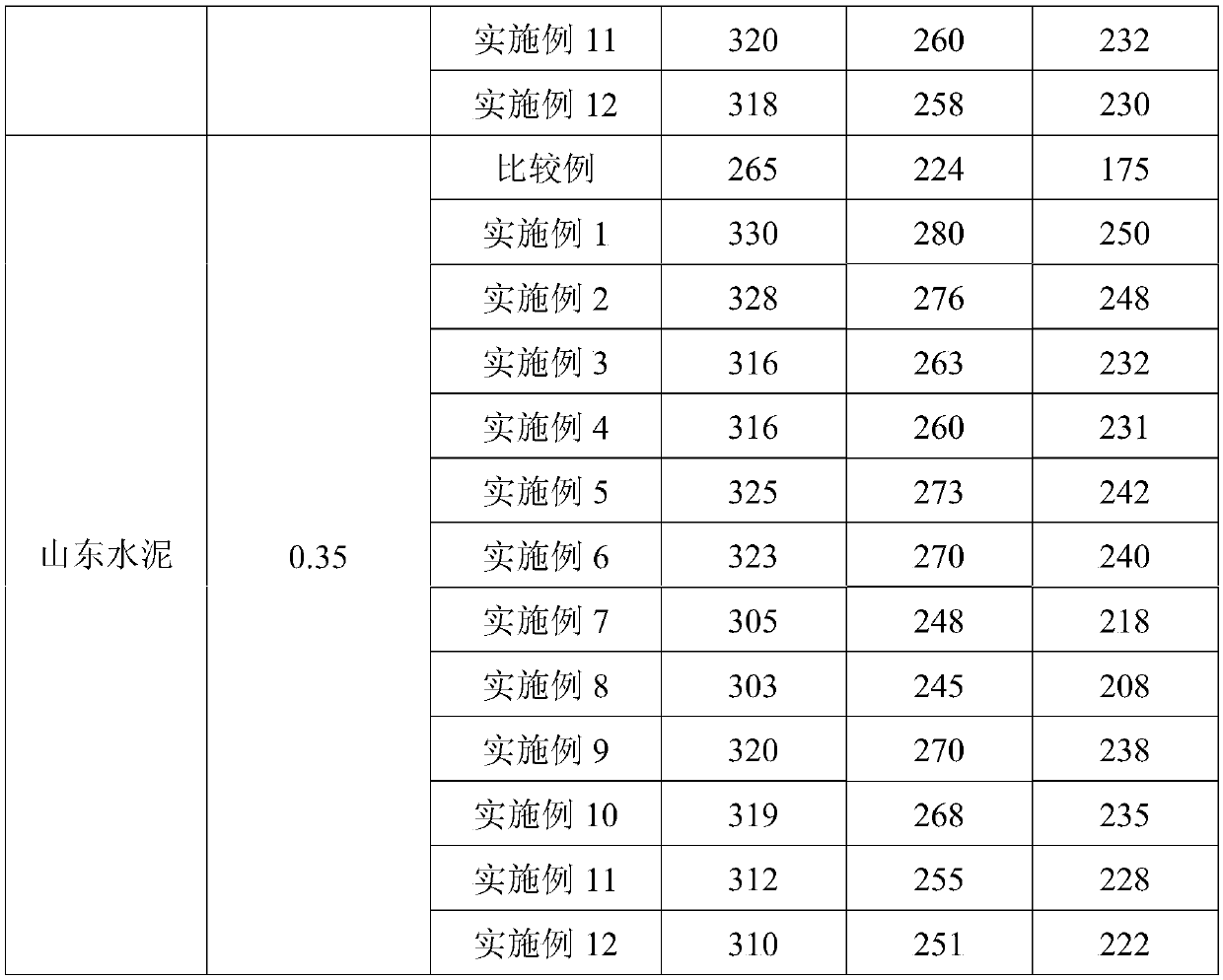

Examples

Embodiment 1

[0029] First, 7.82g of methacrylic acid, 1.06g of fumaric acid, 1.91g of allyl chloride, 0.61g of dibenzoyl peroxide, and 86.36g of dimethyl sulfoxide will be added to the reactor successively, and the stirring time between each feeding After 18 minutes, the reactor was filled with nitrogen repeatedly 3 times to deoxygenate and then sealed for 30 minutes, and the temperature was raised to 90°C for polymerization reaction. After 3 hours of reaction, 91.76g of methanol was added, and the precipitate was repeatedly washed 4 times, and the precipitate was vacuum-dried at 60°C. To constant weight, the carboxylic acid-chlorinated hydrocarbon copolymer is obtained; 48.5g dimethyl diallyl ammonium chloride and 0.45g isopropanol are added in another reactor, and then 562.94g water is added to prepare the mass concentration It is an 8% aqueous solution, and the reactor is filled with nitrogen repeatedly 4 times to remove oxygen and then sealed for 20 minutes. Add 0.89g of ammonium cerium...

Embodiment 2

[0031] The polycarboxylic acid dispersant solution with a concentration of 40% obtained in Example 1 was stored at 6° C. for 30 days, and its implementation effect was measured.

Embodiment 3

[0033] First, 7.17g of methacrylic acid, 1.63g of maleic anhydride, 2.03g of 4-bromo-1-butene, 0.76g of azobisisobutyronitrile, and 108.34g of dimethyl sulfoxide will be successively added to the reactor. The stirring time is 5 minutes at intervals, the reactor is filled with nitrogen repeatedly 3 times to remove oxygen for 25 minutes, and then sealed, and the temperature is raised to 110°C for polymerization reaction. After 2 hours of reaction, 102.92g of methanol is added, and the precipitate is washed repeatedly for 3 times, and the precipitate is placed at 80°C Dry under vacuum to constant weight to obtain carboxylic acid-brominated hydrocarbon copolymer; 8.83g methacryloxyethyl dimethyl butyl ammonium bromide and 0.36g n-propanol are added in another reactor, and then Add 450.14g of water to prepare an aqueous solution with a mass concentration of 2%, fill the reactor with nitrogen gas repeatedly for 4 times to remove oxygen and then seal it for 10 minutes, add 0.33g of ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com